Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 9 Feb 2010 22:40 from: David click the date to link to this post click member name to view archived images |

Hiya Guys Been reading through forum for similar problem and could only find Possible Printer Calibration issues. I am fairly condident that my Printer is Calibrated ok, yet I am having fairly big discrepancies over 3 A4 sheets joined together in Landscape origination. During printer configuration the outer box of the printout measures 180mm x 240mm, yet when the proof sheet is printed out the horizontal bar measures 150mm, but the vertical bar only measures 249.5mm, instead of the 250mm expected. The Roller Factor is 100% and the Head Factor is 100%. On printout of a few sheets of A4 paper to join together, the grid spacings seem really good at 50mm(they had been 52mm), yet on a staggered A4 paper layout, when jointing together, the placing of an A4 sheet centred on the joint of 2 A4 sheets below, show the sheet out of alignment by 1mm at either end of the sheet. The only reason I would question this, is because using a previous inkjet printer, an Epson 820 Photo Printer, I was able to align these bang on and this has always amazed me. My current new printer is a Epson Stylus Photo PX710W. I have to add, this is after a fresh install of the software running 0.91c. Would appreciate any thoughts people may have on this, and whether I have Templot set correctly. Did check correct paper size, from a previous post, and this was A4. Hope someone can help. Kind Regards Dave |

||

|

posted: 10 Feb 2010 10:16 from: Martin Wynne

click the date to link to this post click member name to view archived images |

David wrote: On printout of a few sheets of A4 paper to join together, the grid spacings seem really good at 50mm(they had been 52mm), yet on a staggered A4 paper layout, when jointing together, the placing of an A4 sheet centred on the joint of 2 A4 sheets below, show the sheet out of alignment by 1mm at either end of the sheet.Hi Dave, The printer calibration function can only set the printed output to a specific size. It can't do anything about misalignments if two pages printed at the same time don't properly match each other, or if the printed grid squares aren't all exactly the same size. That is due to failings in the printer feed mechanism or paper slipping problems. You may possibly be able to correct for problems using the data distortion functions (main > program panel, then program > expert > data distortions > menu options), although I'm not too hopeful about that -- and I'm minded to remove them from Templot in future. It's a long time since I dismantled a printer, so I don't have much idea how the PX710W paper feed works, sorry. Some general points to bear in mind are: 1. Laser printers heat the paper, which can cause differential shrinkage and mis-match problems. Generally ink-jet printers produce much better results for accurate track templates. 2. Don't use high resolution "photo quality" printing for track templates. It is much better to set the plain "Text" or "Letter Quality" option in the 300dpi to 720dpi range. 3. Don't use shiny paper which might slip on the feed rollers. Matt paper or thin card is better. 4. Consistent paper feed relies on having a clean perfectly round roller with no accumulations of fluff or other foreign matter. Don't leave the printer parked with paper in the rollers, as the pressure could create a flat on the roller. 5. Avoid large areas of solid colour which could make the paper too wet and cause cockling. If you are printing large scale templates for 0 Gauge and above it is worth changing the timber and rail infill to a lighter colour, or to hatching instead of solid infill. 6. Try not to use ordinary thin office paper. Thicker 160gsm paper (which feels like very thin card) is very much easier to trim and fit together accurately, and the extra thickness makes for a more controlled feed and less trouble with shrinkage or cockling. It also makes a much firmer template to work on for track construction. 7. Open a sealed pack of paper and allow it to acclimatise to the ambient conditions for a few days before printing. 8. Modern printers are quite flimsy in construction. Make sure that all the feet are standing firm on a flat level surface. Any twist in the printer frame is likely to cause inaccuracies in the printed result. A printer propped up on a pile of books will definitely not produce accurate templates. regards, Martin. |

||

|

posted: 10 Feb 2010 14:00 from: David click the date to link to this post click member name to view archived images |

Hiya Martin, thx for your reply....David wrote:On printout of a few sheets of A4 paper to join together, the grid spacings seem really good at 50mm(they had been 52mm), yet on a staggered A4 paper layout, when jointing together, the placing of an A4 sheet centred on the joint of 2 A4 sheets below, show the sheet out of alignment by 1mm at either end of the sheet.Hi Dave, The 50mm grid spacings are dead on, as are the red 70mm border marks. During printer configuration the outer box of the printout measures 180mm x 240mm, yet when the proof sheet is printed out the horizontal bar measures 150mm, but the vertical bar only measures 249.5mm, instead of the 250mm expected. The Roller Factor is 100% and the Head Factor is 100%. Martin, is this discrepancy of 0.5mm on the proof sheet anything to worry about, when the printer calibration test measures fine, prior to the proof printout. My current new printer is a Epson Stylus Photo PX710W. Although an epson, it is similar to a Hp, the paper enters and does a 180 deegree turn on its self. Not sure how it would cope with 160gms. Can see the point of your suggestion though. The older printer was a rear feed. Thanks for your contribution martin, might try the older printer as i still have it. Need to get a parallel covertor as using a Laptop now. Thanks Dave |

||

|

posted: 11 Feb 2010 21:22 from: Dellboy

click the date to link to this post click member name to view archived images |

Hello Dave I have a similar model Epson printer and some slippage does occur in the paper feed meaning adjacent sheets do not always line up perfectly. The important thing is when you lay them out to join up, is to line up your sheets longitudinally as accurately as you can (I use a string line of taut cotton). I have laid out 30 sheets plus before now and found little real problem, the discrepencies are too small to worry about. Unfortunately, excellant as they are in other respects, these printers having a 180 degree paper turn cannot handle a paper weight above 90gms. This is heavier than normal good quality paper but lighter than card. I had some difficulty finding good quality 90 gms paper but it is about and produces quite sturdy prints. Not as good as 160gms card though! Regards Derek Have since found this weight information to be incorrect, see my subsequent message of 12 Feb 2010 |

||

| Last edited on 12 Feb 2010 16:17 by Dellboy |

|||

|

posted: 12 Feb 2010 07:35 from: richard_t

click the date to link to this post click member name to view archived images |

I have an HP OfficeJet 55xx, supplied by work, and that too has a 180 turn feed. It copes well with 160gsm normal card/paper. I've not tried photo paper through it though. I've not tried it with Templot mind you. |

||

| Last edited on 12 Feb 2010 07:36 by richard_t |

|||

|

posted: 12 Feb 2010 07:54 from: Martin Wynne

click the date to link to this post click member name to view archived images |

richard_t wrote: I have an HP OfficeJet 55xx, supplied by work, and that too has a 180 turn feed. It copes well with 160gsm normal card/paper.Likewise my trusty 10-year-old HP DeskJet 720C, which still produces crisply accurate templates, including on 160gsm and thicker card. However, the 180 turn feed is via a large roller behind a hatch at the rear. I imagine it much depends on the diameter of the return roller. The latest low-profile printers and all-in-ones obviously have a smaller return roller, if they are restricted to 90gsm max. Thanks Derek for the information about the David's Epson printer -- something to bear in mind when buying. regards, Martin. |

||

|

posted: 12 Feb 2010 09:56 from: David click the date to link to this post click member name to view archived images |

Hiya Guys Thanks for your replies....... I will get some 160gsm and try with PX710W printer, I think. Had a Parallel to Usb come in the post today, so I will resurrect my old Epson 820. Was always amazed at the accuracy of printouts from Templot, I'm sure this is an issue with the printer. Like the idea of the cotton, Derek... Thanks for all the tips guys, will let you know how i get on with the 820 Printer and Card. Regards Dave |

||

|

posted: 12 Feb 2010 16:11 from: Dellboy

click the date to link to this post click member name to view archived images |

Dellboy wrote: Hello Dave Well folks - stand back in amazement! In view of the comments made on this subject I did some research on the web regarding paper weights without much success so decided to give Epsons technical a call re my specific printer (Epson Stylus Photo PX700W). I had to listen to 5 plus minutes of sales blurb but then I did get a human to speak to. It was difficult to get a direct answer to a simple question as they are reluctant to discuss anything in other than Epson product speak but eventually managed to get a paper weight out of them and they quoted 90 gms maximum (as they had quoted to me before). This I now understand is Epsons heaviest paper therefore I now suspect a standard answer for all Epson printers. However after I pressed them for an absolute maximum paperweight, the reply eventually came back "120gms should be possible for non Epson papers". But ---- if using their Epson premium photo paper can take up to 255 gms !!! A slight difference from 90gms !!! Usual caviats were provided by them re must only use their paper to achieve this capacity in their product. So in view of the above I decided to try an experiment with my PX700W. Put a few sheets of non-Epson 160gm card in and it fed through perfectly with excellant print quality. Thanks for raising the subject Dave, as a result I've learnt something today! Regards Derek |

||

|

posted: 12 Feb 2010 17:47 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Just to add to this, if anyone has an older Canon printer such as an i850, that'll happily handle 224g/m² Bristol board. This is obviously not quite what Canon intended, but it works and is probably a heck of a lot cheaper than printer manufacturer's specialist papers. |

||

|

posted: 13 Feb 2010 22:45 from: David click the date to link to this post click member name to view archived images |

Hiya guys Thanks for all your replies, been a while gettting back due to trials and tribulations. Tried the 160gsm on the PX710W Printer and amazingly, it worked fine. I can see the advantage of using the thicker paper and tried martins method of butting sheets together, which with the thicker paper, seemed better than overlapping which i had tried previously. Tried reverting to my old epson 870 Stylus Photo, but the results were marginal. Although the rear paper feed does lend itself to thicker papers. I have discovered that by adding 1 sheet at a time in a staggered configuation, in a landscape orgination, it was possible to achive good rresults. I think this may have been an oversight on my part regarding previous experiments and correct methods. Thanks for your efforts and support calls, Derek.... and martin, thx for your support to... and everyone that contributed to this thread. 160gsm is the only way for me now. Regards Dave |

||

|

posted: 4 Mar 2010 12:55 from: Gordon S click the date to link to this post click member name to view archived images |

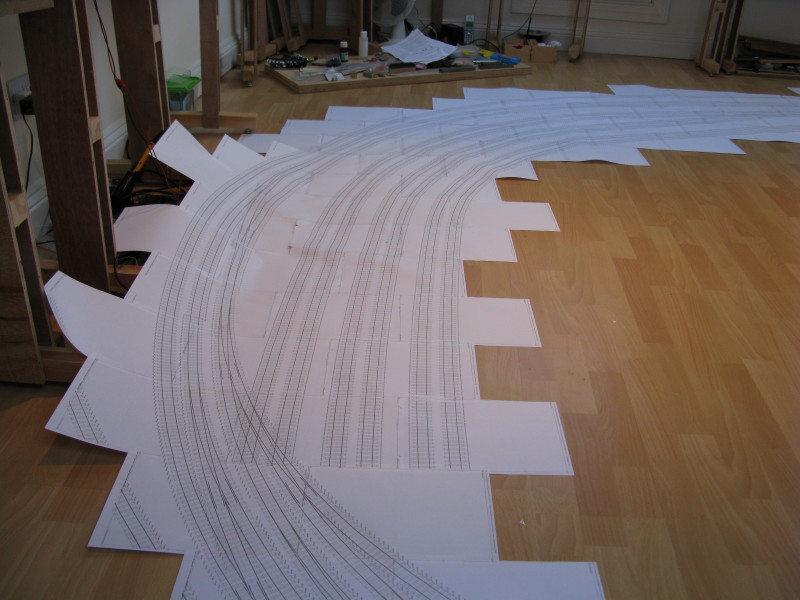

Just catching up on a few posts and thought I would let you know my experience. I'm using an HP Officejet K550 printer and 75/80gm paper. Having calibrated this printer I have found very, very minor discrepancies in alignment, but by cutting two small V's in the paper so that you can see the sheet underneath, you can easily align the prints using the farme lines. This has proven very successful on my own layout and I use the prints for both turnout production and track laying. I have had CAD prints done of my main terminus which is 18' x 3' on a single roll, but otherwise I just stick A4 sheets together with Scotch Magictape. Here's a pic of quite a large number of sheets, probably 100+... 479_040752_000000000.jpg  |

||

|

posted: 4 Mar 2010 13:27 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Gordon, If you are overlapping sheets rather than trimming and butting, an ordinary office 2-hole punch is faster than cutting V notches. Many thanks for the pic. Your knees must have been sore after sticking that lot together! For anyone not aware of it, Gordon's impressive project can be followed here: http://www.rmweb.co.uk/community/index.php/topic/3422-eastwood-town-update/ regards, Martin. |

||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |