Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 5 Mar 2010 17:13 from: Dellboy

click the date to link to this post click member name to view archived images |

Hello folks Well I've now drawn a line under my Templot EM gauge layout and expect to start track building soon! All the baseboards were finished last year based on the 'finalised' layout but the detailed finishing-off by refining alignments, adjusting check rails & timbering etc, plus of course some tinkering about with it have only just managed to be completed. Congratulations to Martin for such a brilliant program. The layout is completely freelance. It consists of a main station, a single line branch and an 8 train turntable for the storage sidings element. Maximum train length of six carriages plus loco. I have two fully interlocked signal frames for controlling the points & signals, one for the station the other for the branch, on order from Modratec. Huge credit to Harold of Modratec for the design of these using their SigScribe program. The working potential of the station has been a major consideration for me and has resulted in a rather complex S&C configuration at the station throat area. I am looking forward to the challenge of building it! The main file is attached below, any comments will be welcome. (There's always scope for a bit more tinkering!) Derek |

||

| Attachment: attach_744_1059_This_is_it_EM.box 589 | |||

|

posted: 5 Mar 2010 17:15 from: Dellboy

click the date to link to this post click member name to view archived images |

The file for the storage turntable attached. Derek |

||

| Attachment: attach_745_1059_This_is_it_EM_Storage_TT.box 469 | |||

|

posted: 5 Mar 2010 18:25 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Wow! You need to trim the top K-crossing check rails on templates 204 and 241 Seriously, that's an impressive plan and you've obviously spent many hours on that. Makes my lack of progress building a couple of small layouts look rather pathetic, really Cheers |

||

|

posted: 6 Mar 2010 11:37 from: Dellboy

click the date to link to this post click member name to view archived images |

Well spotted Paul I had not ventured into K crossing check rails but your comment instilled me to have a go and found it quite easy so the K-crossing check rails have now been shortened. Also I have revisited the scissors crossover in the Storage Turntable file and trimmed the overlength check rails I had left there. So thanks for that. Yes I have spent a fair amount of time on this, started to develope the design, initially on paper, then in Templot about a year ago. Unfortunately there are always other 'jobs' that need doing which seriously restrict the amount of time available. However time spent on planning is well worth it as it gives you the confidence in what you are going to build is going to work! In the longer term it can save considerable time (and fustration!). Derek |

||

|

posted: 6 Mar 2010 13:43 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

Dellboy wrote: I had not ventured into K crossing check rails but your comment instilled me to have a go and found it quite easy so the K-crossing check rails have now been shortened.Derek, I noticed that at least one of your slips was 1 in 8.5 which is beginning to push your luck a bit on the "K" crossings, especially in a terminus throat where propelling would occur. Perhaps you might look at raising your "K" check rails a bit to increase the effective checking length to prevent wrong way problems at the "K"s. The other alternative is to use a switched diamond instead. Or another possibility is re-designing the throat. Jim. |

||

|

posted: 6 Mar 2010 16:39 from: Dellboy

click the date to link to this post click member name to view archived images |

Jim Guthrie wrote: I noticed that at least one of your slips was 1 in 8.5 which is beginning to push your luck a bit on the "K" crossings, especially in a terminus throat where propelling would occur. Perhaps you might look at raising your "K" check rails a bit to increase the effective checking length to prevent wrong way problems at the "K"s. The other alternative is to use a switched diamond instead. Or another possibility is re-designing the throat. Dellboy wrote: Gobsmacked! How on earth did I miss that one? Thanks for pointing it out Jim. I have converted the two offending slips, 1 in 8.75 & 1 in 9, to switched. One of them will be right on top of a baseboard crossmember so I'll have to do a bit of retro woodwork to accommodate the control linkage - serve me right! Two other slips are 1 in 8 and I'll have a look at the radii in case there may be a problem there as well. The others are 1 in 7 or less and should not present a problem. Thanks again Jim Derek |

||

| Last edited on 6 Mar 2010 16:57 by Dellboy |

|||

|

posted: 6 Mar 2010 19:27 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

Gobsmacked! How on earth did I miss that one? Thanks for pointing it out Jim. I have converted the two offending slips, 1 in 8.75 & 1 in 9, to switched. One of them will be right on top of a baseboard crossmember so I'll have to do a bit of retro woodwork to accommodate the control linkage - serve me right! Two other slips are 1 in 8 and I'll have a look at the radii in case there may be a problem there as well. The others are 1 in 7 or less and should not present a problem. Derek, All the best with your construction. I've reverted to the simple life in my latest plan - not a slip or diamond in sight. Jim |

||

|

posted: 6 Mar 2010 21:12 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Jim Guthrie wrote:I'm just starting on the trackwork right now, making up my first V on the new layout.Must be something in the air - I've just cut and stained a load of timbers |

||

|

posted: 7 Mar 2010 14:14 from: Dellboy

click the date to link to this post click member name to view archived images |

Dellboy wrote:

