Share and show, right?

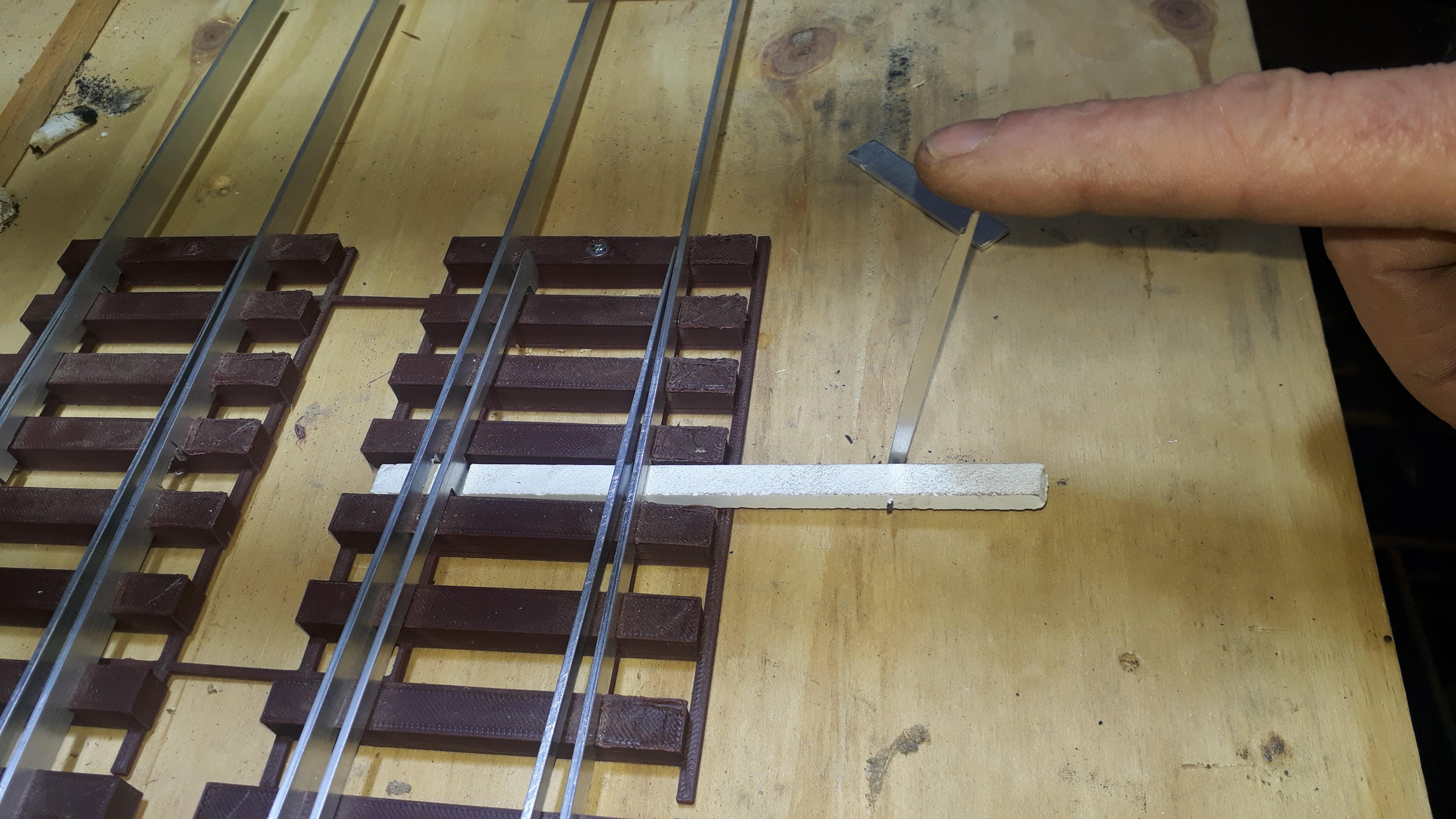

Really no problems at all, nothing, everything went very smoot.

To call it a success? yes and no.

Frogs and safety rails could be wider to receive the wheel/flange (not deeper) better thus the distance between the flange baring surface and the safety/guardrail can be 0.5 mm smaller/shorter, 41mm to 40mm perhaps even 39mm.

Does this make any sense?

I will make a drawing of what i mean tomorrow.

If you see anything that can be improved please share your thoughts.

Thanks for reading, with best regards Igor

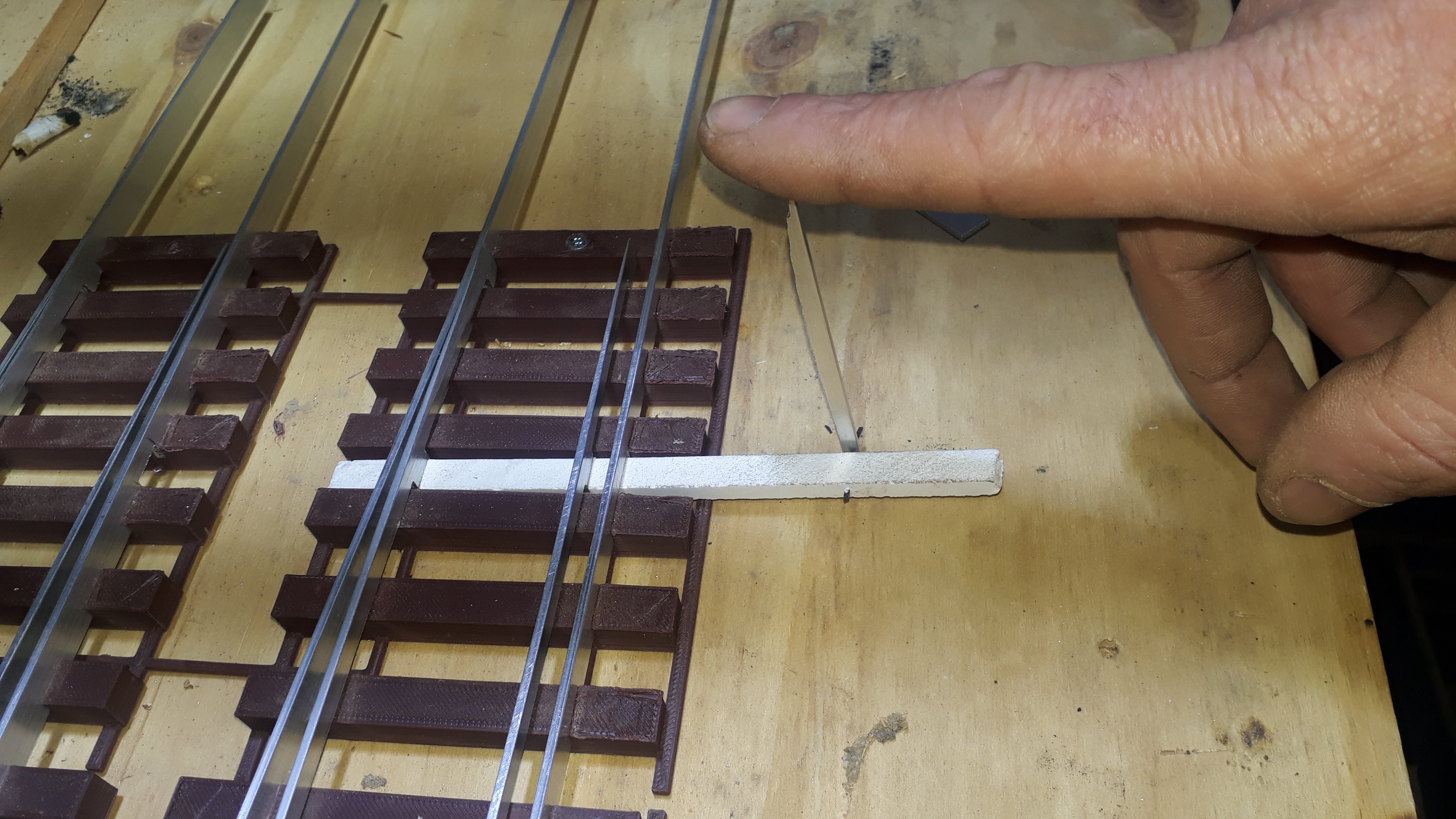

Really no problems at all, nothing, everything went very smoot.

To call it a success? yes and no.

Frogs and safety rails could be wider to receive the wheel/flange (not deeper) better thus the distance between the flange baring surface and the safety/guardrail can be 0.5 mm smaller/shorter, 41mm to 40mm perhaps even 39mm.

Does this make any sense?

I will make a drawing of what i mean tomorrow.

If you see anything that can be improved please share your thoughts.

Thanks for reading, with best regards Igor

message ref: 548

Search

Search