Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

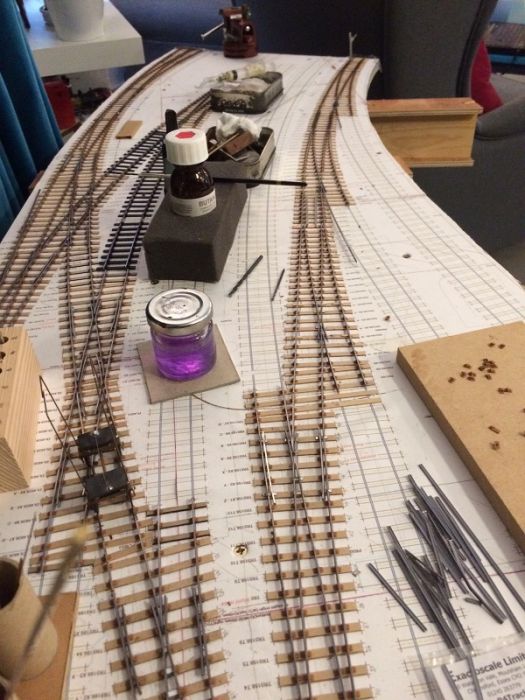

posted: 3 Oct 2014 22:50 from: Andrew Duncan

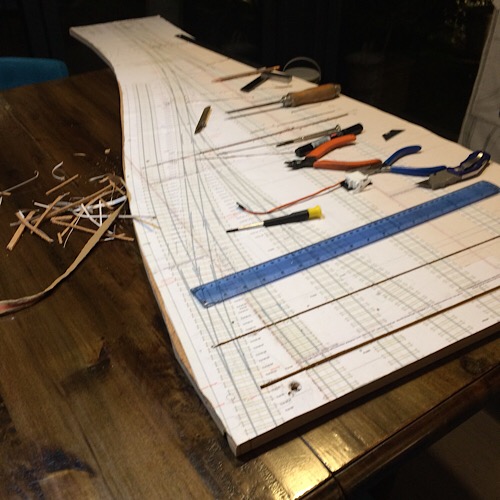

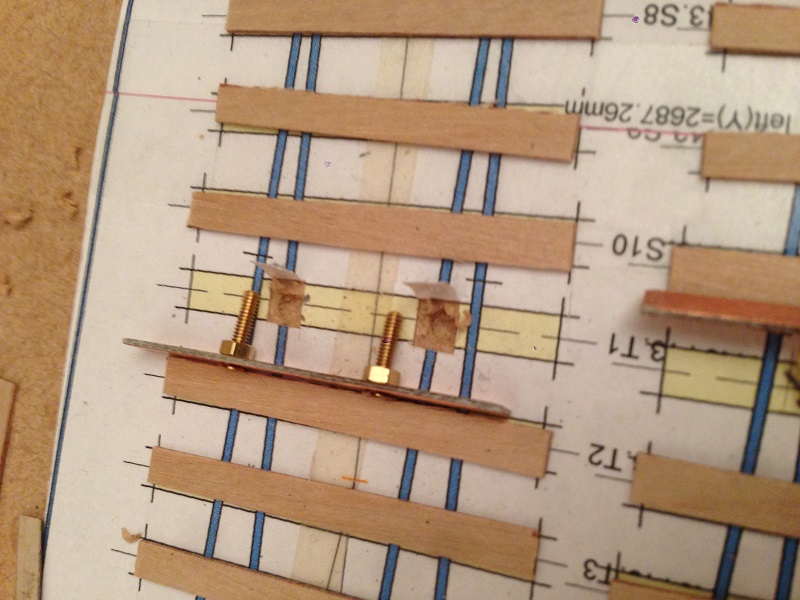

click the date to link to this post click member name to view archived images |

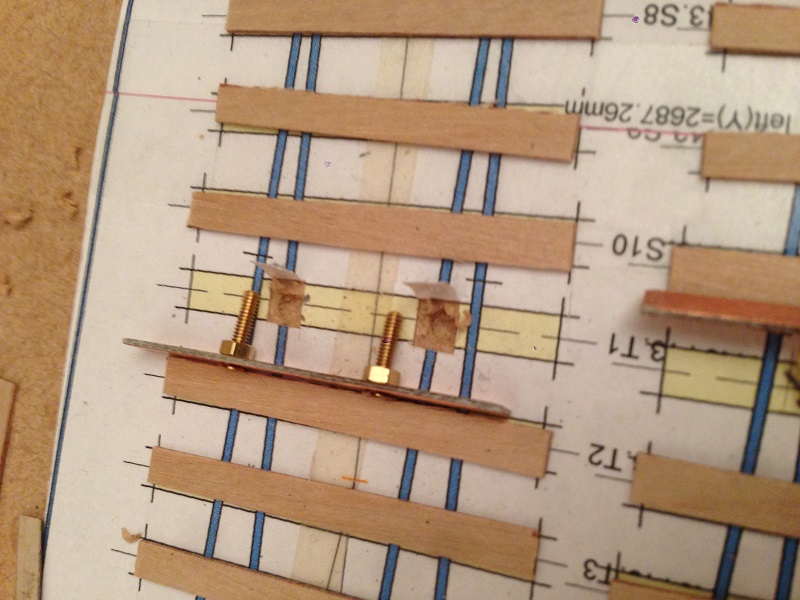

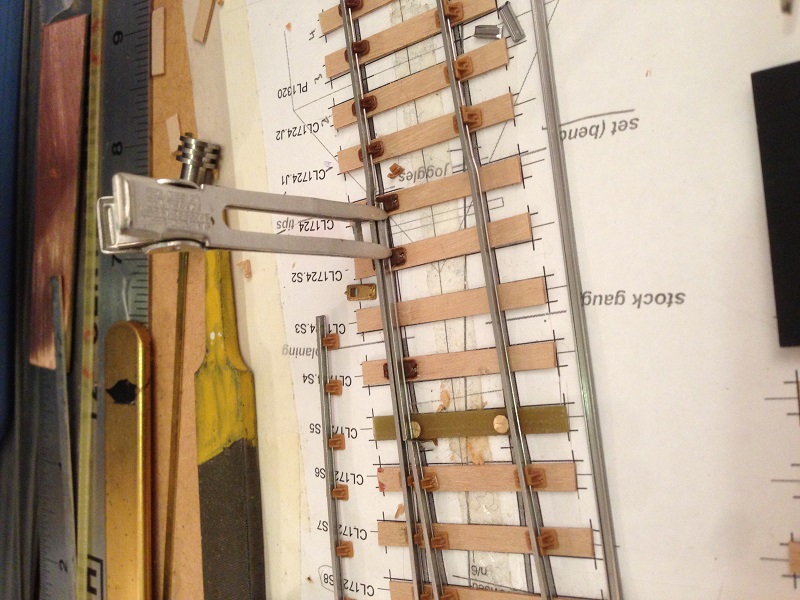

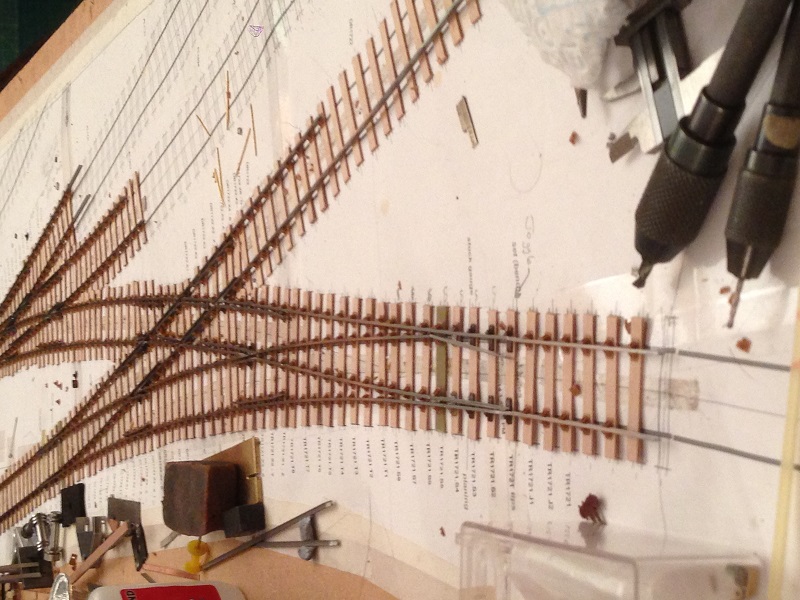

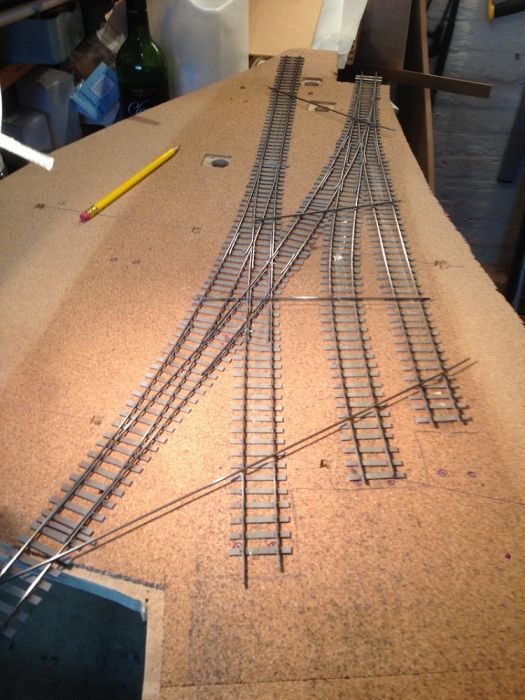

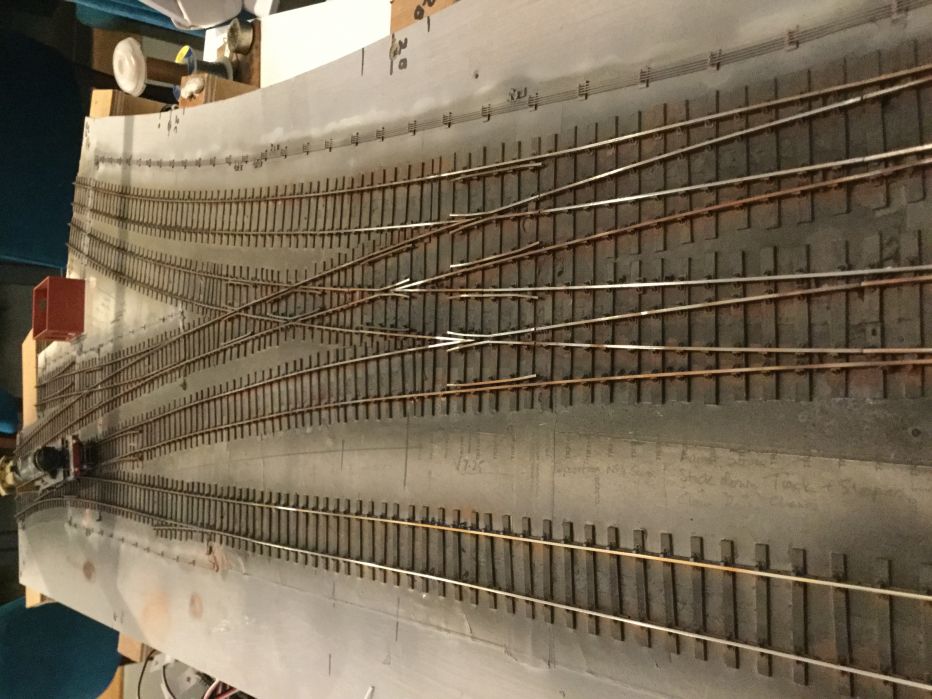

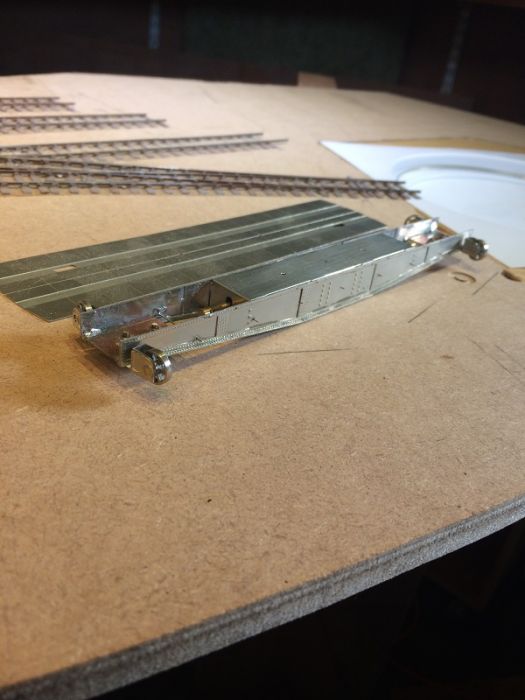

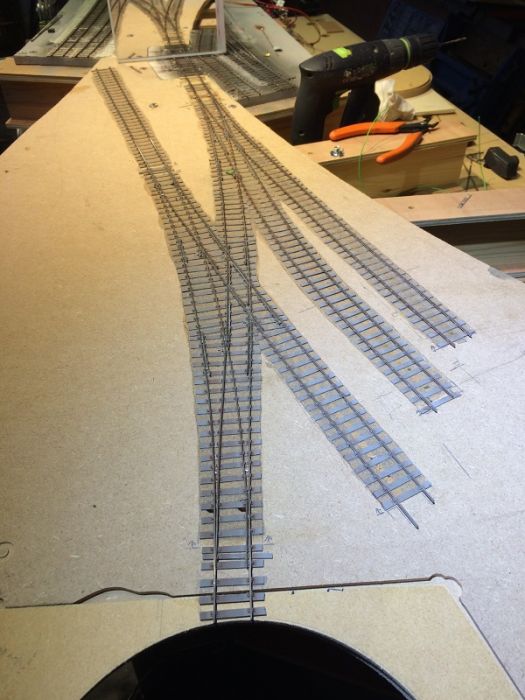

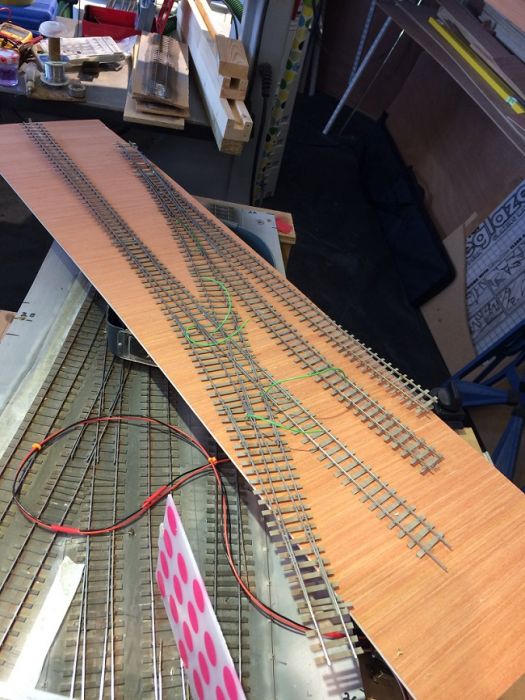

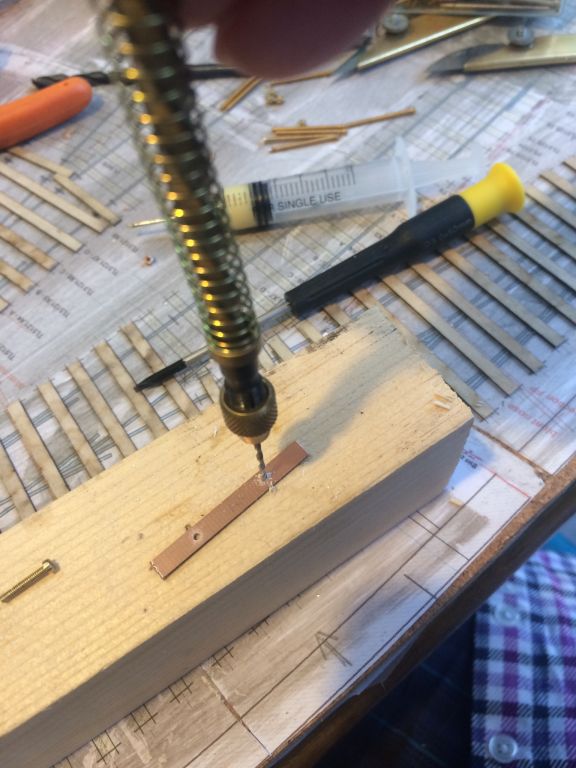

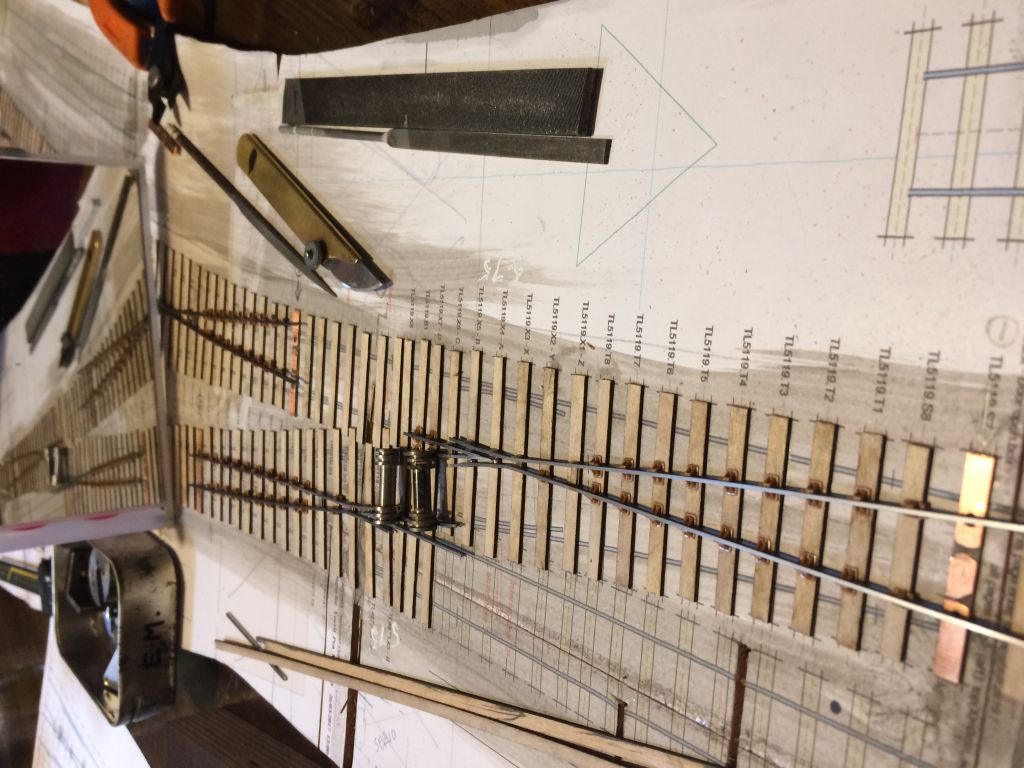

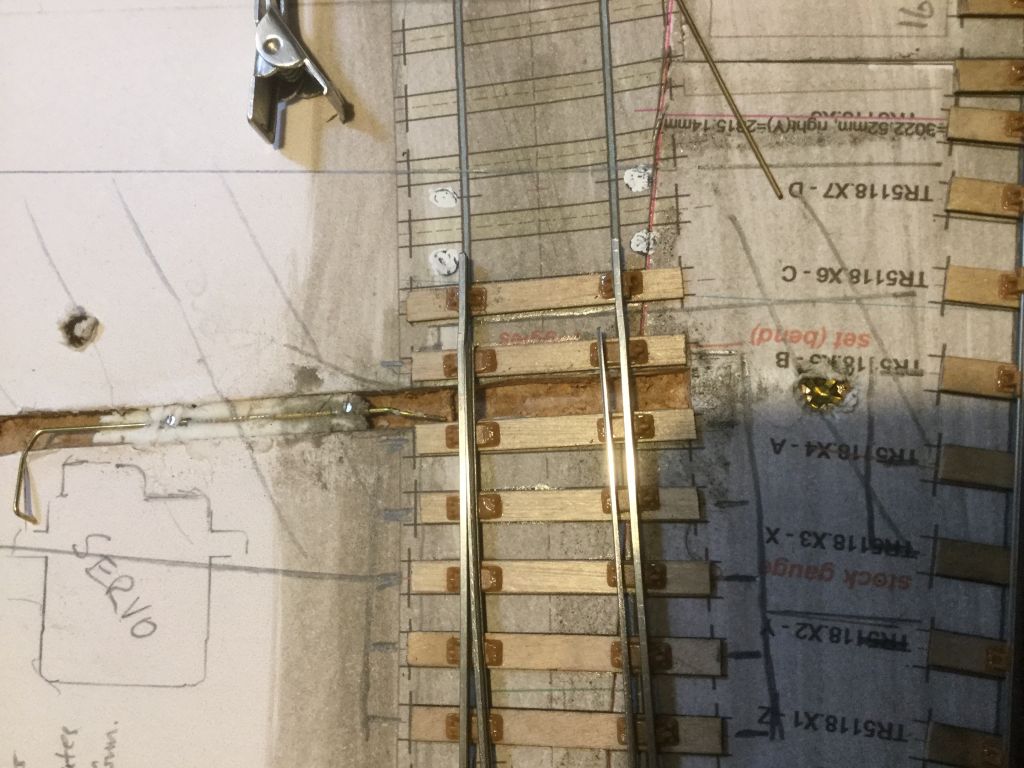

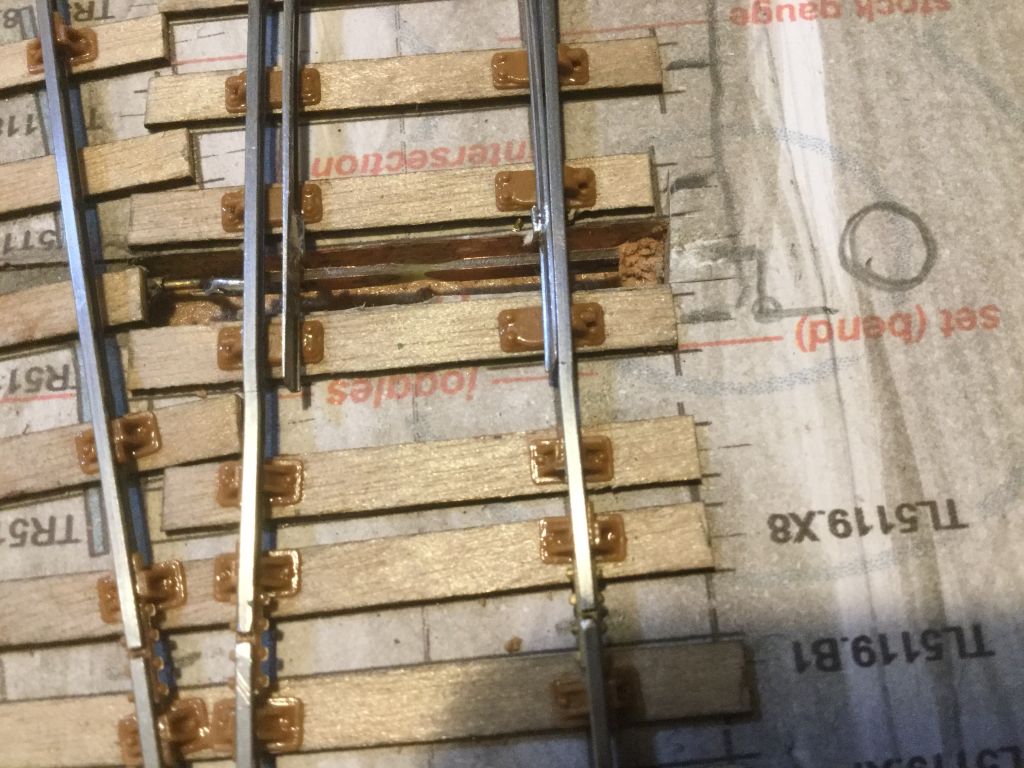

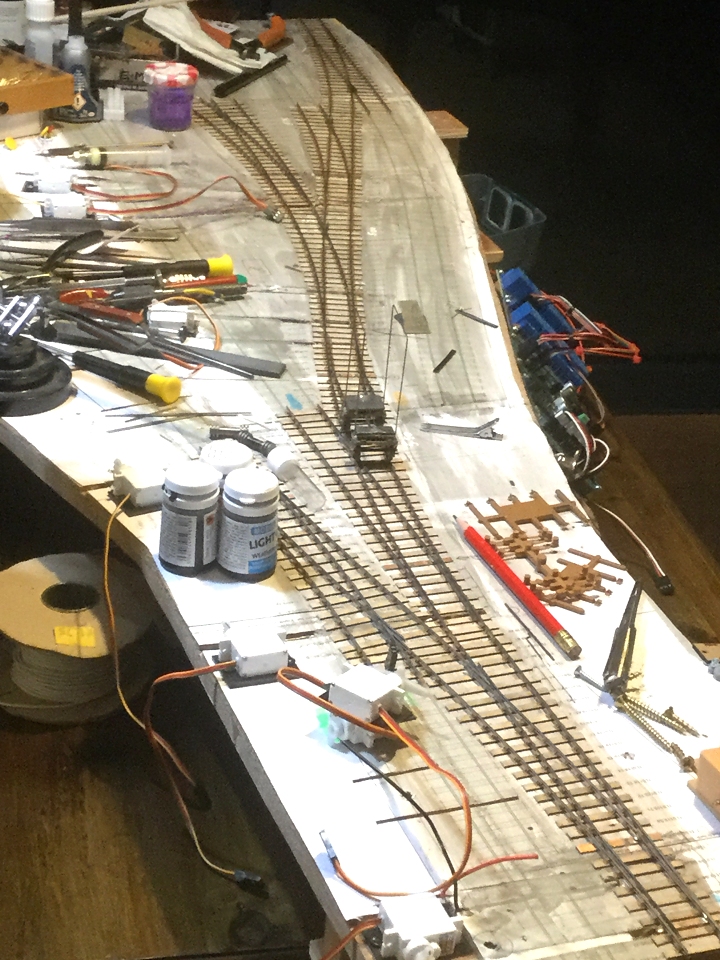

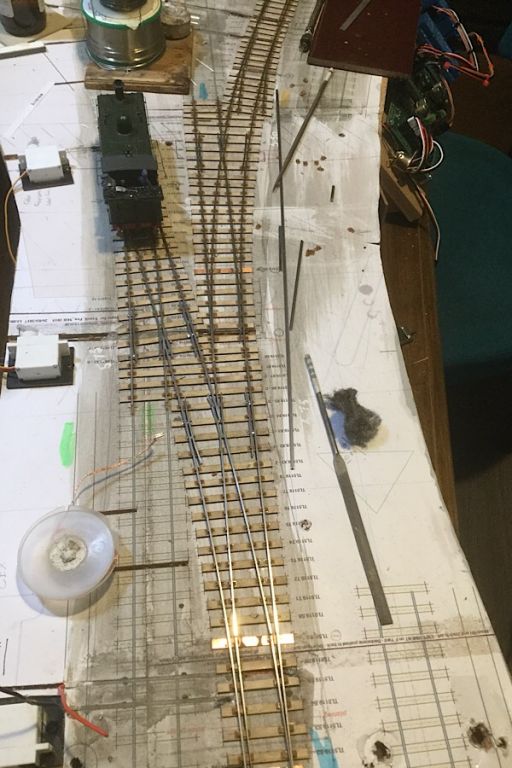

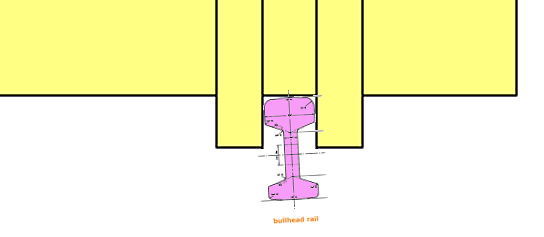

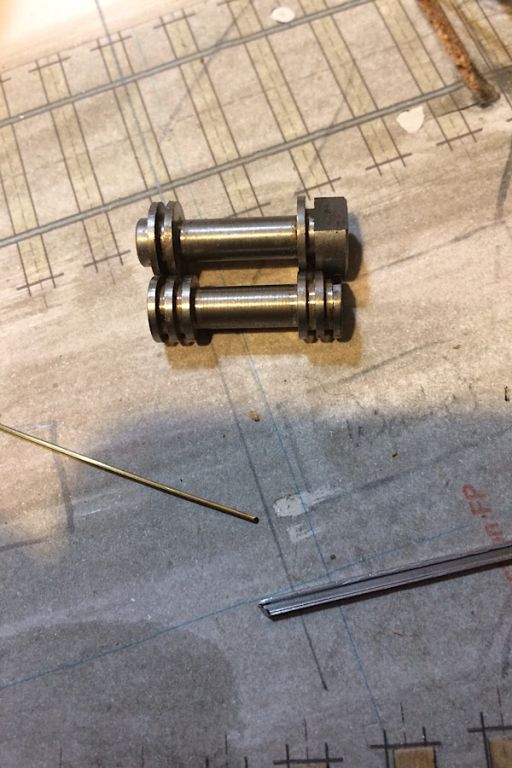

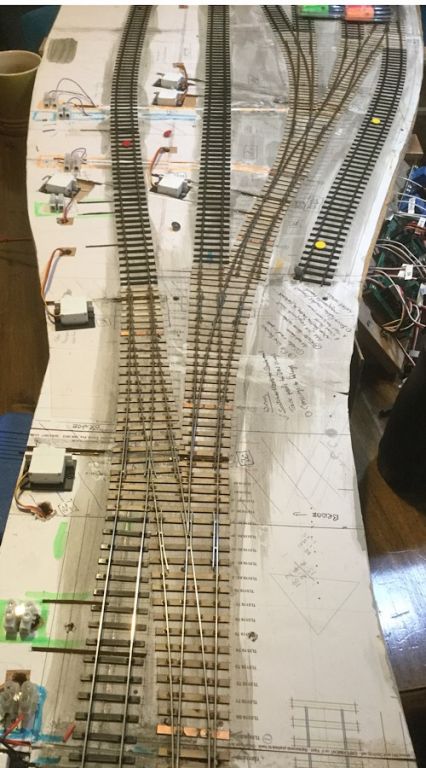

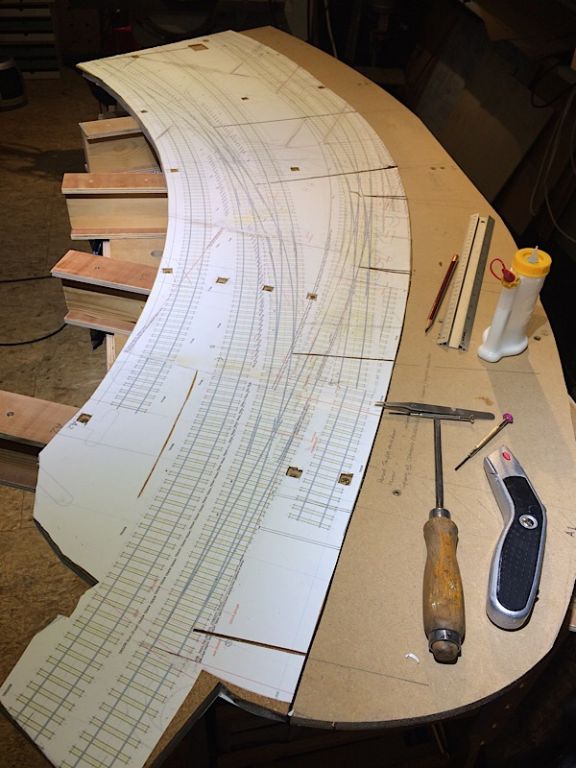

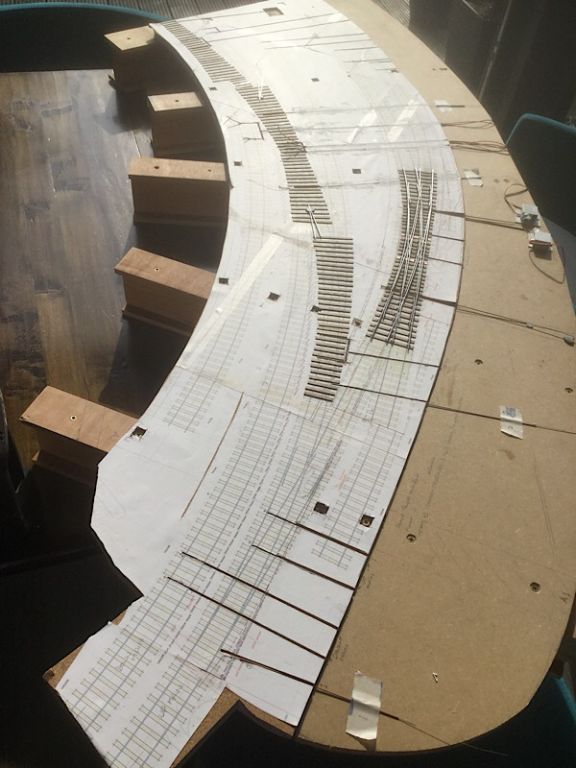

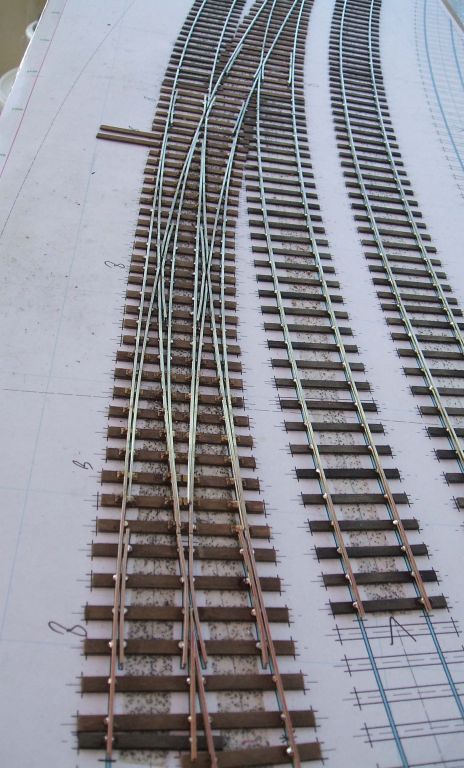

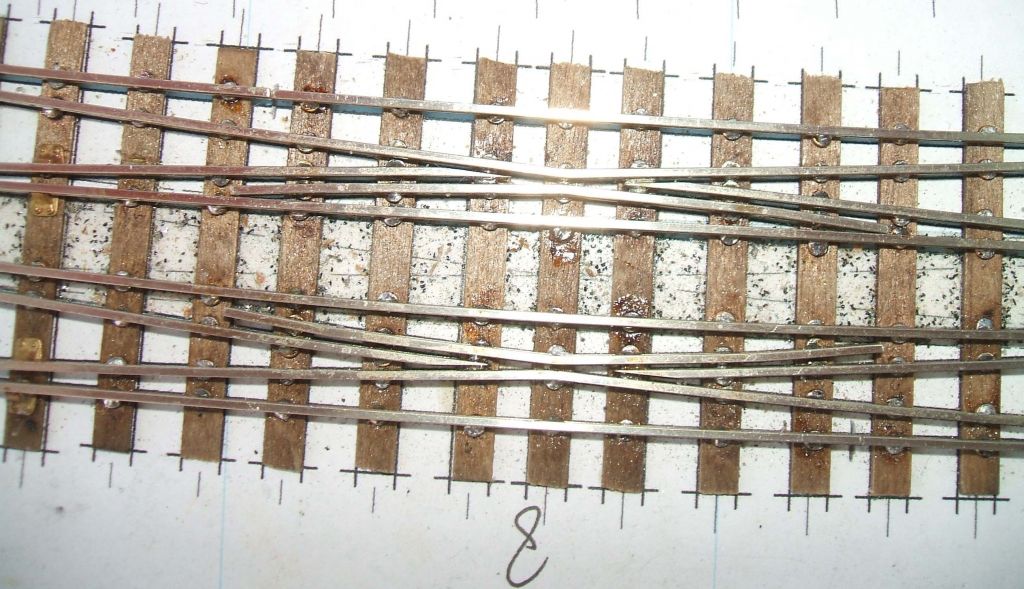

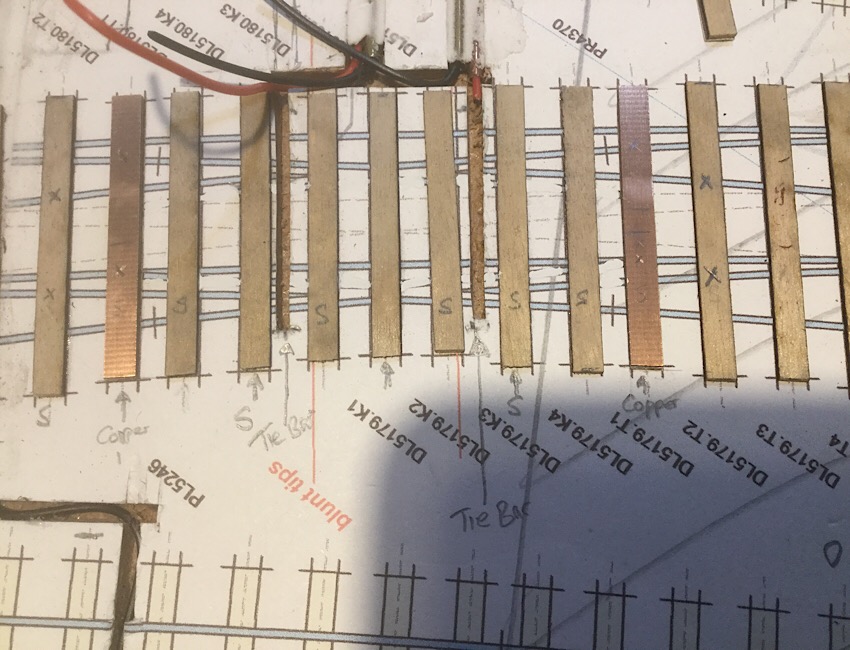

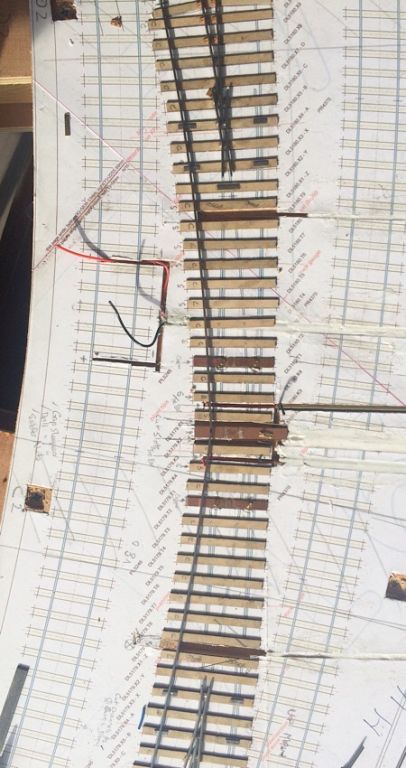

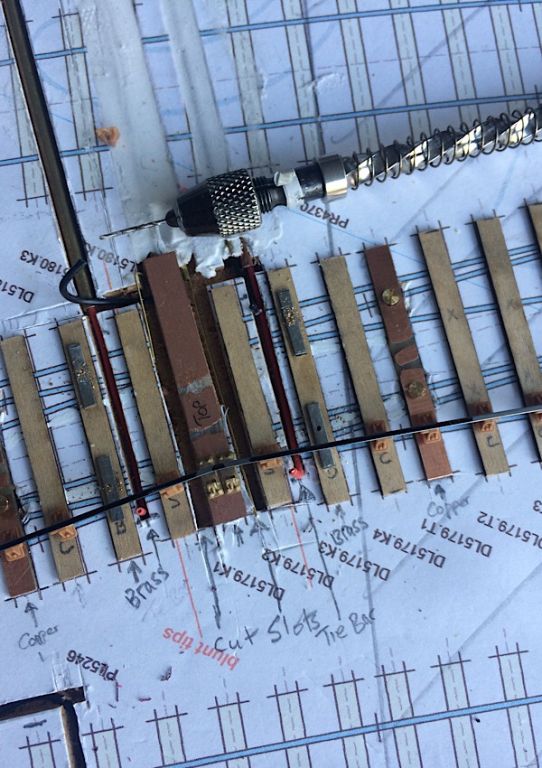

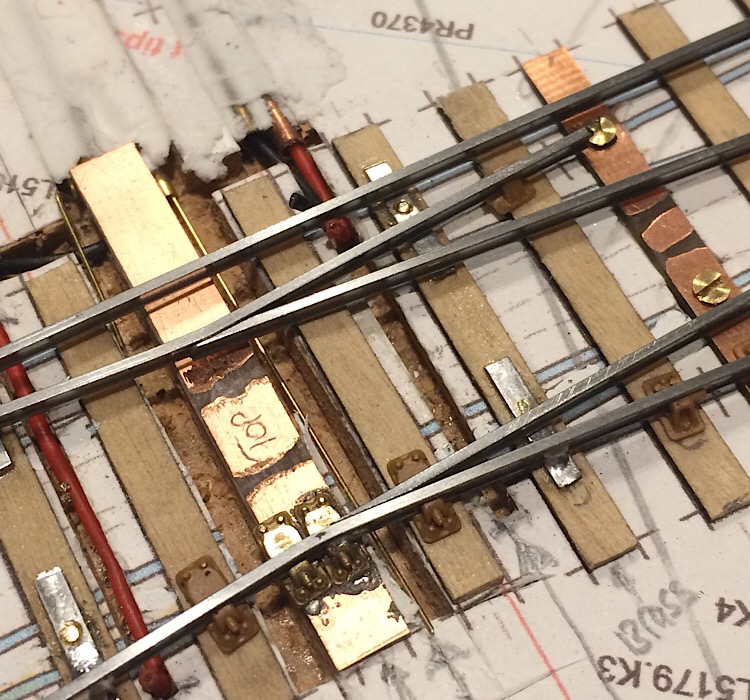

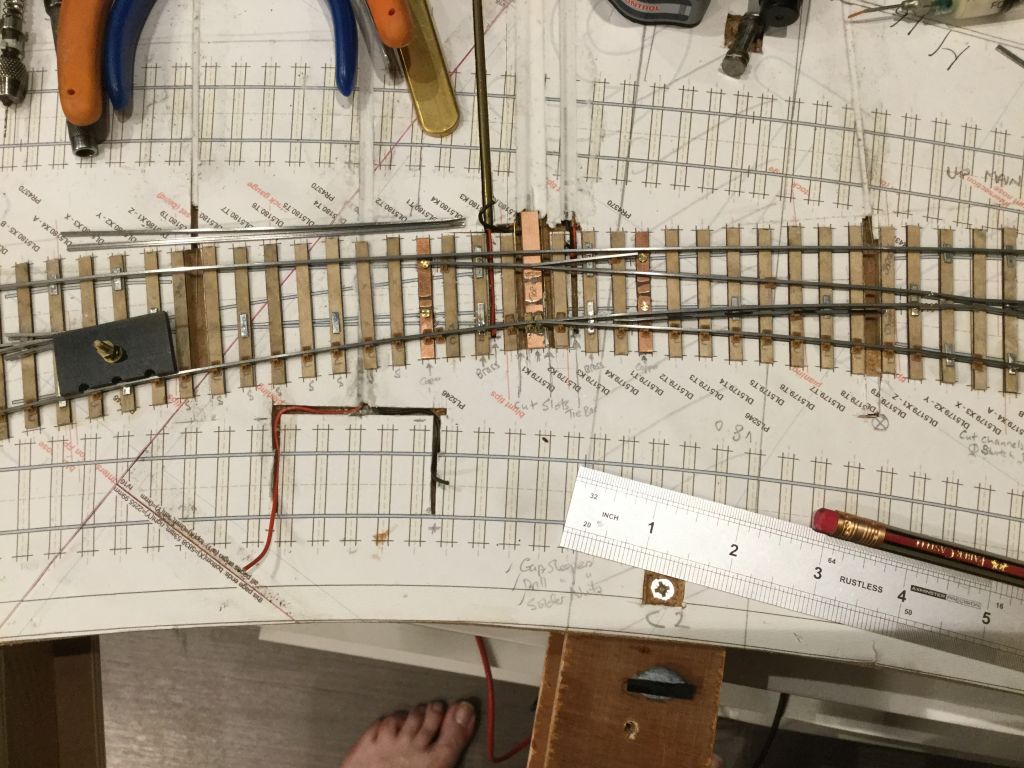

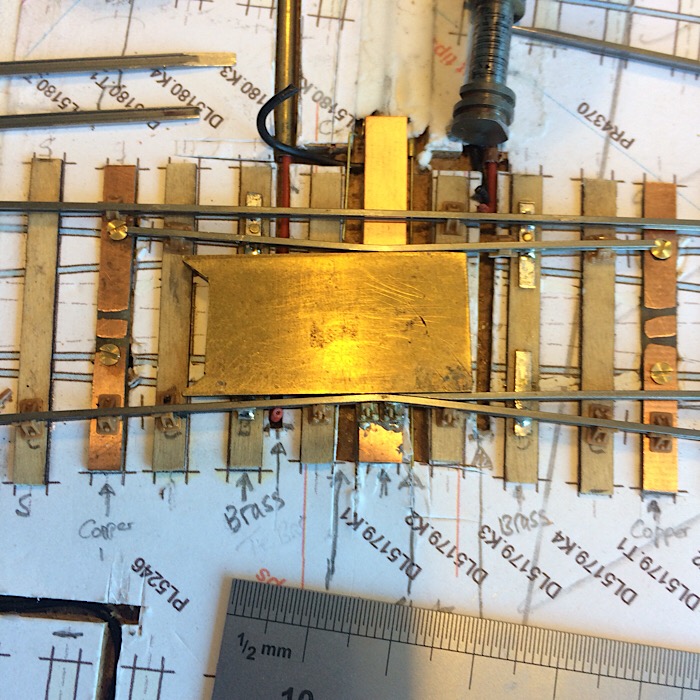

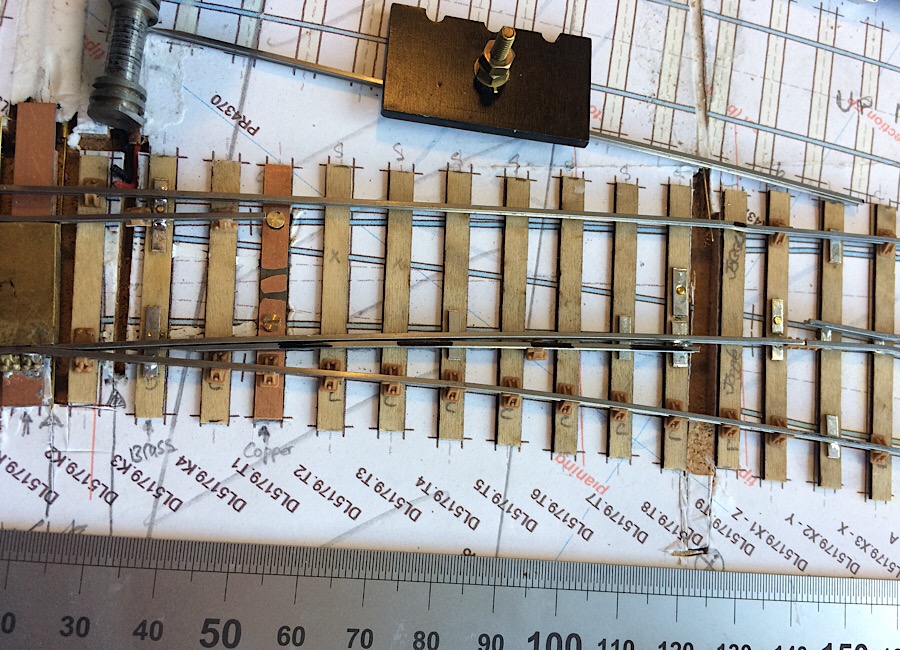

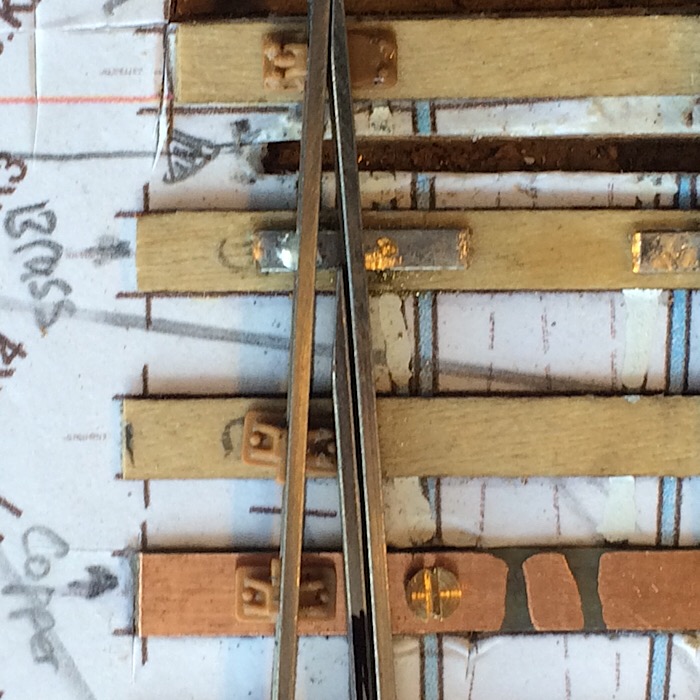

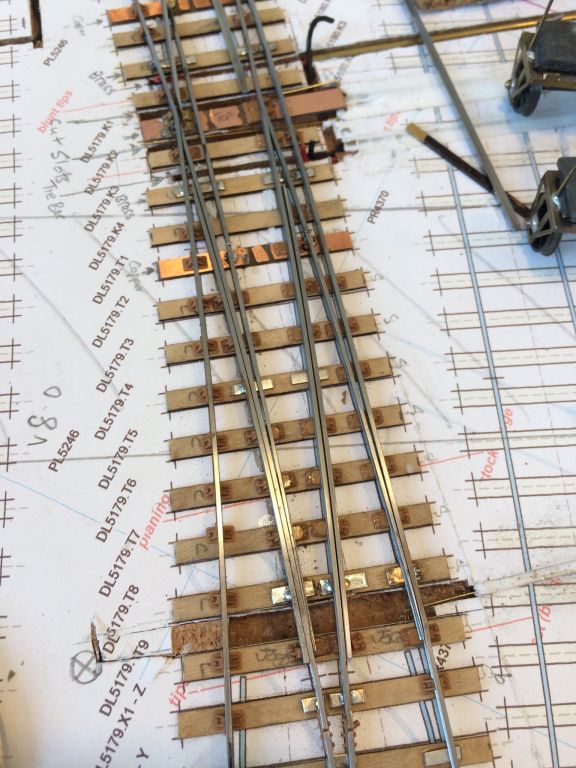

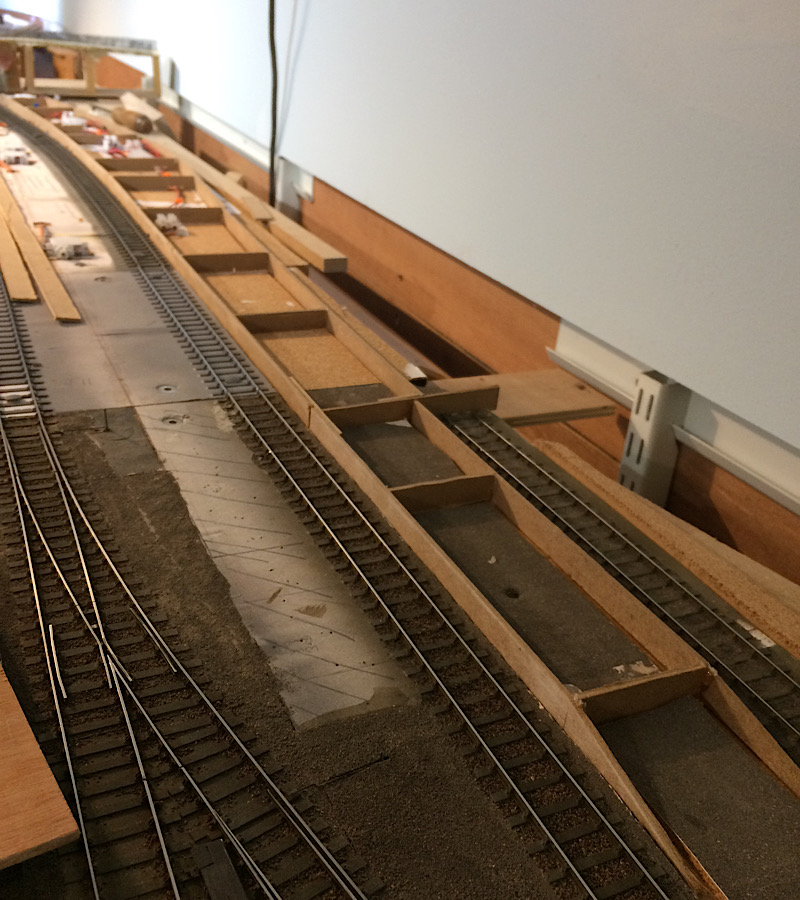

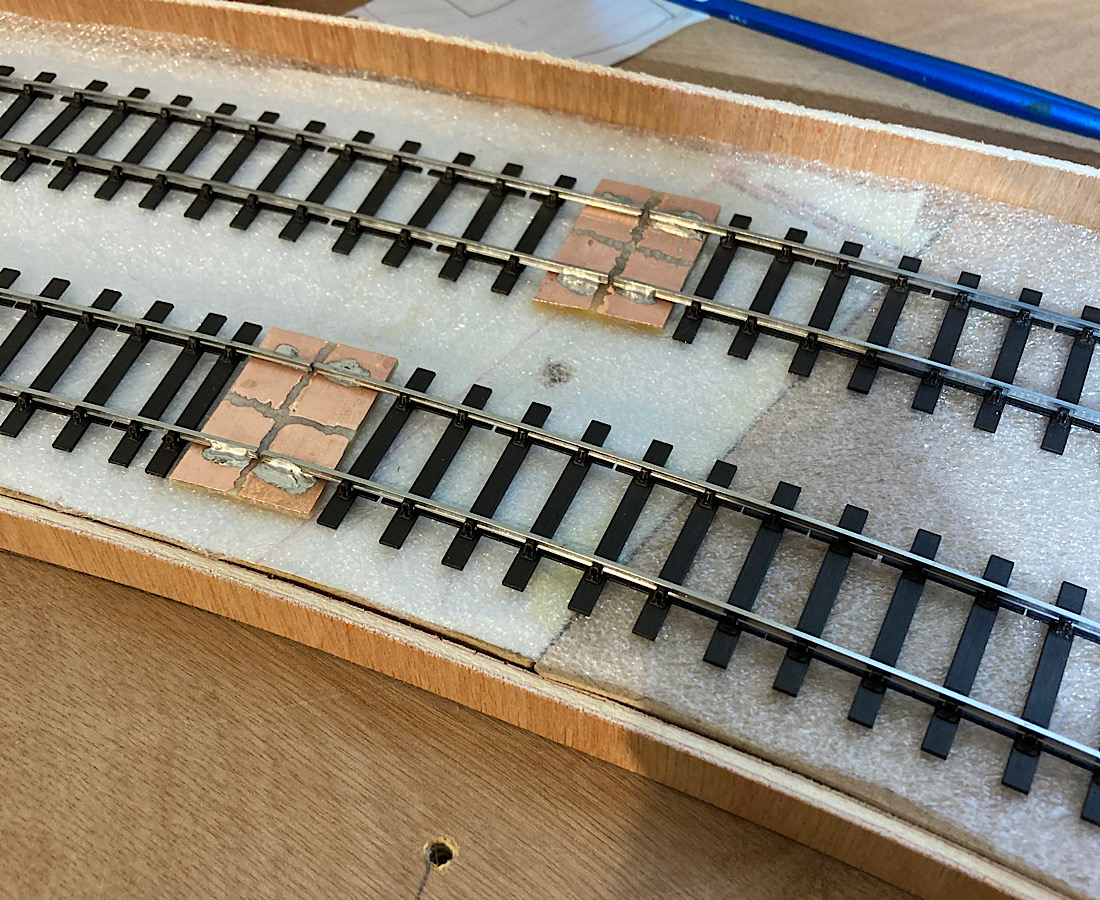

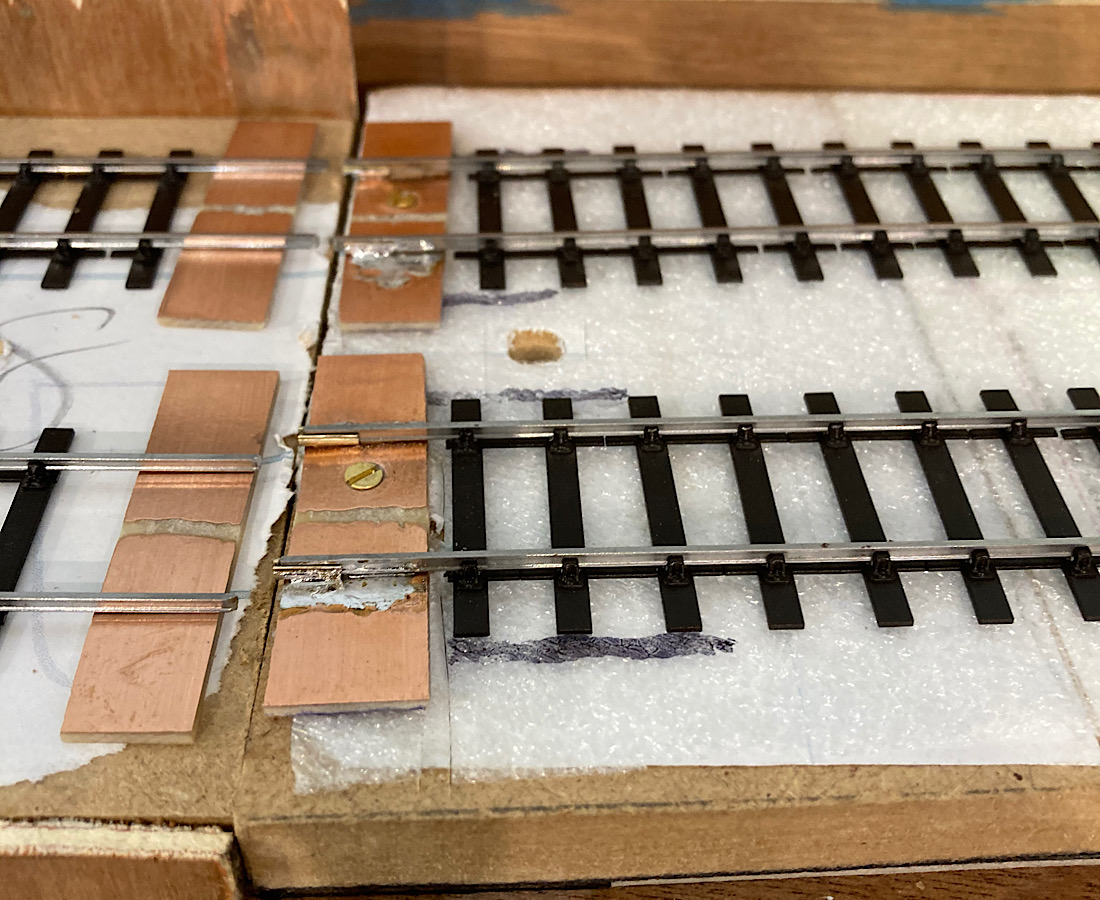

Hello Martin, one and all. I've uploaded some images of my progress on the trackwork for Yeovil Pen Mill so far. Progress has been pretty slow of late as I'm building the shed where the layout is going to live as well at the moment and this from scratch, so until that is finished further track making will be limited. The photos are all of the MPD between the junction. I'm going to try to lay it and ballast at the same time which the more I think about it the more nerve racking it is. I'll report back once I've summoned up the courage to put sleeper to wood glue... 2787_031707_450000000.jpg  Early stages with most of the timbers in place and some rail laid in. At this early stage I was constructing the crossings in situe. I've now copied the idea of a chap on this site who makes all the crossings bonded to the wing rails with thin brass strip unsoldered underneath which makes a very solid job of it! 2787_031702_460000000.jpg  A friend, Dave Doe, told me in no uncertain manner that my ideas of using bent wire to provide the hinge for the loose heeled switches was very poor engerneering practice and generally a no no. I conceded defeat and actually found using 8BA or 10BA nuts soldered to the bottom of the sleeper rather satisfying to do. The appropriate bolt recessed bolt in the sleeper top produces the hinge to which the rail is soldered. 2787_031704_250000000.jpg  and here is the switch blade about to be soldered in position. 2787_031705_320000000.jpg  this shot shows the basic point work in an almost finished state. Just the trackwork to finish and crossing wires installed, before taking outside to spray. It also shows in exaggerated form, the distinctive dogleg produced by the loose heel of the switch. 2787_031658_470000000.jpg  Sprayed and wired, the track is very fragile in this state so I took a tip from Iain rice and soldered some rail across the point work to reinforce it . All I've now got to do is get up the courage to lay it in a bed of glue and ballast it all in one just like Norman Solomon!! Martin I'm aware that this isn't strictly 'correct' continuing in 'Baffled beginners' part of the forum. Would you prefer that I put this under track building topic instead? If so, is it possible to move it if it is more relevant elsewhere? Kind regards and thanks for this really fantastic program. Andrew |

||

|

posted: 3 Oct 2014 23:14 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andrew, Good to see your progress. As you can see, I have moved your message to start a new topic. Your previous topic on track planning Yeovil Pen Mill is at: topic 2326 regards, Martin. |

||

|

posted: 10 Oct 2014 22:28 from: Richard_Jones

click the date to link to this post click member name to view archived images |

Hi Andrew Very impressed.... Keep up the good work best wishes Richard |

||

|

posted: 25 Oct 2014 22:45 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Richard and Martin Thanks for the encouraging and kind comments. Much appreciated Kind regards Andrew |

||

|

posted: 26 Sep 2015 19:12 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

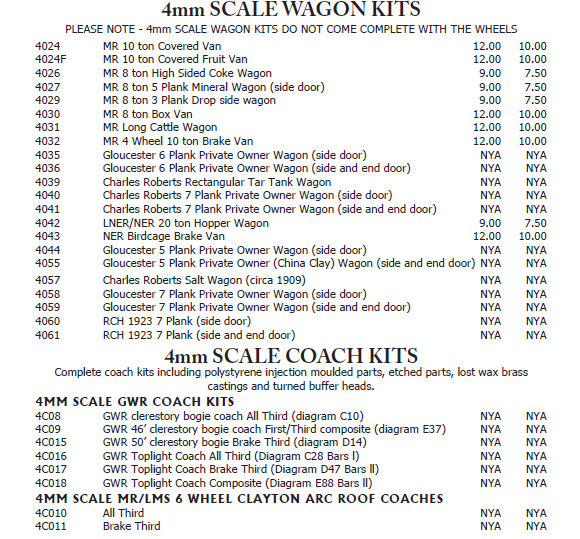

Yeovil Pen Mill update Sept 2015 I thought I'd post a couple of pictures of my progress in the garden, even if layout progress has been minimal in the last 6 months or so. The shed for the layout was quite a challenge. not having ever built anything this size from scratch before(22' x 11') I thought at various points over the last year (I started it in August 2014) that I'd bitten off more then I could chew. But I seem,with quite some help from my middle daughter Jeanne, to have almost got there now. It's even got power and heating in it but as you can see from the interior shot, with a work bench and a band saw, there isn't room to finish the baseboards which will go down the centre of the room! Ho hum. 2787_261334_500000000.png  2787_261338_200000000.png  This shot shows the very wide roof which over shoots on the right hand side(hidden by the bushes) by 4' to provide cover under it for garden tools etc. I'll report more as time and progress dictate. Kind regards Andrew |

||

|

posted: 19 Feb 2017 20:58 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

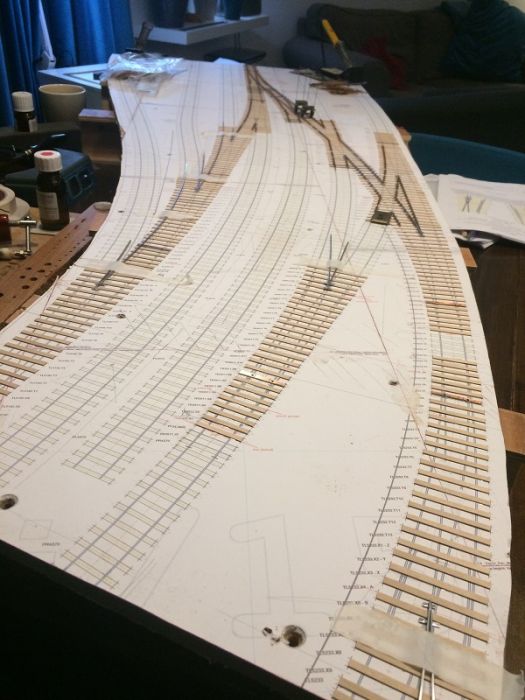

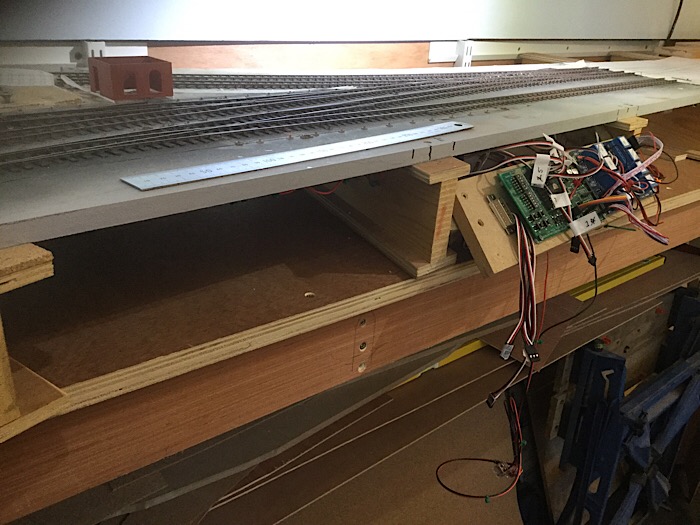

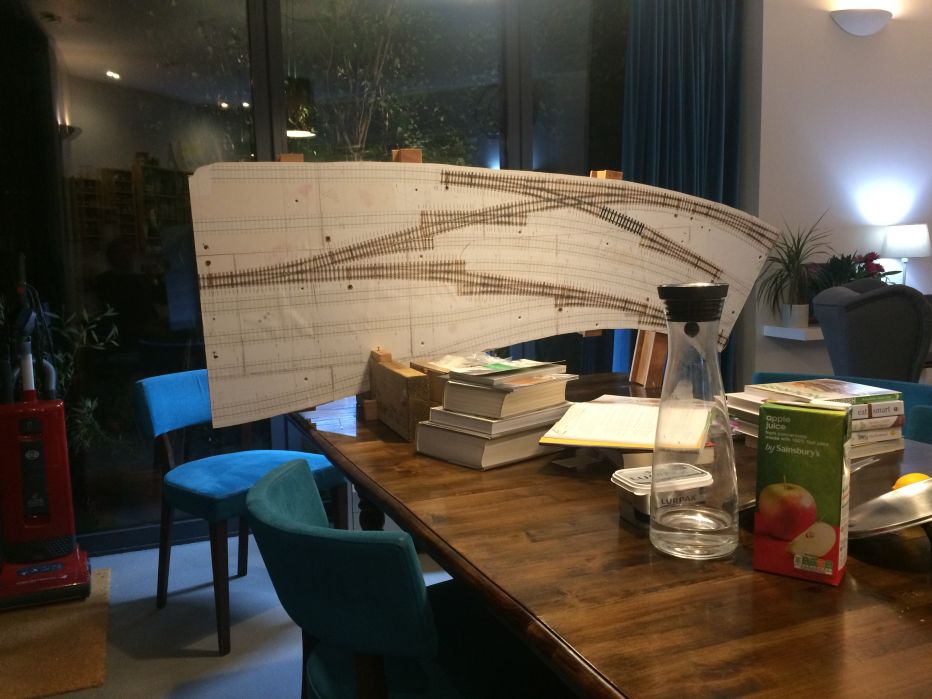

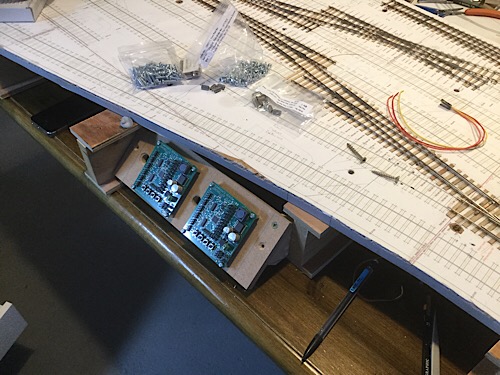

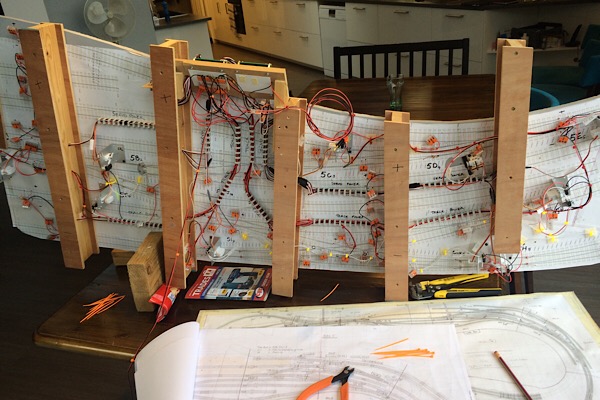

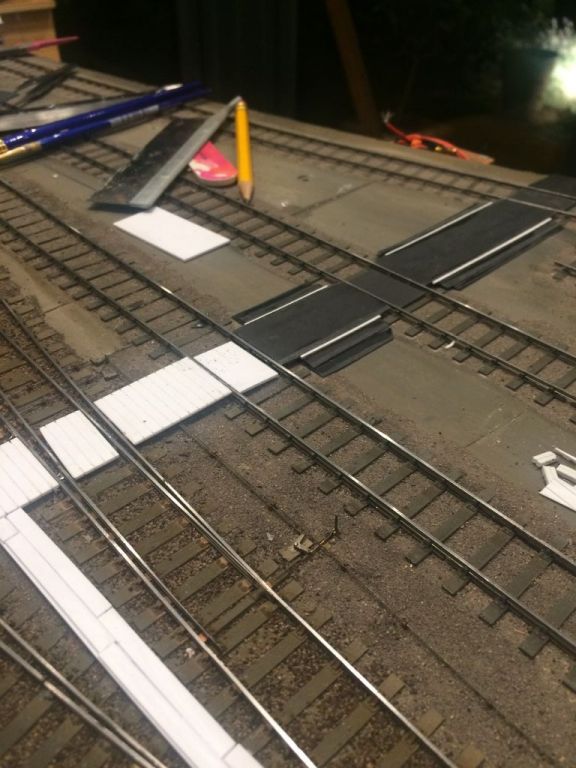

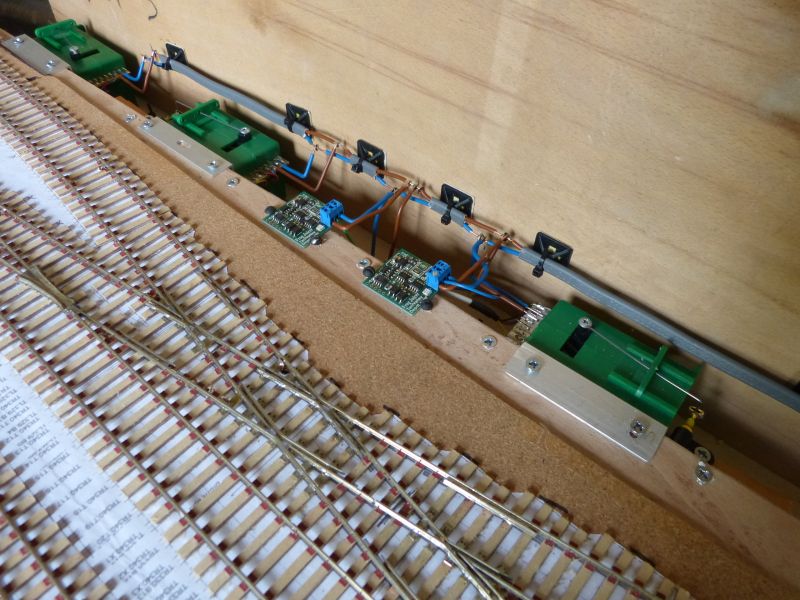

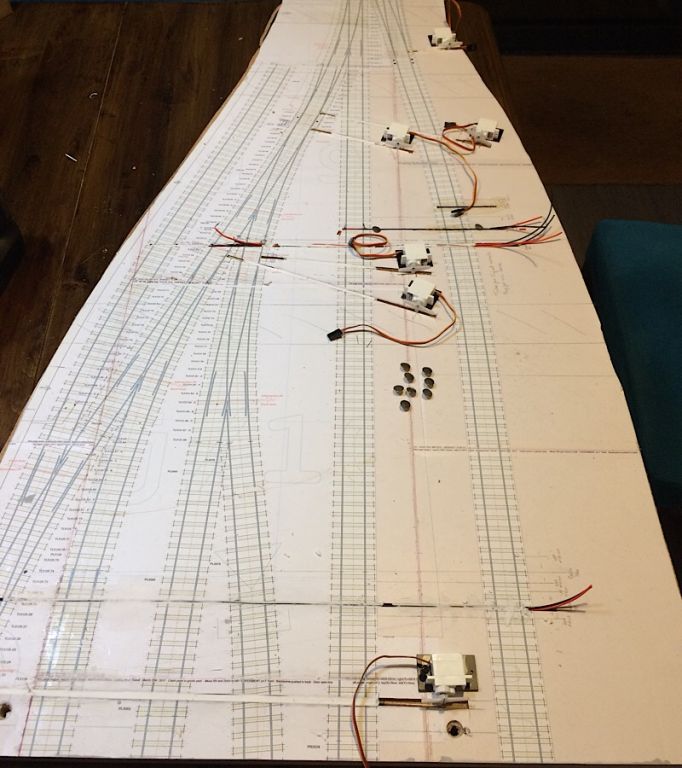

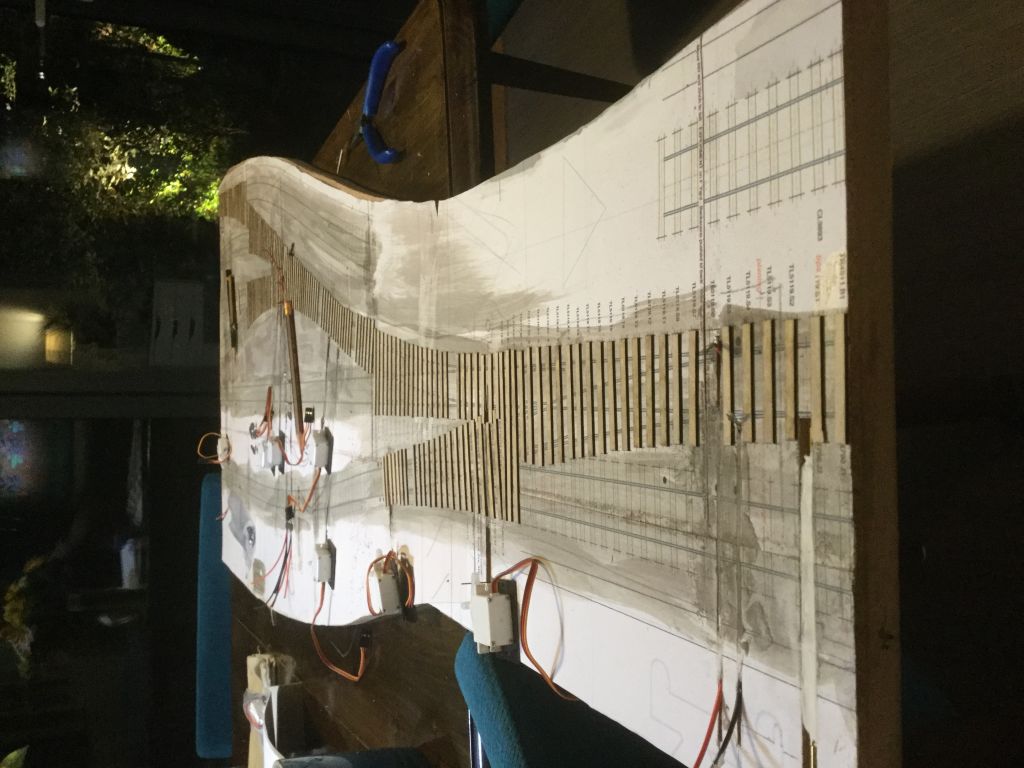

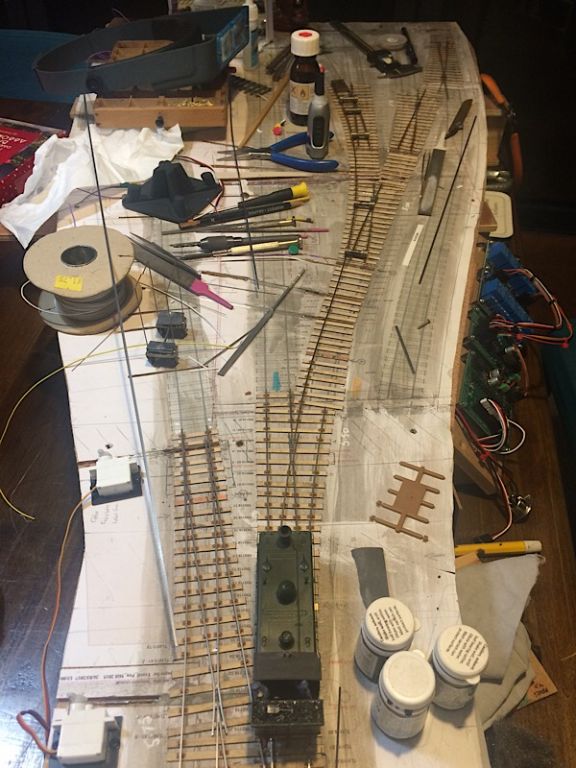

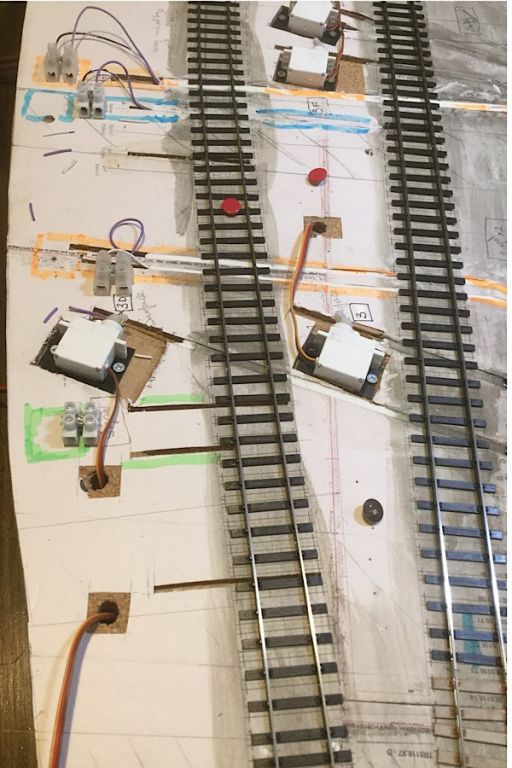

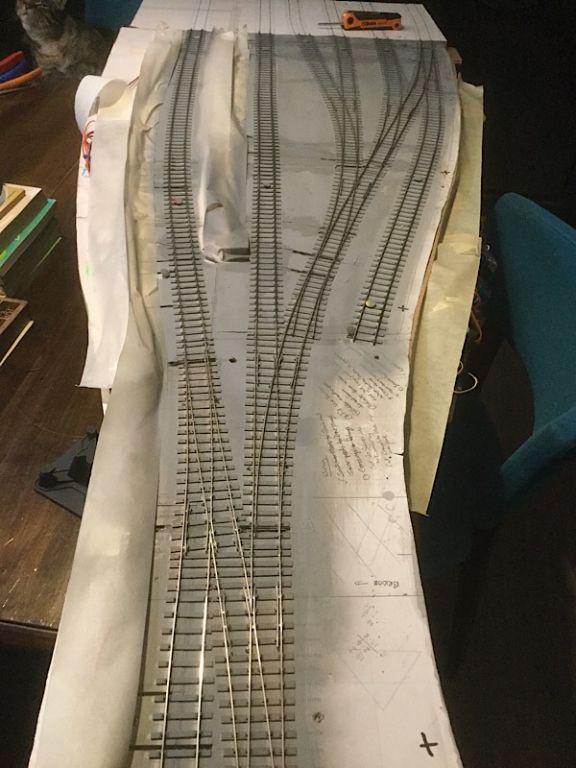

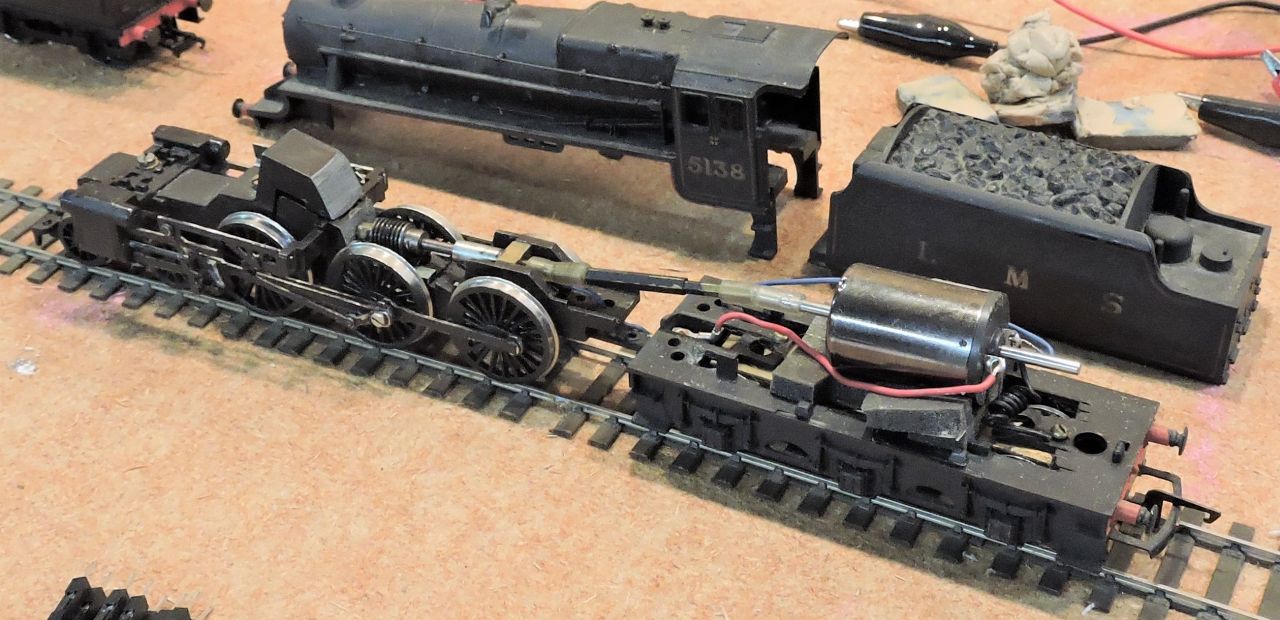

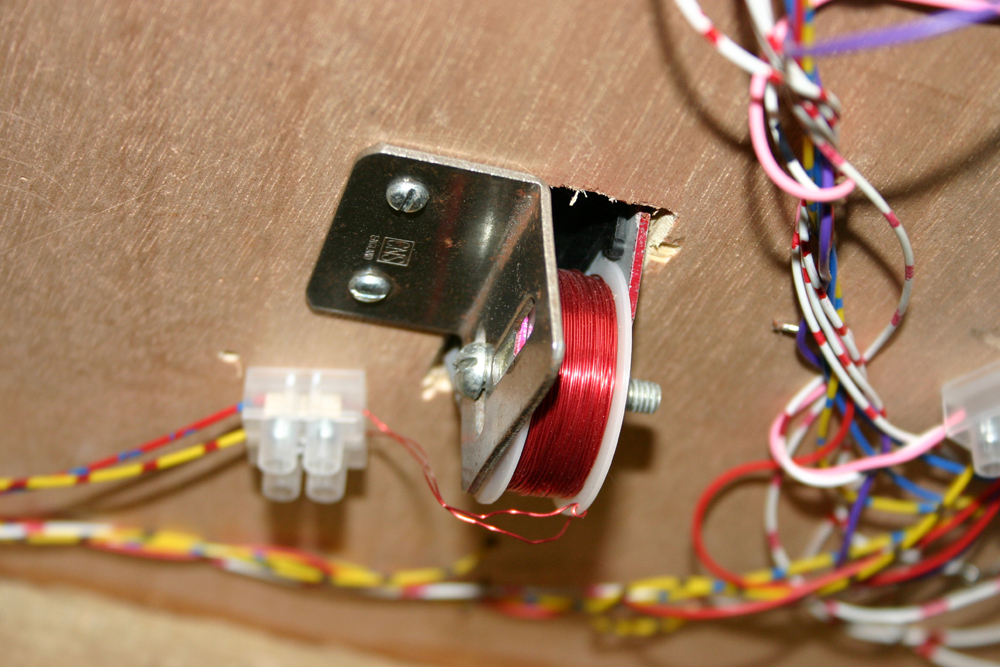

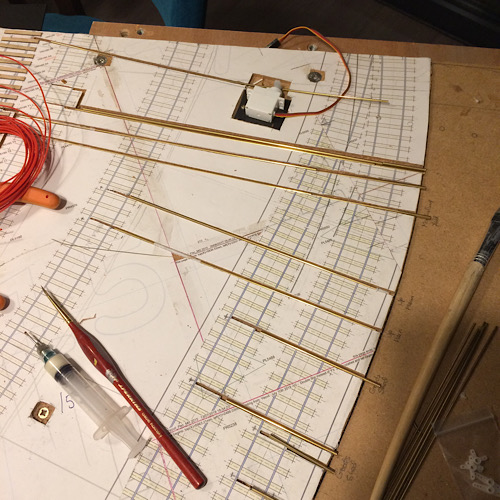

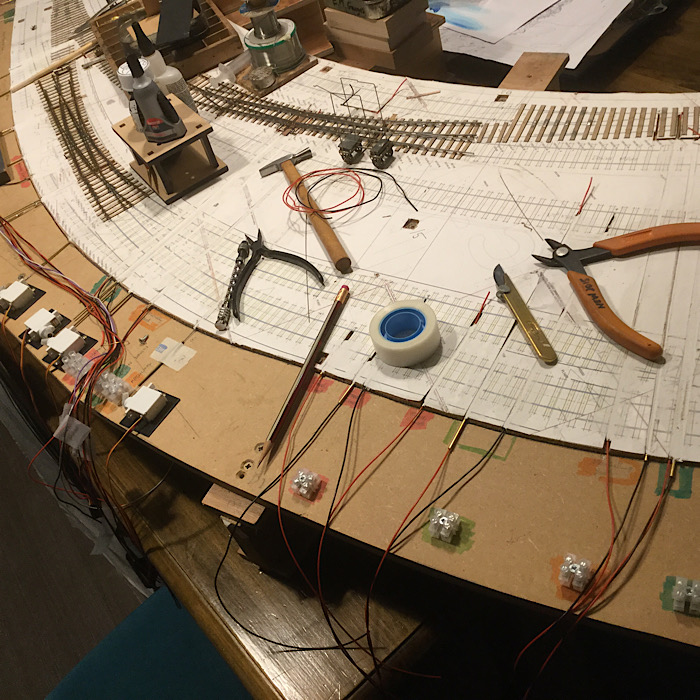

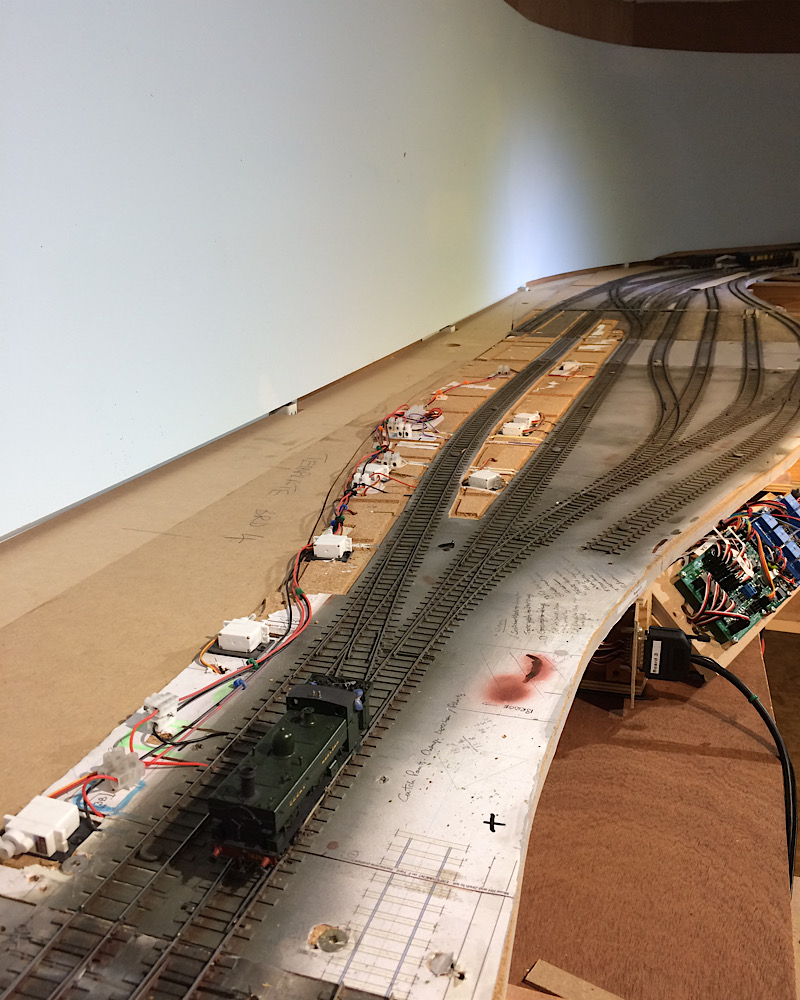

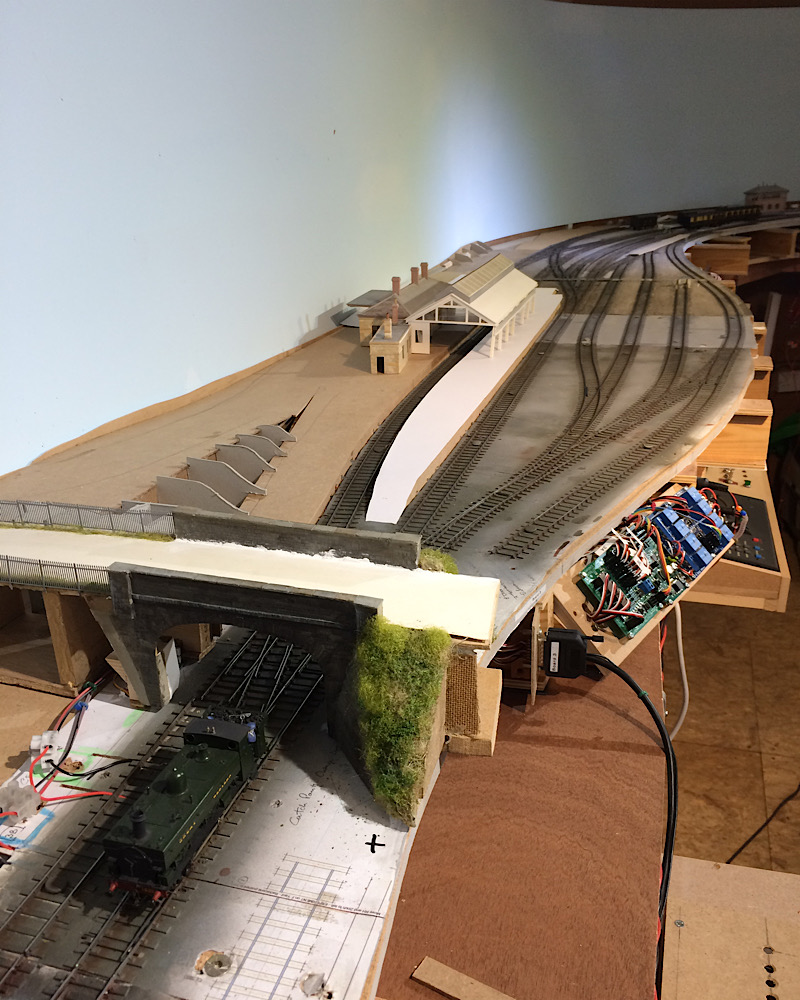

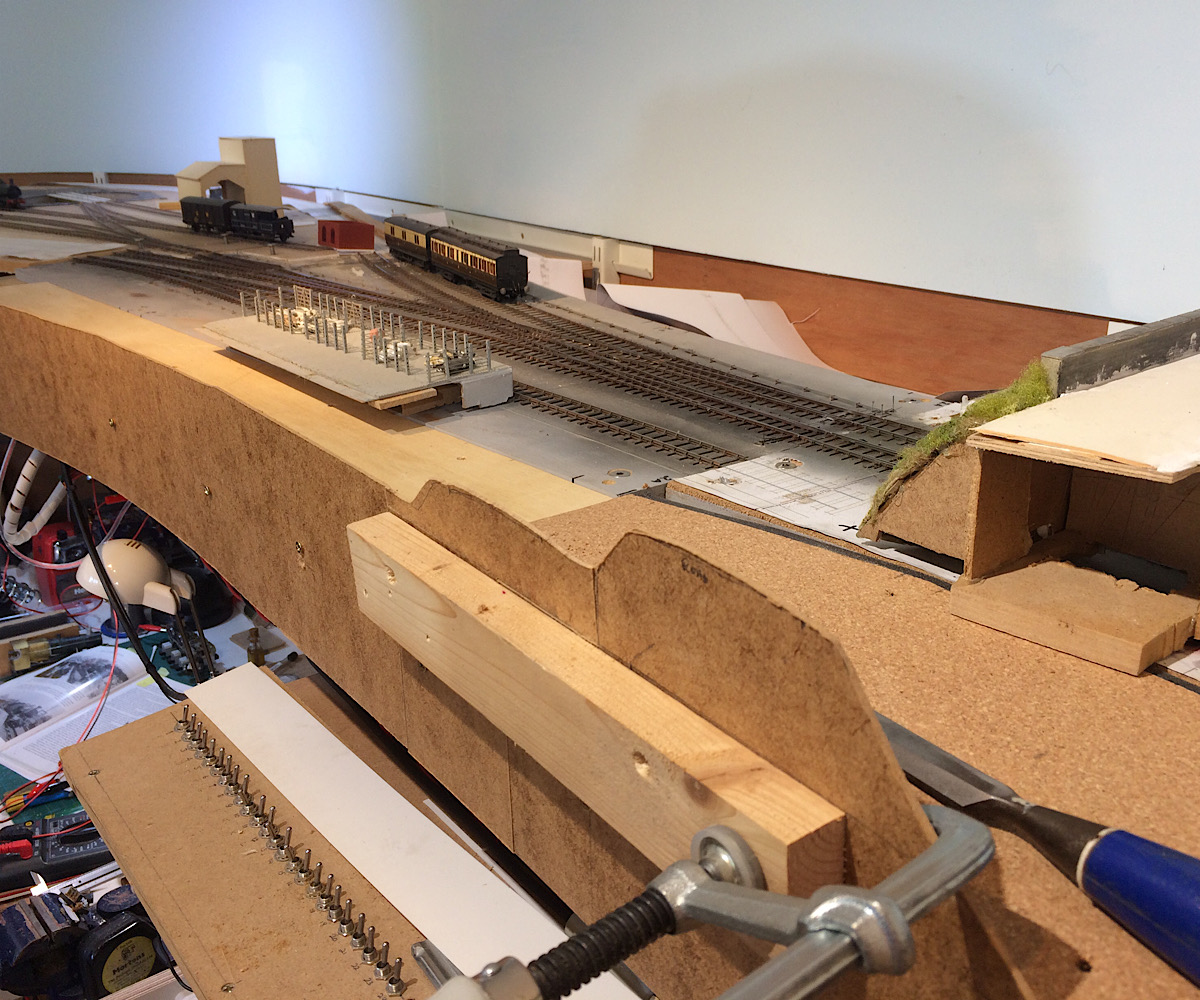

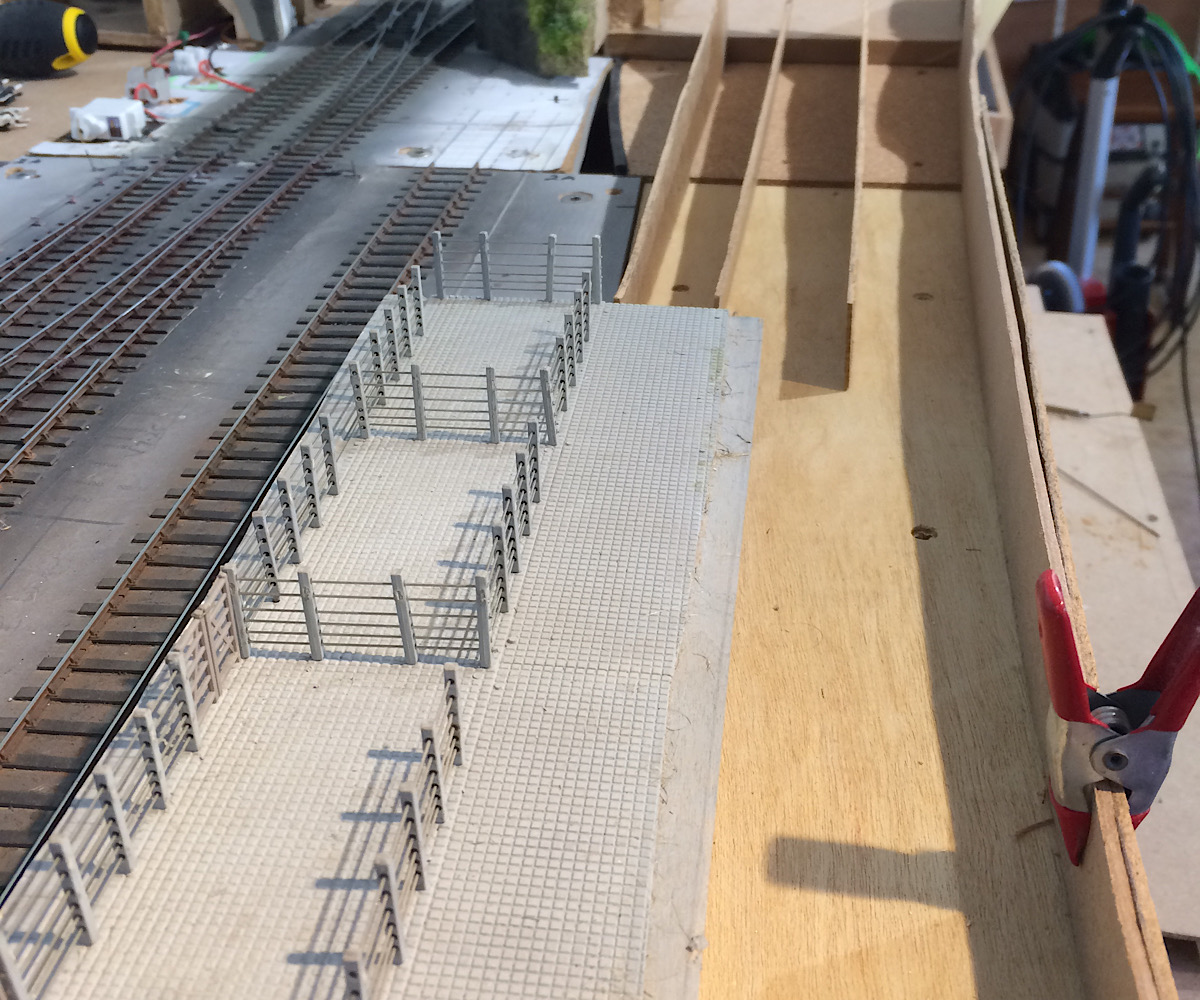

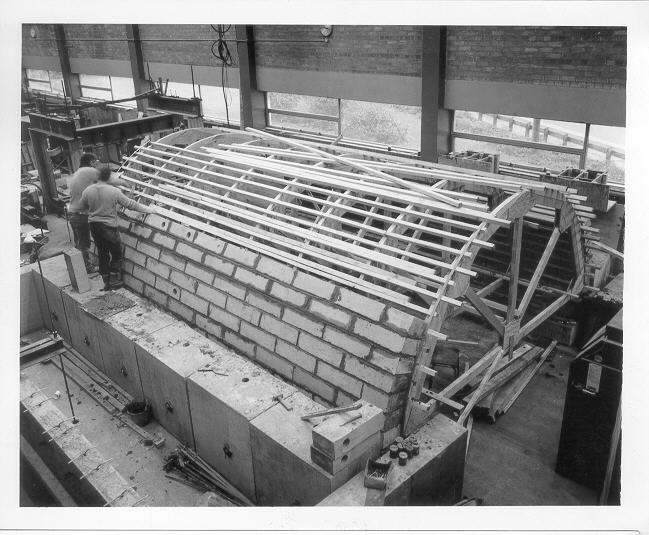

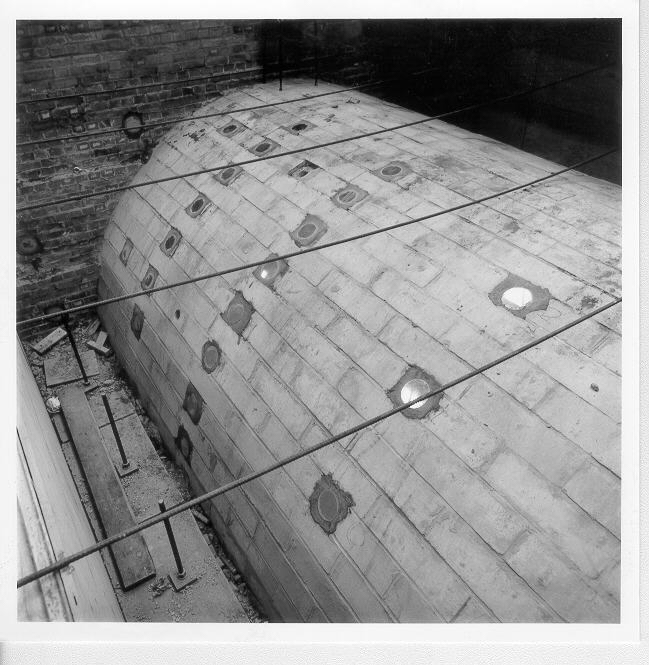

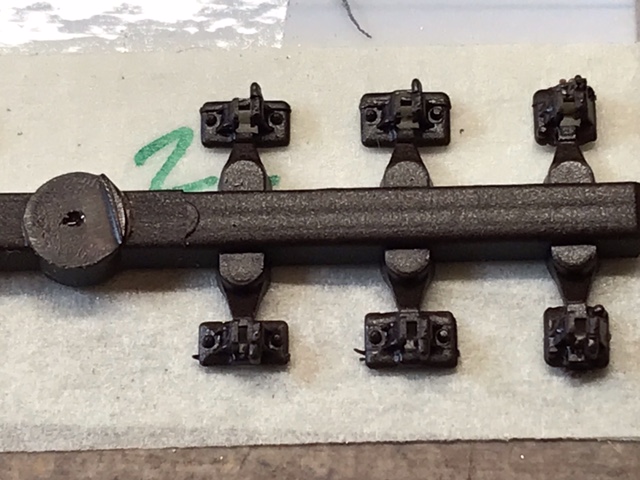

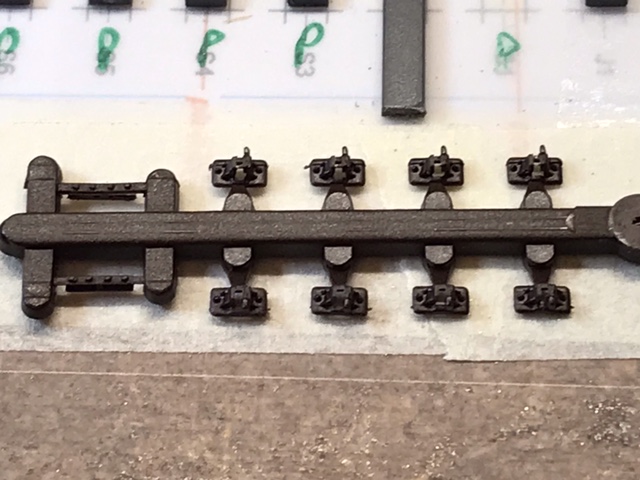

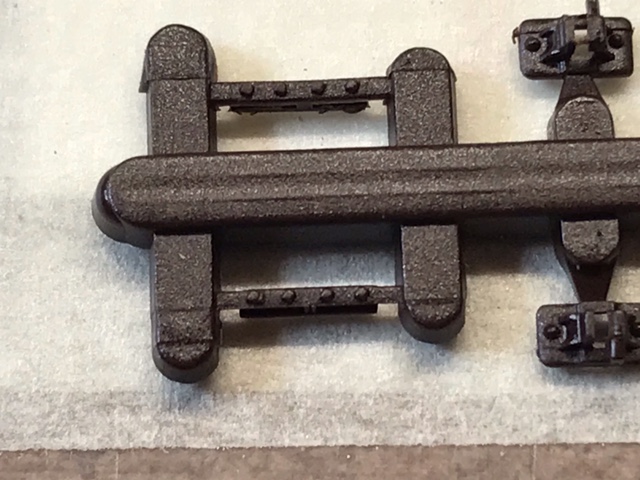

Hello Everyone I've started to make a little more progress now with Yeovil track work. I've still not stuck down and ballasted the MPD track to its baseboard for a variety of reasons, but I have built the next base board joining the MPD which is the double junction board. I thought it might be of interest to describe the methods I've used for this as its rather different to the approach that I started to take with the MPD. With that I'd built the track on sleepers double sided to the paper templates with the intention of removing the template at the end (which I did) and then laying the lot "Norman Solomans style " in one go and ballasting...job done! Well I still haven't plucked up the courage to do this, so... I then got interested in Howards Bolton's method of building track with the crossings pre fabricated directly on a spare template which in part is what I've followed in this next board which you'll see in the photos below. I say partly because I'd already stuck down the sleepers with double sided tape again intending to do the same as I had before. This time however I did not remove the template at the end of the track building, I just lifted it off its temporary construction board and stuck it in place with some "3M stuff" (does anyone know of an alternative glue that sticks well but allows adjustment before it goes off?) that did not swell the paper and sticks like the proverbial. This time I've stuck it directly to the baseboard (another departure from before when I used 3mm cork) which is 12mm MDF sealed with a coat of paint to prevent / reduce swelling and shrinkage which in turn is mounted on four 90mm high supports which in turn sit on the layout sub base(18mm ply). Why did I go for such a complicated set up? My need / requirement here is to have the layout broken up into sections 3' to 4' long so that I can build each section in the comfort of our main living room and so that if there any problems in the future I can remove a section from the main layout in the shed and bring it into the house to work on. Luckily for me I'm married to a pretty tolerant woman who still seems to be very fond of me despite my rather eccentric hobby. Maybe its something to do with her training as a psychotherapist, I think I'm probably an interesting case study for her...can't otherwise understand why she should put up with a bit of trainset on the end of our dining table week in week out? Anyway domestic arrangments apart, back to the layout. Here are few pictures of what Ive been describing above...if I can recall how to upload? 2787_191503_490000000.jpg  This view shows the underside wiring including the servos for turnouts controlled by the Megapoints electronics which seem rather like magic to me....! 2787_191512_420000000.jpg  Yeovil point rodding under construction last month. Unlike Howards point rodding mine doesn't have to work luckily, as even this non working set up took an age to do. Incidentally I used Modelu point rodding stools which really are quite exquisite models (if only I could see all the detail!) Howards cranks, compensators etc and Eileen's metre long 0.4mm straight brass wire( this may have been a mistake as I've since read that brass gets damaged easily and perhaps nickel silver would have been stronger). I'm getting rather strange effects on the computer screen now so I think I'll quit whilst I'm ahead and try and upload this as it is. Kind regards Andrew |

||

|

posted: 20 Feb 2017 06:45 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hello Andrew, Many thanks for the update. Good to see such progress. It's nice to see the rodding being built into the pointwork as you go. On many layouts this gets left to last and considered part of the scenic department. And since no-one commented on your shed, may I add belatedly that looks to be a very inviting place to build a railway. And the pictures are a pleasant reminder of summer, on what here was a very grey day. regards, Martin. |

||

|

posted: 20 Feb 2017 16:37 from: Nigel Brown click the date to link to this post click member name to view archived images |

Thought the shed looked inviting as well. What form of heating are you using for it? Cheers Nigel |

||

|

posted: 20 Feb 2017 18:29 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Martin Thanks for your comments on both the point rodding and the shed. it probably is unusual to see rodding put in at this stage but having been influenced by Howards methods and hearing some unhappy stories from people who tried to install it after ballasting I think I'm glad I did it at this stage. As to the problem that I emailed you about last night resulting in your questions about pasting from Word and was I using IE or Edge? I was using Internet Explorer 11(I think...last one before Edge) but no it wasn't pasted from Word. I think I've been using IE 11 for a number of years and don't recall having this problem before? I presume that you don't feel the photo size was the problem at about 2MB? As an experiment I'm uploading another photo here which is only about 600KB. We'll see what happens but I'm still using IE 11. Later I'll try Chrome and upload a larger image to see how that does. Kind regards Andrew You'll notice that I haven't infact uploaded the image because as soon as I did it went funny as it had last night so I deleted it. I'll try Chrome later! |

||

|

posted: 20 Feb 2017 19:13 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Nigel Brown wrote: Thought the shed looked inviting as well. What form of heating are you using for it?Hello Nigel I'm using a 190w green house heater which gives background heat all year round. And for those days when its freezing and I'm working in there I have a little 2kw heater which is ususally set on 1kw. I can get away with so little heat because the floor has 4" of insulation in it and the walls and roof 6" and although Imade up the windows myself I did buy double glazing units for them as well. In fact the door which is curved has also got insulation in it as well...a bit mad or anal but I really enjoyed the whole experience of building it. Kind regards Andrew |

||

|

posted: 20 Feb 2017 21:34 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

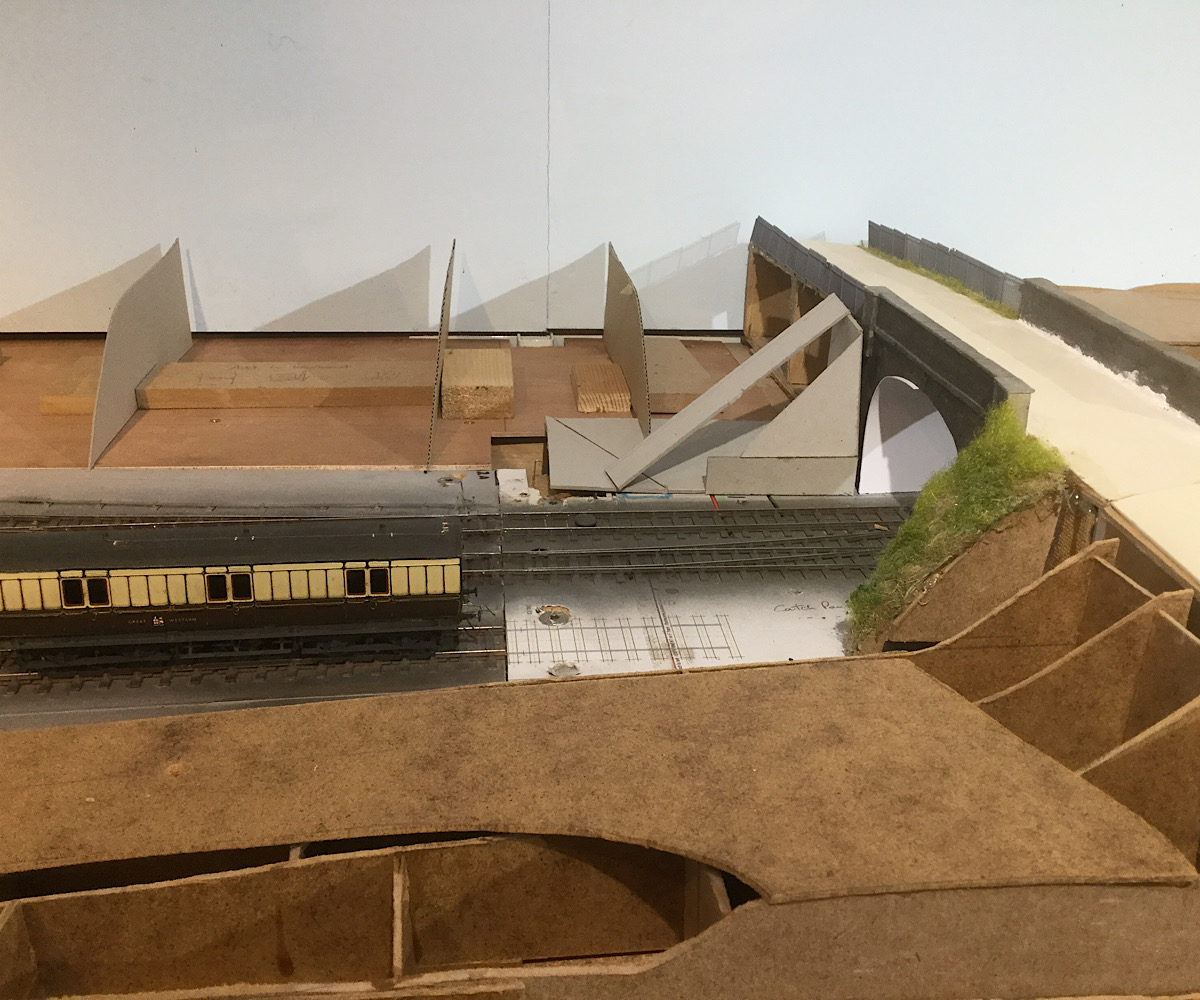

Martin This image is uploaded from Chrome. It shows the Yeovil junction board which may make more sense of my description of the construction that I posted yesterday. But it's only 610KB. Andrew 2787_201626_110000000.jpg  |

||

|

posted: 20 Feb 2017 22:03 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

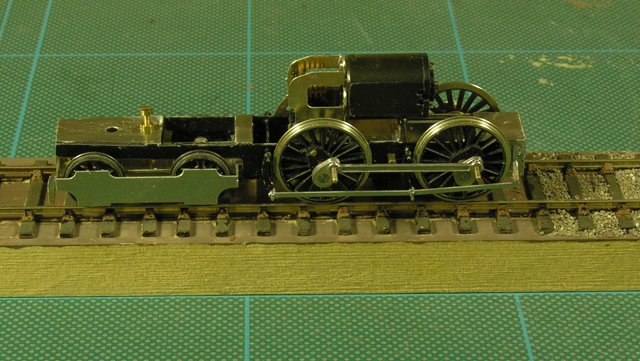

And this one is from Chrome but about 2MB in size. This shows the track and rodding sprayed and I'm almost ready for ballasting. But before I do that I must test it out electrically with a loco. Problem is all my locos bar a mongrel 43xx Mogul are still in 16.5mm gauge from my original Maiden Newton / Yeovil layout in 00. And that one loco doesn't have pick ups fitted let alone a chip fitted. It is just visible in this photo bottom left, but looks a bit sorry for itself sitting there tenderless....2787_201643_530000000.jpg  |

||

|

posted: 1 May 2017 22:34 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

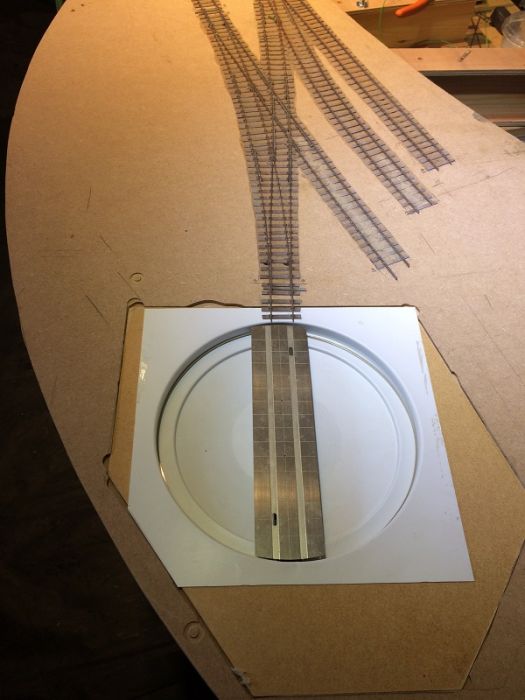

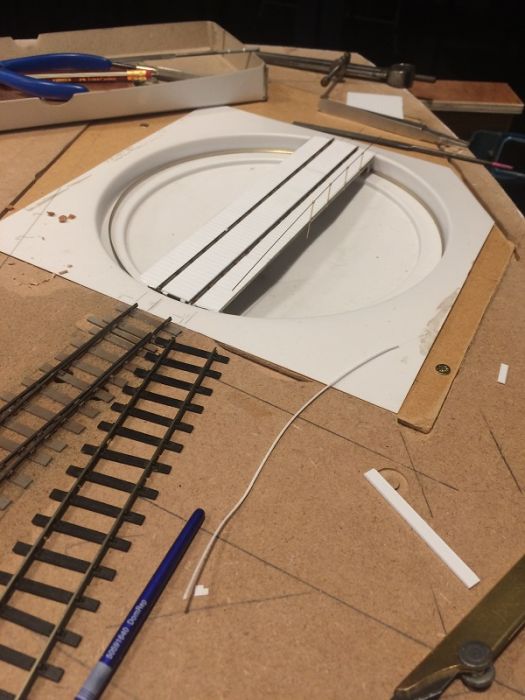

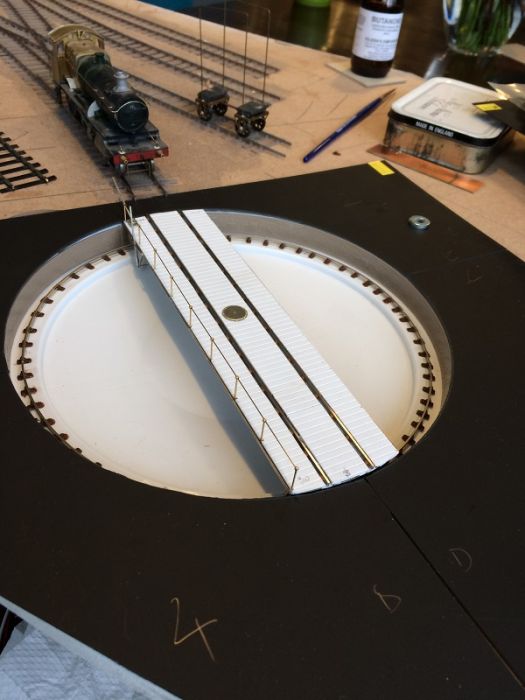

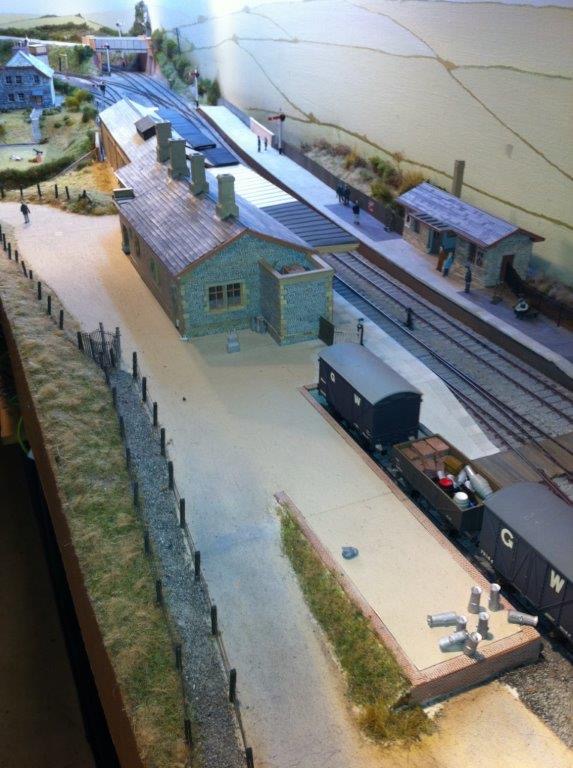

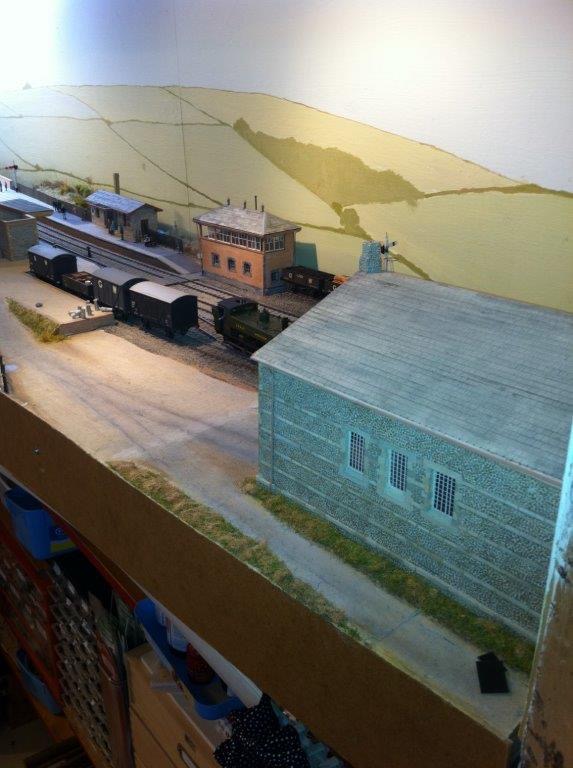

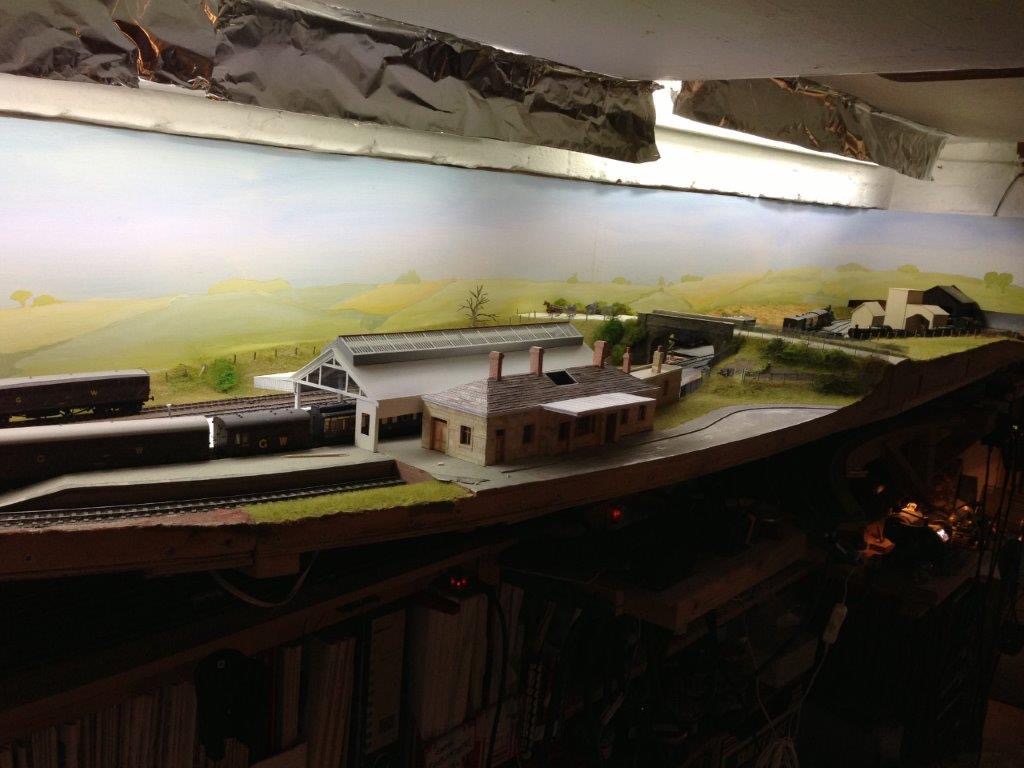

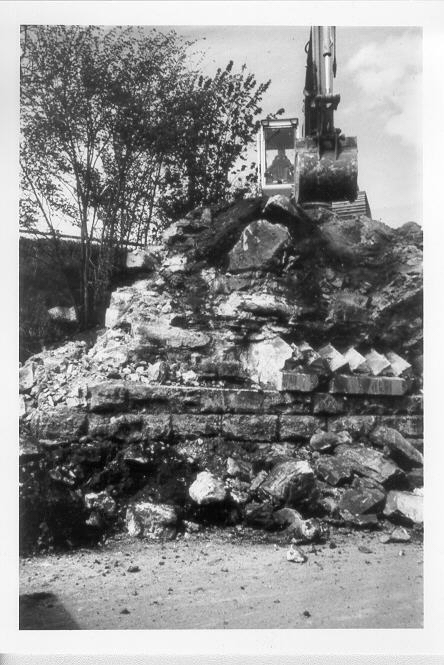

Hello everyone Uploading these photos almost drove me round the bend tonight. Try as I might I couldn't get the captions to work or get the pictures to load in anything other then haphazard order.....!!!! So anyway here's a bit more progress with the MPD. I'm using a London Road Models turntable 50' (although it should only be 44') which is turning into a very nice model and its driven by a Chatham models turntable drive which, so far has proved a relatively easy install once I'd got the wiring the correct way round! The track that I built 3 years ago went down surprisingly easily although I've not rested it yet under power. Like the junction I'll be using Megapoints controller and servos to switch the turnouts. Handily there are four spare ways on the junction board that will deal with them. This time though I'm going to use conventional micro switches to change the polarity of the crossings. I hope the chronology is reasonably clear. Andrew 2787_011703_150000000.jpg  2787_271836_510000000.jpg  2787_011708_360000000.jpg  2787_011707_580000000.jpg  2787_011706_450000000.jpg  2787_011650_330000000.jpg  |

||

|

posted: 6 May 2017 20:45 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello everyone A bit more progress on the turntable. The top photo shows a Mainline Mogul with the cab and fire box cut off and a spare Mitchell cab and firebox substituted. When its finished I hope itll be difficult to tell it from a real Mitchell Mogul? Anyway its sitting the almost finished Turntable bridge, just the far handrail stanchions to add and we'll almost be there. The lower photo shows the gound work progress around the turntable area along with the well stone wall. Andrew 2787_061530_360000000.jpg  2787_061532_180000000.jpg  |

||

| Last edited on 11 May 2017 21:00 by Andrew Duncan |

|||

|

posted: 9 May 2017 09:22 from: ScottW

click the date to link to this post click member name to view archived images |

Lovely work, Andrew, very inspiring. Looking forward to the next update. Scott |

||

|

posted: 11 May 2017 20:58 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Scott Thanks very much for your kind comment. I'll post more as I progress! Kind regards Andrew |

||

|

posted: 24 May 2017 17:37 from: Michael Henfrey

click the date to link to this post click member name to view archived images |

Very impressive. Can I ask, What did you use to get the colours of the sleepers and chairs looking like that in the 6th post down. It looks about spot on for what I am aiming for. Cheers |

||

| Last edited on 24 May 2017 17:40 by Michael Henfrey |

|||

|

posted: 28 May 2017 00:00 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Michael Henfrey wrote: Very impressive. Can I ask, What did you use to get the colours of the sleepers and chairs looking like that in the 6th post down. It looks about spot on for what I am aiming for.Hello Michael Thanks for your comments. It's been over two years since I built this track but from memory having built it, whilst still attached to the paper template I fist sprayed it with grey primer which sticks well to wood and metal and provides a good neutral lightship background for further colouring. I then took it out into the garden and gently attacked it with my airbrush using a mid grey brown for sleepering and a darkiskish rust colour for the rail sides. It now needs further colouring with dry brushing and powders or ground pastels to give it some variation in colour and, as this is an MPD then a bit more grime and filth. I think that when in doubt keep it light in colour and under state. Kind regards Andrew |

||

|

posted: 6 Jul 2017 21:39 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello everyone At the end of the month I'm treating myself to a Missenden Abbey summer retreat so hope to be reporting some decent progress on my return, fingers crossed! Kind regards Andrew |

||

|

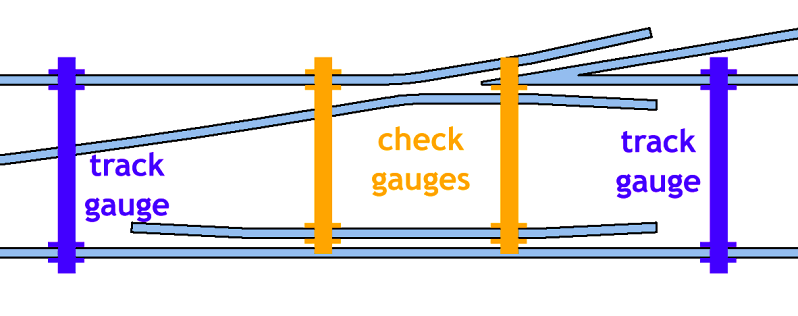

posted: 10 Aug 2017 22:07 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

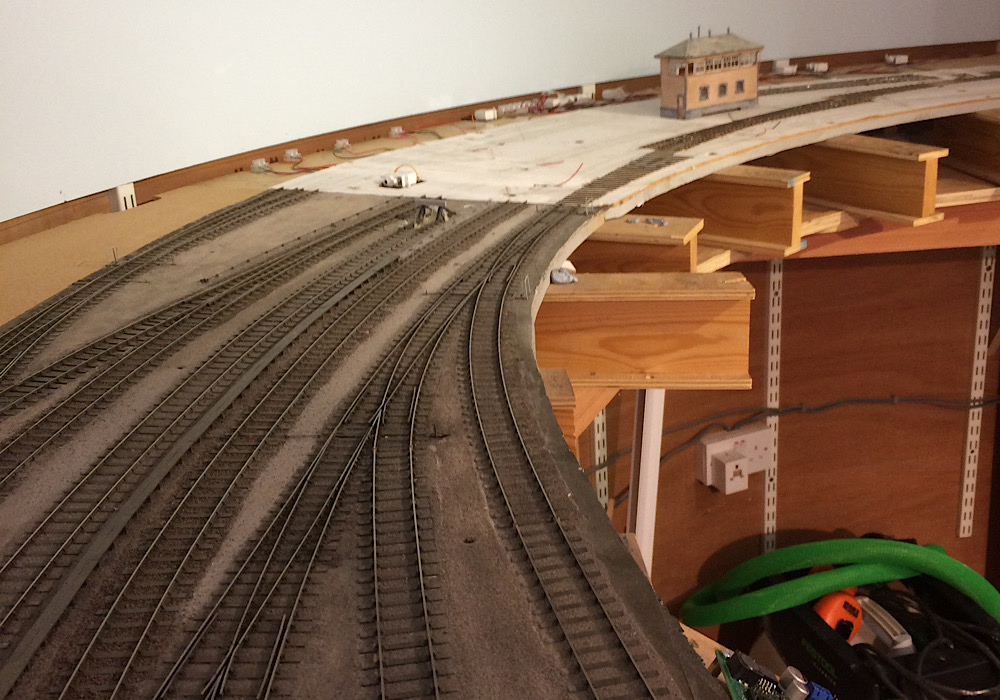

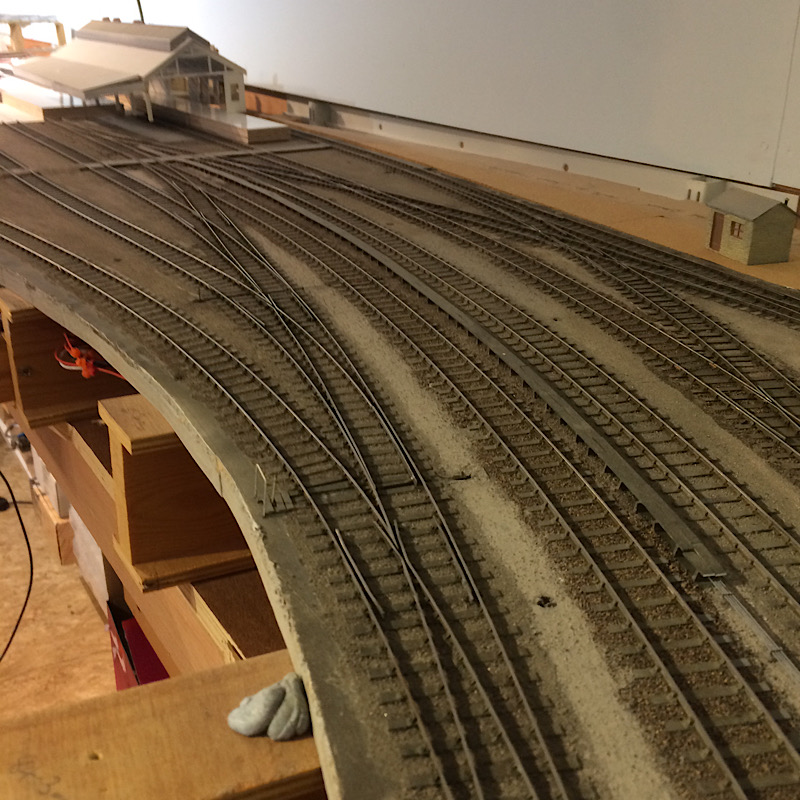

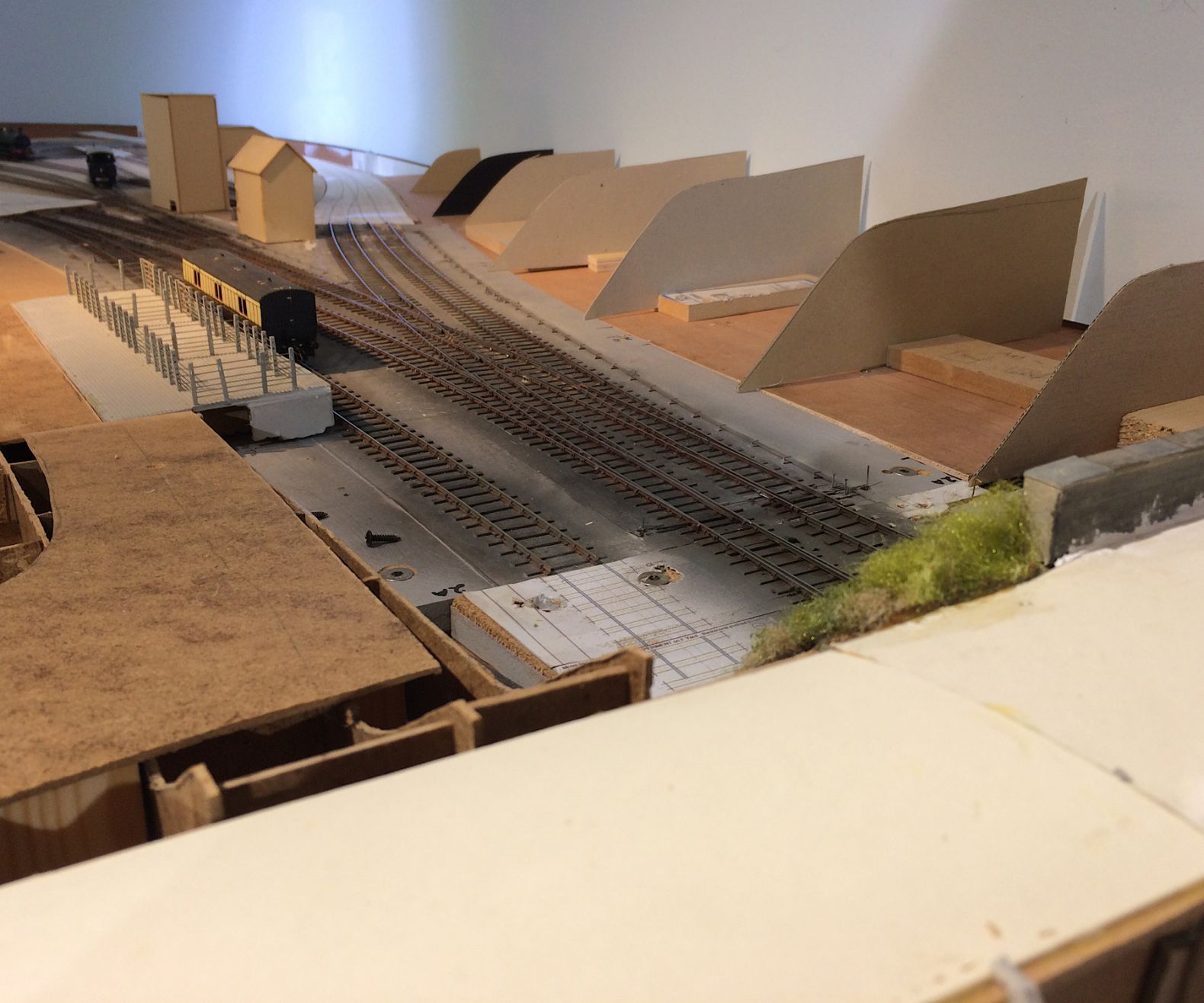

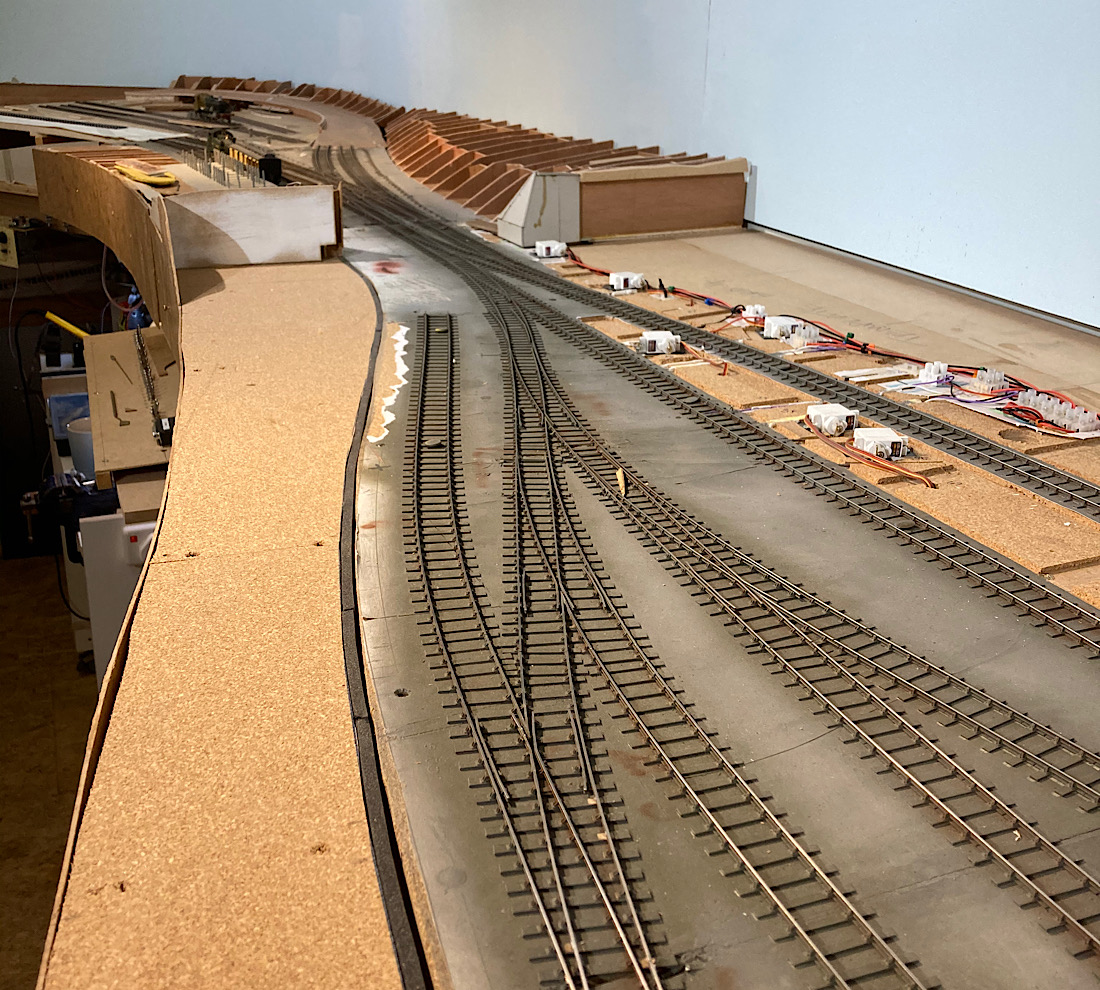

Hello Everyone Well I'm back from a great week at Missenden Abbey. Did I achieve my aim of making some significant progress? Well yes I did although I must admit it doesn't look that impressive, but on the other hand building point work with C&L components is not a quick process and my hopes that I might return with a baseboard largely complete evaporated in the first few days there! On the other hand Tony Gee (one of the tutors) showed me how he build the crossings with a simple set of gauges, that allowed me to make my first really reliable crossing (the bit I always find the hardest to do consistently where the wing rails and knuckles line up with point of the V) and that was probably the biggest single move forward for me. Add to that seeing how other modellers do things or just store their tools and materials is an education in itself. So thanks go to Tim, Barry, Pat (who allowed me to borrow and ruin his cutting mat), David, Mark, Chris who organises the whole thing and Simon( who I think follows this thread) for all your help support and kind comments. Edit. I realise i missed out Mick Bonwick who provided the spray booths and who could do quite astonishing things with an airbrush! Below are a couple of photos of progress to date on that board. 2787_101646_050000000.jpg  Here is view looking south towards the platforms with the up and down main line running either side of the carriage siding in the centre of the picture and on the left a row of three turnouts giving on to the marshalling yard area directly opposite the platforms. 2787_101652_300000000.jpg  and here's a view in the opposite direction with the platform (when its built) immediately on the left of the turnout and my "dodgy trackwork detector wagon" about half way down the board. This is a lovely example of how Templot enables beautiful curved trackwork to be built in a way that I would never achieve left to my own devices. Great program Martin, thank you. Kind regards, Andrew |

||

| Last edited on 5 Sep 2017 22:38 by Andrew Duncan |

|||

|

posted: 5 Sep 2017 22:30 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

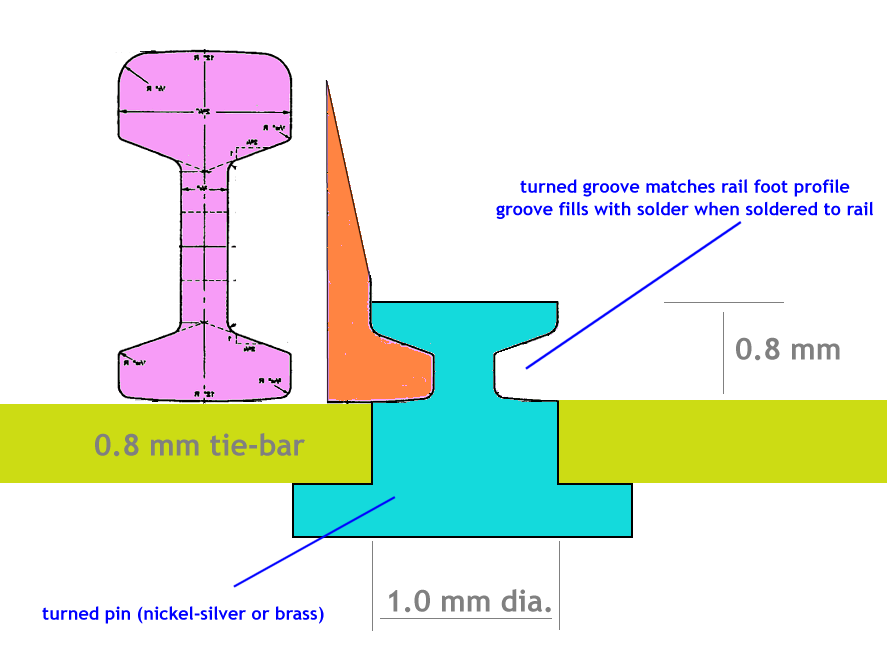

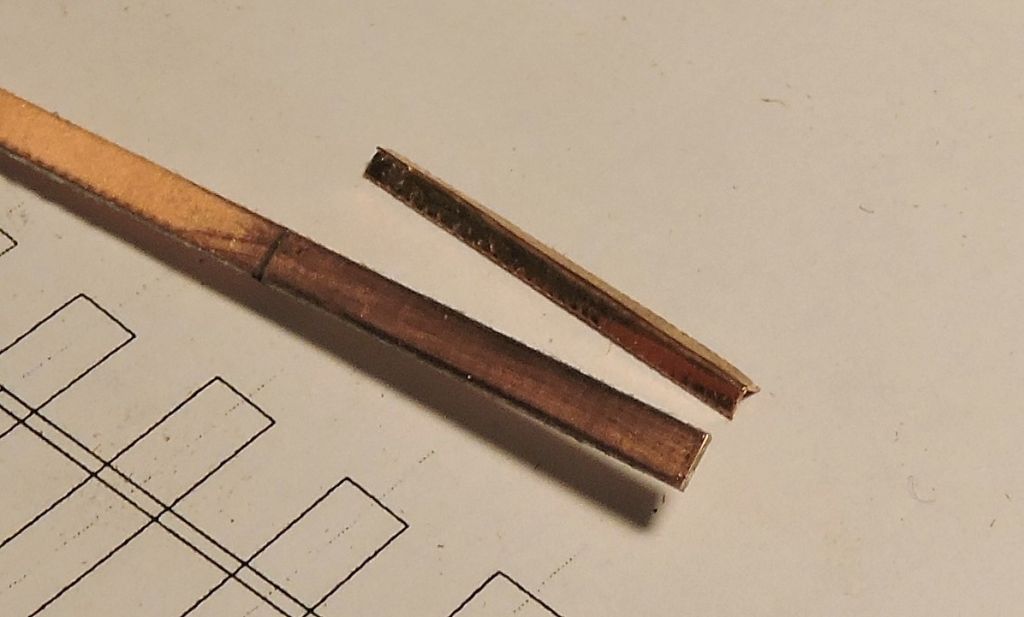

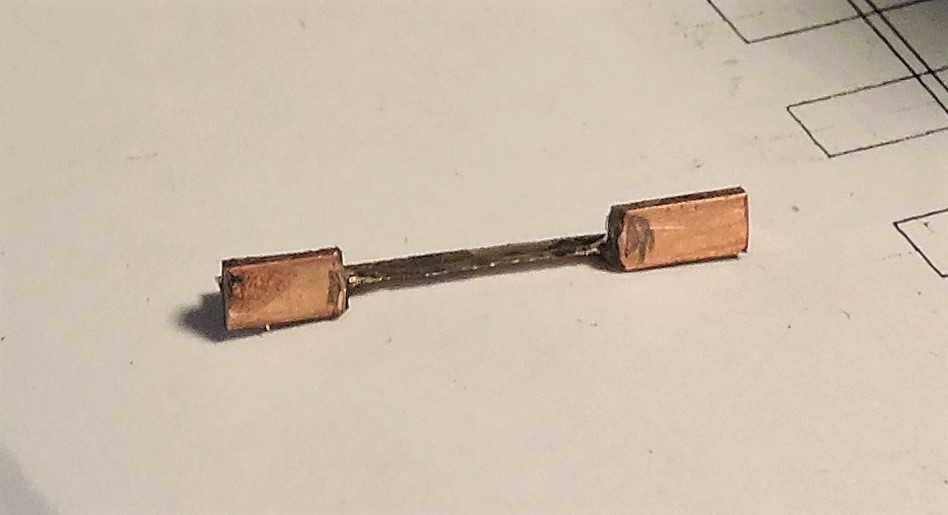

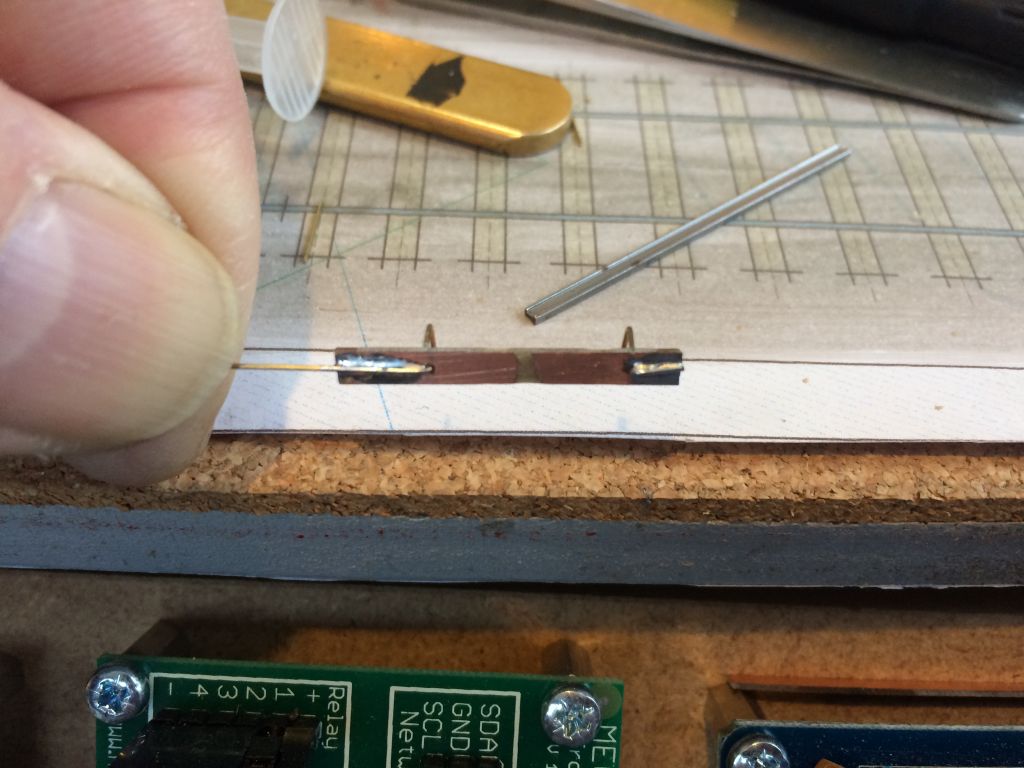

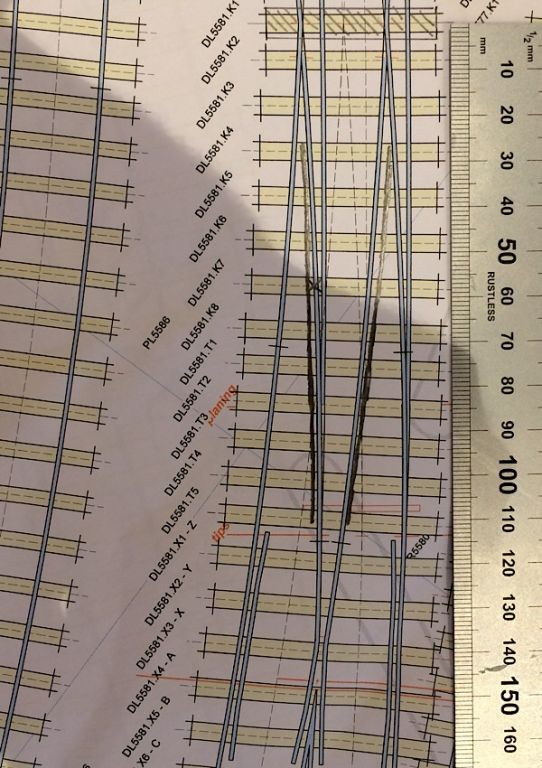

Hello everyone A bit more progress here on the base board above. I'm now working on the last three turnouts on this baseboard.of the layout. 2787_051722_450000000.jpg  When I was at Missenden Abbey earlier last month both Tony Gee and Mark Tatlow suggested a very similar "hidden tie bar arrangement" which as these three turnouts are near the front of the layout I thought I may try out.I'll let you know how i get on. Andrew |

||

| Last edited on 5 Sep 2017 22:31 by Andrew Duncan |

|||

|

posted: 13 Sep 2017 11:48 from: Richard_Jones

click the date to link to this post click member name to view archived images |

Hello Andrew, Once again, very impressed by your progress I had a quick look back through your thread and don't think I have missed it, but could you provide any more details of your "sub-baseboard" (my terminology) that allows you to work on "manageable" piece of trackwork, and how that integrates/assembles into the overall layout (or point to where I missed it! many thanks Richard |

||

| Last edited on 13 Sep 2017 12:24 by Richard_Jones |

|||

|

posted: 13 Sep 2017 19:59 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

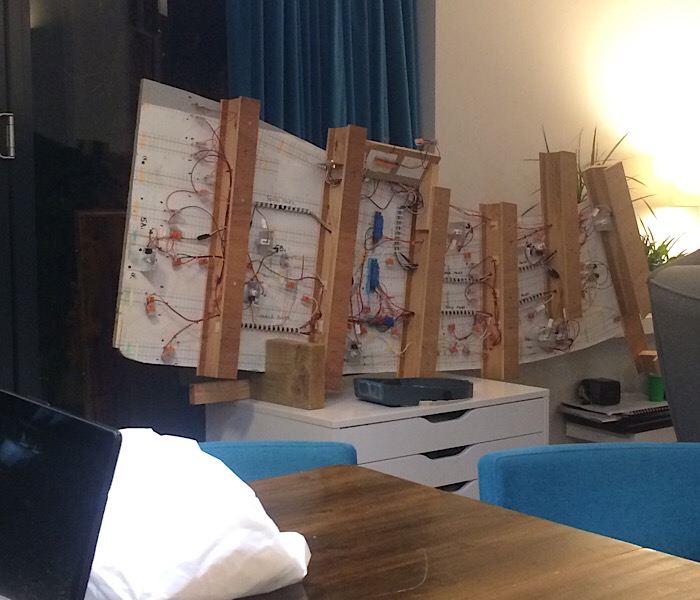

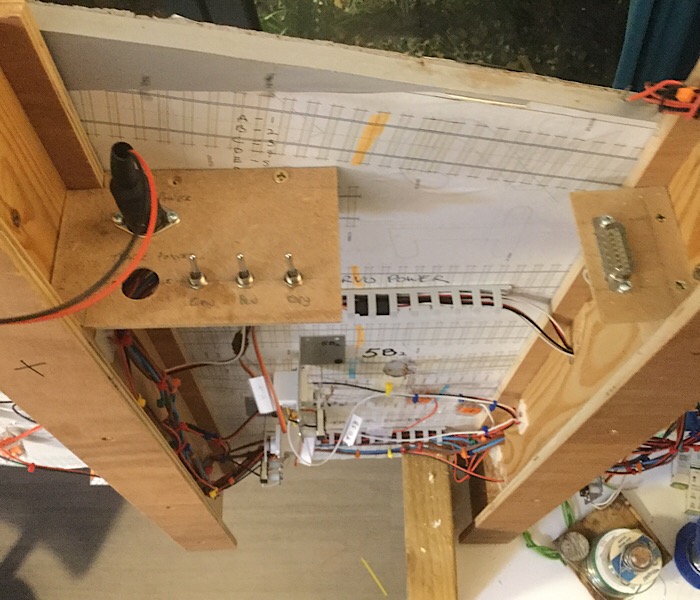

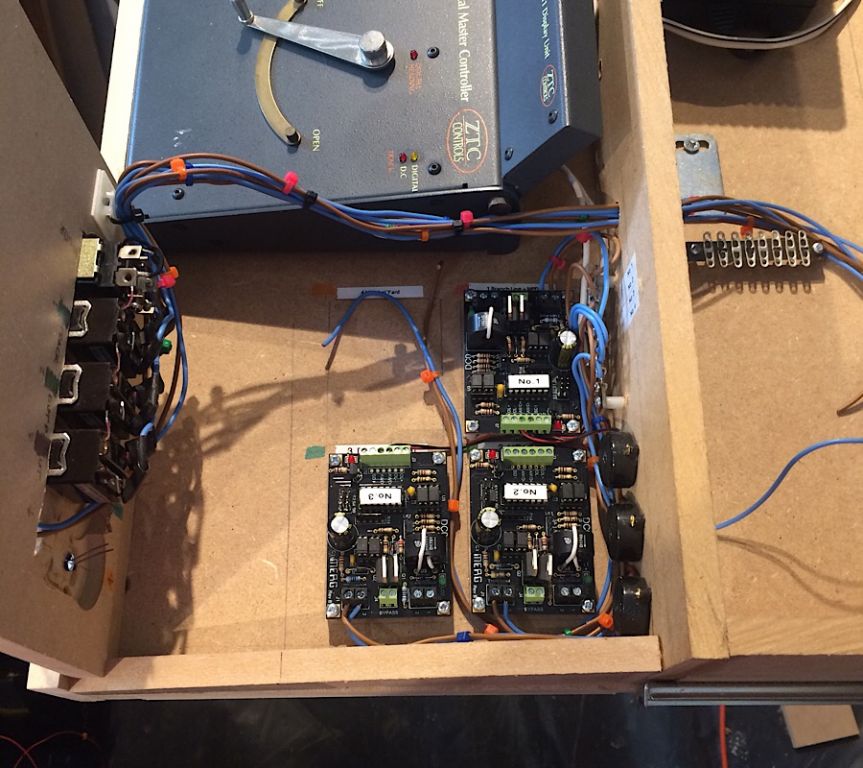

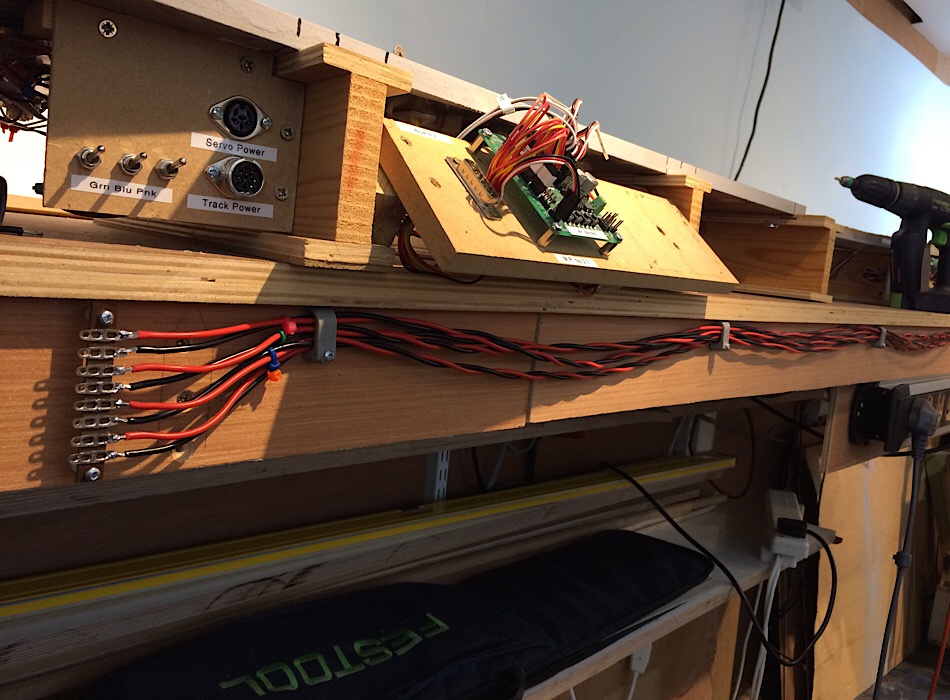

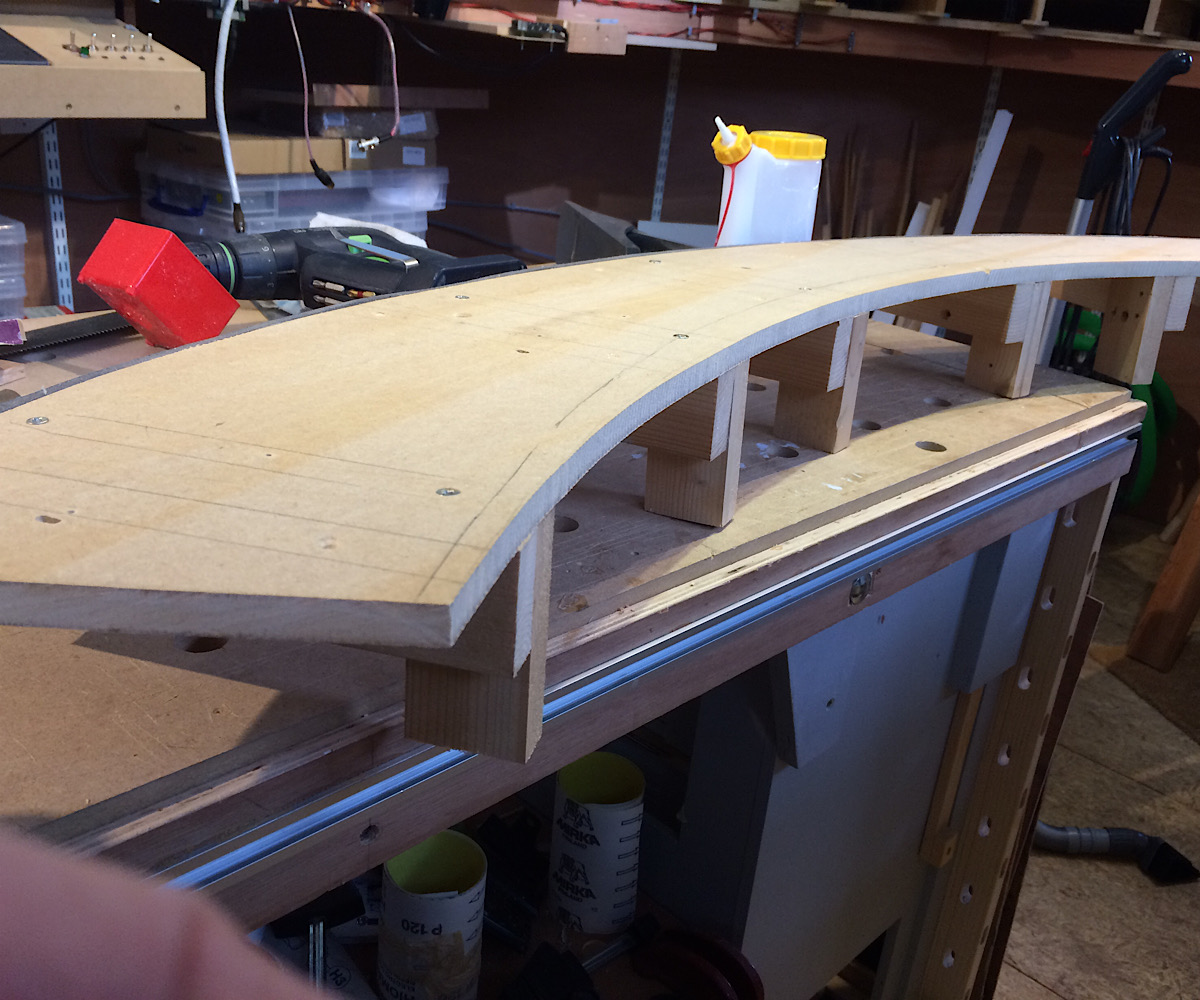

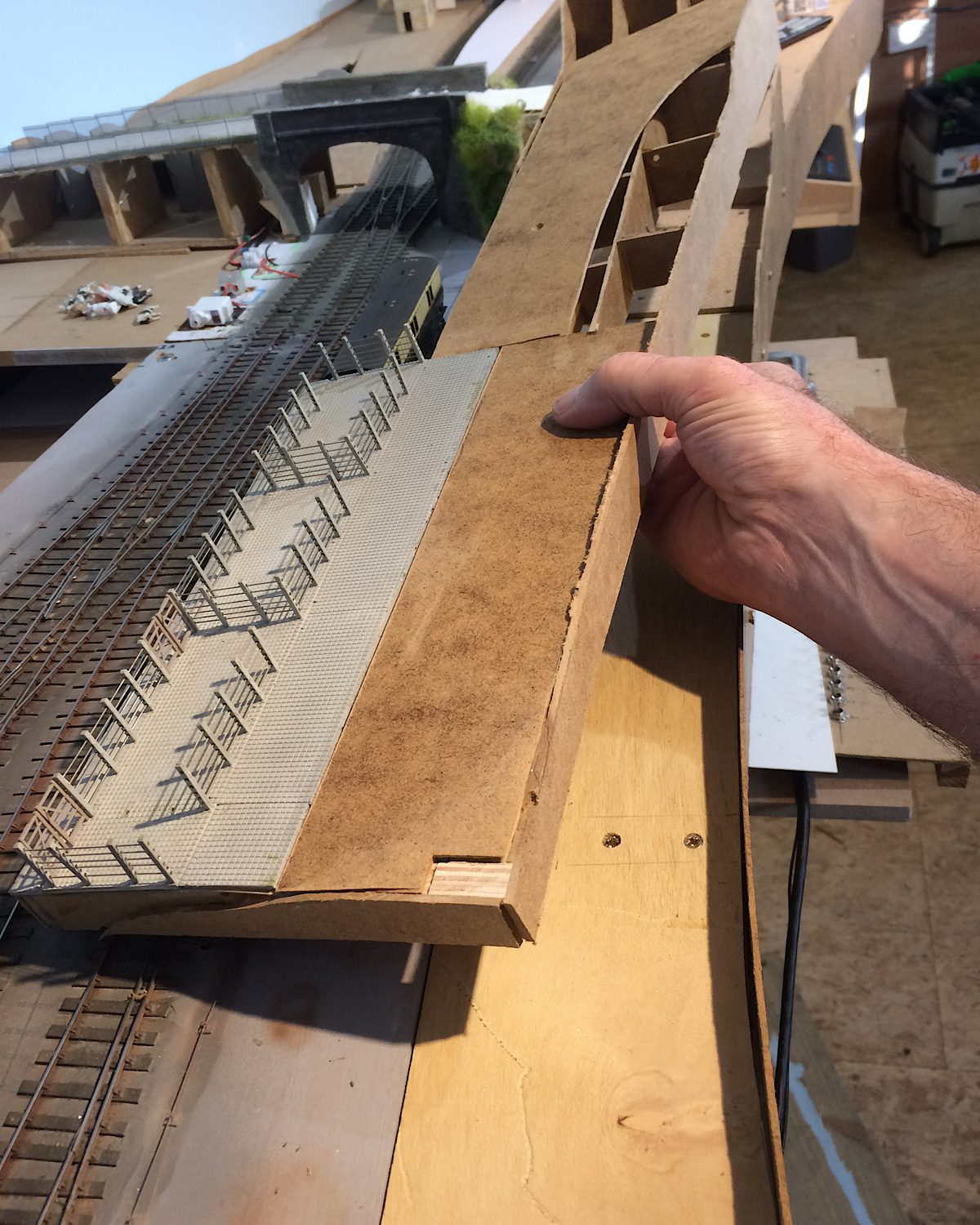

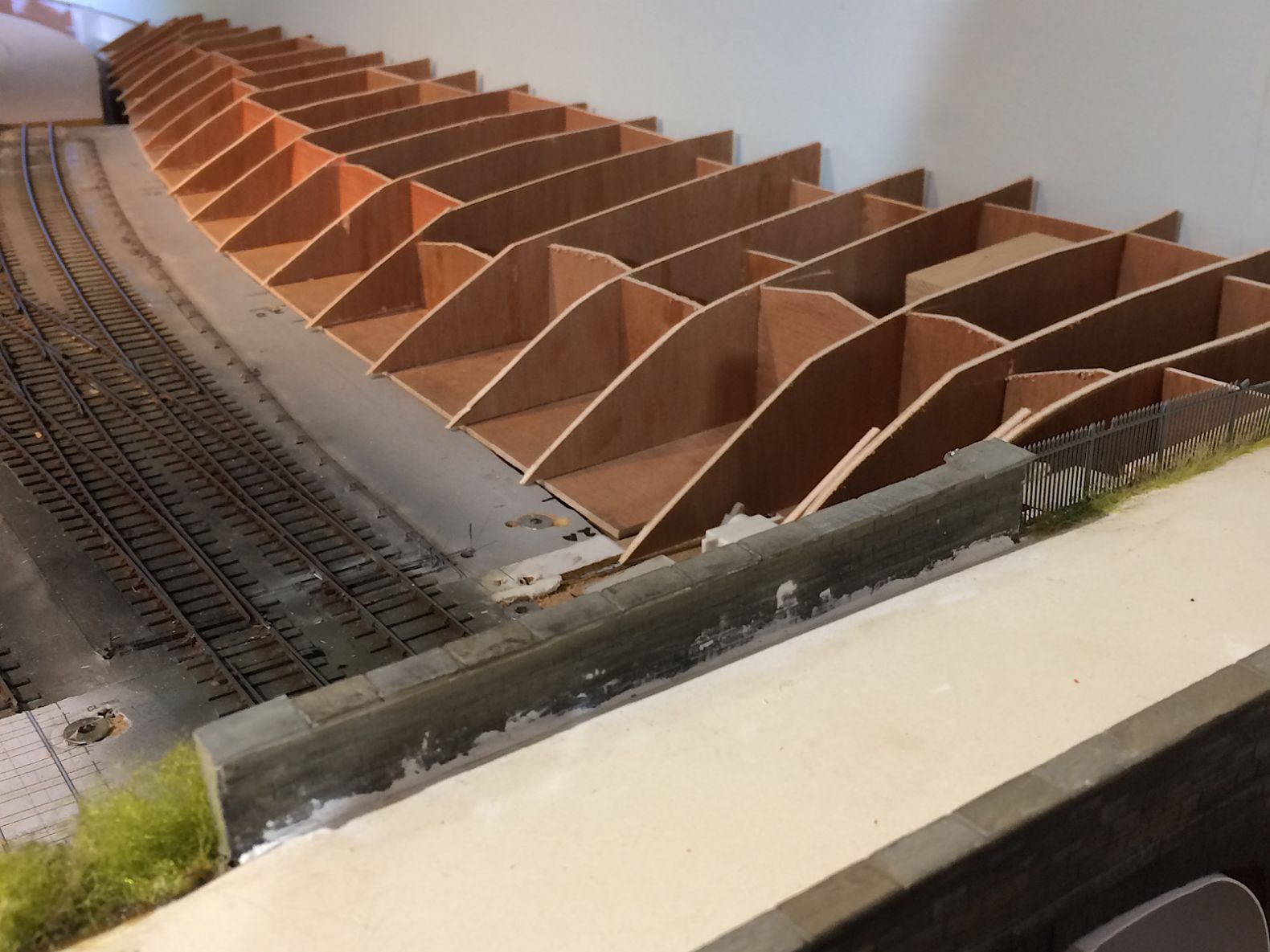

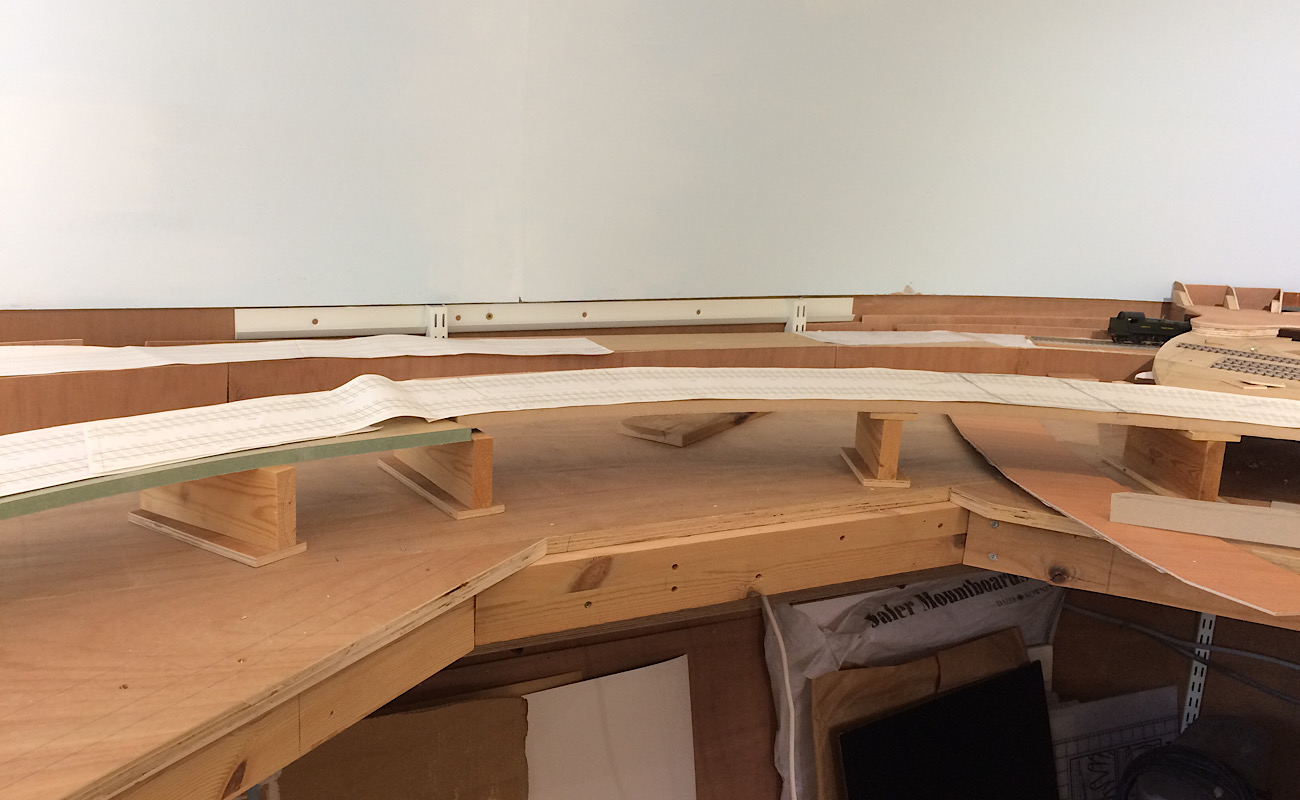

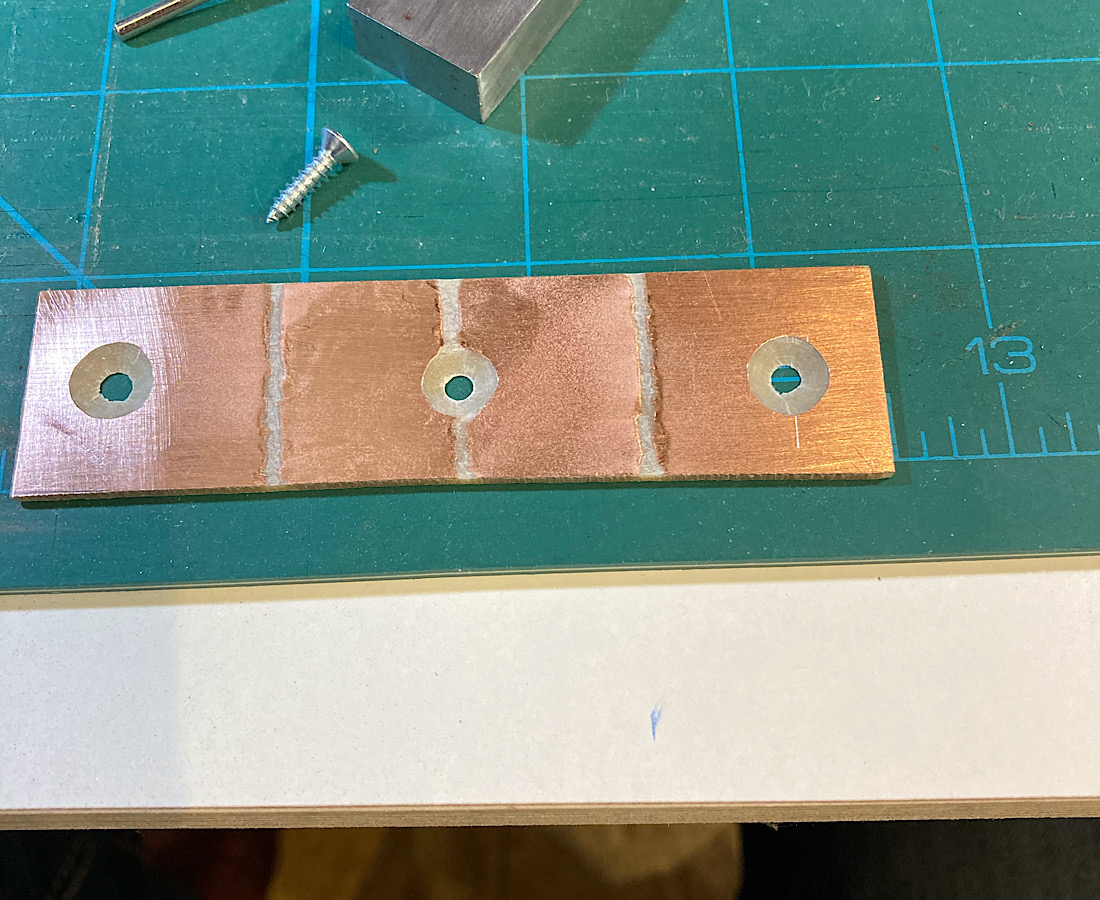

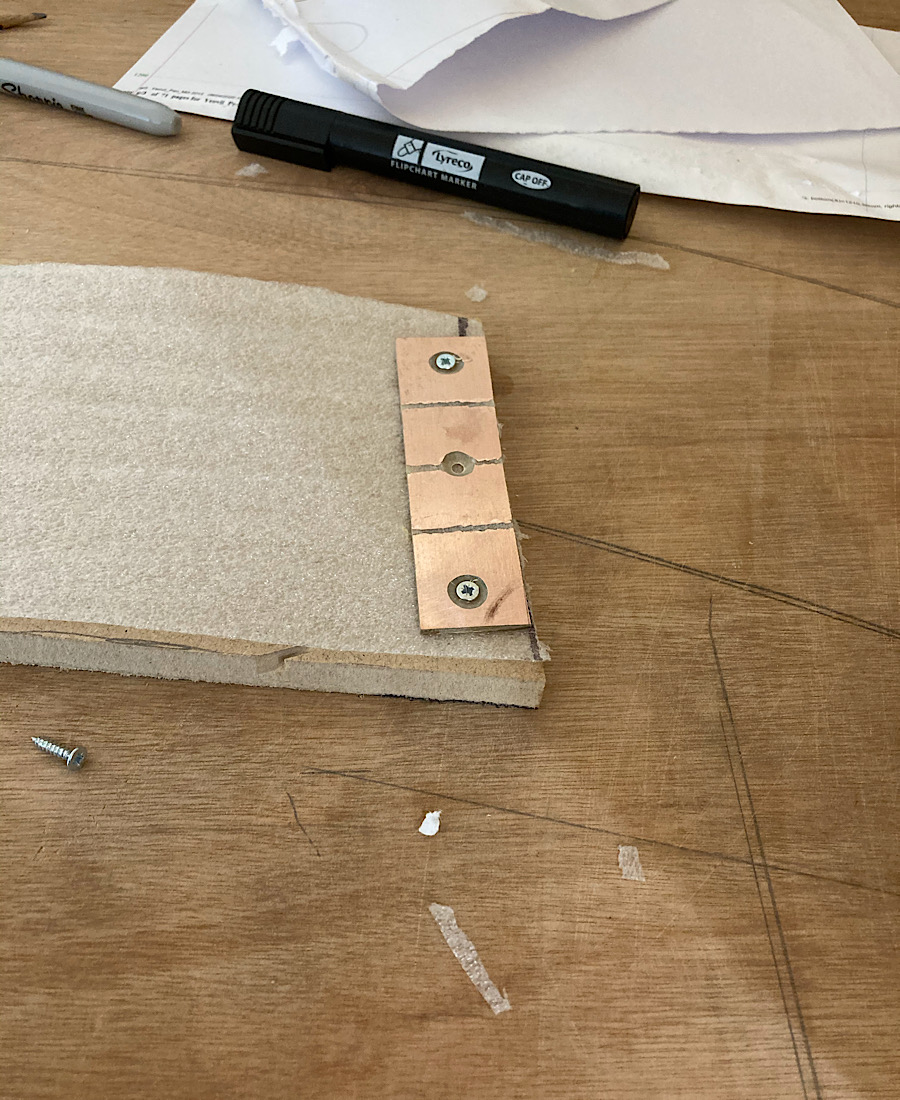

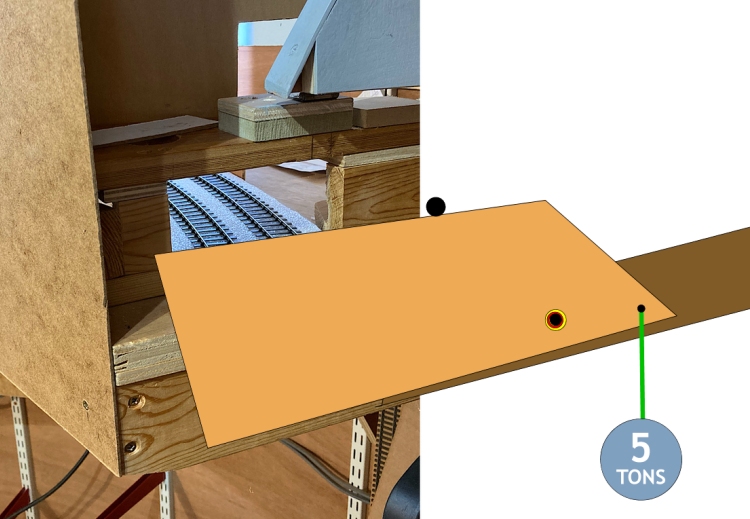

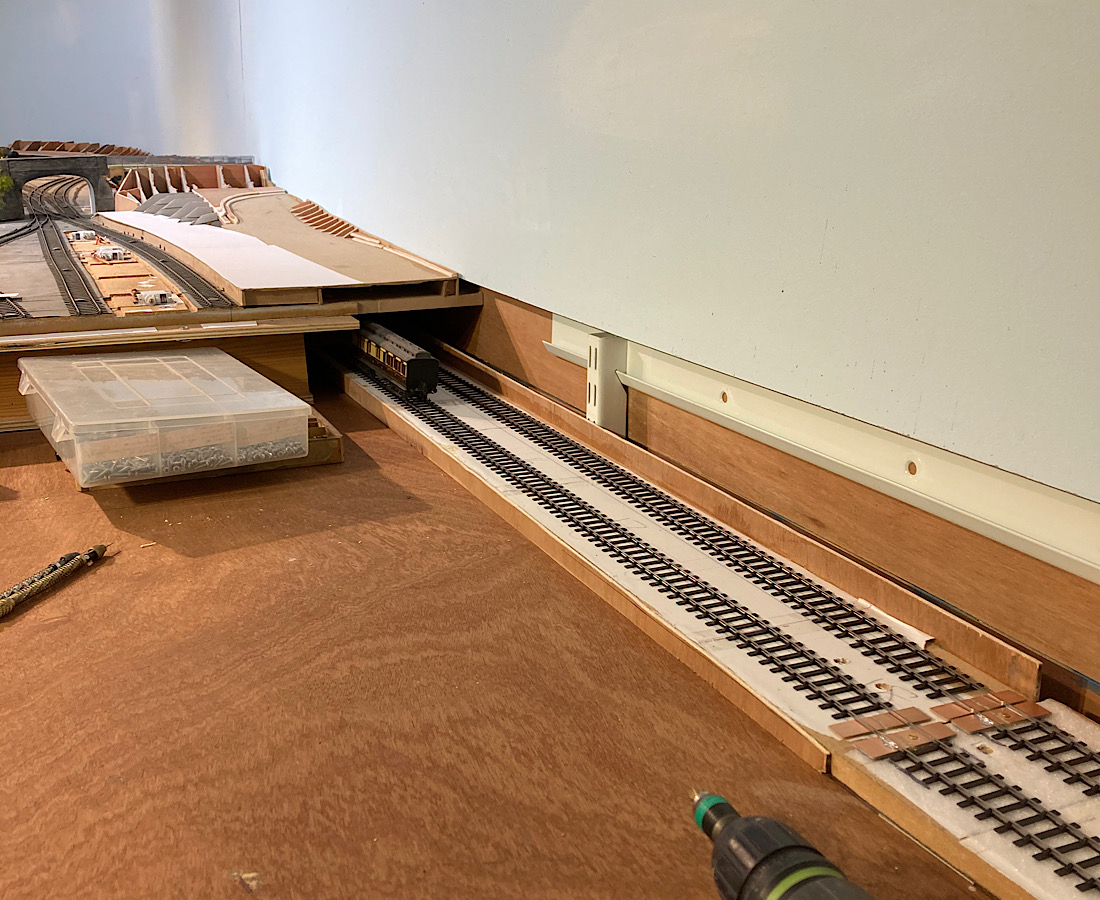

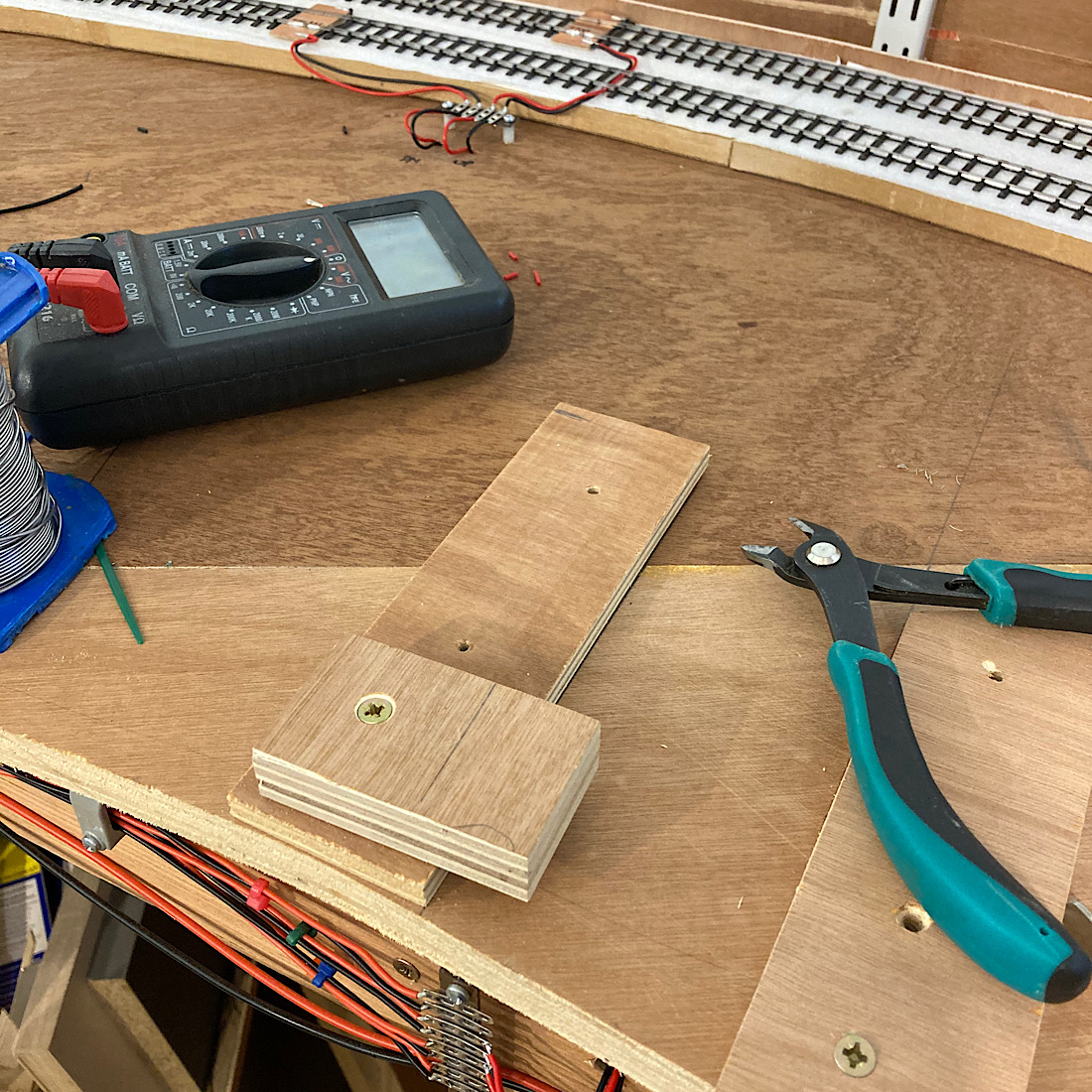

Richard I'm sorry to hear that you're not making the progress that you'd have liked but when you last updated Singleton you'd been drawn down the 7mm path which I'm sure is a fascinating alternative to 4mm, it would be great to see any progress there? I popped down the garden earlier to take a couple pictures that may at least partially answer your question. The layout is hung off Spur shelving brackets screwed to the walls, so that there are no legs to get in the way and take up precious space in my shed. The brackets support a bed of 18mm ply cut approximately 2' (600mm) deep (from back to front ) that goes all around the perimeter of the shed with a lifting flap at the door. On top of this shelf the various layout baseboards (between 3'6" & 5'0" long ) sit approximately 3.5" (90mm) above that surface supported on 3" X 1" batten topped and tailed with strips of 12mm ply about 3" wide. The ply tops to these supports also provide the method of joining the various baseboards together. I'll take a photo of that later, if I can, to make it clearer. Now nearly every time I load pictures something goes awry so I'll keep my fingers crossed that I don't lose the lot so may do this in two or more posts. Kind regards Andrew 2787_131455_260000000.jpg  2787_131457_520000000.jpg  |

||

| Attachment: attach_2492_2547_IMG_0077.JPG 313 | |||

|

posted: 13 Sep 2017 20:15 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Richard Just to finish off this post, you know I think the reason I've been able to make the progress that I have, is a lot to do with this type of construction. It enables me to be sat in the main family room where we live most of the time pottering around with stuff whilst still be relatively sociable. I don't have to disappear off into the loft or cellar or shed! Anyway here's another picture. If I'm still unclear please do ask. Andrew2787_131513_550000000.jpg  |

||

|

posted: 13 Sep 2017 22:23 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

PS I realise that looking at these pictures that you might be wondering what happens at the front of the layout? I'm intending to use a sort of Iain Rice / Barry Norman / Flintfields type of jigsaw scenery which will plug into the 90mm gap between the 18mm ply shelf and the underside of the baseboards themselves. Andrew |

||

|

posted: 13 Sep 2017 22:47 from: Richard_Jones

click the date to link to this post click member name to view archived images |

Hi Andrew, many thanks for your informative and interesting reply - its a very nice concept, but as Singleton won't have a permanent home, I will have to fall back on single self supporting baseboards, but keeping them to a manageable size so that I can work on one (or two) at a time in the kitchen/utility room. As (lack of) progress is again about to be impacted by a 3 month trip to the Southern Hemisphere, visiting family, I wondering if I can get one or two vehicles and tools in my luggage to work on whilst I am away - many years ago I took my portable workshop (by plane) to the North of Scotland and although it raised a few eyebrows at security, it was allowed through - not so these days! best wishes Richard |

||

|

posted: 13 Sep 2017 23:24 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello RichardI hope you have an enjoyable time down south and perhaps get in some gentle modelmaking as well. Bon vacances. Andrew |

||

|

posted: 20 Sep 2017 23:53 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

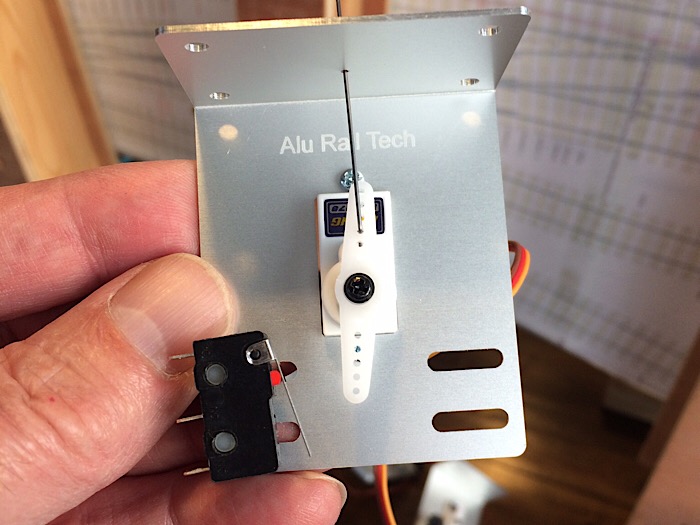

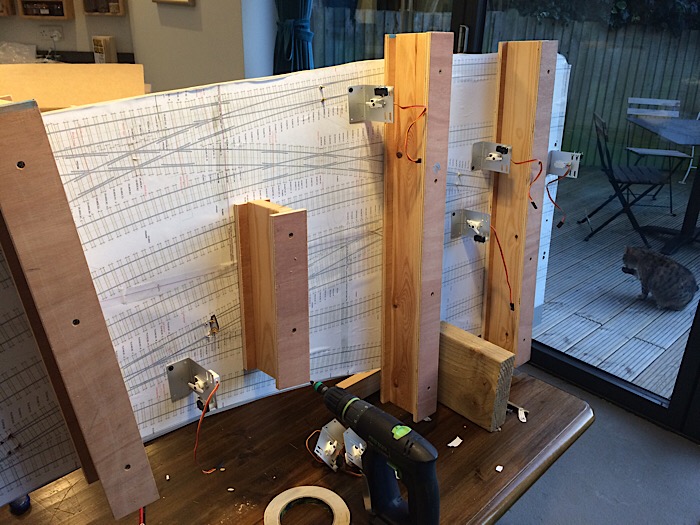

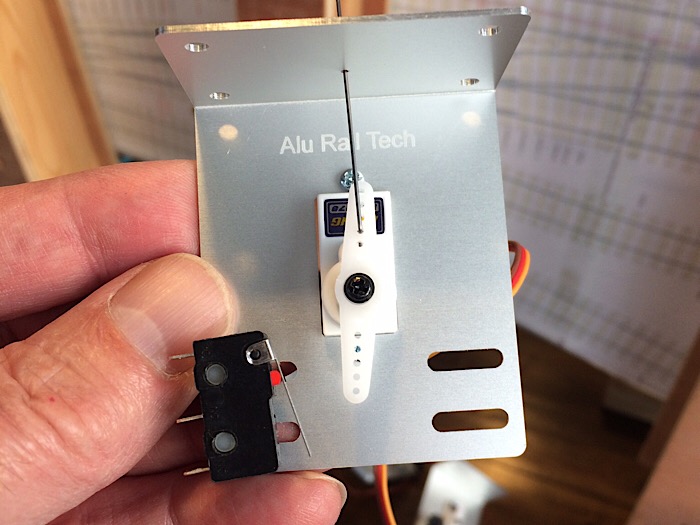

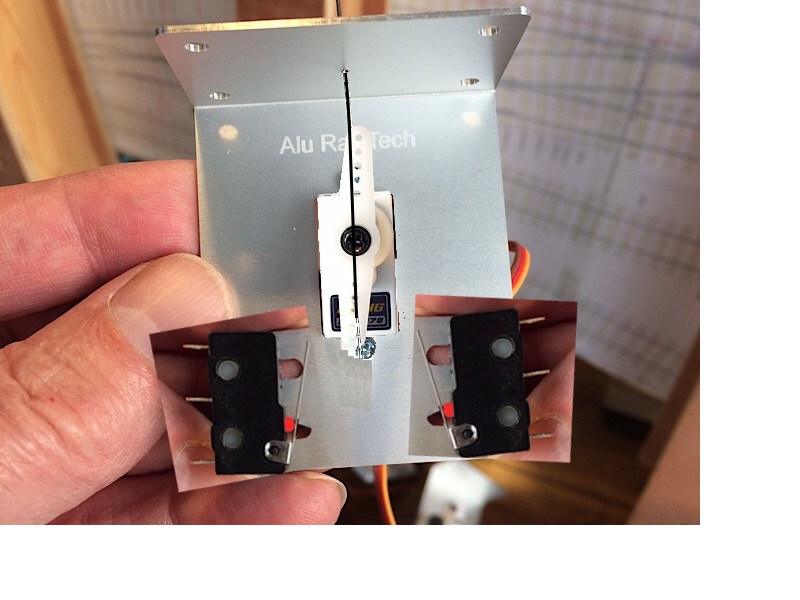

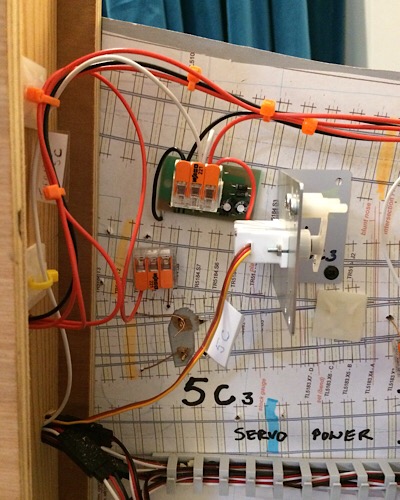

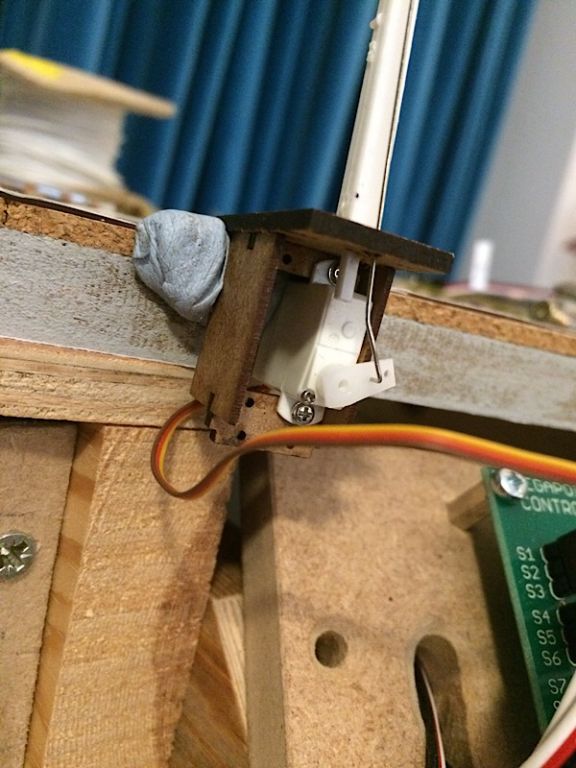

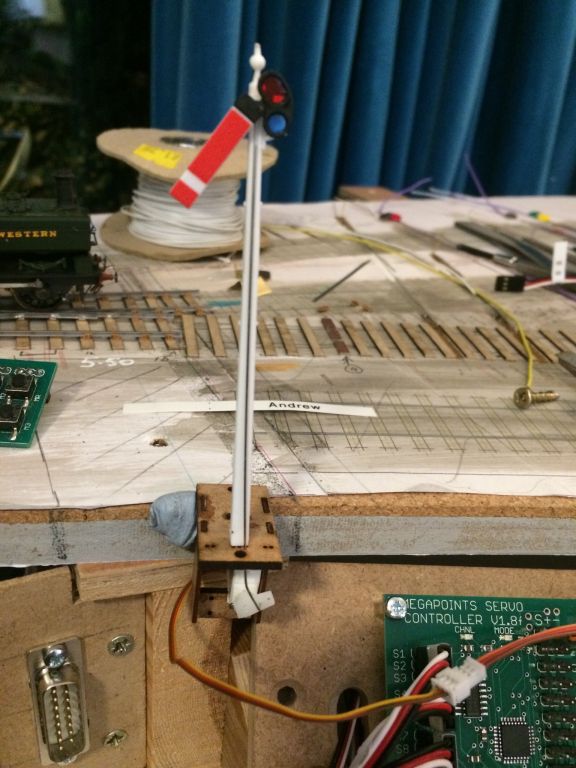

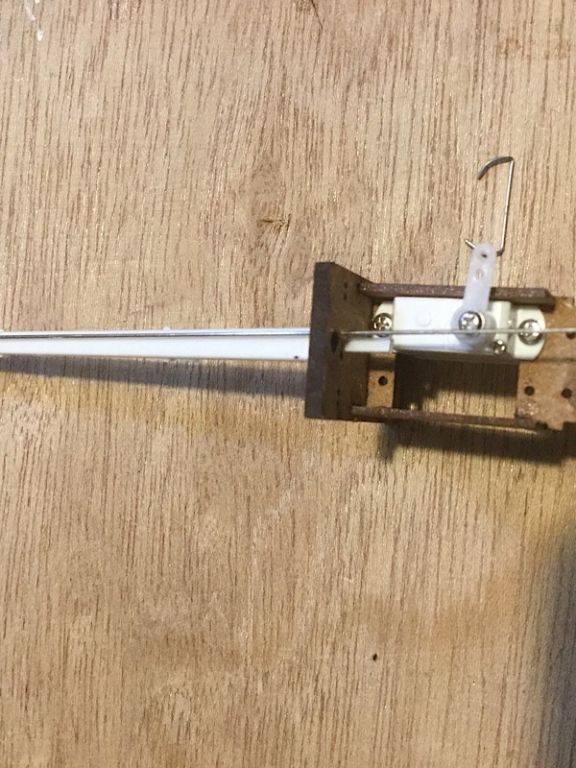

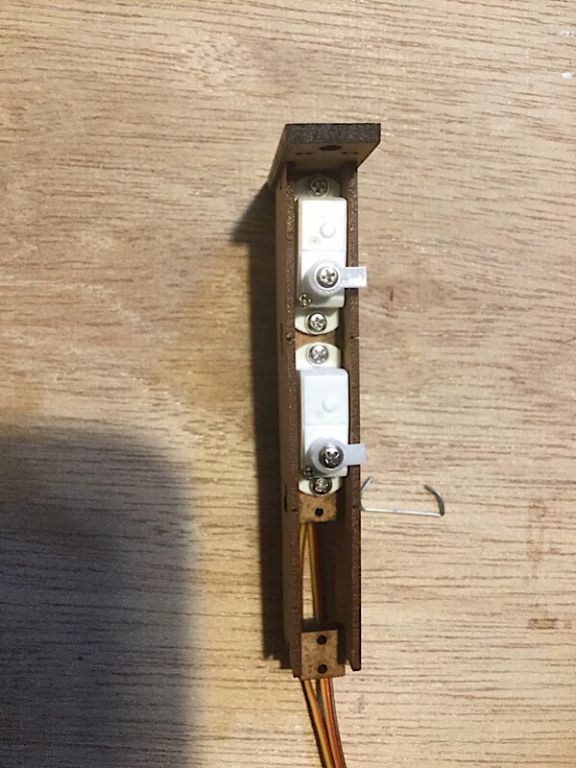

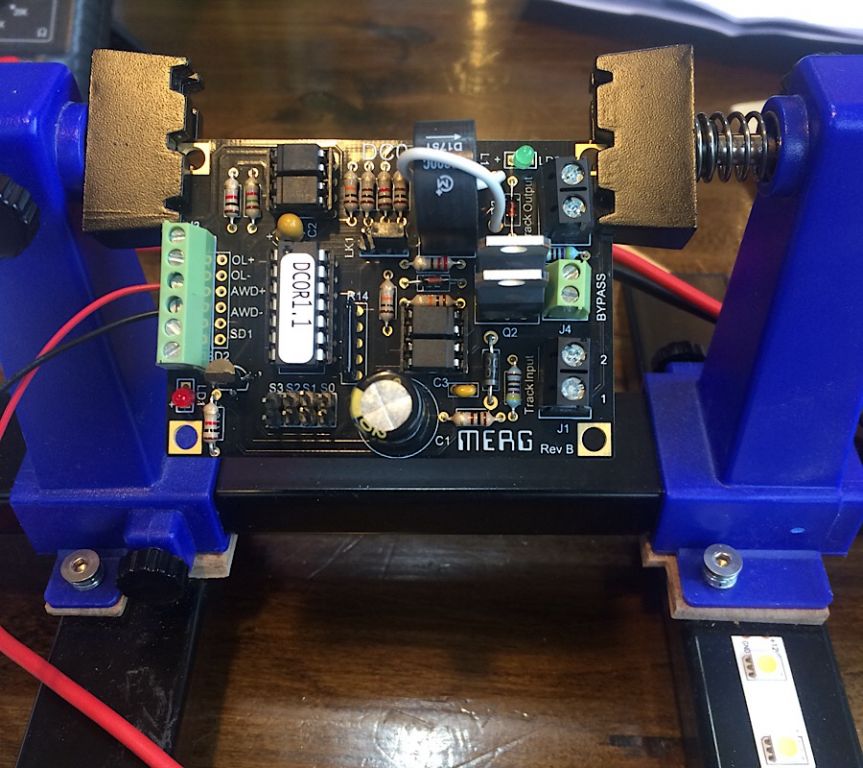

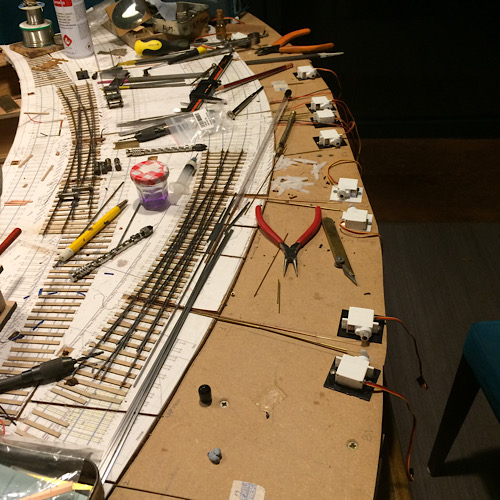

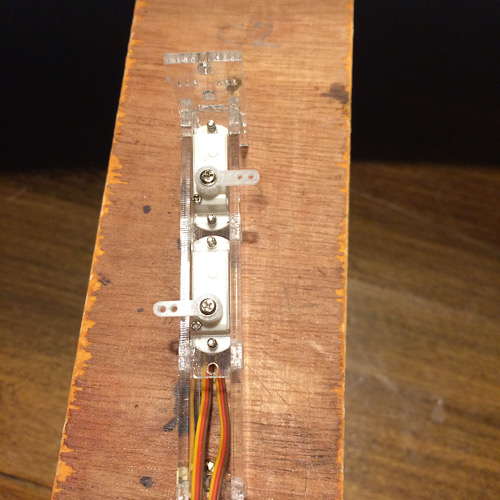

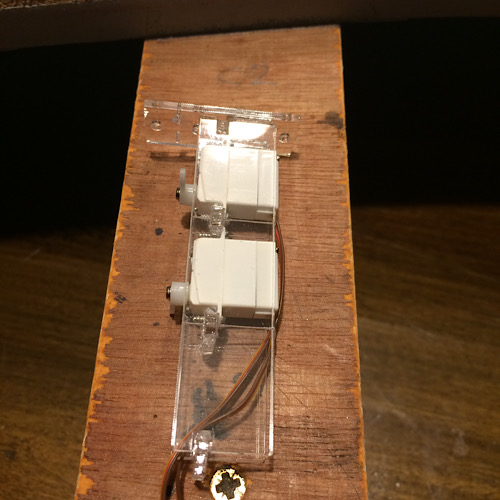

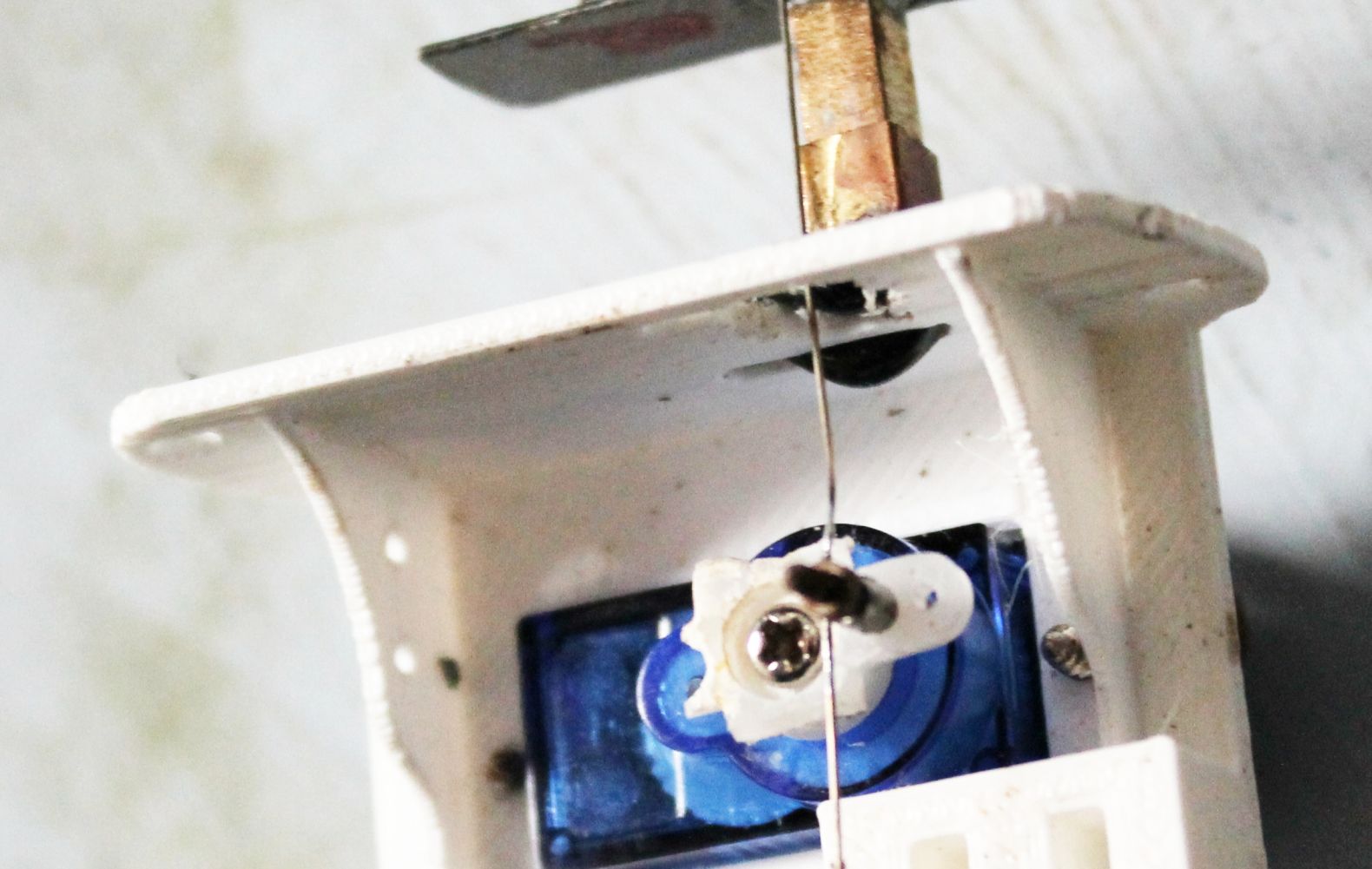

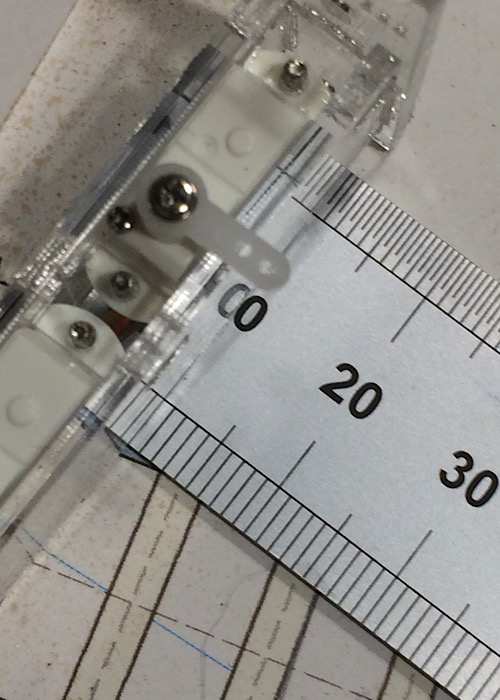

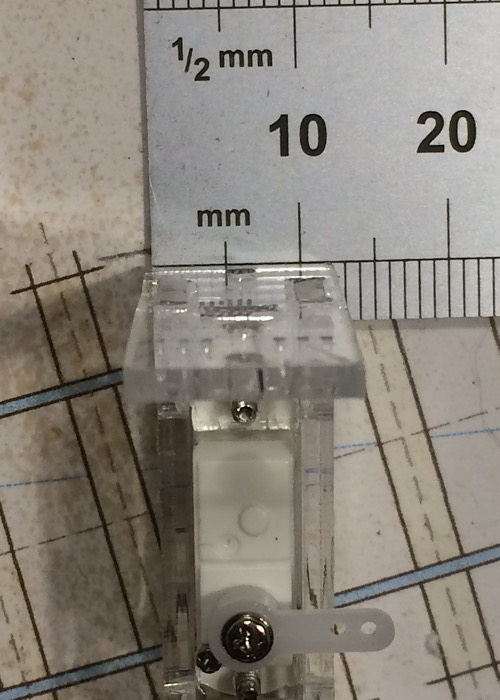

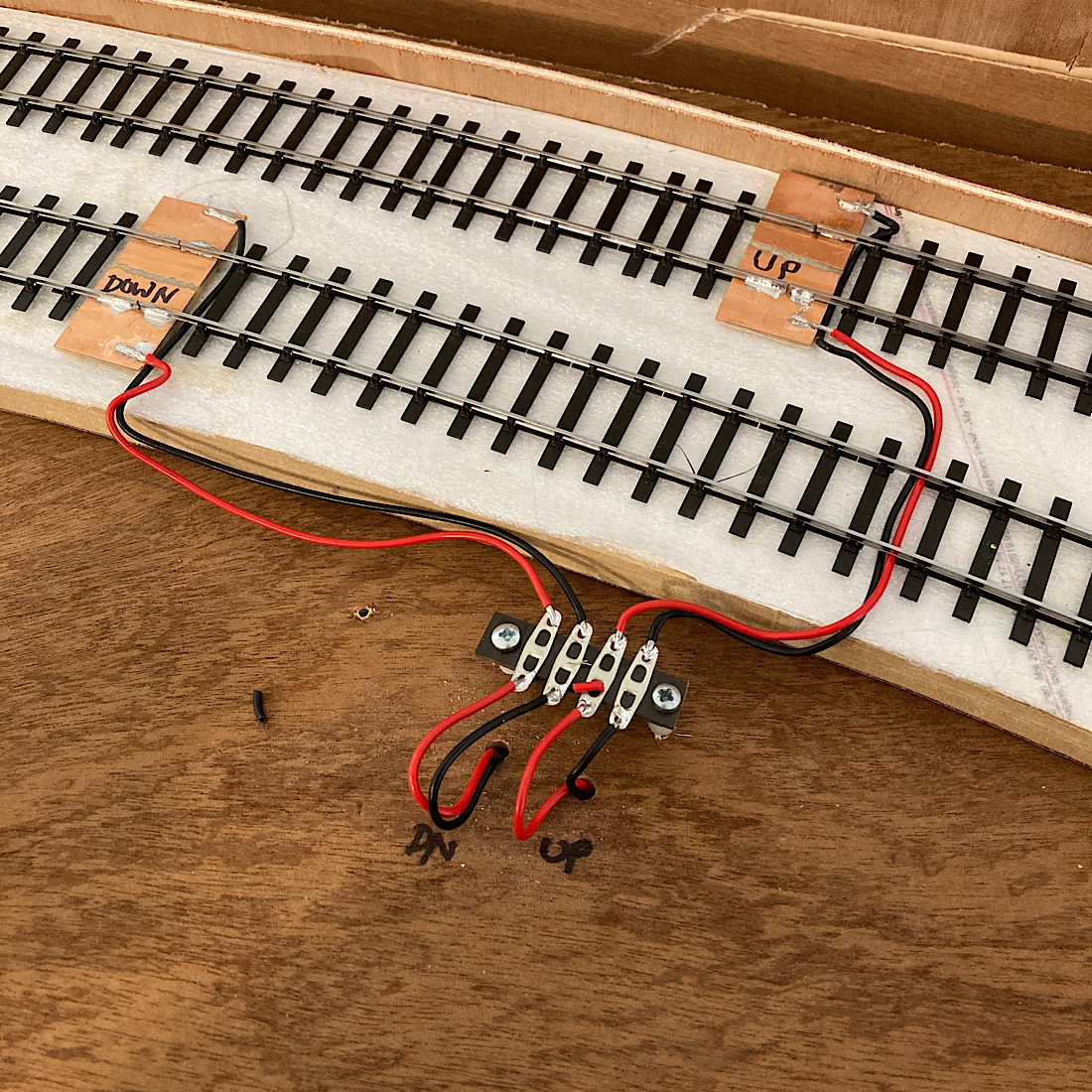

Hello everyone Here's a picture or two of tonight's progress. I'm starting to install the servos for the turnouts. Somewhere on the Scalefour E forum I found a link to the company Alu Rail Tech who produce these rather knatty little right angle brackets for holding not only the servo but also one or two microswitches. On the underside of the baseboard I've stuck a mirror image print out of the track so that I don't get confused when wiring up. This I omitted to do with the junction board producing some unexpected results. Andrew 2787_201839_300000000.jpg  2787_201838_360000000.jpg  2787_201843_250000000.jpg  Here's the other side standing on the end of the kitchen table this evening looking almost Picasso-esq.... EDIT Minor point probably but I think I meant Dali-esq! Apologies to both. |

||

| Last edited on 21 Sep 2017 07:26 by Andrew Duncan |

|||

|

posted: 1 Oct 2017 19:23 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

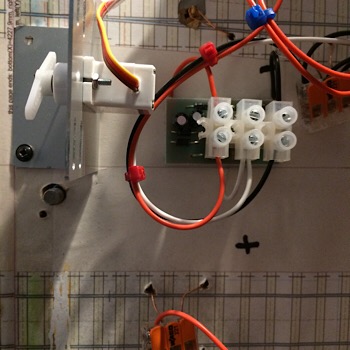

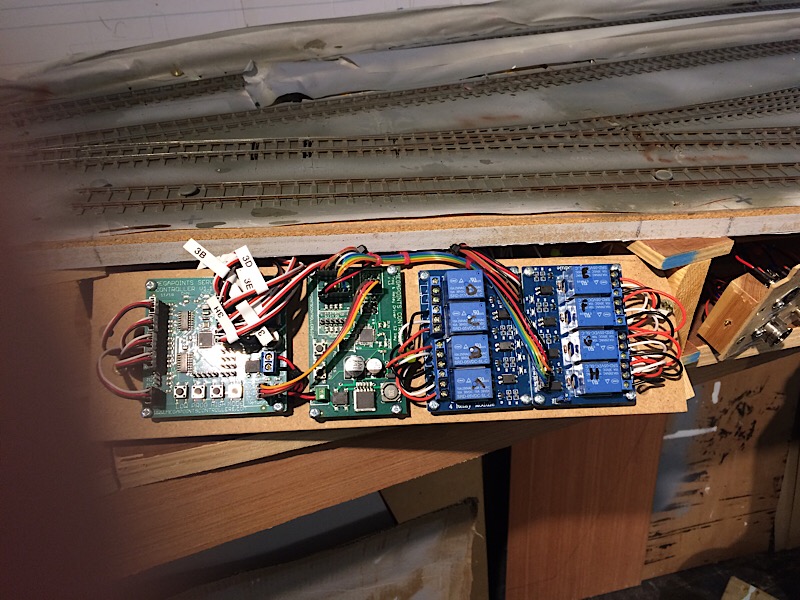

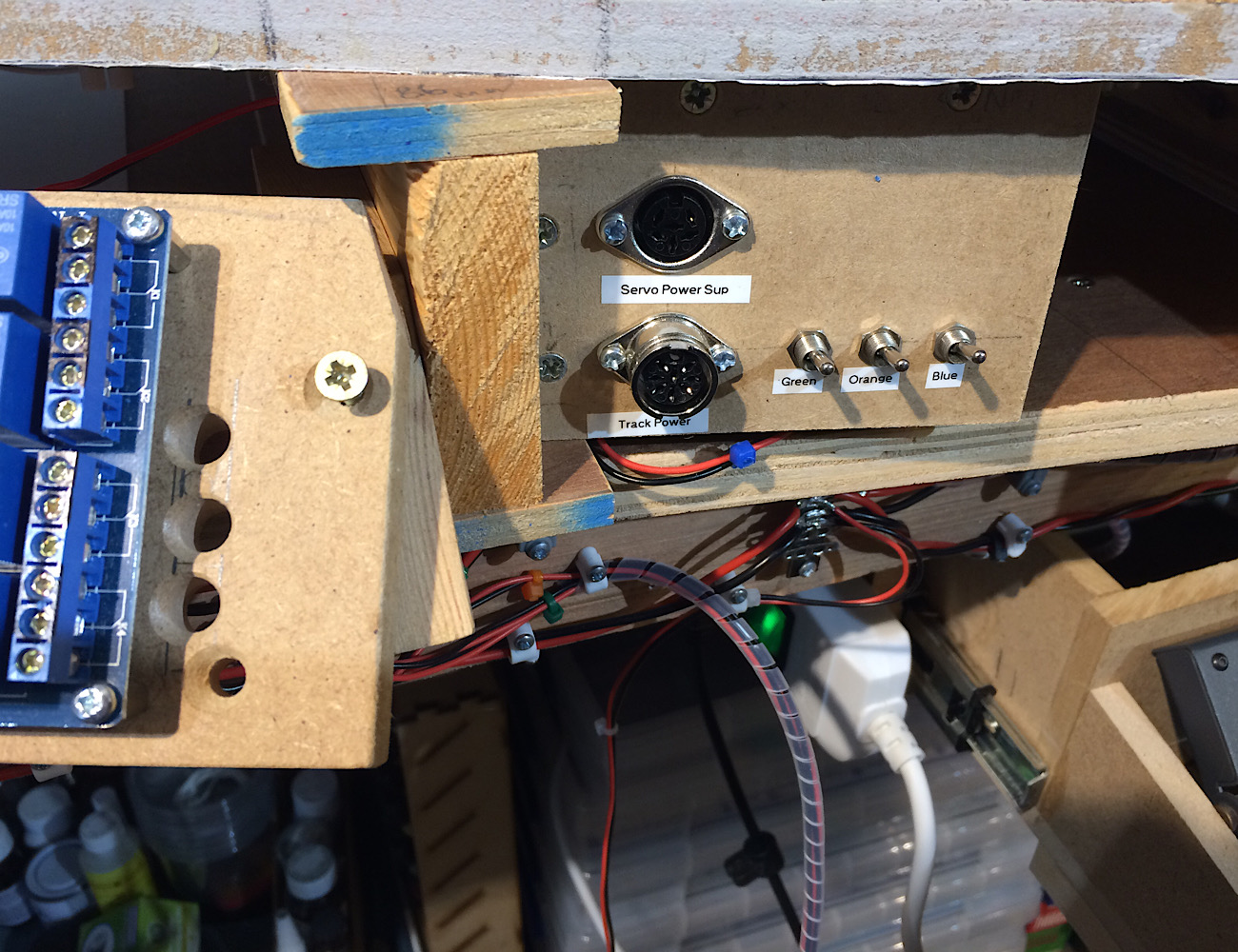

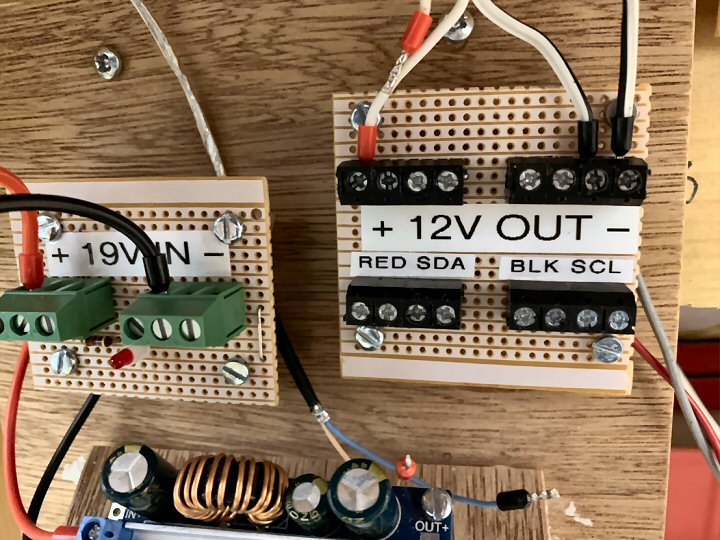

Hello A minor update on progress. The photo below shows he baseboard I've been working on temporarily in place to check clearances and all seems ok! 2787_011413_460000000.jpg  The next photo shows the start of the megapoints installation for both turnouts and signals. 2787_011421_560000000.jpg  That's it for now. Kind regards Andrew |

||

|

posted: 19 Oct 2017 23:18 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

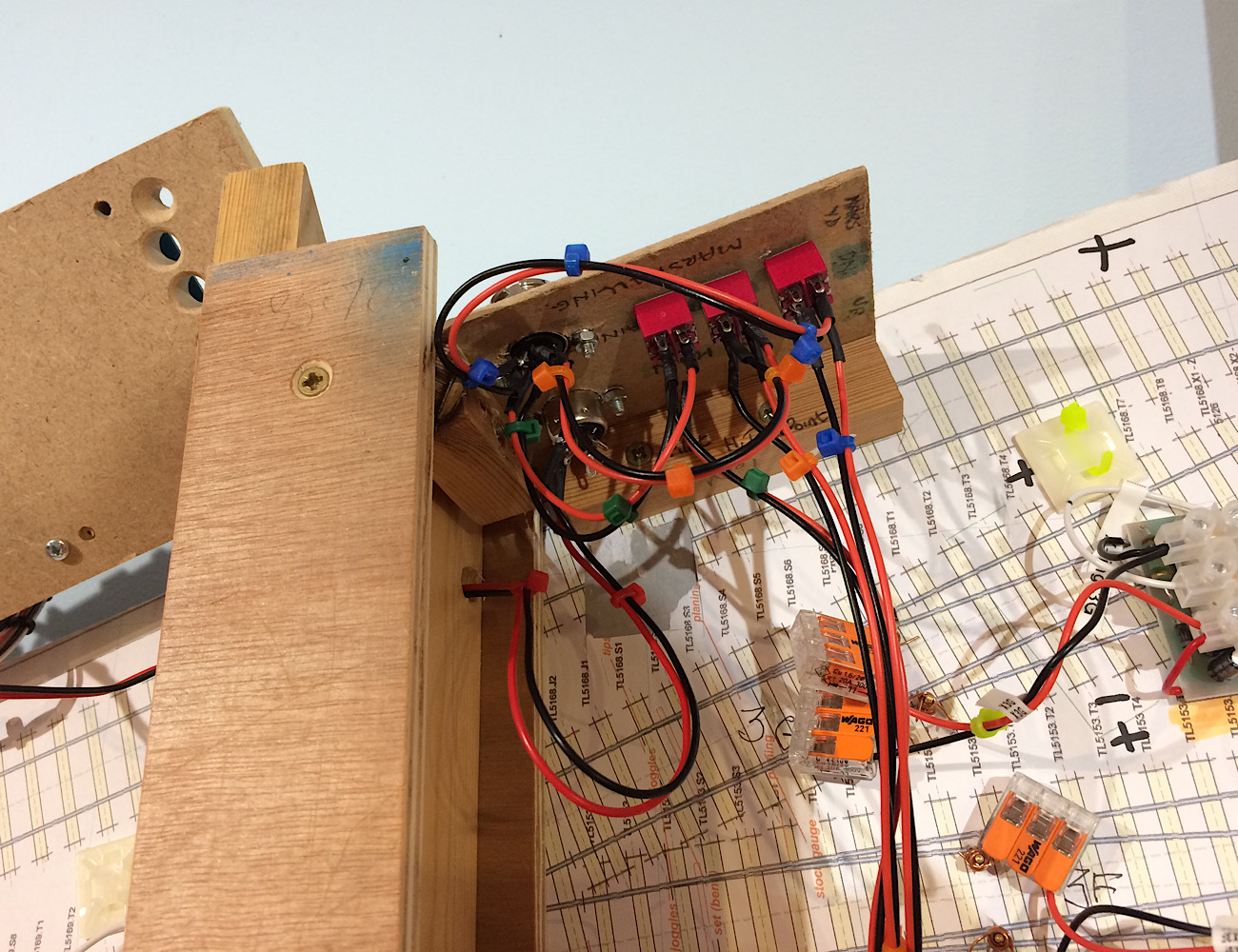

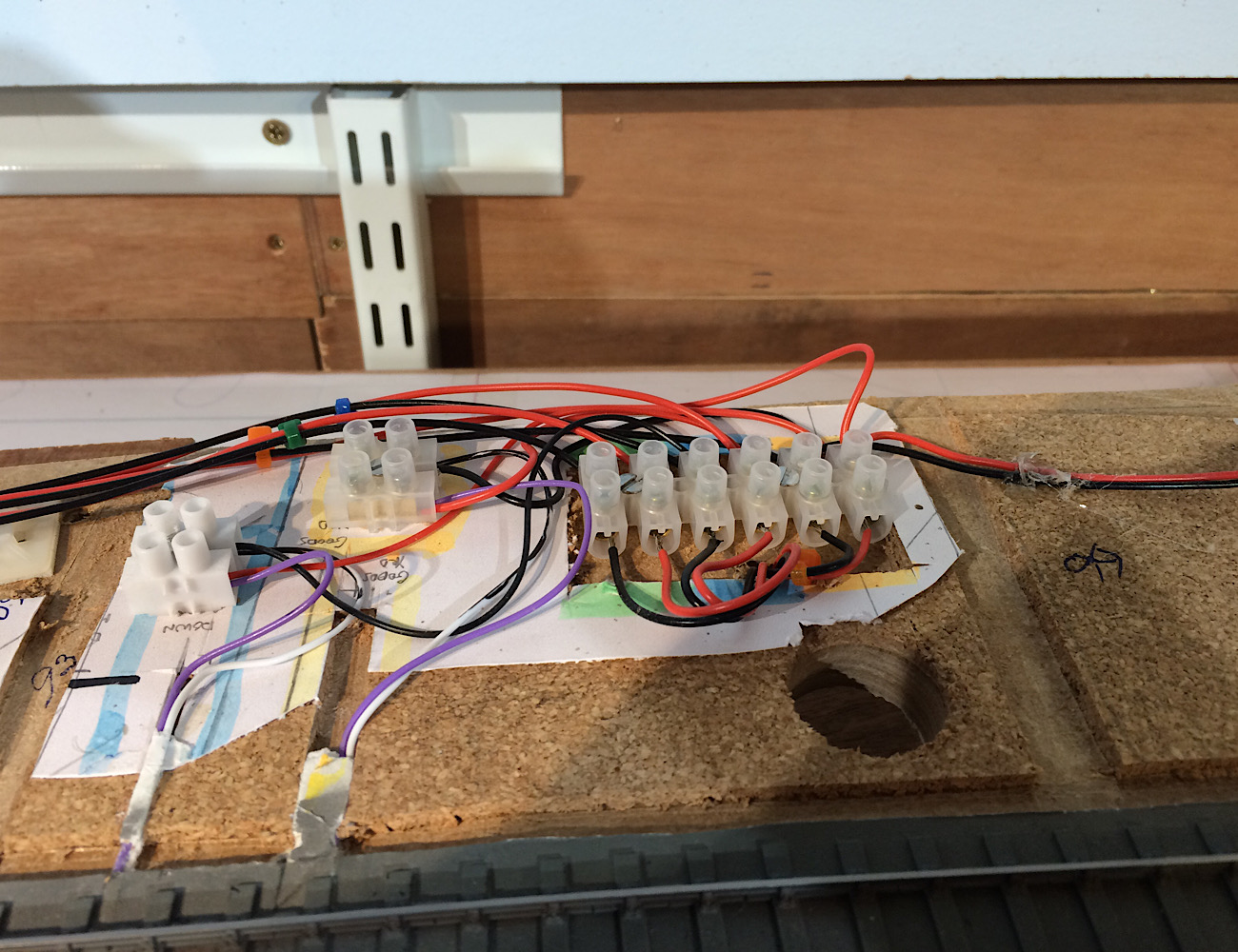

A brief update of my progress in the last few weeks and a request for help. I’ve completed the basic wiring for the servos to the Megapoints control boards, there are two on this baseboard because I’ve got 11 turnouts and five or six signals including three working(I hope) ground signals which are easily visible ( I’m not going to the trouble of making a tiny disc rotate a couple of millimetres if I can easily see it. 80/20 rule). A very welcome upgrade that Dave Fenton has done to the latest Megapoint control boards is that the servos no longer chatter to each other which is a blessed relief and what’s more for a modest sum you send back your old boards to be up graded. My two old ones will be going back for that upgrade just soon as I can summon up the energy to unplug them and put them in the post. The question I have is has anyone got any good ideas on logging wiring and how to keep a track of it all? At present I’m labelling each end of the servo wires going back to the boards with the turnout number and the track feeds are colour coded red and black. The crossing feeds to the micro switches are white. In addition I’ve printed out Templot plans of each baseboard at 20% of full size on A3 paper and have plotted the exact positions of all feeds along with turnout numbering, but still feel that I’m not doing enough to make fault finding later, as easy as I can? Here’s a photo of the underside 2787_191809_330000000.jpg  Kind regards Andrew |

||

|

posted: 20 Oct 2017 06:27 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Andrew, It all looks very nice! Regarding the wiring identification you might try attaching labels from a P-touch or similar. Just use a unique three or four digit identifier at each end. I prefer to keep the wiring a bit loose (and not very tidy) so that I can tug on a wire to find where it terminates. There's another reason for doing it that way. Bundling the wires into a nice neat cable harness tends to increase the cross-talk between electrical signals. Usually that's not a problem for typical model railway conductors, but servos have really lousy noise-immunity and it's not difficult to couple enough energy into their inputs to trigger a cycle. It's quite likely that is one source of the chattering you have observed. Regards, Andrew |

||

|

posted: 20 Oct 2017 12:38 from: Phil O

click the date to link to this post click member name to view archived images |

I agree with Andrew, keep all servo cabling well away from traction cabling, if they have to get close too each other wrap them in foil as this helps to shield them from each other. Phil |

||

|

posted: 20 Oct 2017 12:47 from: John Shelley

click the date to link to this post click member name to view archived images |

Phil O wrote: I agree with Andrew, keep all servo cabling well away from traction cabling, if they have to get close too each other wrap them in foil as this helps to shield them from each other.Or use a screened wire, easier than trying to wrap foil around. Earth the screen, or foil, of course. John |

||

|

posted: 20 Oct 2017 15:06 from: Phil O

click the date to link to this post click member name to view archived images |

John Shelley wrote: Phil O wrote:JohnI agree with Andrew, keep all servo cabling well away from traction cabling, if they have to get close too each other wrap them in foil as this helps to shield them from each other.Or use a screened wire, easier than trying to wrap foil around. Earth the screen, or foil, of course. I wrap the foil around the whole bunch of cables, not each individually. I only had to do it once where there was a conflict of the two cable runs, overal about 9inches or so on each run was enough to stop the twitch. Phil |

||

|

posted: 20 Oct 2017 15:18 from: John Shelley

click the date to link to this post click member name to view archived images |

Phil O wrote: JohnDid you connect the foil to earth or just leave it disconnected? John |

||

|

posted: 20 Oct 2017 19:03 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

I have not found shielding to be very effective. I think that's because the interference is mainly induced (bit like a transformer). If you do run into horrible problems with servos, all is not lost. You can "front-end" the input with an opto-isolator and that makes them pretty immune to interference. I don't want to turn Andrew's thread into a discussion about servos. PM me if you need more info. Regards, Andrew B |

||

|

posted: 20 Oct 2017 19:11 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: I don't want to turn Andrew's thread into a discussion about servos.Nor me. But I would simply add a pull-up resistor at the servo end. What is the sink/source capacity of the driver? regards, Martin. |

||

|

posted: 20 Oct 2017 21:14 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: But I would simply add a pull-up resistor at the servo end. What is the sink/source capacity of the driver?Hi Martin, You could certainly give that a shot, but if I understand correctly what's going on here, that might actually make the problem worse I'm referring to the cheapest analog servos (SG90 type). When the input goes positive it fires a monostable and that starts a servo positioning cycle. The width of the input pulse provides the desired position information. There's not too much data available on the chip inside the servo but from what I've seen the input goes straight into the base of a NPN transistor. If the input signal rises to around 0.7 volts, the transistor turns on and triggers the monostable cycle. Rather than increasing the noise margin a pull-up resistor can actually reduce it. One solution that does seem to help is to elevate the servo's 0 volt rail above the 0 volt rail of the controller. That can be done with a diode, a resistor and a capacitor. The voltage drop through the diode raises the the servo's 0 volt rail by around 0.7 volts and that does add quite a bit of noise margin. Unfortunately it also violates the servo's spec (such as it is), but in practice it doesn't seem to cause a problem. Oh dear! Maybe we should start a new thread on servos Regards, Andrew B |

||

|

posted: 23 Oct 2017 22:48 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Gentlemen Thank you for your varied if slightly worrying thoughts about the servos picking interference. My hope is that as the leads to the servos are all pretty short (the longest lead is about 2' 6" long and the Megapoints boards are mounted on the baseboards for that reason) that they wont pick up anything significant in the way of interference and all will be well. However I thought the tip about screening with foil was a useful one that also seems easily doable if push comes to shove. Indeed when I referred to the servos "chattering" on the old version board it was I believe, not because of interference, but because the power was constantly on in that version. If I understood Dave correctly, the new version of the software now turns off after a moment of moving the servo, hence chatter no longer, just silence. Until the system is tested with the full force of my ZTC 5amp powered 511 I suppose I'm not really going to know the score. It occurs to me that perhaps I should get some trackwork finished and test it before going too much further. Perhaps I'll also drop Dave Fenton an email to get his take on it as well? Many thanks for all your various thoughts on the subject. Kind regards Andrew PS if you have any further thoughts on logging wiring in a meaningful way that makes problem solving easier down the line, I'd be interested to hear your thoughts. |

||

|

posted: 23 Oct 2017 23:27 from: Tony W

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote: The question I have is has anyone got any good ideas on logging wiring and how to keep a track of it all? At present I’m labelling each end of the servo wires going back to the boards with the turnout number and the track feeds are colour coded red and black. The crossing feeds to the micro switches are white.Hi Andrew. That all looks quite neat and tidy. Documenting your layout wiring is often overlooked but certainly essential for anything more than a shunting plank, but can seem a pretty thankless task. A combination of circuit drawings and wiring lists is a good starting point. My preferred wiring method relies on soldered tag strips which can be numbered. A list of connections between tags, the colour of the wires and the function of each wire helps fault tracing. Colour coding is also very helpful as you are doing. Standardisation of repeating circuits is a good idea. Make a record of the wiring through connectors between baseboards pin to tag strip each side. The wiring record for my layout Green Street eventually had to be kept in a lever arch file as there was so much of it, but then the wiring for it did become somewhat complicated by the design spec. Indeed much of the documentation for the wiring was done before the actual layout wiring was commenced and I still ran out of spare solder tags on occasion as new functions were added in the light of experience. Regards Tony. |

||

|

posted: 24 Oct 2017 14:53 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Tony Thanks very much for your thoughts and experience which I think maybe just what I'm looking for. I've a couple of questions for you which I've put in your text below... Tony W wrote: Hi Andrew. My preferred wiring method relies on soldered tag strips which can be numbered. A list of connections between tags, the colour of the wires and the function of each wire helps fault tracing. Colour coding is also very helpful as you are doing. Standardisation of repeating circuits is a good idea. What do you mean by repeating circuits? Make a record of the wiring through connectors between baseboards pin to tag strip each side. Do you have a copy of what you've done that you might be able to show me, a photograph or scan of one of the pages perhaps?You maybe regretting having answered my questions so fully now, but any help that you can give me would be most appreciated. Kind regards Andrew |

||

| Last edited on 24 Oct 2017 19:16 by Andrew Duncan |

|||

|

posted: 25 Oct 2017 17:25 from: Tony W

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote: Hello TonyHi Andrew. Basically yes. A circuit drawing or diagram can cover any number of scenarios, from the trackwork with section power feeds, crossing feeds, isolating gaps, section breaks (although if using DCC you may not have any), to the control boards for said layout. A wiring list is simply a list of connections between tags, the colour of the wires and the function of each wire. Repeating circuits. If a circuit is duplicated several times, it makes sense to use the same colour wires and physical layout each time within that circuit although not necessarily for the control wire to it. That commonality means you will be more familiar with individual circuits that go to make up the whole. I will scan some examples for you. Most of the originals are in .doc format for ease of editing as changes are made. Regards Tony. |

||

|

posted: 25 Oct 2017 22:52 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Thanks very much Tony. I’ll look forward to seeing some examples as well when you have a moment. Kind regards Andrew |

||

|

posted: 2 Nov 2017 01:01 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Andrew. Well that has proved a useful exercise. On visiting some of the files I wished to send you as examples of how I did things, I discovered that they either needed correcting or were in the process of being updated but had not been completed, so has spurred me on to do so. Rather than post them as pictures, I think it better to add them as attachments as some of the text will be too small to read otherwise. This will take three postings. The first file is the Track plan wiring schematic for Green Street and may take a bit of studying. Board 1 is to the left of the vertical dotted line, then board 2 to 4. The tracks are numbered from the bottom upwards. |

||

| Attachment: attach_2553_2547_Track_plan_electrics.GIF 346 | |||

|

posted: 2 Nov 2017 01:04 from: Tony W

click the date to link to this post click member name to view archived images |

The second file is for the connecting cable between boards 1 and 2 and are I hope largely self explanatory. |

||

| Attachment: attach_2554_2547_Wiring_list_1.GIF 315 | |||

|

posted: 2 Nov 2017 01:12 from: Tony W

click the date to link to this post click member name to view archived images |

The third file may be of some use if you have a Three throw turnout to deal with. As the blades overlap, it is important that the two point motors throw sequentially to avoid stressing the drive mechanisms. I have used Fulgurex point motors modified with 10 way connectors and ribbon cable jumpers to allow easy disconnection if required. A major consideration with an exhibition layout. I am sure you will have further questions once you have studied these. Regards Tony. |

||

| Attachment: attach_2555_2547_Three_throw_turnout.GIF 1033 | |||

|

posted: 2 Nov 2017 10:18 from: JFS

click the date to link to this post click member name to view archived images |

Tony W wrote: Hi Tony, Very interesting! But a bit of clarification needed - sorry if you have given this elsewhere and I have missed it. What are the lines A,B,C and D? Also the Ind and Ex designation - which I might be able to guess! The diagram looks as if each of the switches 1 - 12 are just three pole, but if it were that simple, then as-drawn, throwing any one of them shorts a,b,c together - which cannot be the case - in which case, what are each of the three "poles" for, and what stops them being operated together? Best wishes, Howard |

||

|

posted: 2 Nov 2017 12:37 from: Tony W

click the date to link to this post click member name to view archived images |

JFS wrote: Tony W wrote:Hi Howard.Hi Tony, That is the problem of publishing one page of a manual intended for personal use out of context. I suspected that further explanation would be required. A,B,C,D are the four controller buses nominally available to switch to a track section. Ind is short for Industrial and is the power station empire. If you have operated the layout you will know what I mean by that. Controller D is permanently connected to this. Ex is short for extra and is unused at present. The three switch poles on section feeds 1 - 12 are individual relay contacts. The long term plan was for micro processor control of the signal box interlocking and power feeds to sections 1 to 12 will be selected using 2 bit binary control, hence only one relay contact can be made at a time with "00" being off. At present, as a temporary measure and we all know about those, only controllers A and B are available via centre off toggle switches, in effect manual Cab control. You are correct about the shorting issue, it is not uncommon for an operator to forget to restore a section feed switch when they have finished with it and then set up another route using another controller. If the loco overruns the section gap between the two controllers, a short occurs and Pentrollers don't like it up em as we discovered the hard way long ago. Hope this answers your questions. Regards Tony. Edit: Perhaps the attached file may help. |

||

| Attachment: attach_2556_2547_Section_feeds_and_isolators.gif 993 | |||

| Last edited on 2 Nov 2017 16:54 by Tony W |

|||

|

posted: 2 Nov 2017 17:41 from: JFS

click the date to link to this post click member name to view archived images |

Many thanks Tony - I guessed correctly with "ind" - but incorrectly with "Ex"!! Best wishes, |

||

|

posted: 3 Nov 2017 22:51 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Tony Thanks very much for downloading these for me. I'll take a closer look over the weekend and see what I do and do not understand and come back to you with any questions if I may? Kind regards Andrew |

||

|

posted: 3 Nov 2017 23:40 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Andrew. I thought it had all gone quiet! By all means. Regards Tony. |

||

|

posted: 4 Nov 2017 17:19 from: Richie Kynaston click the date to link to this post click member name to view archived images |

Very impressed with the trackwork construction. If i can achieve anything halfway as good in 7mm, i'll be happy! Keep up with the updates. Rich |

||

|

posted: 5 Nov 2017 22:18 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

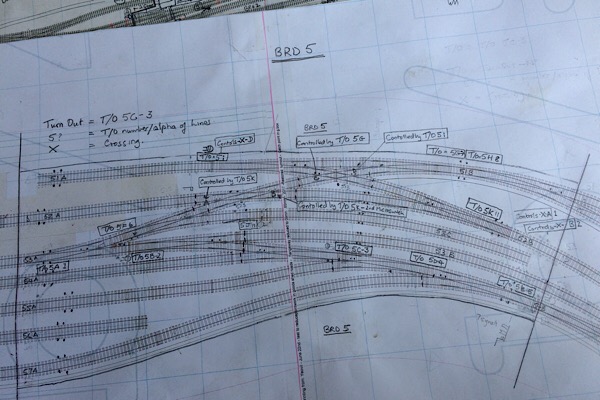

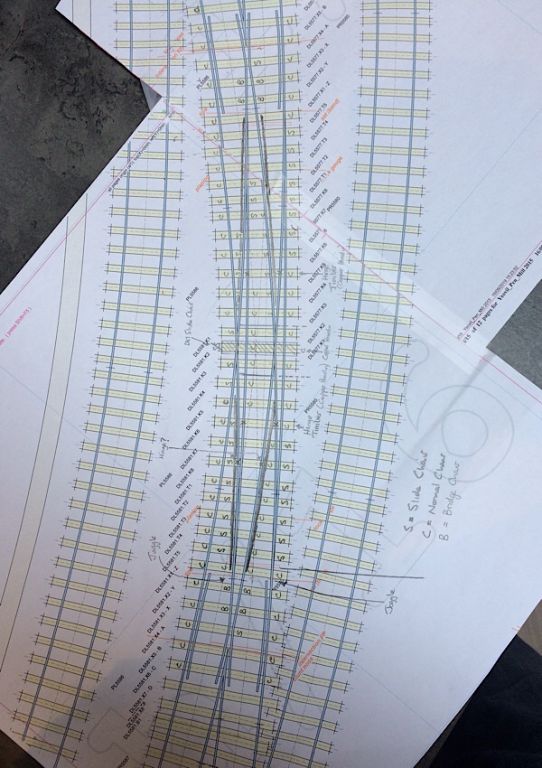

Hello Tony Thanks for uploading the second wiring diagram it does help to get a better sense of the layout. I've not got very far so far this weekend but have managed to scan my current record of baseboard no 5 (a print out of the current section of the layout printed at 20% sizing Edit COPY ATTACHED) of turnouts numbered and all wiring points logged on it. The position of the droppers are marked, usually in pairs, at the point they are soldered to the rail, as I've often found in the past that I've forgotten where the feeds are, which can be very frustrating! I've numbered the turnouts all starting 5 as the baseboard is number 5. They begin 5A, 5B etc and work there way through to 5K. I don't, as you observed have the need for isolating sections as this is DCC, so my next job is, I think, to number the feed wires which I have already pencilled in. Again here I've used the board number to dictate the first numeral but I'm beginning to think this is over kill and I'll probably just re-number them 1-50 or so...? Then make a list of the wires and their function as you have on a separate Word document. Any thoughts you have would be gratefully accepted. Thanks again for your support and ideas. Kind regards Andrew Edit: I've just noticed that the scan ive uploaded has cut a few inches off the left hand end of the baseboard chopping the first turnout in half! |

||

| Attachment: attach_2564_2547_Yeovil_North_Board_5_-TO_Numbering_-_200_DPI.pdf 349 | |||

| Last edited on 5 Nov 2017 22:38 by Andrew Duncan |

|||

|

posted: 5 Nov 2017 22:29 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Richie Kynaston wrote: Very impressed with the trackwork construction. If i can achieve anything halfway as good in 7mm, i'll be happy! Keep up with the updates.Hello RichThank you for your kind words and encouragement. Its always good to hear !! Kind regards Andrew |

||

|

posted: 5 Nov 2017 23:35 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Andrew. Have you considered numbering the points as they are / would have been in the signal box diagram as this will save cross referencing later on. The signals will also have to be added to the scheme as well. This is the system I used on my layout, fictitious though it is. The points with an M prefix are those that would have been manually operated with hand levers had it existed. There is no right or wrong way to do it, but at the end of the day you need to have something that works for you and that you can understand. Also give some thought to being able to break down the DCC fed areas into smaller sections, i.e. using plugs and sockets to enable faults to be isolated more easily. As it happens I do have a passing interest in Yeovil Pen Mill as a good friend of mine always wanted to model it in P4 but sadly never got the chance, so it is nice to see it taking shape in your capable hands. Regards Tony. |

||

| Last edited on 5 Nov 2017 23:38 by Tony W |

|||

|

posted: 6 Nov 2017 22:28 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Tony Thanks very much for the idea of using the signal box diagram. Deceptively simple ideas are often the inspired ones, and your idea seems to come very much in that category. You're right of course about the signals which aren't on that plan but need to be included and although I've allowed for them electronically I've not yet given them sufficient thought physically in either location or construction method. As a result of a comment of Howard Bolton's that I came across the other day I've been following Steve Hewitt's authoritative thread in RM Web on signal construction which is both fascinating and instructive. Now your thoughts on fault finding have set me thinking as to whether I've got enough places to "break" wires for fault finding. That'll require a bit more thinking I think, so for the moment I'll conclude by thanking you for your comments on on your connection with Yeovil and the compliment of it being "in safe hands". I was really quite touched by your words. Kind regards Andrew |

||

|

posted: 7 Nov 2017 22:37 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Andrew. One other thing. You may have noticed that the track diagram was marked issue 9. When you modify the layout, make sure you update the documentation to match. There is nothing worse than trying to fault find with out of date reference material. Guess how I know. Regards Tony. |

||

|

posted: 8 Nov 2017 13:18 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hmm wise words Tony but that’s going to require self discipline...! When you say version 9 where they track plan changes or something elsethat you’d changed?Andrew |

||

|

posted: 8 Nov 2017 22:21 from: Tony W

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote: When you say version 9 where they track plan changes or something else that you’d changed?AndrewHi Andrew. A mixture of things really. The layout was extended once with the addition of an off scene industrial siding, which required the replacement of a turnout with an outside slip, but mostly it was down to errors and amendments made over the course of time. The most recent change (from issue 8 to 9) was replacing the pencil drawn original with the computer graphic I posted, but I took the opportunity to update one of the point motor numbers from M2 to M2a for clarity. This change had been noted in red ink on the earlier working copy some years ago, so no, I don't exactly rush to do the updates, just make a note of them at the time. Regards Tony. |

||

|

posted: 15 Jan 2018 19:43 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello TonyI thought I’d replied to your response above but apparently not so my apologies for the lack of acknowledgment and thanks for the explanations! Kind regards and a happy new year. Andrew |

||

|

posted: 15 Jan 2018 22:53 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

I’m in retail and quite apart from the challenges that that brings Christmas is our busy time so unfortunately gets in the way of model railways. So progress has been a bit slow of late. I have however now started add the plain track that connects all the point work on this base board, very roughly cutting it slightly long for its location and jus placing it down to be able to attach the droppers in place. My plan then is to spay track colour on both the plain track and point work, lift the plain track and then commence balasting of the turnouts. Then replace the plain track in a bed of PVA and ballast at the same time. My fear is that the two different methods of balasting may look different but I shall have to cross that bridge if and when the happens. A couple pictures to follow Andrew |

||

|

posted: 16 Jan 2018 23:51 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

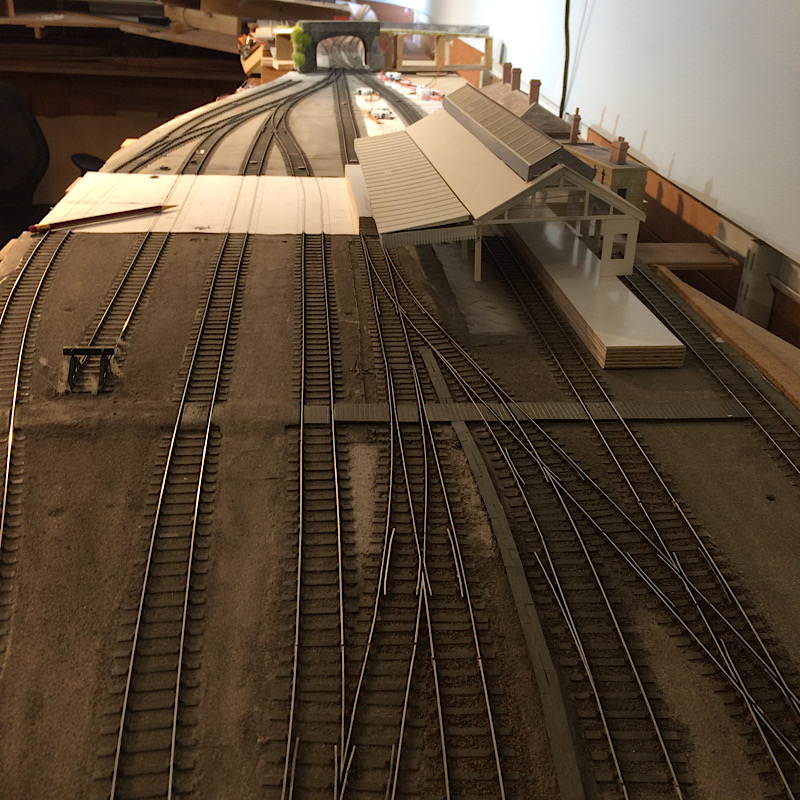

And here they are. I’ve also just realised that I’ve yet to build the catch point to protect the down main from carriages wandering out of their siding between the up and down main lines. A friend pointed out its absence a couple of months ago and sure enough when we checked the photos there it was... 2787_161841_420000000.jpg  2787_161844_160000000.jpg  So little more trackwork before spraying and ballasting and I need to install the dummy point rodding as well. Andrew |

||

|

posted: 14 Jul 2018 05:11 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

I can barely believe that its been 6 months since I’ve reported any progress on Pen Mill. I’ve not been totally idle, nor have I made great leaps forward. The catch point is in on the carriage siding. I’ve added all the feeds/ droppers in now, so the amount of wires underneath have burgeoned. I’ve almost got all microswitches switching the correct polarity. I’ve even got close to getting the diamond crossings being switched by their adjacent turnouts. It remains to be seen whether the micrswitches stay correctly aligned to give reliable switching over time. I maybe worrying unnecessarily but I’m beginning to wonder whether I’d have been better off either using either Megapoint electronic control ( as I did on the junction baseboard)or frog juicers for this? Does anyone have any experience of the Gaugemaster frog juicer. I have bought a couple but not used them yet and since read that they will only take a couple of amps ( my ZTC has a 5 amp output) power going through them? The other problem of the microswitces is that they are bulky and despite the elegance of the Alu Rail brackets, being under the baseboard, am I asking for trouble having a system that can go out of adjustment and needs baseboard removal to get at them? In retrospect I think I may regret the microswitch and end up replacing them in part or completely with electronic control. Hers a photo of the current state of progress of the underside so you can see a bit of what I mean. 2787_132336_080000000.jpg  Looking at this now I’m so glad I stuck (a mirror image) a copy of the plan to the underside, as I’ve found my ability to remember what I’ve just look at topside and retain that a few moments later when looking at the underside is very limited. So the plan stuck underneath is a godsend. And whilst talking of that and taking some advice from a number of you and Tony in particular, on record keeping, I’ve attached a picture of my wiring records which I’m reasonably pleased with. 2787_132348_590000000.jpg  It’s not very clear but it shows exactly where each pair of droppers are, turnout numbering and what turnouts control the 4 diamond crossings. There’s a legend,top left, that reminds me what my abbreviations mean! So now it’s July and in two weeks or so I’m off to Missenden again so there at least I’ll be able to get something done largely without interruption I hope. Kind regards Andrew |

||

|

posted: 14 Jul 2018 19:46 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Andrew. It crossed my mind only a couple of days ago that you had not posted anything for while, so it is good to see that you are still making progress. Regards Tony. |

||

|

posted: 15 Jul 2018 00:37 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Thanks Tony and yes it is good to be back “at it” again. I’m hoping to be able to make some good progress in the next few weeks. Having said that I find building the point rodding a bit of a slog and I’m not attempting to make mine work! The other thing that’s occupying me is the ballasting. From photos it appears to be largely ash and cinders with a little stone ballast between the rails in places. I’ve considered ballasting stone first and then covering much of it with a very fine material ( fine sand or powdered stone might be suitable?). Or maybe the other way round, adding a bit of stone ballast here and there? I’ll try an experiment or two with some oddments of track before I commit to a particular approach. Kind regards Andrew |

||

|

posted: 6 Aug 2018 08:10 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

I’m back from a great week at Missenden. Below is a photo of my progress there. In the photo you can see that I’ve almost finished ballasting and the rather disjointed look is because I’m trying to have the main lines neatly balasted whilst having the goods yard and marshalling areas with no obvious ballast at all, just ash. And I ve found this quite challenging to reproduce realistically. So bear with me whilst I attempt to finish this off. Anyway I had a really good time at Missenden and my thanks go to Tim Peacock who is rarely flawed by any modelling problem, to Barry and Tony the tutors who were very helpful to me once again, the gang in Studio one, Mick Bonwick for his advice on weathering and David Brandreth and Chris Langdon for running the whole show. A great week chaps! 2787_060252_200000000.jpg  I’ll do a bit more of an update later this week if I can get round to it Kind regards Andrew |

||

| Last edited on 6 Aug 2018 08:11 by Andrew Duncan |

|||

|

posted: 8 Aug 2018 22:57 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello everyone Here’s a bit more detail of the ballasting I did whilst at Missenden. This is the sort of effect that I’m after generally within the station limits. So the line in the middle with dark we’ll kept ballast is the main up line and from photographs appears reasonably well looked after. The coach siding ( above it in the photo) and the goods yard are just ash by the look of it, up to sleeper top level and this I’ve found quite hard to achieve as yet. 2787_081711_350000000.jpg  The photo below shows some progress since being back, with the walk way beside the carriage siding under construction made simply from Evergreen strip chopped up in my Northwest Shortlines chopper( a great tool for this sort of repetitive work). Next I need to work out how to do the road surfaces between the sidings in the goods yard which, in this scale, needs the barest minimum of texture to suggest what would have been a pretty smooth surface. Gloss paint and talcum powder have been suggested to me, so that’s one option that sounds feasible. Better reread Gordon Gravetts book on the subject! 2787_081738_340000000.jpg  Kind regards Andrew |

||

|

posted: 8 Aug 2018 23:09 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote:Gloss paint and talcum powder have been suggested to me, so that’s one option that sounds feasible. Better reread Gordon Gravetts book on the subject!Hi Andrew, Or gloss paint and chinchilla dust (from pet shops). It has just a fraction more texture than talcum powder, and is a useful material all round the layout for roadways, tarmac, etc. Good to see your progress. cheers, Martin. |

||

|

posted: 10 Aug 2018 07:20 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

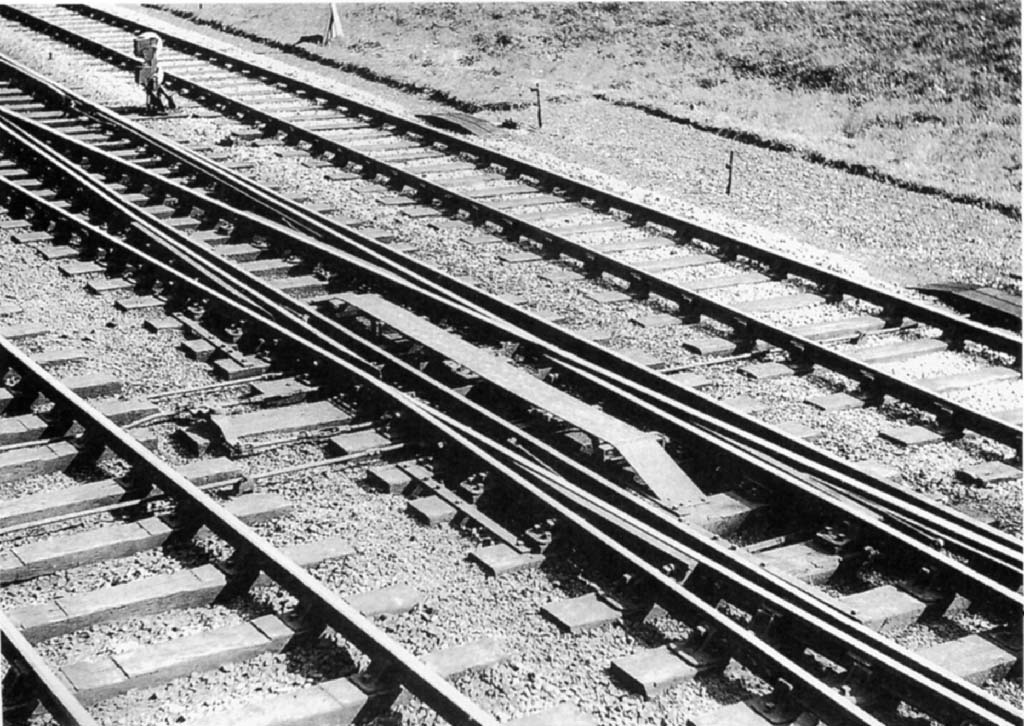

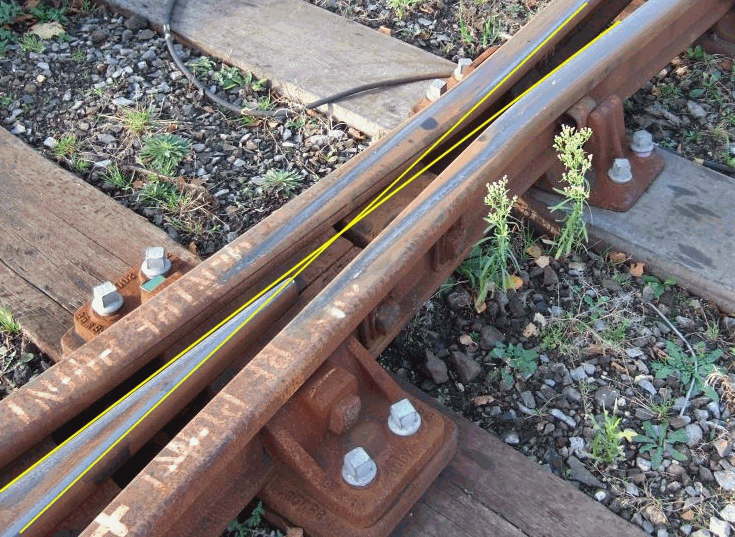

Martin Wynne wroteHi Andrew,Hello Martin Interesting stuff chinchilla dust. I tried some whilst I was at Missenden and although finer than the finish in the photos above, it was still a little coarse to my eye. The look I’m trying for is in this photo taken from the road bridge at the end of the platforms south end of the station. Looks very smooth at that distance with just the odd lump of detritus here and there. 2787_100216_220000000.jpg  Thanks for your for your encouragement. Kind regards Andrew |

||

|

posted: 10 Aug 2018 13:40 from: Phil O

click the date to link to this post click member name to view archived images |

Hi Andrew, Have you tried wood ash? This tends to be pretty fine, although you may need to sieve out bits of charcoal, where the wood has not fully burnt. Phil. |

||

|

posted: 10 Aug 2018 14:01 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote:Interesting stuff chinchilla dust. I tried some whilst I was at Missenden and although finer than the finish in the photos above, it was still a little coarse to my eye.Hi Andrew. How to make dried chinchilla dust smoother: http://www.sealantsandtoolsdirect.co.uk/manufacturers/sealants_and_tools_direct/sandtd_decorating_products/wallpaper_and_flashing_seam_roller_P27836.html A useful tool around the layout. Martin. |

||

|

posted: 10 Aug 2018 23:07 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Phil O wroteHave you tried wood ash? This tends to be pretty fine, although you may need to sieve out bits of charcoal, where the wood has not fully burnt.Hello Phil Yes I have in past but not on this occasion. And you’re right it may need sieving but depending on how lumpy it is may determine whether I need to sieve or not. I know I’ve got some somewhere, I’ll give it a try and let you know. Thanks for the idea. Kind regards Andrew |

||

|

posted: 10 Aug 2018 23:18 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Martin Wynne wrote:How to make dried chinchilla dust smoother: direct/sandtd_decorating_products/wallpaper_and_flashing_seam_roller_P27836.htmlHello Martin Neat idea. Think I may have one of these somewhere in the cellar. Might work well with the ash idea as well? Many thanks Andrew |

||

| Last edited on 11 Aug 2018 06:48 by Andrew Duncan |

|||

|

posted: 11 Aug 2018 00:35 from: John Palmer click the date to link to this post click member name to view archived images |

I have found a pestle and mortar a useful way of reducing the grain size of ballast and other scenic materials. A woman's stocking can be used to control the application of powdery materials. I recently tried the Gravett technique of talc on wet gloss paint to simulate a tarmac surface with some success, although the texture can be vulnerable to subsequent unwanted abrasions. Getting the yard surface up to top of sleeper height has been a problem for me too. Since the track concerned is being constructed in situ I still have the option of applying Das clay or the like around the sleepers that have been glued in place before fixing chairs and rails to the sleepers. I suspect that trying to build up the ground after the rail is in place might well lead to unacceptable results. However, this particular project (part of my planned West Highland layout) has gone on the back burner with I grapple with the revival of a forty-year old layout, the trackwork on which was finished long ago. |

||

|

posted: 11 Aug 2018 07:43 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello John Thanks for the pestle and mortar idea and yes I tried the stocking idea with the chinchilla dust for the first time last week but still found it too coarse. Maybe with Martins idea of a roller to flatten the lumpy bits that may now work. As I don’t have any chinchilla material (lasts weeks experiment was borrow from a friend) I’ll try the wood ash through a stocking and roller it flat where necessary and see how that comes out Watch this space! Kind regards Andrew |

||

|

posted: 11 Aug 2018 07:57 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello again John I forgot to reply to your thought on ground levels. I thought I’d try just building up the ground between sidings with card cut, of course, to shape from a spare print out of the area that Templot can provide at the push of a button. This is when I’ll find out how closely I’ve laid my track to the Templot plan! As to the ballast levels between the rails this is less of a problem. The bit outside the rails between the sleepers may well have to done manually with dilute PVA and ash. Laborious but for areas at the front of the layout probably worth doing Incidentally I’ve got a long barrow crossing to make through point work and I’ll try the print out technique there as well. Might save a lot of time. Andrew |

||

| Last edited on 11 Aug 2018 09:07 by Andrew Duncan |

|||

|

posted: 11 Aug 2018 13:17 from: Nigel Brown click the date to link to this post click member name to view archived images |

I'm a sucker for ready to use stuff. On the yard on my 3mm layout I used some stuff from Greenscene called textured paint; Squires sell it, £3.79 for a 125 ml bottle. Comes in various colours, mainly shades of grey. The colour doesn't matter, as I paint it once dry with dilute acrylics. The paint, being acrylic, can also be diluted with water, useful if you want it easier to work with. Re raising the yard level, I've just bought some 3mm thick foamboard; you get loads in a pack of A1 sheets, for not a lot of money. Can think of various uses. Nigel |

||

|

posted: 12 Aug 2018 19:46 from: Ian Allen

click the date to link to this post click member name to view archived images |

Andrew, I don't know if this is of interest to you: t_yeovil_pen_mill.jpg http://www.ukrailwayana.com/ At Stafford Railwayana Auctions. It didn't sell in May. Ian http://www.ukrailwayana.com/ At Stafford Railwayana Auctions. It didn't sell in May. Ian |

||

| Last edited on 12 Aug 2018 19:47 by Ian Allen |

|||

|

posted: 13 Aug 2018 05:32 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Nigel Brown wrote: I'm a sucker for ready to use stuff. On the yard on my 3mm layout I used some stuff from Greenscene called textured paint; Squires sell it, £3.79 for a 125 ml bottle. Comes in various colours, mainly shades of grey. The colour doesn't matter, as I paint it once dry with dilute acrylics. The paint, being acrylic, can also be diluted with water, useful if you want it easier to work with.Hello Nigel The textured paint sound interesting. Is it like a fine version of Sandtex the exterior paint? Have you, by chance, got a close up photo of it that you could post? Foam board would I think be too thick for my purposes here. I only need to pack it up just over half a mill to get top of sleeper height as I’m using the thin sleepers which I think are 0.8mm thick. Kind regards Andrew |

||

|

posted: 13 Aug 2018 09:57 from: Graham Idle

click the date to link to this post click member name to view archived images |

Hello Andrew, How about using greyboard as a packing material. It's available in a variety of thicknesses, 600micron, 750micron or 800micron might be just right. I can recommend ( http://www.funkypen.co.uk/GREYBOARD1.html ) as I have them before. Regards, Graham Nigel Brown wrote:I'm a sucker for ready to use stuff. On the yard on my 3mm layout I used some stuff from Greenscene called textured paint; Squires sell it, £3.79 for a 125 ml bottle. Comes in various colours, mainly shades of grey. The colour doesn't matter, as I paint it once dry with dilute acrylics. The paint, being acrylic, can also be diluted with water, useful if you want it easier to work with. Hello Nigel |

||

| Last edited on 13 Aug 2018 10:01 by Graham Idle |

|||

|

posted: 13 Aug 2018 13:32 from: Nigel Brown click the date to link to this post click member name to view archived images |

Andrew Duncan wrote

528_130823_580000000.jpg  528_130826_030000000.jpg  It's used in the goods yard. The first pic is as laid, the second has various washes of dilute acrylic paint sloshed on it. The focus in the second pic is a bit odd; everything is a bit out of focus. As it comes it's a bit thick, and can dry out a bit in the bottle becoming a bit thicker, but it can easily be thinned using water. Goes on fairly easily; you need to work it a bit to avoid clumping. But you can get it pretty smooth with just the odd "stone" showing. Nigel |

||

|

posted: 13 Aug 2018 23:00 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Hello Nigel Thanks for the pictures, nice layout and very neat trackwork. I can see what you mean about effect you’ve got in the goods yard which although as you say is a little unfocused it has a good feel. Have you written up the construction of the layout anywhere on here or any of the other forums? I’d be most interested to see more, there aren’t many 3mm layouts around and I presume much of it youve built from scratch? Thanks again Kind regards Andrew |

||

|

posted: 13 Aug 2018 23:22 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

2787_131835_110000001.jpg  A ,little more progress over the weekend and this evening. I’ve finished the carriage siding walk way now and made a good start on the barrow crossing for which I used Evergreen v groove board which was a bit of a cheat not using separate planks for it, but I think it’ll look ok when finished? It’s quite long and an odd mix of planked surface and then where it crosses the sidings they just used ash built up,to height. So for that I’ve sanded three layers of plastics Into the rough shape and I’ll use some filler to smooth it out finallyA couple of pictures below to show what I mean. 2787_131835_110000000.jpg  Andrew |

||

| Last edited on 13 Aug 2018 23:37 by Andrew Duncan |

|||

|

posted: 13 Aug 2018 23:44 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andrew, I have rotated the pictures for you. The answer when using a phone camera is to turn it the other way up. The camera lens on the back should be at the top. If you use the the phone near-horizontal, first tip it up vertical and then back down. The orientation sensors don't work while the phone is horizontal. cheers, Martin. |

||

|

posted: 14 Aug 2018 00:33 from: Nigel Brown click the date to link to this post click member name to view archived images |

Andrew Duncan wrote: Hello Nigel Hi Andrew No write-up yet, partly because I'm a slow builder! I get side tracked by building rolling stock. Some pics have appeared in Mixed Traffic, the 3mm Society newsletter, and on RMweb. At the moment I'm forcing myself to build the cassettes for the fiddle yard, which I've been avoiding for years. Once that's done I can retest the whole of the trackwork then it's a question of finishing off the scenery. The first board (essentially the second pic) just needs scenic details, there's more to do on the shorter second board. The buildings are scratch built, the stock mainly from kits. The coaches in the second pic are a clerestory composite from Blacksmith and a toplight brake third from Worsley Works etches. The Dukedog is a Blacksmith body on my own etched chassis. For wagons the Society has a large offering mainly from Parkside, some Cambrian models, and a few other sources. More 3mm stuff can be found on http://sites.google.com/site/3mmpublic/ Nigel |

||

|

posted: 14 Aug 2018 01:20 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Hi Andrew, If you want very fine powder to mix with paint etc for textured surfaces you could try Aluminium Oxide powder. It is often sold for air-eraser guns used to clean paint/rust/etc of equipment or models. HTH Rob |

||

|

posted: 14 Aug 2018 22:48 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Hi Andrew,Thanks Martin Oddly enough I think I did have the phone held upright / portrait but obviously got something wrong? Andrew |

||

|

posted: 14 Aug 2018 23:01 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Rob Manchester wrote: Hi Andrew,Hello Rob Thanks for the idea. If the stuff I have in stock doesn’t satisfy then I’ll give your idea a go. First I’m going to try wood ash and possibly a roller if necessary which I anticipate will give me a bit more variation then talc. Then we’ll see! Earlier this evening I was trying packing up the ground level to sleeper top height with thin card. A lot of work which ended up in the bin eventually! Nothing ventured nothing gained. Kind regards Andrew |

||

|

posted: 14 Aug 2018 23:28 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Ian Allen wrote: Andrew, I don't know if this is of interest to you: t_yeovil_pen_mill.jpgHello Ian Lovely sign but rather outside my pocket at present, I suspect. Thanks for thinking of me. Kind regards Andrew |

||

|

posted: 15 Aug 2018 00:24 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote:

Andrew, I have talked to people who have built models with goods yards, carriage sidings and the like in the past and they often use very thin sleeper material in the parts that will be ballasted to the sleeper tops. I seem to remember one chap used 30 thou plasticard 'timbers' on the normal track and switched to 10 thou on the ones where the ground level was to be nearly up to the sleeper tops. 10 thou ( 0.010" ) is about 0.75 inches in 4mm scale which could be suitable. Maybe try that on Yeovil Town Regards Rob |

||

|

posted: 16 Aug 2018 21:07 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Rob Manchester wroteAndrew,Hello Rob That’s a really good idea and thank you passing this idea on...if only I’d thought of doing this before! BUT as I’ve alread laid the track I think my compromise will be to try a layer of PVA and ash and if that looks ok great. If it still looks a bit low I’ll try another layer of glue and ash. I’ll post a photo once done and you can judge for yourself how it’s come out. Thanks again Kind regards Andrew |

||

|

posted: 16 Aug 2018 22:44 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Andrew, The track that is laid on the thinner sleepers has packing underneath to make the rail to baseboard height the same as the normal height sleepers. Just in case anybody was thinking of the layout looking like it was suffering the roller coaster effect Keep up the good work with the layout - it is looking good. Rob |

||

|

posted: 17 Aug 2018 08:18 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Rob Manchester wrote: Andrew,Hello Rob Thanks for your comments and encouragement, much appreciated. I also wondering if in building the track for the next baseboard I do as you suggest with the thin sleepers? The only problem that I foresee in doing this maybe in trying to match the two different approaches in construction at the baseboard joint and I suppose in the overall in the look. I shall have to see how the ash on PVA works and take it from there. Kind regards Andrew |

||

|

posted: 17 Aug 2018 12:32 from: Nigel Brown click the date to link to this post click member name to view archived images |

If you need a source of thin sleepers, I'd suggest looking at Plastruct and Evergreen strip. I've used them entirely on my 3mm layout, although in my case they're not thin. Plastruct and Evergreen are slightly different materials, so you need to check that the solvent you use works on whatever you choose. Nigel |

||

|

posted: 17 Aug 2018 18:34 from: Tony W

click the date to link to this post click member name to view archived images |

The track in goods yards and sidings was often lower than the adjacent running lines anyway. I achieved this effect by using 1/16" cork underlay for the sidings and 1/8" cork under the running lines. The difference was achieved by sanding the thicker cork down to match over a foot or so. The sleepers were of the same thickness 1/32" ply. Regards Tony. |

||

|

posted: 19 Aug 2018 08:34 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Nigel Brown wrote: If you need a source of thin sleepers, I'd suggest looking at Plastruct and Evergreen strip. I've used them entirely on my 3mm layout, although in my case they're not thin. Plastruct and Evergreen are slightly different materials, so you need to check that the solvent you use works on whatever you choose.Hello Nigel Yes I think I’d be inclined to this route with Evergreen as that’s what I normal use and probably have in stock. A ndrew |

||

|

posted: 19 Aug 2018 12:53 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Tony W wrote: The track in goods yards and sidings was often lower than the adjacent running lines anyway. I achieved this effect by using 1/16" cork underlay for the sidings and 1/8" cork under the running lines. The difference was achieved by sanding the thicker cork down to match over a foot or so. The sleepers were of the same thickness 1/32" ply.Hello Tony As far as I can tell the main line and goods yard are all at the same level at Yeovil which makes life simpler. But I wasn’t aware that this was often the case. Do you know why they would make goods yards lower? Andrew |

||

|

posted: 19 Aug 2018 13:28 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote:Do you know why they would make goods yards lower?Hi Andrew, Unbraked vehicles don't roll away uphill. Gravity has nothing to go wrong and never fails. cheers, Martin. |

||

|

posted: 19 Aug 2018 13:47 from: Nigel Brown click the date to link to this post click member name to view archived images |

I wondered if that's why Machynlleth yard had two hefty Iron Minks used as buffer stops! | ||

|

posted: 19 Aug 2018 15:19 from: Tony W

click the date to link to this post click member name to view archived images |

Andrew Duncan wrote: Tony W wrote:Hi Andrew. As Martin has already explained, it is for safety reasons. Although the exit from the yard would be protected by Safety points, it is better not to allow vehicles to roll away toward them in the first place, with all the attendant problems that would cause.The track in goods yards and sidings was often lower than the adjacent running lines anyway. I achieved this effect by using 1/16" cork underlay for the sidings and 1/8" cork under the running lines. The difference was achieved by sanding the thicker cork down to match over a foot or so. The sleepers were of the same thickness 1/32" ply.Hello Tony As far as I can tell the goods yard of my current modelling project Brimsdown wasn't lower than the running lines either. Nor was the siding adjacent to the running line at the regulation track centres being standard track spacing as far as I can tell. Regards Tony. |

||

|

posted: 19 Aug 2018 21:57 from: Ariels Girdle click the date to link to this post click member name to view archived images |

Does it not have something to do with ballasting too - at least in recent times? Main lines tend to be deep-ballasted whereas sidings usually have little or none at all. | ||

|

posted: 20 Aug 2018 00:09 from: Andrew Duncan

click the date to link to this post click member name to view archived images |

Tony W wroteHi Andrew. As Martin has already explained, it is for safety reasons. Although the exit from the yard would be protected by Safety points, it is better not to allow vehicles to roll away toward them in the first place, with all the attendant problems that would cause.Hello Martin and Tony Very sensible and practical idea. Great stuff gravity, utterly reliable. Thanks for the explanation. Andrew |

||

|

posted: 27 Aug 2018 21:35 from: Andrew Duncan

click the date to link to this post click member name to view archived images |