James Walters

Member

- Location

- Bexhill West

Hello all,

I'm hoping some experts might be able to offer me some advice regarding a scissors crossing on an S curve. Let me explain...

In our S4 area group, we have been discussing the idea of each building a simple plank, with the idea that each plank will be able to connect to a central hub. All of which is to be very simple and give us something to play with at our meetings. The boards themselves will all be laser cut and interchangeable, so in effect we can mix-and-match where boards go. I anticipate the 'planks' being almost-disposable, and being knocked-up to demo track building, various scenic techniques etc.

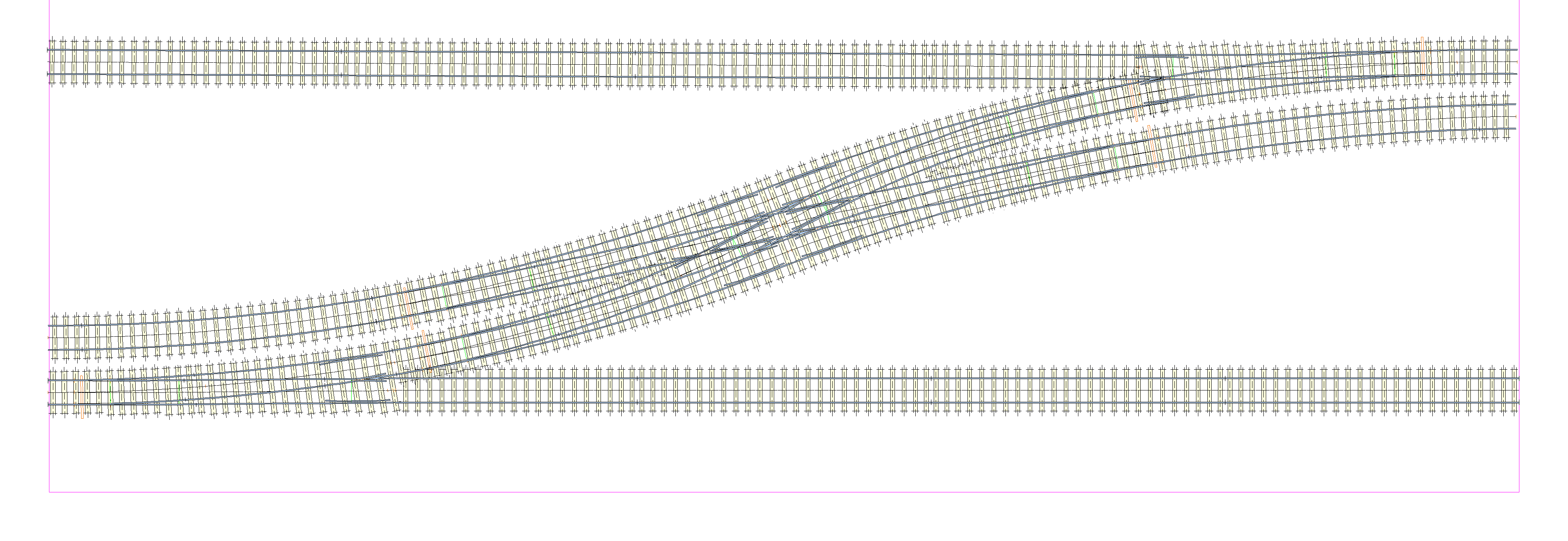

Here is the basic concept for the Hub board.

So, on to my question(s):

1. Is the scissors in this example likely to work and/or is it buildable? There has been conflicting advice as to whether or not it is buildable and so ask here for some expert advice. Suggestions to alternative approaches would be very welcome too.

I hope it's not too big an ask.

As a novice, I'm still finding my way with the techniques required to complete the scissors itself, and close inspection will show that the V crossings and K crossings need work. I'll attempt to solve these once the basic concept has been established.

Attached are the .box and .bgs file

I hope it all makes sense. For information the Hub Board is proposed to be 1200mm x 450mm.

James

I'm hoping some experts might be able to offer me some advice regarding a scissors crossing on an S curve. Let me explain...

In our S4 area group, we have been discussing the idea of each building a simple plank, with the idea that each plank will be able to connect to a central hub. All of which is to be very simple and give us something to play with at our meetings. The boards themselves will all be laser cut and interchangeable, so in effect we can mix-and-match where boards go. I anticipate the 'planks' being almost-disposable, and being knocked-up to demo track building, various scenic techniques etc.

Here is the basic concept for the Hub board.

So, on to my question(s):

1. Is the scissors in this example likely to work and/or is it buildable? There has been conflicting advice as to whether or not it is buildable and so ask here for some expert advice. Suggestions to alternative approaches would be very welcome too.

I hope it's not too big an ask.

As a novice, I'm still finding my way with the techniques required to complete the scissors itself, and close inspection will show that the V crossings and K crossings need work. I'll attempt to solve these once the basic concept has been established.

Attached are the .box and .bgs file

I hope it all makes sense. For information the Hub Board is proposed to be 1200mm x 450mm.

James

Attachments

message ref: 6407

Search

Search