Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 4 Feb 2016 09:01 from: Tim Lee

click the date to link to this post click member name to view archived images |

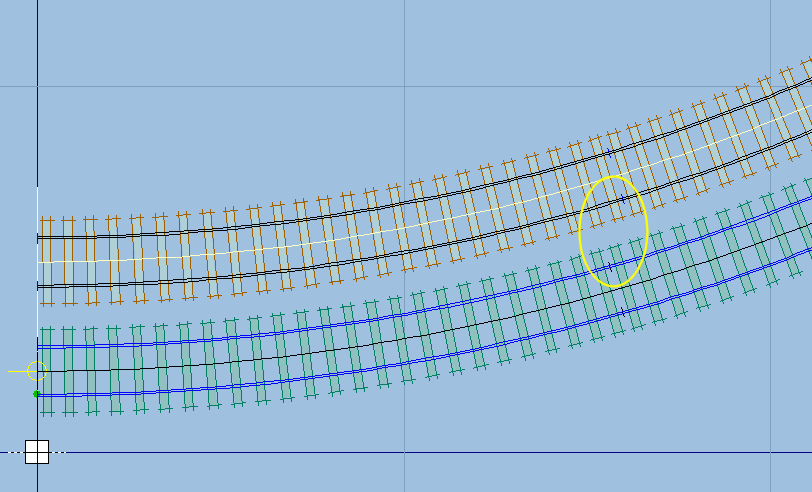

Hi, I am slowly trying to get to grips with the basics. One thing I am struggling a bit with is how to interlace the sleepers after inserting a turn out (see file attachment). Is there a tutorial for this? Regards Tim |

||

| Attachment: attach_2228_2839_trackpad_screenshot_2016_02_04_0852_27.png 446 | |||

|

posted: 4 Feb 2016 12:50 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Tim Lee wrote: One thing I am struggling a bit with is how to interlace the sleepers after inserting a turnout.Hi Tim, There are several ways of proceeding. Generally you need to shove some of the timbers, and/or roll in a shorter length of rail. For best results that usually means rolling in a full rail and then rolling a bit of it back out. I notice that you are using 45ft rails with 12" joint sleepers. So I'm guessing you are modelling pre-grouping practice? In which case you may prefer to swap the timbering style to equalized incremental which generally makes timber shoving easier (although it doesn't make a lot of difference in this case). I have made a short bit of scruff video showing these options. No editing done, this is a scruff video as recorded with my mouse fumblings. It's attached below and should open in the Templot video player. Press the SPACE bar to stop/start at any frame. If on a Mac computer it may not play, so here is the same thing in the awful fuzzy Apple MP4 format which should play on any device. Click it to stop-start at any frame: http://flashbackconnect.com/Default.aspx?id=iDq77LX4vlQLB6yDxFSRpg2 regards, Martin. |

||

| Attachment: attach_2229_2839_scruffy_shove.fbr 421 | |||

|

posted: 4 Feb 2016 14:27 from: Tim Lee

click the date to link to this post click member name to view archived images |

Martin Wynne wrote:Tim Lee wrote:One thing I am struggling a bit with is how to interlace the sleepers after inserting a turnout.Hi Tim, Hi Martin, Thanks a lot .... brilliant and simple .... very impressed with templet so far. I am modelling the Midland Circa 1900 ... Monsal Dale Station. This is a first try to get a simple section to practice track building hopefully to be used as a test track. If the track building goes well I shall then try to overlay the Mensal Dale track plan and see how I get on. On the off chance ... you wouldn't have any ideas where I might look for some prototype information/drawing/photo which would tell be what the tie and stretcher bar config would have been in this era? Regards Tim |