Jim Decided to convert the two 1 in 8 slips to switched as well as I would hate to have to retroft these to switched if they didn't work properly. At least the control linkage for these will be clear of the baseboard cross framing! Glad to hear you have started building your new layout Jim, also Paul has made a start. Definitely something in the air. Best wishes Derek |

||

|

posted: 27 Aug 2012 23:58 from: Dellboy

click the date to link to this post click member name to view archived images |

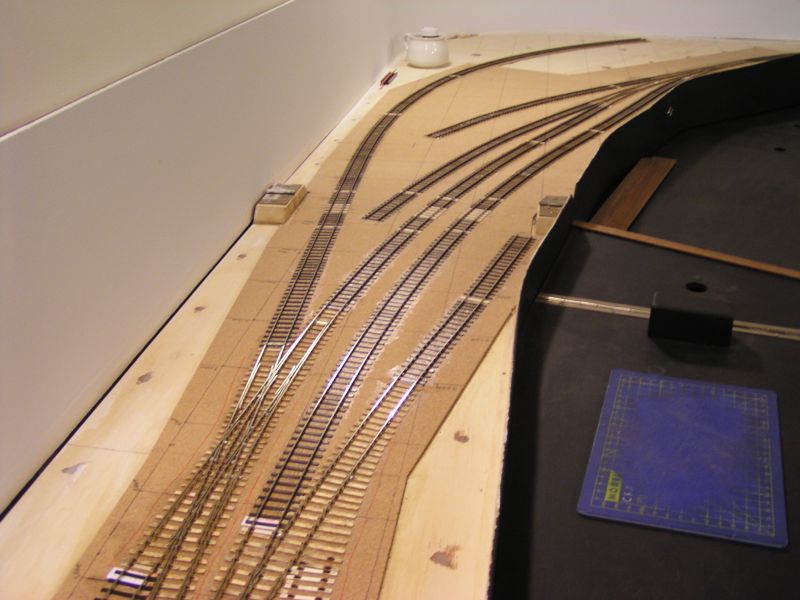

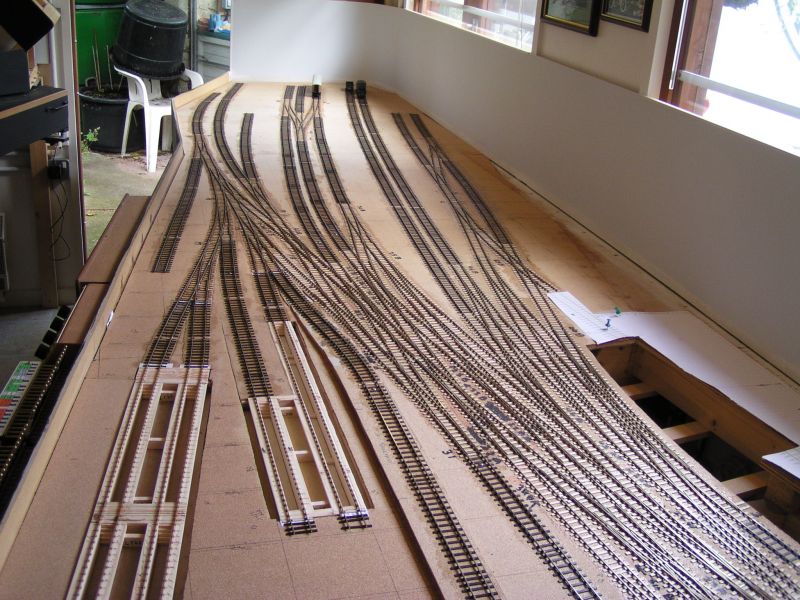

Two and a half years and 8,506 chairs later all the S&C has been built and all track laid apart from the coal drops siding and the turntable closure panels so thought I'd show a few pics to prove that there is life beyond Templot !! I have also attached the Templot box file. 1821_271832_500000000.jpg  1821_271830_450000000.jpg  1821_271842_490000000.jpg  29 August - replaced the box file with the correct 'final' ! |

||

| Attachment: attach_1486_1059_This_is_it_EM_REV_E_66_Joggled_T_-_Final.box 341 | |||

| Last edited on 29 Aug 2012 23:08 by Dellboy |

|||

|

posted: 28 Aug 2012 00:10 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Derek, that's great. Close on 300 templates, and all built! Many thanks for sharing. Martin. |

||

|

posted: 28 Aug 2012 08:59 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

Derek, That is pretty impressive and looks great. My own layout, started at about the same time as yours but with a very small fraction of the number of templates is not so far advanced as you. Jim. |

||

|

posted: 28 Aug 2012 10:41 from: JFS

click the date to link to this post click member name to view archived images |

Derek, Really nice! And quick work too. You mention chairs and I assume that you have used them functionally (to apply that many cosmetically requires about 2 lifetimes!) will you say a bit about your construction methods? Best Wishes, Howard. |

||

|

posted: 28 Aug 2012 11:38 from: RedgateModels

click the date to link to this post click member name to view archived images |

wow | ||

|

posted: 28 Aug 2012 12:15 from: Nigel Brown click the date to link to this post click member name to view archived images |

Wowee! Great! Now comes the bit I find less interesting and holds me up - doing the scenery. | ||

|

posted: 28 Aug 2012 13:17 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Actually, I counted 8508 chairs That's an impressive bit of track - I wish I had the space to do something like that! |

||

|

posted: 28 Aug 2012 13:29 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Paul Boyd wrote: Actually, I counted 8508 chairs http://85a.co.uk/forum/gallery_view.php?user=1821#gallery_top Click the small image to see the normal size one, then click the link below it to see the full-size original. It will take a few seconds to load, and need sideways scrolling on most screens. Martin. |

||

|

posted: 28 Aug 2012 21:52 from: Dellboy

click the date to link to this post click member name to view archived images |

JFS wrote: Derek, Really nice! And quick work too. You mention chairs and I assume that you have used them functionally (to apply that many cosmetically requires about 2 lifetimes!) will you say a bit about your construction methods? Best Wishes, Howard.Howard All the S&C and a small amount of track has been built with ply sleepers and plastic chairs, a mixture of EMGS (C&L) and Exactoscale chairs. The plain line is C&L. The S&C was all built on the work bench using the double sided tape on the printed templates method. All the crossings were prefabricated and are soldered to brass shims. For the Main Station Throat, sections of S&C up to 1,200 long were made up and sometimes laid as one piece. Baseboards are graded softwood framed and quite heavily constructed (will take my 6 ft weight without groaning) with 9mm marine ply covering glued and screwed down. Track base is 3mm sheet cork glued to the ply with Copydex, track is glued on to the cork again with Copydex. Overall alignment was achieved by spending two whole days very accurately drawing a 100mm centres grid over the entire baseboard and using this to position the Templot printouts for all the track. This allowed me to build different parts knowing it would all link up perfectly, thus I was able to build and lay all the S&C before the plain line. Electrical connections are via 0.7mm brass droppers soldered to brass shims under the rails and to the sides of the rails to represent a chair. Best wishesDerek |

||

| Last edited on 28 Aug 2012 22:04 by Dellboy |

|||

|

posted: 28 Aug 2012 21:58 from: Dellboy

click the date to link to this post click member name to view archived images |

Paul Boyd wrote: Actually, I counted 8508 chairsPaul 8,506 is the number of chairs I got through and includes the ones that decided to fly out of my tweezers at the most inopportune moment or simply disappear off the work bench without trace !! |

||

|

posted: 28 Aug 2012 22:39 from: JFS

click the date to link to this post click member name to view archived images |

Derek. Many thanks for this - I hope it will give others the confidence to use functional plastic chairs! For me it is the only way to go - despite the naysayers who tell everyone it is not strong enough / cannot be adjusted etc. Well I never had issues! One detail you did not mention was how you did the switches - did you just use plastic slide chairs or did you use rivets here? I am building my track in situ, but if you build on jigs, this can be a tricky aspect. Many thanks, Howard. |

||

|

posted: 29 Aug 2012 12:36 from: Simon Dunkley

click the date to link to this post click member name to view archived images |

Paul Boyd wrote: That's an impressive bit of track - I wish I had the space to do something like that!I agree - very impressive. Scarily, I realised that I do have the space to do that: my garage is 17' x 9'... That is a very distracting thought! Simon |

||

|

posted: 29 Aug 2012 13:20 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Hi SimonScarily, I realised that I do have the space to do that: my garage is 17' x 9'... That is a very distracting thought!I look forward to your photos in a couple of years time |

||

|

posted: 29 Aug 2012 13:24 from: Simon Dunkley

click the date to link to this post click member name to view archived images |

Paul Boyd wrote: Hi SimonYeah, right: it can take me that long to finish a single wagon! |

||

|

posted: 29 Aug 2012 13:25 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Hi HowardFor me it is the only way to go - despite the naysayers who tell everyone it is not strong enough / cannot be adjusted etc.Are people still saying that plastic chairs are not strong enough, even after all this time and evidence? Although I seem to have switched to Masokits chairs, I've built a reasonable amount of track with plastic chairs on ply timbers and have no qualms about strength or adjustability! |

||

|

posted: 29 Aug 2012 20:18 from: Nigel Brown click the date to link to this post click member name to view archived images |

Paul Boyd wrote: Are people still saying that plastic chairs are not strong enough, even after all this time and evidence? Although I seem to have switched to Masokits chairs, I've built a reasonable amount of track with plastic chairs on ply timbers and have no qualms about strength or adjustability!All the track I've built in 3mm scale has been plastic chairs on plastic sleepers. Strength is not a problem, neither is adjustability. I can't see myself using any other method for bullhead track. I guess the naysayers are those who make assumptions without trying it. Cheers Nigel |

||

|

posted: 29 Aug 2012 21:41 from: Dellboy

click the date to link to this post click member name to view archived images |

JFS wrote: Derek.Howard There is not a single rivet to be found anywhere on the layout! Brass shims under the nose assemblies but otherwise plastic glued to ply throughout including slide chairs. In the far distant past I soldered rails to tack heads on the baseboard then progressed to bench building using ply and rivets (P4 track) with white metal cosmetic chairs but having revived my interest in railway modelling I am now fully converted to the plastic chair. I have not experienced any problems at all, I find it quite rigid enough to handle when gluing down and the chairs can be eased off the timbers with a sharp scalpel should there be any retro adjustment needed, far easier to adjust than with soldered rivets or for that matter copperclad and quicker to build. I must admit I was very sceptical until I tried it but plastic chairs tick all the right boxes for me and the end result does look really good. I confess though I did use copperclad for the hidden sidings S&C for speed of build and to kick start me back into track building after far too many years of inactivity. Derek |

||

| Last edited on 29 Aug 2012 21:56 by Dellboy |

|||

|

posted: 29 Aug 2012 22:11 from: JFS

click the date to link to this post click member name to view archived images |

Derek, I fully agree and I go the same route as you with no issues. There has been an issue with the slide chairs since they go not grip the rail and many people seem to end up with undergauge issues at the switches. For my current job I have attached the slide chairs to the rail using Loctite 435, then stuck the chairs to the timbers with solvent - problem solved! As Paul speculates, most of the naysayers I meet have always used rivets and will always use rivets! But as a friend of mine suggested "When your riveted track needs cosmetic chairs fixing, the quickest way to do it is to rip it all up and rebuild it with functional plastic chairs!!" Best Wishes, Howard. |

||

|

posted: 29 Aug 2012 22:43 from: Dellboy

click the date to link to this post click member name to view archived images |

Howard I agree, always use Loctite to glue the rail to the slide chairs before fixing them to the timbers. I pre-curve my rails as accurately as possible and leave one stock rail floating over the slide chairs until the opposite stock and switch rail are in, then glue the stock slide chairs down by gauging off the opposite switch rail. I should mention I joggle my stock rails as well which helps. Derek |

||

|

posted: 29 Aug 2012 22:44 from: Glen Suckling

click the date to link to this post click member name to view archived images |

JFS wrote: . There has been an issue with the slide chairs since they go not grip the rail and many people seem to end up with undergauge issues at the switches. In O scale I use plastic chairs and timbers everywhere except for the slide chairs where I use cast brass chairs soldered to PCB sleepers (and the stock rail). Glen |

||

|

posted: 30 Aug 2012 09:29 from: Paul Boyd

click the date to link to this post click member name to view archived images |

I'll add my name to the Loctite 435 brigade! When I needed to remove some slide chairs once, I ended up having to chisel the broken remains off the rail. How much more strength is needed? With plastic slide chairs, I do exactly the same as Derek. |

||

|

posted: 30 Aug 2012 10:18 from: Phil O

click the date to link to this post click member name to view archived images |

Hi Derek I should mention I joggle my stock rails as well which helps. What method do you use to joggle your rails? Please, as I have a few to do and being a GW modeller it is noticeable when they aren't joggled. Cheers Phil |

||

|

posted: 30 Aug 2012 10:57 from: JFS

click the date to link to this post click member name to view archived images |

Dellboy wrote: I pre-curve my rails as accurately as possible Derek, Looks like Great Minds think alike again. For me this is a very important step which is not emphasised enough - I think that with plastic chairs and solvent one potential risk is "creep". In other words, if you have to force a chair into place and then weld it, it might stay put for a while, but in time the rail will find its way home again. By pre-curving all the rails such stress is eliminated and the chair is merely encouraging the rail to stay where it wants to be anyway! As Paul says, Loctite 435 is a permanent joint - strength is not an issue! Best Wishes, Howard |

||

|

posted: 30 Aug 2012 12:02 from: Raymond

click the date to link to this post click member name to view archived images |

Phil O wrote: Hi DerekI have a method. I'll get the kit out this afternoon, write it up later, and post it.I should mention I joggle my stock rails as well which helps. Raymond |

||

|

posted: 30 Aug 2012 13:32 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Hi PhilWhat method do you use to joggle your rails? Please, as I have a few to do and being a GW modeller it is noticeable when they aren't joggled.The method I use is simple - I cut a slot about 3mm wide by about 10-12mm long in a piece of 0.5mm nickel silver or brass sheet. Slip the slot over the rail and squeeze in the vice - one joggle! You do need to make sure you joggle in the right direction, and eventually the "tool" will become too distorted to use, so just make another one. Although the joggle is quite small (0.5mm) it does show. Much more than that would look exaggerated, I think. Edit - I've just found a picture on my website that shows this - it's here. |

||

| Last edited on 30 Aug 2012 13:37 by Paul Boyd |

|||

|

posted: 30 Aug 2012 14:04 from: Raymond

click the date to link to this post click member name to view archived images |

Paul Boyd wrote: Hi PhilSound similar to mine though I have yet to replace the original tool I made. This is what I do for steel rail and assume it would work for nickel silver also. A piece of nickel silver 1.5mm thick to which is soldered on opposite sides two ‘fingers 0.9mm thick by about 7mm with a gap of 1.6mm between their inner edges. The rail is slid between the ‘fingers’ and the whole lot then squeezed hard in the vice. Make sure the centre of the needed joggle area is between the inner edges of the ‘fingers’. Hope that helps, it may also be an idea to anneal the rail too. Raymond |

||

| Last edited on 30 Aug 2012 14:08 by Raymond |

|||

|

posted: 30 Aug 2012 14:39 from: Phil O

click the date to link to this post click member name to view archived images |

Hi Chaps Thanks very much for your replies, they are very similar to what I had in mind. Cheers Phil |

||

|

posted: 30 Aug 2012 20:53 from: Dellboy

click the date to link to this post click member name to view archived images |

Phil O wrote: Hi DerekPhillI should mention I joggle my stock rails as well which helps. Looks like you've got your answers already. I notch a piece of 0.3mm thick steel plate and I find this gives sufficient joggle. I tried the vice method initially but my vice had jaw serrations which marked the sides of the rail so I ended up using a few taps of a light hammer on one side of the steel plate, turn it over, repeat hammering on other side, job done. Must have a smooth hard surface to do this on though, I use a piece of Tufnol. The other advantage of this method was I didn't have to move away from the workbench which would have affected the production run!! By the way all my rail is Nickel Silver. Derek |

||

| Last edited on 30 Aug 2012 20:55 by Dellboy |

|||

|

posted: 31 Aug 2012 16:28 from: Phil O

click the date to link to this post click member name to view archived images |

Hi Derek Thanks, we all seem to be singing from a similar hymn sheet. Cheers Phil |

||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |