- Location

- West of the Severn UK

- Info

That’ll do! I still understand Roman numbers,

I wasn't very serious

How about a barcode?

Martin.

message ref: 4061

TEMPLOT 3D PLUG TRACK - To get up to speed with this experimental project click here. To watch an introductory video click here. See the User Guide at Bexhill West.

That’ll do! I still understand Roman numbers,

I wasn't very serious-- I think I can do numbers as on a 7-segment display, without too much work.

How about a barcode?

Martin.

How about a tally system? Straight lines again. (I do actually still use that occasionally!)

Hi Martin@Paul Boyd

Hi Paul,

How about a brick number which looks like this -- 170-136-102 ?

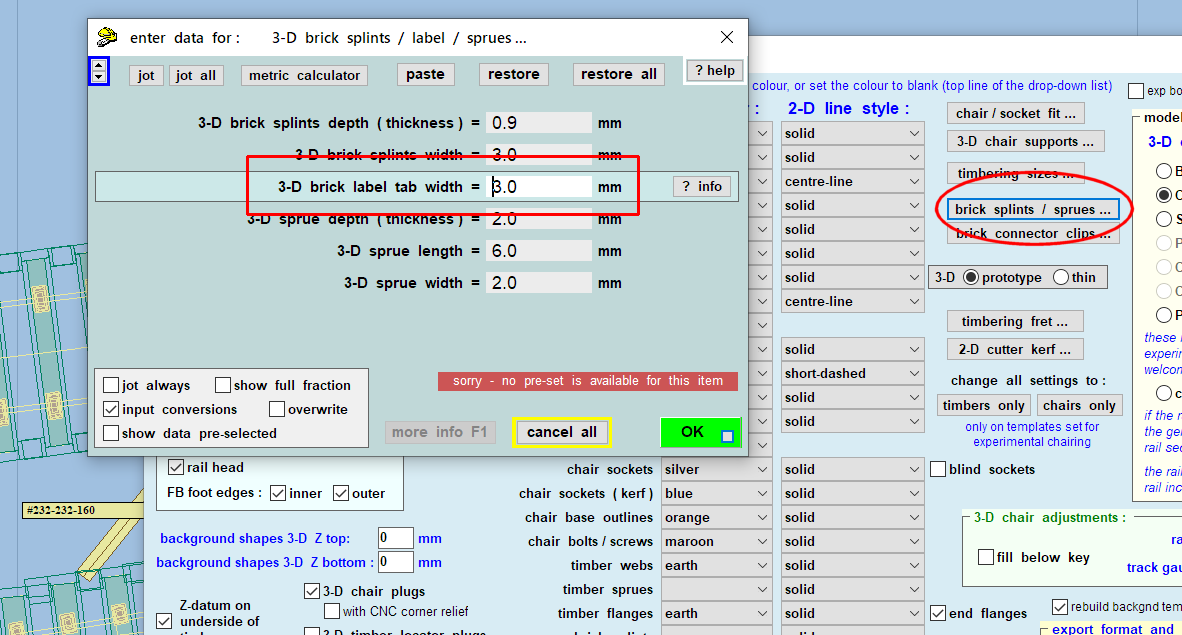

i.e. the RGB code for the brick colour. It could be added automatically along every splint. It would be unique to each brick and not need any user input. For reference it could appear on the menu:

View attachment 3488

Clicking it shows the colour dialog to change it, if needed (for the selected template).

cheers,

Martin.

Hi Martin@Paul Boyd

Thanks Paul.

I was trying to find something which requires no input from the user. But it's tricky, because not all bricks may have splints (or clips).

I'm thinking now that if there are any label shapes in the brick (usually only one), the export will write the colour ref on it to create a number tab. Or any other ref the user has specified as the label text (if it's doable in 7-seg, e.g. FHP34 is doable, KRW18 isn't). Sized to match the splints. The user would place this label tab attached to the brick somewhere convenient. It would be lost in the ballast as the splints.

If there are no label shapes, the DXF export will add one, placed centrally within the brick. It might be lucky and miss all the clips and sockets, but not be very readable if there are timbers running over it! A warning will appear, so that the user can delete it, or cancel the export, go back to the trackpad and move it to a sensible place.

This illustrates a frequent problem in Templot, where something which looks simple isn't. Templot can easily create a number tab. But where to put it, so that it is attached to the brick but not conflicting with anything, requires a human eye or some serious programming.

cheers,

Martin.

@Paul BoydUltimately though, it is all manageable without having the bricks identified on the print - it comes under "nice to have"!

.

In case I forget to mention it ever again, when the control template is a "brick template", the gauge indicator on the info panel shows orange instead of the normal yellow:

View attachment 3500

This is just an easily visible reminder while extracting bricks from the track plan, there is no significance related to the track gauge.

The control template becomes a "brick template" when stored while in bricklaying mode, or if a stored brick template is copied back into the control. Or you can set it as a "brick template" manually as above (program menu), so that storing it will create a stored brick template regardless of whether in bricklaying mode or not.

The control template is never itself included in DXF/STL exports, it must be stored as a background template to be exported.

In a further design change, exporting a timbering brick will now include only templates marked as a brick template as above, instead of being based solely on the marker colour. This avoids conflict with the use of marker colours for other templates in the track plan which happen to be in the storage box at the time of export.

This means that timbering bricks created prior to version 234a will not be exported from 234a until the templates have been marked as brick templates as above.

234a released soon.

cheers,

Martin.

@Paul BoydHi Martin,

Sounds good! Will brick templates be obvious in the storage box, in much the same way that library templates are?

Cheers,

Paul

@Paul Boyd

Hi Paul,

Now done:

View attachment 3532

Brick templates are marked with a B in the list. I had to move it over a bit to leave space for the reminder blobs.

View attachment 3531

When showing the drawing, there is a B in the margin for brick templates.

cheers,

Martin.

I haven't implemented any option to skew the label from horizontal on the trackpad grid. I have to draw the line (!) somewhere, or it never will be finished. Maybe one day.

.

In order to skew the label tabs at any angle I have had a rethink.

The label text is now drawn on a modified splint, and the background label shapes play no part in the 3-D exports.

I have made a very scruffy bit of video to explain the process:

https://flashbackconnect.com/Default.aspx?id=C-Jmd_OgSUjS5isyOWlhMQ2

To set the width of the splints and labels:

You can also now set the thickness of the text on the label.

I will explain it all properly one day.

cheers,

Martin.

@Paul BoydShowing/hiding brick templates would make it much easier to spot if an underlying template had been changed though.

@Paul BoydIt does still work in 234a! The only thing I found was that even if both the show on trackpad and show on output boxes were unticked, the shape would still export to the STL file. I'm guessing that's not intentional?

@Paul BoydI wouldn't worry too much about a keyboard shortcut for show/hide brick templates, but maybe (yet another!) button at the top of the screen? Even then, I think the menu options are fine as they are.

Those show boxes on the background shapes dialog were mainly intended for background maps and picture shapes. I haven't yet given them any thought for the DXF/STL exports. But now that you have mentioned them, it's an obvious way to have a shape-specific option for the export -- currently it is all shapes or none. I will include the show on output option for the export in 234b. Thanks for the nudge.

cheers,

Martin.

.

@Paul Boyd

BUG WARNING

There is a bug in 234a -- the brick clips claws / tommy bar setting is not saved correctly in BGS3 files.

Sorry about that, I will get it fixed soon.

Martin.

@Paul Boyd

Hi Paul,

I have now implemented the rectangle shapes as another brick component -- slabs. They can be twisted to any angle and sized to whatever you want. By default the same thickness as the splints, but can be any thickness. They can be added anywhere you like (but if placed under the chair sockets the sockets will be reduced in depth and blinded). Unlike using splints, each slab can be a different size.

Various uses spring to mind, such as on bridge decks, or as platform spacers. Or a screw hole could be drilled in them as a fixing tab.

View attachment 3642

View attachment 3643

n.b. when used as support skates, any twisting is ignored.

Will be in 234b shortly.

cheers,

Martin.

@Paul BoydI think I found a couple of "quirks"

@Paul Boyd

Hi Paul,

Yes, since releasing 234b earlier I have already started on 234c to fix a couple of quirks.

There are several changes in 234b for the timbering bricks. After all these years I have finally kludged my way around the restrictions of the original BGS format, to allow additional functions to be added to the background shapes. It was obvious the slabs needed a twist function, but there was just no way the twist angle setting could be forced into the old format. It was a lot of work to fix, with dozens of changes scattered all through Templot, and I'm sure I have missed a few. But now that we have a new internal format, the background shapes can be expanded in future in several ways if needed. I should have done it years ago.

View attachment 3649

A shape can now be marked as a brick shape, so there is no need to swap the trackpad to view them.

If 1 is ticked, adding a shape will mark it as a brick shape. If 2 is ticked, it will be given that marker colour to match the current brick templates, otherwise it will be set initially to light grey.

Option box 3 is now honoured in the DXF/STL exports, so individual shapes can be switched on and off if needed.

The menus at 4 contain the additional functions and settings for brick shapes.

View attachment 3648

5 can be used to mark or unmark the selected shape as a brick shape.

• If you have any BGS3 files with brick shapes from earlier versions, you will need to go through them and tick this box 5 for each one. Sorry about that, experimental stuff can be a nuisance at times.

There are new menu functions:

View attachment 3650

View attachment 3652

and bug fix from 234a:

View attachment 3651

and a shortcut for the brick track templates:

View attachment 3653

The slab thickness is set on this button, at least for now:

View attachment 3654

The slab rectangles can be twisted, moved, sized and corners dragged manually by mouse action.

N.B. to set a specific slab size, this must be done before any twisting by entering the original square-on dimensions:

View attachment 3655

View attachment 3656

After twisting, the corner co-ordinates are not available to see or edit.

I will try to get a video done showing these functions being used.

There are a few other changes -- I have improved the legibility of the 7-seg characters, and adjusted the default size of the timber webs for better slicing in Cura.

I'm hoping that the timbering can now be left for a while so that I can get back to the switch and crossing chairs.

But I shall have to come back to it, because at present none of the above is yet reflected in the printed paper templates or PDF or other outputs.

cheers,

Martin.

@Paul BoydAh - I know what another quirk was! If I add clip at notch, it shows as a target mark. I then have to modify shape then untick and re-tick brick shape for 3D export. Was that one of the quirks you picked up?

The icing on the cake, with jam on top, would be to have all the 3D export settings saved,

p.s. I noticed on your screenshot "Estimated cost £61.84". What's that about? I doubt it will use 3 full rolls of filament?

Search

Search