||

|

posted: 4 Feb 2016 15:36 from: Martin Wynne

click the date to link to this post click member name to view archived images |

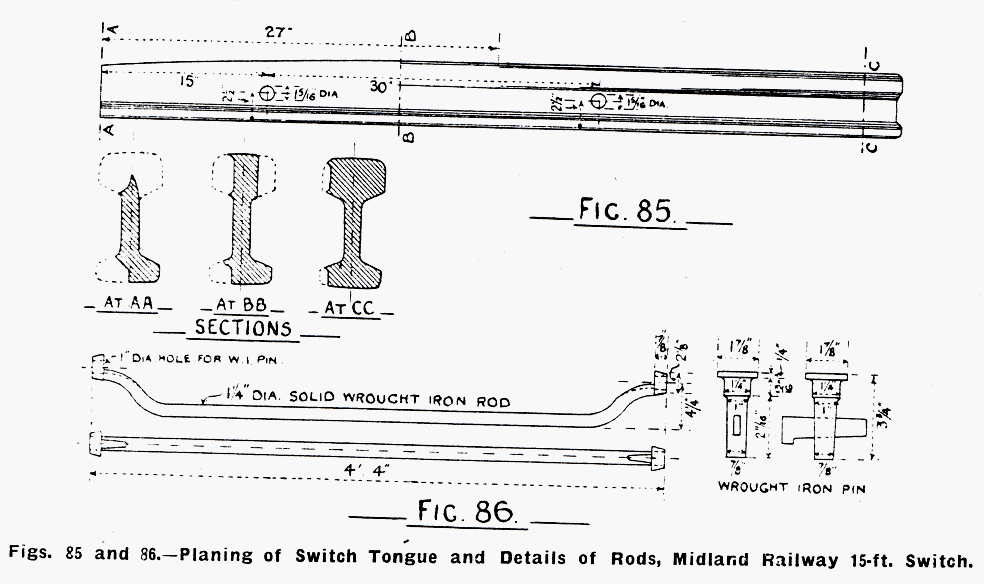

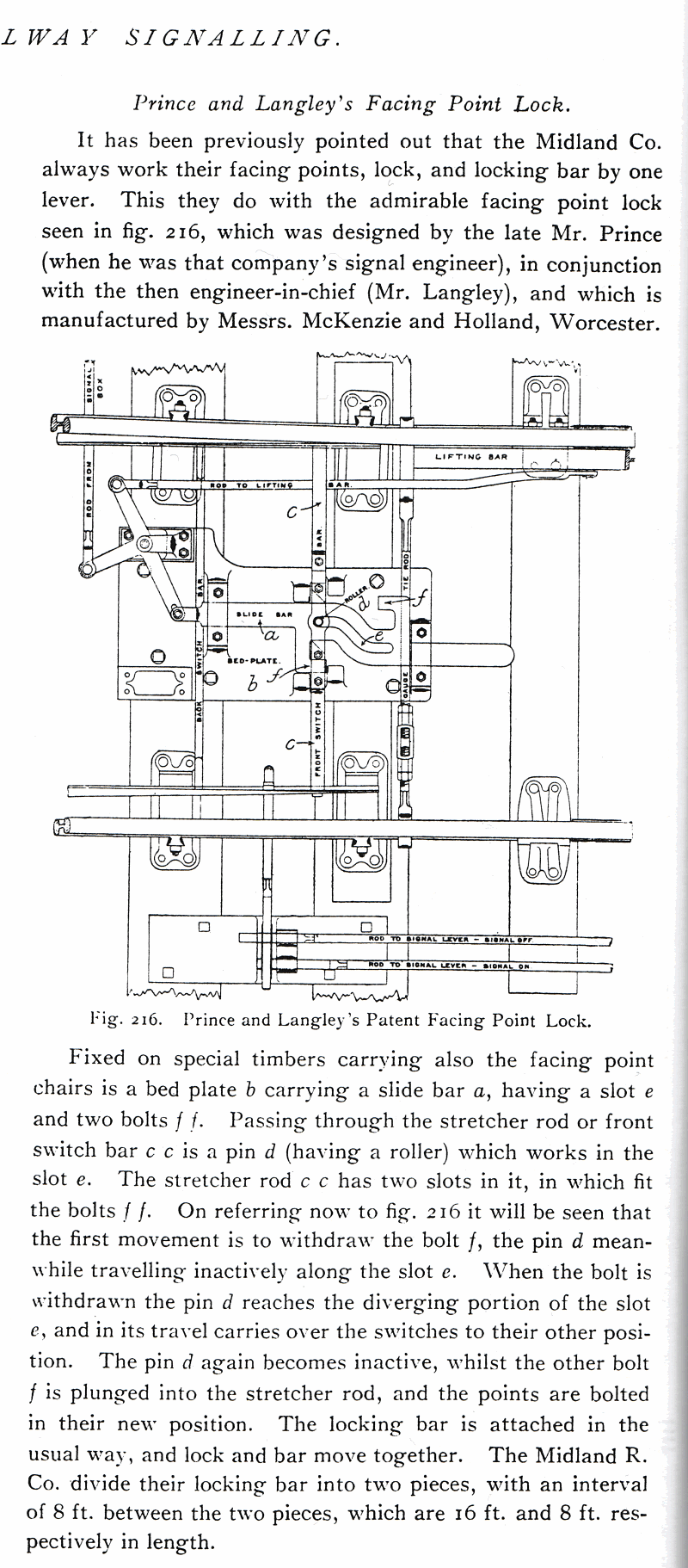

Tim Lee wrote:On the off chance ... you wouldn't have any ideas where I might look for some prototype information/drawing/photo which would tell be what the tie and stretcher bar config would have been in this era?Hi Tim, Most pre-group companies used forged round bars as stretcher bars, fitted into holes in the switch blades and secured with cotter pins or wedge keys. Usually there would be two such stretcher bars. This Midland Railway drawing shows that: 2_041023_280000000.png  Sorry I don't have any information about the drive arrangements. Sorry I don't have any more info about your specific location or period. Your best bet is probably the Midland Railway Study Centre in Derby: http://midlandrailwaystudycentre.org.uk They are likely to have a better quality version of the above drawing, or direct you to where to find it. Also the HMRS Study Centre at Swanwick Junction is in Midland territory and likely to have material: http://hmrs.org.uk/museumstudycentre/ regards, Martin. |

||

|

posted: 4 Feb 2016 16:04 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks Martin ... the drawing is really useful. I have asked the question of the MR Study Centre .... so we will see what comes back. Its a shame I live too far away to pop in as I am sure a couple of hours trawling through the collection would be productive. Regards Tim |

||

|

posted: 4 Feb 2016 16:30 from: Martin Wynne

click the date to link to this post click member name to view archived images |

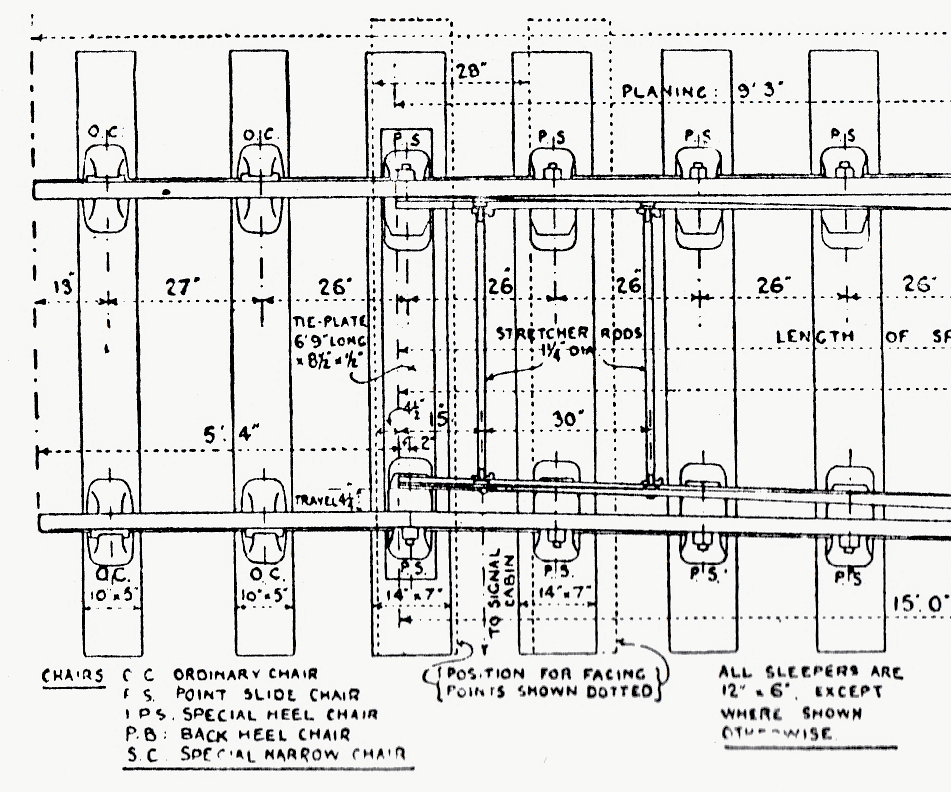

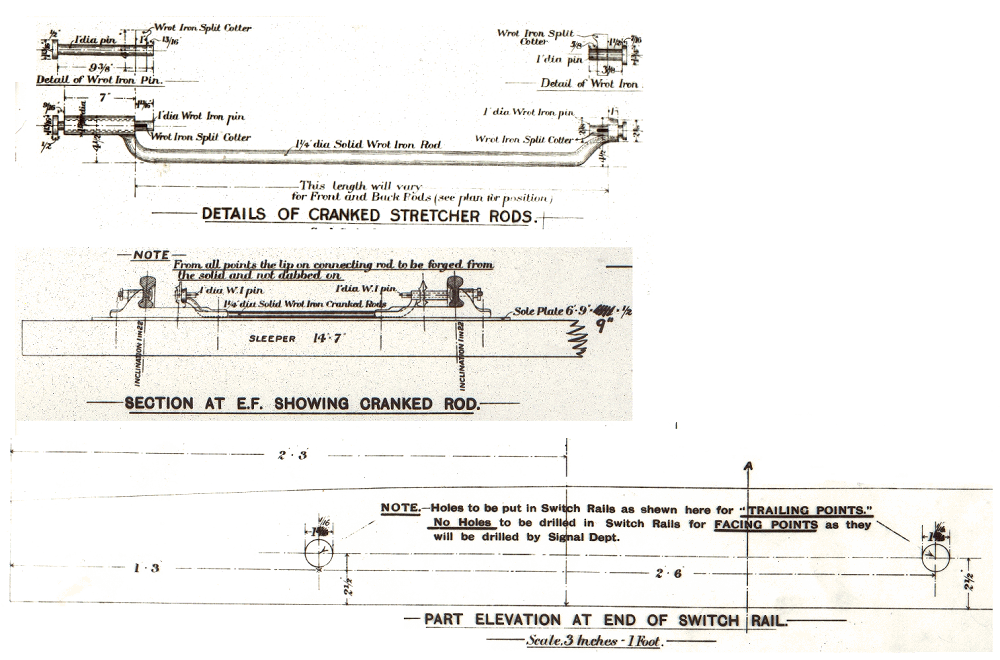

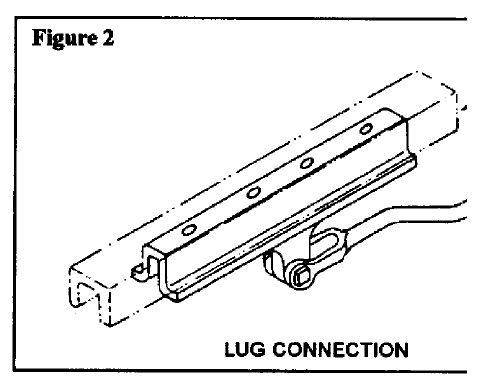

Hi Tim, Just to explain the drawing. The tapered pin is fitted through the switch blade from the back. It is then inserted through a collar (or sometimes into a full tapered socket) which is forged into the end of the stretcher bar. The wedge key is then driven through the slot in the pin to secure it, and pull the taper tight into the collar. Sometimes the pin has an extended head which runs through holes in the stock rail. This ensures that the switch blades are held down onto the slide chairs and unable to kick up under traffic. The leading stretcher bar would usually have a lug or collar forged into the lower part to which the drive connections would be attached. That's not shown on the bar drawing, and only sketched on the plan: 2_041124_540000000.png  The full scan of that plan is here: gallery/2/original/2_191726_470000001.jpg regards, Martin. |

||

|

posted: 4 Feb 2016 16:46 from: Tim Lee

click the date to link to this post click member name to view archived images |

Martin, Thanks a hundred times .... this is fantastic. Now the head scratching starts (as no doubt it has done of many before me!) However I was encouraged by Chris Gough's efforts on Cadhay sidings ... so perhaps there is hope. I note there is no switch anchor on the drawing? Regards Tim |

||

|

posted: 4 Feb 2016 17:04 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Tim Lee wrote:I note there is no switch anchor on the drawing?Hi Tim, Switch anchors are used to prevent the switch blade creeping forward. It's important that the tip is kept behind the set or joggle in the stock rail and can't creep in front of it. For the reason there is no switch anchor on the drawing, contact the Midland Railway drawing office ... Anchors were not universal at this time. Early pointwork often looks quite flimsy compared to modern high-speed junctions. regards, Martin. |

||

|

posted: 4 Feb 2016 19:42 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Tim, I have found this scan of Midland Railway stretcher bars. I don't know where it came from, so apologies if it is infringing someone's copyright. It is obviously from an early date, because the rail inclination is shown as 1:22 instead of 1:20. 2_041436_060000000.png  A full-size scan is at: gallery/2/original/2_041435_200000000.jpg regards, Martin.. |

||

|

posted: 4 Feb 2016 20:20 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks Martin, That's a very nice drawing. Tim |

||

|

posted: 5 Feb 2016 13:15 from: David R

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Sometimes the pin has an extended head which runs through holes in the stock rail. This ensures that the switch blades are held down onto the slide chairs and unable to kick up under traffic.This extended head would also prevent longitudinal movement of the switch blades thus rendering switch anchors unnecessary. Dave R |

||

|

posted: 5 Feb 2016 13:55 from: Tim Lee

click the date to link to this post click member name to view archived images |

That make sense. Tim |

||

|

posted: 5 Feb 2016 23:28 from: Tony W

click the date to link to this post click member name to view archived images |

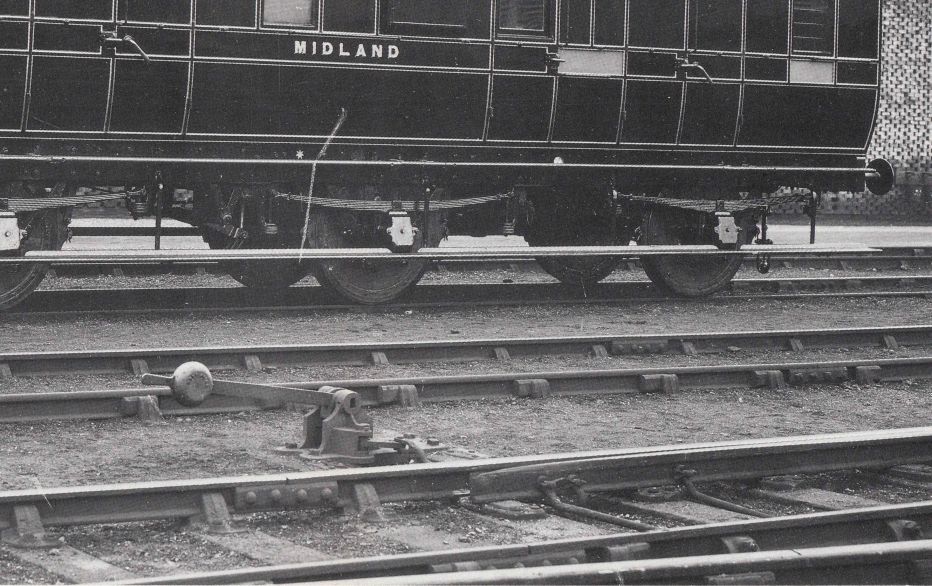

undefined You may find the following pictures of interest. They show the switch blades of a 3 throw turnout at Butterley at the Midland Railway Centre. Although these are a special case, the operating components appear to be pretty standard. The two rods attached nearest to the tips of the blades are the operating rods connected to point levers in this case. Regards Tony W. 2151_051819_170000000.jpg  2151_051825_160000000.jpg  |

||

|

posted: 5 Feb 2016 23:54 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks Tony, Excellent pictures .... very interesting and much appreciated. Regards Tim |

||

|

posted: 12 Oct 2017 09:50 from: Tim Lee

click the date to link to this post click member name to view archived images |

I have a quick question on sleeper placement. When you have parallel running lines (up and down routes) is there a tendency to adjust the sleeper positions so that the positions mirror each other ... I have seen this on a fair few photos but wondered if this was coincidence of by design. Tim |

||

|

posted: 12 Oct 2017 15:43 from: Tony W

click the date to link to this post click member name to view archived images |

Tim Lee wrote: I have a quick question on sleeper placement. When you have parallel running lines (up and down routes) is there a tendency to adjust the sleeper positions so that the positions mirror each other ... I have seen this on a fair few photos but wondered if this was coincidence of by design.Hi Tim. It would obviously make sense where point rodding and signal wires need to pass under the tracks, but otherwise I would have thought not. It may well have been down to the head ganger and how fussy he was. The relative position of the rail joints would also have a bearing on this. In our case baseboard joints will be a major consideration. Regards Tony. |

||

|

posted: 12 Oct 2017 20:20 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks Tony ... makes sense | ||

|

posted: 13 Oct 2017 06:52 from: Martin Wynne

click the date to link to this post click member name to view archived images |

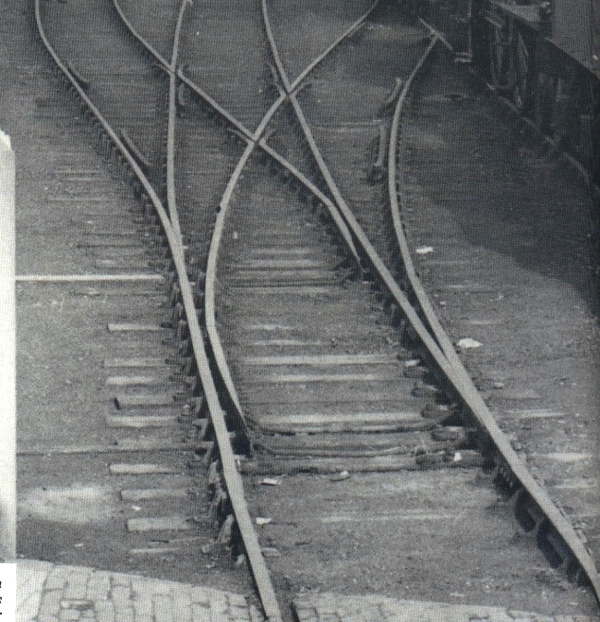

Hi Tim, In the case of curved track it is physically impossible. The outer track is longer than the inner track, but the rail lengths and sleeper spacings remain the same. So the position of the joints and sleepers would get increasingly out of step as you move along the curve. Here you can see that on a sharp curve the joints get out of step very quickly, starting from being in line on the left: 2_130141_060000000.png  On long straight tracks it would be possible to align the rail joints and spacings, but there is no reason to do that and it would be a lot of extra work -- it's likely that shortened rails would be needed on one track or the other at the start of the straight. It would be necessary to align the joints because the sleeper spacings are not constant within a rail length, being closed up towards the joints at each end of the rail. regards, Martin. |

||

|

posted: 13 Oct 2017 09:06 from: Tony W

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Hi Tim,Hi Martin. Yes, I did consider that. The big difference between the real railways and our models is the degree of curvature. Real railways tend to curve in one direction and then curve back again as they head across the countryside, so what goes out of line will come back into line again at some point, albeit briefly. Our models tend to either be largely straight or go round in circles, which would be the worst case scenario. I agree that on the whole it would be more trouble than it is worth and apart from special situations is probably more by coincidence than by design. Any pointwork will also have an influence. Incidentally it should be noted that rail lengths were often laid to avoid having a joint above short under bridges as the hammer blows could potentially damage the structure and these would tend to align the track panels at these locations and by implication for some distance either side. What they did on longer bridges I am not sure as rail joints on the structure would be unavoidable. Regards Tony. |

||

|

posted: 15 Oct 2017 08:17 from: Tim Lee

click the date to link to this post click member name to view archived images |

I think that the main reason for the question is that often when I look at trackwork after either a crossover or slip leading of to a siding and head shunt the sleeper positions superficially look as if they have been adjusted to make sleepers and joints align as the twin tracks head towards the signal box. I fully admit there is nothing thorough or scientific and it may well be either coincidence or even not true (just looks that way from a distance). I just wondered if it might have been common practice to simplify rodding runs. Tim |

||

|

posted: 15 Oct 2017 12:59 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Tim, I think for rodding runs in plain track it is more likely that individual sleepers would be shoved along a bit, rather than adjust entire rail lengths and joint positions. But rodding runs can be significant in the design of timbering layouts for complex junctions, where timber positions are fixed by the chairing requirements. Tony's point about keeping rail joints away from structures beneath the track is significant I think. If the rail lengths and joints are adjusted to do that, it would likely align the sleepers on double track. If the track is reasonably straight, they could remain aligned for some distance on each side. There are a great many small bridges and culverts beneath the track, often poorly recorded. This RAIB report is about the collapse of one such which had a CWR expansion joint immediately above it: http://www.gov.uk/government/uploads/system/uploads/attachment_data/file/410854/120322_R052012_Bromsgrove.pdf See also this response: http://www.newcivilengineer.com/rail-culvert-collapse-triggers-safety-fears/8628390.article regards, Martin. |

||

|

posted: 19 Oct 2017 10:16 from: Tim Lee

click the date to link to this post click member name to view archived images |

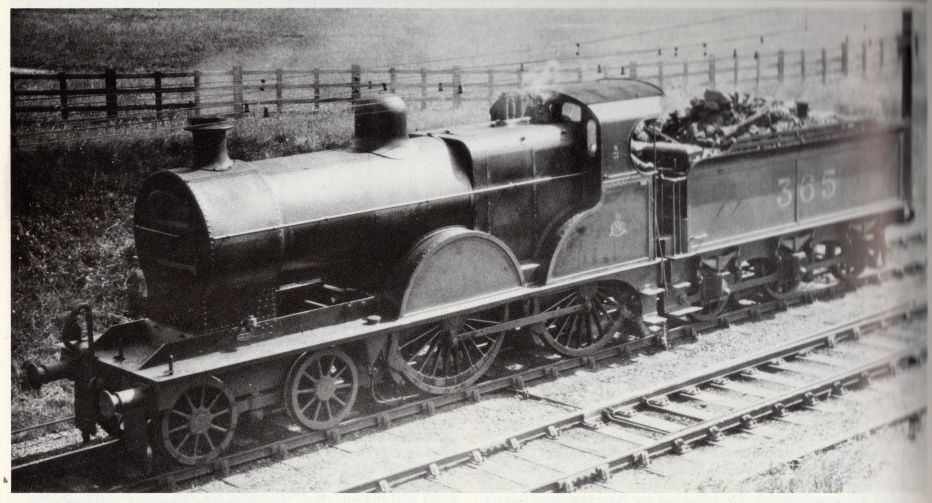

Tony W wrote: undefinedTony, I hope you don't mind me returning to this post for a little further clarification of what I am looking at ... I confess the more I look at it the more muddled I get. No longer necessary ... someone has kindly explained things. Attached is an image of a period MR 3 way turnout for comparison ... the point rodding attachment is quite clear I think .... and I am assuming it would be the same if attached to a crank rather than a lever. Tim |

||

| Attachment: attach_2534_2839_post-26366-0-09851300-1508406275.jpg 695 | |||

| Last edited on 19 Oct 2017 12:26 by Tim Lee |

|||

|

posted: 19 Oct 2017 12:38 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Tim. That picture is quite unusual. Normally on a three throw turnout the shorter blades are between the long switch blade and the stock rail. This means a flange has only one one switch blade tip to negotiate rather than two thus reducing the risk of derailment. Perhaps they learned the hard way. Tony. |

||

|

posted: 19 Oct 2017 12:50 from: Tim Lee

click the date to link to this post click member name to view archived images |

Tony W wrote: Hi Tim. That picture is quite unusual. Normally on a three throw turnout the shorter blades are between the long switch blade and the stock rail. This means a flange has only one one switch blade tip to negotiate rather than two thus reducing the risk of derailment. Perhaps they learned the hard way.As the 'dark arts' of the 3 way turn out are not something I am contemplating grappling with at present I shall log this for later study. Its the rodding connection I was particularly interested in. From what I have found both in the image above and also in 'Midland Railway Portrait' plate 107, I am assuming that the connection would have been the 180 degree 'hook' arrangement to just the nearest blade, with the independent stretcher bars keeping all rigid and moving together? I assume there would have been no difference between lever actuation and the connection to a rodding crank linked back to the signal frame? Tim |

||

|

posted: 19 Oct 2017 13:04 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Tim, Tony, More pics of a Midland 3-throw switch and stretcher bars here: topic 2291 - message 15251 Click the pics to see the high-resolution originals. The high-res version of the GER drawing is here: gallery/2/original/2_280950_180000000.jpg regards, Martin. |

||

|

posted: 19 Oct 2017 13:51 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Tim. As Three throws are a special case, I would not like to infer that only one blade was connected to the control rodding for a standard turnout. General practice seems to be that the control rod was connected at the same place as a tie bar in order to control the amount of blade movement and hence the open tip gap. What the Midland specifically did needs someone with more specialist knowledge than I. I know the Midland avoided them like the plague, but arranging a facing point lock without a tie bar at the switch blade tips would be difficult. Regards Tony. |

