- Location

- Reigate

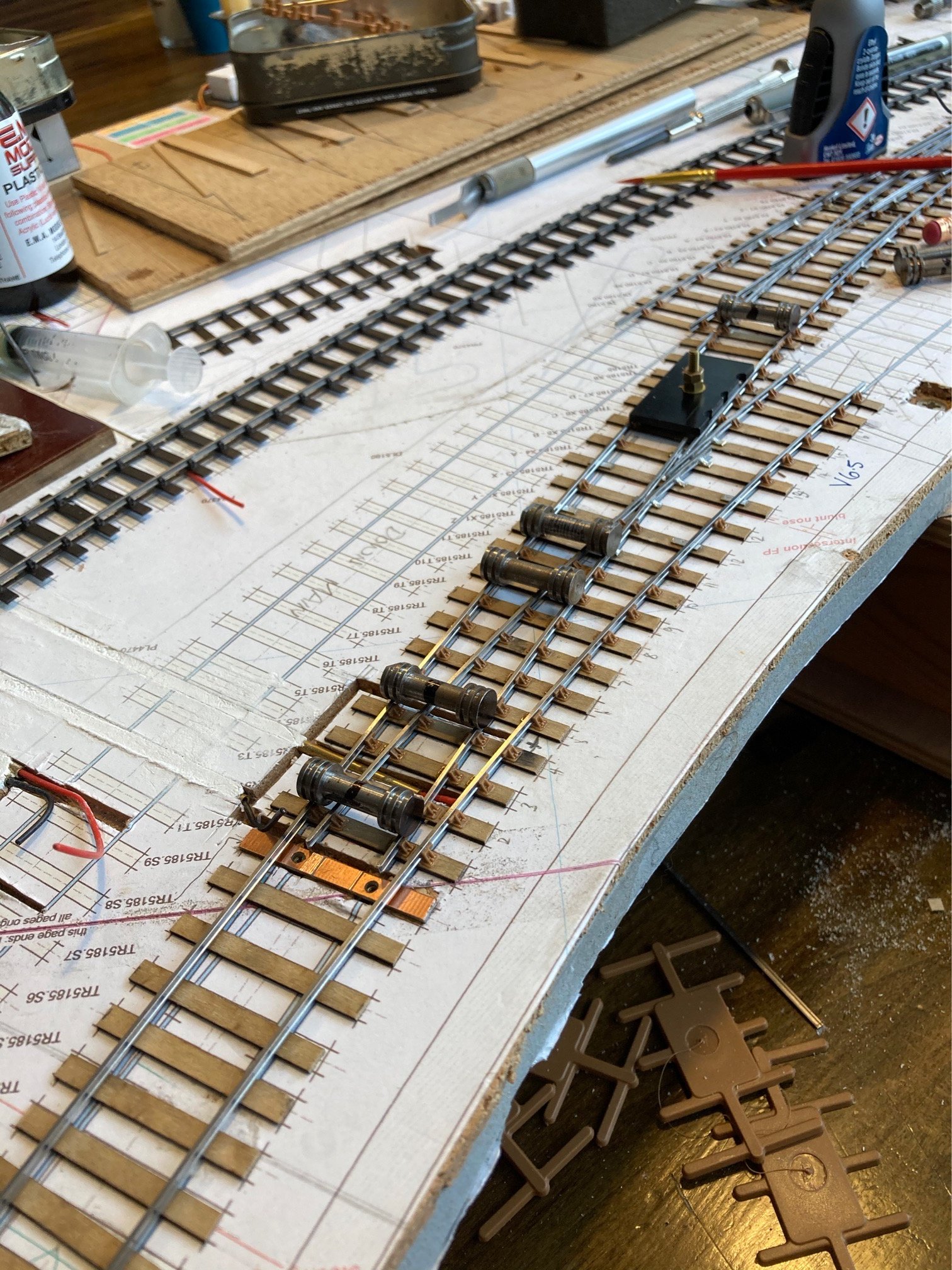

Here is a bit more progress. The south end of this board, and the marshaling yard connection across the down main line to up main gradually taking shape with the stock rails going in

And then with the stock rails installed and the newly filed switches lying between the rail awaiting their turn. The near end rails arent soldered to the paxolin sleeper yet, as I need to match them to rails on the next board, so that'll come a little later.

Hope to do another update over the weekend...

Andrew

And then with the stock rails installed and the newly filed switches lying between the rail awaiting their turn. The near end rails arent soldered to the paxolin sleeper yet, as I need to match them to rails on the next board, so that'll come a little later.

Hope to do another update over the weekend...

Andrew

message ref: 423

Search

Search