Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@LittleWestern

Hi James,

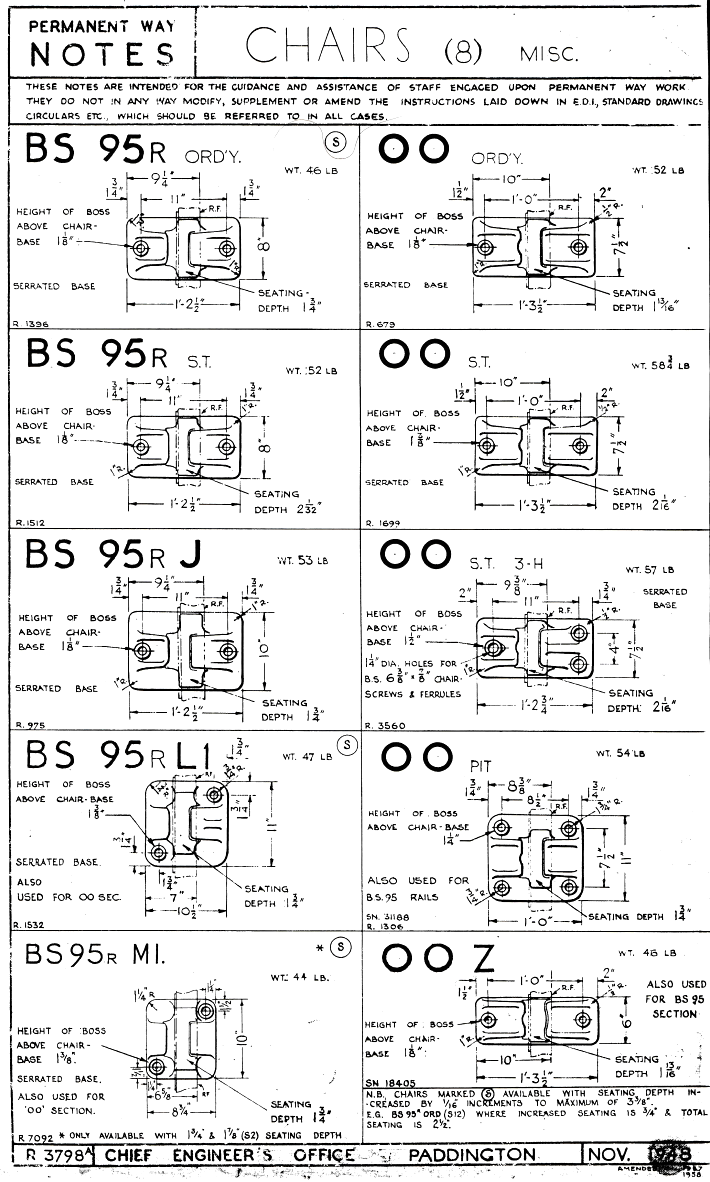

I have scanned the Paddington 1948 drawing:

As you can see, the GWR J joint chair is available only for BS-95R rail. There is no corresponding chair for the GWR OO (1900) rail section. I have never seen a drawing of such, or any reference to one.

It is very likely that GWR-owned sidings in industrial areas would still be using the old OO rail in 30ft lengths, or earlier rail sections. If they are private sidings, the only way to know about the track would be from photographs. They might be flat-bottom rails, or bullhead rails using REA chairs or earlier pre-grouping chairs, or GWR OO chairs.

Whatever, there is no need for joint chairs or wider joint sleepers in sidings, because the low speed and occasional traffic does not require strengthened rail joints.

The GWR changed from the OO rail to BS-95R rail after WW2, but it was a piecemeal changeover as local stocks of OO were used up.

Where BS-95R rail was used in GWR main running lines, the BS-95R J joint chairs may have been used. Or not. I rather doubt the GWR would have used them on branch and secondary lines.

For detailed chapter and verse on all this you need to contact the Great Western Study Group -- my knowledge of GWR is limited.

Some more topics about joint chairs here:

https://85a.uk/templot/archive/topics/topic_3508.php

https://85a.uk/templot/archive/topics/topic_3690.php

https://85a.uk/templot/club/index.php?threads/gwr-j-chairs.34/

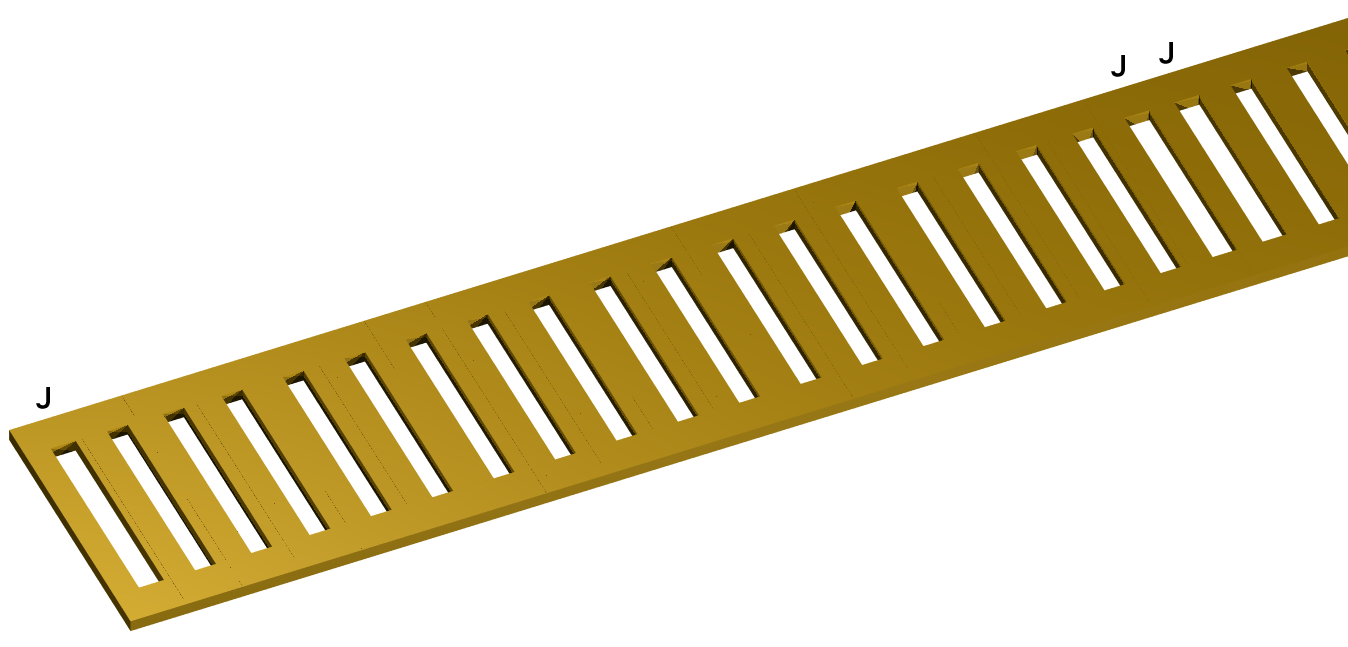

You do not need TinkerCAD to create a jig for plain track, because Templot can export a timbering fret directly, in 2-D or 3-D files, DXF or STL:

The above is for 45ft rails with 19 sleepers, and 12" wide joint sleepers at J, and closed up sleeper spaces towards the joints.

Ask again at (4 pages):

https://85a.uk/templot/club/index.php?threads/building-3d-track.520/

for more info about creating timbering frets by FDM printing or laser cutting. (It's not easy for CNC milling because of the need for square internal corners.)

If FDM printing, you could add some vertical lugs to act as rail guides for track assembly.

cheers,

Martin.

Hi James,

I have scanned the Paddington 1948 drawing:

As you can see, the GWR J joint chair is available only for BS-95R rail. There is no corresponding chair for the GWR OO (1900) rail section. I have never seen a drawing of such, or any reference to one.

It is very likely that GWR-owned sidings in industrial areas would still be using the old OO rail in 30ft lengths, or earlier rail sections. If they are private sidings, the only way to know about the track would be from photographs. They might be flat-bottom rails, or bullhead rails using REA chairs or earlier pre-grouping chairs, or GWR OO chairs.

Whatever, there is no need for joint chairs or wider joint sleepers in sidings, because the low speed and occasional traffic does not require strengthened rail joints.

The GWR changed from the OO rail to BS-95R rail after WW2, but it was a piecemeal changeover as local stocks of OO were used up.

Where BS-95R rail was used in GWR main running lines, the BS-95R J joint chairs may have been used. Or not. I rather doubt the GWR would have used them on branch and secondary lines.

For detailed chapter and verse on all this you need to contact the Great Western Study Group -- my knowledge of GWR is limited.

Some more topics about joint chairs here:

https://85a.uk/templot/archive/topics/topic_3508.php

https://85a.uk/templot/archive/topics/topic_3690.php

https://85a.uk/templot/club/index.php?threads/gwr-j-chairs.34/

You do not need TinkerCAD to create a jig for plain track, because Templot can export a timbering fret directly, in 2-D or 3-D files, DXF or STL:

The above is for 45ft rails with 19 sleepers, and 12" wide joint sleepers at J, and closed up sleeper spaces towards the joints.

Ask again at (4 pages):

https://85a.uk/templot/club/index.php?threads/building-3d-track.520/

for more info about creating timbering frets by FDM printing or laser cutting. (It's not easy for CNC milling because of the need for square internal corners.)

If FDM printing, you could add some vertical lugs to act as rail guides for track assembly.

cheers,

Martin.

message ref: 4914

Search

Search