||

|

posted: 19 Oct 2017 15:29 from: Martin Wynne

click the date to link to this post click member name to view archived images |

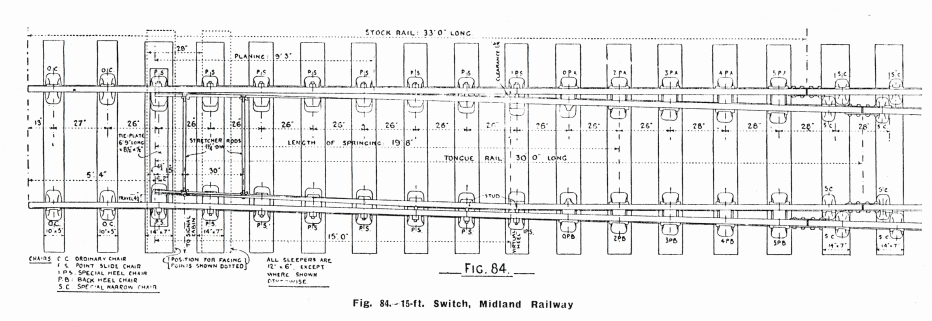

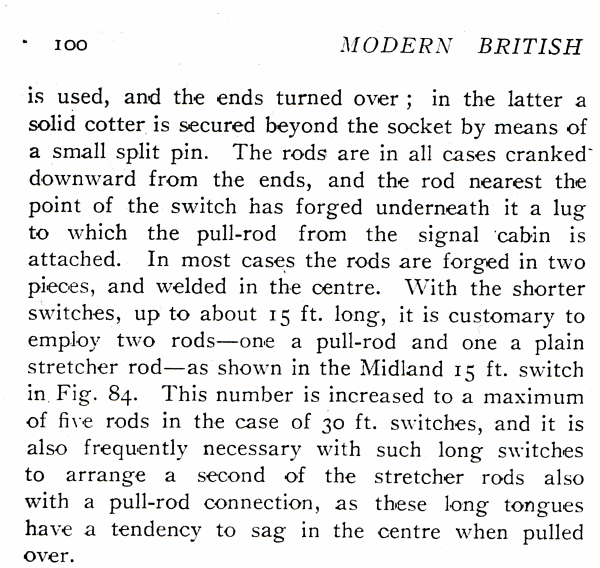

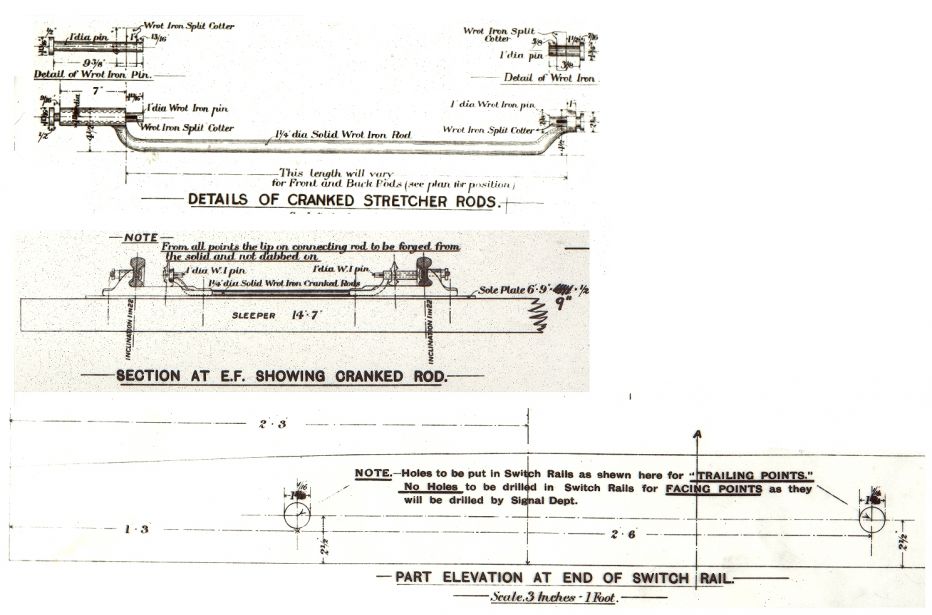

Hi Tim, Here is a drawing of a MR 15ft switch. It shows the rodding connection attached to the front stretcher rod as a dashed line: 2_191021_380000001.png  High-res version of this here: gallery/2/original/2_191021_380000001.png Here is the text from Allen (1915) which explains that there is "in all cases" a lug on the front stretcher rod to act as a pull rod: 2_191021_370000000.png  Lots more there about the design of the stretcher rod fixings and cotter pins if you want it? regards, Martin. |

||

|

posted: 19 Oct 2017 16:02 from: Tim Lee

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Hi Tim,Thank you Martin, That would appear pretty definitive ... particularly as it mentions the Midland by name in referring to the Midland 15ft switch. The thing which threw me was that there was no reference to lugs on the stretcher bar drawings and prototype photos from the period seem few and far between. One of the few I have turned up to date is this one. 2999_191058_280000000.jpg  As you see the actuation is not attached to the stretcher bar but rather is a separate bar turned through 180 degrees similar to the three way turn out actuation I posted earlier. Should I assume that this was only used for lever actuation? |

||

| Attachment: attach_2535_2839_point_actuation_detail1.jpg 250 | |||

|

posted: 19 Oct 2017 17:16 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Tim, Well clearly, when Allen said "in all cases" he didn't mean that one. Or this tandem, where the rodding on the left doesn't seem to line up with either stretcher rod. 2_191205_530000000.jpg  Sorry, I don't know where it is or which company. I can't see any reason why the arrangement would be different for hand levers from that for rodded operation. There might be a difference between passenger lines and goods lines and yards. In the former case there would also be the detector rods, attached to the actual blades. That would mean making switch blades with 3 fixing holes, so if detection is not needed, using the spare hole for a drive connection might be a simple alternative. regards, Martin. |

||

|

posted: 19 Oct 2017 17:22 from: Tim Lee

click the date to link to this post click member name to view archived images |

You wouldn't happen to have a picture or diagram of how detection worked ...another hole in my knowledge! I assume that Monsal Dale being mainline would have had detection in 1902? The other thing I have also wondered ... and again as a caveat i may be showing my lack of knowledge here .... because there is a goods siding and a lie by loop at Monsal Dale, would there have been any catch points? |

||

|

posted: 19 Oct 2017 17:35 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Tim. Assumption is always dangerous because sooner or later someone will prove you wrong! Tony. |

||

|

posted: posted: 19 Oct 2017 17:46 from: John Shelley

click the date to link to this post click member name to view archived images |

Tony W wrote: Hi Tim. Tony, Are you assuming that? John, from St Ciers, formerly Harrow. |

||

|

19 Oct 2017 17:46 from: Tim Lee

click the date to link to this post click member name to view archived images |

Tony W wrote: Hi Tim.I'm Learning that one fast I know I won't get a definitive answer, just hoping to establish what would have been the most likely condition for my particular model I wish someone could turn up a drawing or better still a photographic example of the lug connection on the front stretcher rod which is a Midland example .... I have examples for other companies. All I have at the moment is a dotted line on the switch drawing and a definitive text entry which is then directly contradicted by the examples posted - which definitely don't attach to the stretcher bar. |

||

|

posted: 19 Oct 2017 18:06 from: Martin Wynne

click the date to link to this post click member name to view archived images |

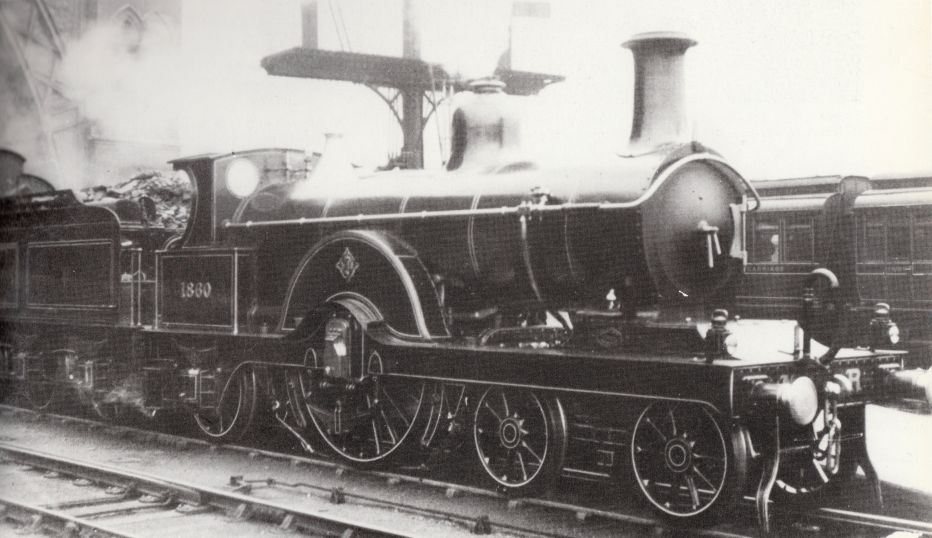

Tim Lee wrote: You wouldn't happen to have a picture or diagram of how detection worked ...another hole in my knowledge! I assume that Monsal Dale being mainline would have had detection in 1902?Hi Tim, Here is a scan from Raynar Wilson, 1904. This is the combined "economical" facing point lock and detector used on the MR. It is interesting that the detector rod is attached to only one switch blade, and there is no detection of the lock position. I see Mick Nicholson has posted a similar scan on RMweb while I was scanning this. 2_191301_420000000.png  regards, Martin. |

||

|

posted: 19 Oct 2017 18:26 from: Tim Lee

click the date to link to this post click member name to view archived images |

may be a stupid question ... but is detection only required on facing points? | ||

|

posted: 19 Oct 2017 19:06 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Tim Lee wrote: may be a stupid question ... but is detection only required on facing points?Hi Tim, No. Ground signals controlling movements over trailing crossovers are often connected through detectors. There are some great photos of ground signals and detectors from Mick Nicholson in this RMweb topic: http://www.rmweb.co.uk/community/index.php?/topic/84244-lner-signals-controlling-movement-from-sidings-to-running-lines/#entry1407888 regards, Martin. |

||

|

posted: 20 Oct 2017 13:23 from: Tony W

click the date to link to this post click member name to view archived images |

John Shelley wrote: Tony W wrote:Hi John.Hi Tim. A lifetime of bitter experience. It is not an infallible rule of course, but the odds do seem to go that way. Regards Tony. |

||

|

posted: 20 Oct 2017 14:05 from: Tim Lee

click the date to link to this post click member name to view archived images |

John Shelley wrote: Tony W wrote:Ahha! I see what you did thereHi Tim. |

||

|

posted: 20 Oct 2017 19:34 from: Ariels Girdle click the date to link to this post click member name to view archived images |

Here's a fantastically detailed picture of Basford (MR) in 1922 showing rodding runs, turnouts, point detector etc. Maybe of use?2831_201431_180000000.jpg You can probably get a better copy from the NRM - ref DY12483 |

||

| Last edited on 20 Oct 2017 19:36 by Ariels Girdle |

|||

|

posted: 21 Oct 2017 09:34 from: Tim Lee

click the date to link to this post click member name to view archived images |

That's a great picture come what may and going straight in my folder .... I found this one, which to me also suggests that the rodding doesn't link directly to the stretched bars, though one would need a higher res image to be certain? Tim2999_210431_140000000.jpg  What I think I am seeing is what I assume is a rod link to the ground signal from the front of the switch blade .... then the front stretcher bar, and then the actuation rod coming in to the switch blade adjacent to the front stretcher bar? |

||

|

posted: 21 Oct 2017 09:46 from: Tim Lee

click the date to link to this post click member name to view archived images |

2999_210448_430000000.jpg Here is another example which also appears to have the rodding unconnected with the stretcher bars2999_210446_190000000.jpg Here is another example which also appears to have the rodding unconnected with the stretcher bars2999_210446_190000000.jpg |

||

| Last edited on 21 Oct 2017 09:48 by Tim Lee |

|||

|

posted: 21 Oct 2017 10:17 from: Ariels Girdle click the date to link to this post click member name to view archived images |

I tend to agree. You seem to be opening up a real can of worms here. | ||

|

posted: 21 Oct 2017 11:26 from: John Palmer click the date to link to this post click member name to view archived images |

The purpose of detection is to prove that a point tongue has assumed the correct position for clearance of its related signal. For this reason a detector rod is connected to a point tongue (toe of switch), rather than to the stretcher bar. If the detector rod were attached to the stretcher bar and that stretcher had become disconnected from its associated switch rails, detection would prove nothing about the position of the switch tongues. In the Getty image, the detector rod is attached to the open switch tongue furthest from the detector This is consistent with the adjacent ground signal reading only over one route, probably that diverging to the left. Assuming the picture shows both signal and points in the 'normal' position, the detection arrangement proves that the tongue shown open in the picture has nestled in the closed position against its adjacent stock rail when the points are reversed, and that the associated signal can be cleared. It may be of interest that the IRSE booklet dealing with detection (1969 edition) suggests that in a comparable situation the normal arrangement would be to connect the detector blade to the normally closed switch tongue. If the signal for which detection is provided reads over both routes through the points detected, then blades for both switch tongues will be provided in the detector and connected to their respective tongues by independent rods. It seems to me that there is a flaw in the logic of detecting one tongue only. In such a case, if the undetected tongue has become disconnected from its stretcher you may end up with both tongues in the open position or both in the closed position (depending on which tongue has become disconnected). Detection then provides false 'proof' that the points have assumed the correct position, but a derailment on the switch has become almost inevitable. |

||

|

posted: 21 Oct 2017 11:33 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks John, Glad I was reading the arrangement correctly ... appreciate the explanation - I now have a better handle on why! |

||

|

posted: 21 Oct 2017 11:45 from: Martin Wynne

click the date to link to this post click member name to view archived images |

John Palmer wrote: It seems to me that there is a flaw in the logic of detecting one tongue only. In such a case, if the undetected tongue has become disconnected from its stretcher you may end up with both tongues in the open position or both in the closed position (depending on which tongue has become disconnected). Detection then provides false 'proof' that the points have assumed the correct position, but a derailment on the switch has become almost inevitable.Hi John, In the early days there was little thought about disconnected or broken stretcher rods. On the face of it, that should be a very unlikely occurrence given the amount of staff then available for track maintenance. Nowadays we know different after recent major incidents: http://assets.digital.cabinet-office.gov.uk/media/547c9037ed915d4c0d000199/R202008_081023_Grayrigg_v5.pdf The important thing then was to detect that the relevant switch blade was properly closed against the stock rail, before the signal can clear. That's something beyond mechanical failure, and much more likely to go wrong, such as weather conditions or fallen debris affecting the rodding run or clogging the switch blade. regards, Martin. |

||

|

posted: 21 Oct 2017 12:07 from: Tim Lee

click the date to link to this post click member name to view archived images |

Here is another image which again shows the 180 degree actuation rod bend locating into the switch independent of the front stretcher bar. Masborough, 1907 It does seem to suggest that pre WWI at least the Midland connected rodding independently of the front stretcher bar certainly within sidings and goods yards. I am still hoping to turn up a mainline trailing turnout to see if the practice differed - we know it was different for facing due to the requirement for locking. 2999_210706_480000000.jpg  2999_210812_040000000.jpg 2999_210812_040000000.jpg |

||

| Last edited on 21 Oct 2017 13:12 by Tim Lee |

|||

|

posted: 21 Oct 2017 14:20 from: John Palmer click the date to link to this post click member name to view archived images |

Martin Wynne wrote: In the early days there was little thought about disconnected or broken stretcher rods. On the face of it, that should be a very unlikely occurrence given the amount of staff then available for track maintenance. Nowadays we know different after recent major incidents:Indeed, Martin, and it was not merely the number of available staff that mitigated the risk, but the frequency of inspection. I understand that a daily inspection of running lines had become accepted practice by the mid 1860's, but that state of affairs has to be contrasted with the regime in place by the time of Grayrigg, as the report you linked indicates that “For Category 1 track, inspections were required weekly with a maximum interval between inspections of eight days.” This represented a major change that could be justified by the greater reliability of modern track, but which nonetheless enlarged the risk of defects that might have become apparent from a daily inspection remaining undetected for extended periods – as at Grayrigg. I may have misinterpreted the IRSE's suggestion as to which tongue should be detected in a single detection arrangement. Looking at 'Railway Signalling and Communications', it seems that the tongue to be detected in such a case is the one that needs to be closed in order for the related signal to be cleared. Generally this will be the tongue that is open when the switch lies normal. I don't think this affects my conclusion that the logic is flawed, inasmuch as any failure of both tongues to move creates the conditions for a derailment, regardless of whether such failure results from disconnection of tongue from stretcher, weather-related reasons or debris fouling the connections. |

||

|

posted: 22 Oct 2017 08:06 from: Tim Lee

click the date to link to this post click member name to view archived images |

Next Question ...... If we assume that for sidings etc at least, pre WWI turnouts were activated by an independent fixing of the point rodding to the nearest switch blade, can we assume that the rod itself would prevent the point blade rising or moving in relation to the stock rail (apart from laterally). If this is the case, and looking at the drawing which Martin posted earlier - 2999_220303_540000000.jpg  would it be right to assume that the extension shown on the right hand side of the drawing projecting through the stock rail, achieves the same thing on the side opposite to the actuation rod? Edit - correction, looking again at the drawing it would appear that there is no extension through the stock rail - I assume therefore that the switchblade relies on the undercut of the planing to ensure against lift? Am I right in assuming that the extension is primarily used where the stock rail is joggled? |

||

| Last edited on 24 Oct 2017 08:44 by Tim Lee |

|||

|

posted: 23 Oct 2017 14:16 from: Tim Lee

click the date to link to this post click member name to view archived images |

A couple of further images which might suggest this practice on rodding was not limited to sidings etc. 2999_230913_440000000.jpg  2999_230916_080000000.jpg 2999_230916_080000000.jpg |

||

|

posted: 23 Oct 2017 14:45 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Tim, Interesting that in the first pic there are 2 timbers in the switch front. In the second pic only 1 timber. Something else to get right, when adding the fishplates. Nowadays the switch front timbers are indeed timbers (12" wide). In pre-group days they were often plain sleepers (10" wide). Templot does include an option for this in the custom switch settings. So that's two more things to get exactly right in the face of conflicting evidence. Anyone got a pic showing a switch front of 2 timbers, one a timber and the other a sleeper? regards, Martin. |

||

|

posted: 23 Oct 2017 19:14 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thought it might be useful to load this MR drawing of switch blades and stretcher bars for information. | ||

| Attachment: attach_2541_2839_DSC_0012.JPG 265 | |||

|

posted: 30 Oct 2017 09:07 from: Tim Lee

click the date to link to this post click member name to view archived images |

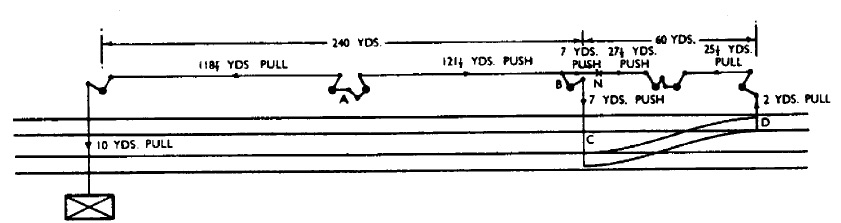

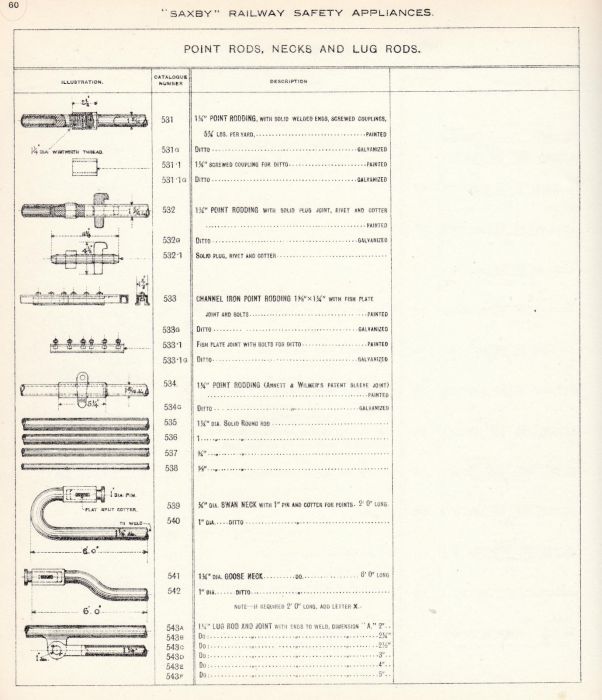

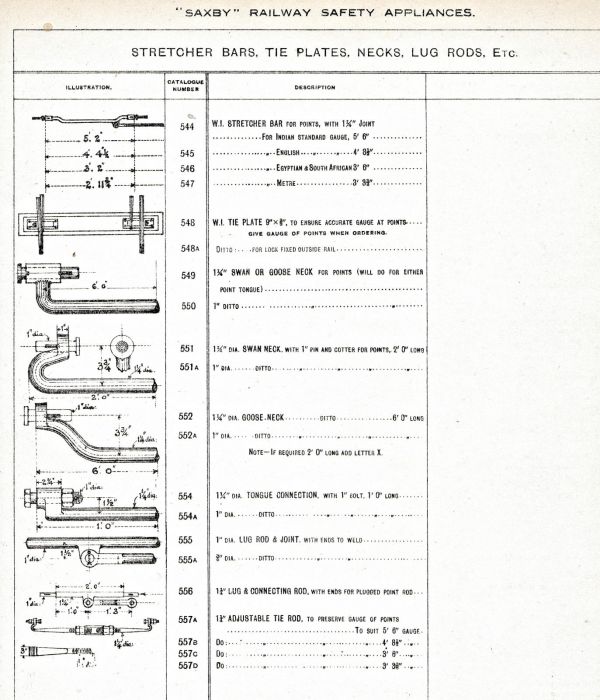

Does anybody have any drawings or images which might describe the connection for circular bar rodding to an intemediary crank within the rod length when two sets of points have to work together ... ie for a crossover on running lines. I am trying to work out how the connection from the bar would have been worked (easy to find examples of channel rodding but not circular). It is the equivalent of this connection but to a bar I am looking for 2999_300608_340000000.jpg  Used to move the crank 'B' on the attached diagram 2999_300609_330000000.jpg  Thanks Tim |

||

| Last edited on 30 Oct 2017 11:09 by Tim Lee |

|||

|

posted: 30 Oct 2017 14:08 from: Tim Lee

click the date to link to this post click member name to view archived images |

I have been kindly sent these ... so all good Tim 2999_300907_540000000.jpg  2999_300908_120000000.jpg 2999_300908_120000000.jpg |

||

| Last edited on 30 Oct 2017 14:59 by Tim Lee |

|||

|

posted: 2 Nov 2017 00:44 from: Tony W

click the date to link to this post click member name to view archived images |

Tim Lee wrote: Next Question ......Hi Tim. I think these stretcher rods are specials for Three throw blades only. See my pictures in message 13 where it is quite clear that the parallel extension is used to allow the stretcher rod to connect to the short inner blade (via the key hole slot) whilst passing through the hole in the longer outer blade without restricting its free movement. Regards Tony. |

||

|

posted: 2 Nov 2017 08:30 from: Tim Lee

click the date to link to this post click member name to view archived images |

Tony W wrote:Hi Tim.Of course .... now you say it that makes total sense. Thanks Tim |

||

|

posted: 28 Nov 2017 07:31 from: Tim Lee

click the date to link to this post click member name to view archived images |

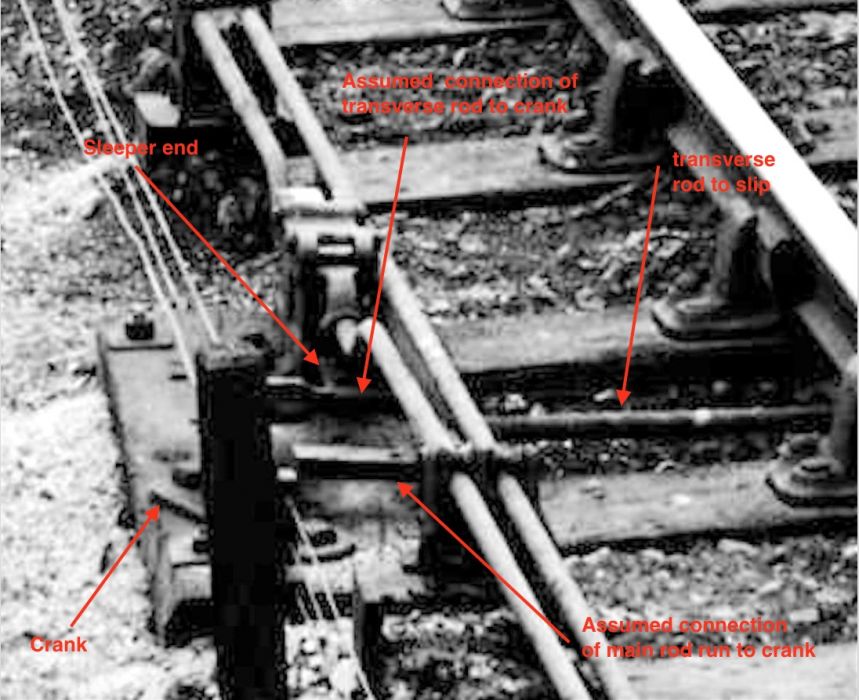

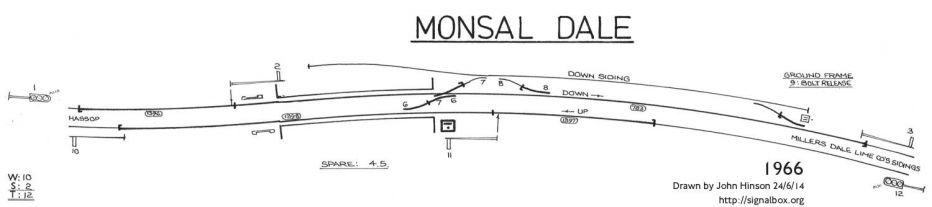

I hope some one can help. I have this detail from the trackwork at Monsal Dale station circa 1911. I am trying to work out what the mechanism is that I am looking at within the line of the outer rodding run just beyond the single slip rod and crank position?2999_280223_500000000.jpg Here is a somewhat grainy zoomed in detai2999_281226_490000000.jpg  Might it be some form of compensator, or is it something to do with the single slip actuation? does anyone have a clearer picture of this type of mechanism? Might it be some form of compensator, or is it something to do with the single slip actuation? does anyone have a clearer picture of this type of mechanism?When I look at the slip rodding what I think I see is the rod locating in the crank before you get to this mechanism and a rectangular bar of sorts connecting from the main rodding run to the crank in front of this - so on the face of it it seems that it is not part of the actuation? Tim edit ... attached is the signal diagram and the picture from which the detail is taken.2999_280729_430000000.jpg  2999_280730_090000000.jpg 2999_280730_090000000.jpg |

||

| Last edited on 28 Nov 2017 17:28 by Tim Lee |

|||

|

posted: 28 Nov 2017 17:42 from: Martin Wynne

click the date to link to this post click member name to view archived images |

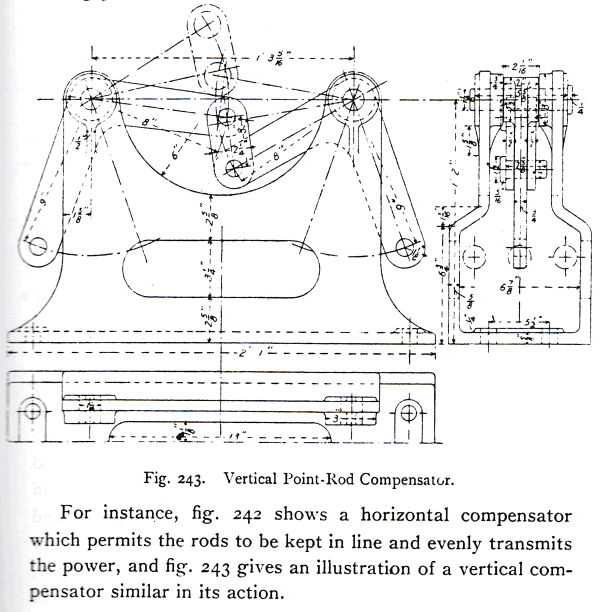

Hi Tim, If it's not a compensator, it is very difficult to imagine what else it might be. There were lots of patent designs for compensators and suchlike, here's a typical vertical compensator: 2_281237_240000000.png  If it is a compensator, it will be roughly half-way between the signal box and the points (assuming no compensation is being done by cross-rods and cranks). The total rodding length in pull should match the total length in push. regards, Martin. |

||

|

posted: 28 Nov 2017 20:32 from: Tim Lee

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Hi Tim,Thanks Martin, I wonder if it is one of these vertical compensators ... just distorted by the foreshortening of the photo? The rods certainly appear to be swan necked down to fix as if the crank on the compensator is perpendicular ... looking at the drawing this would mean that the counter arm would not rise much above the horizontal which would also tie with the photo. I shall go with this hypothesis unless something else presents itself. Tim |

||

|

posted: 28 Nov 2017 22:54 from: Tony W

click the date to link to this post click member name to view archived images |

Tim Lee wrote: I hope some one can help. I have this detail from the trackwork at Monsal Dale station circa 1911. I am trying to work out what the mechanism is that I am looking at within the line of the outer rodding run just beyond the single slip rod and crank position?2999_280223_500000000.jpgHi Tim. I think Martin is correct that what you are looking at in the rod to the left is a compensator, however I think it is for crossover 7 rather than 6. A crossover typically needs a compensator at the mid point in the rodding to reverse the travel of the two ends as well as between the box and the first set of blades if far enough away. The picture appears to be taken from the box. I think the compensator for 6 (in the other rod) would be somewhere near the second cover and thus hidden by the platform. I think it is possible to discern the fixing attachment under the rod to the right of the compensator in the blow up. Tony. |

||

|

posted: 29 Nov 2017 09:07 from: Tim Lee

click the date to link to this post click member name to view archived images |

Thanks Tony, That makes sense. The compensator is interesting ... most of the pictures I have turned up for compensators on the Midland at this period are of the simple variety2999_290404_190000000.jpg  As Martin has suggested this appears to be the later but still vertical pattern. However it does appear to have a cover of sorts to the top and to vary in other ways from the diagram. I wonder if it was a Midland Prototype development and I wonder when it was introduced ... the photo is 1911 and my period is 1903, so it may be that I should model with the simpler form anyway. I have a question out with the Midland Railway study centre to see what they might have within the archive. As Martin has suggested this appears to be the later but still vertical pattern. However it does appear to have a cover of sorts to the top and to vary in other ways from the diagram. I wonder if it was a Midland Prototype development and I wonder when it was introduced ... the photo is 1911 and my period is 1903, so it may be that I should model with the simpler form anyway. I have a question out with the Midland Railway study centre to see what they might have within the archive.Regards Tim |

||

|

posted: 29 Nov 2017 22:46 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Tim. The answer may be as simple as that basic type being incompatible with a cross crank at the same place. Special situations demand novel solutions. Regards Tony. |

||

|

posted: 1 Dec 2017 16:44 from: Tim Lee

click the date to link to this post click member name to view archived images |

2999_011146_360000000.jpg Thought I would just upload some further research images of point rodding and rodding stools I have found as further reference info. 2999_011143_110000000.jpg  2999_011143_280000000.jpg  2999_011143_470000000.jpg  |

||

|

posted: 5 Mar 2019 17:45 from: Keith Norgrove click the date to link to this post click member name to view archived images |

It doesn't seem to have been mentioned that the stretcher bar drawing in this post is specifically for a three throw turnout, and can be seen in the detail photos in following posts. Regards Keith PS. Reading page 2 I find that Tony has already made this point. |

||

| Last edited on 5 Mar 2019 17:51 by Keith Norgrove |

|||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |