Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 20 Dec 2011 20:19 from: workev2000

click the date to link to this post click member name to view archived images |

I am new to Templot and making my own trackwork. I have a number of questions relating to the use of C&L components on Templot templates. I apologise if they have been asked elsewhere, and if there is an existing topic please point me in the right direction.

Would just like to say that whilst I am on a rapid learning curve for the software it is fantastic; hats off to Martin! Ian |

||

|

posted: 20 Dec 2011 20:30 from: alan@york click the date to link to this post click member name to view archived images |

Ian: You may wish to read Iain Rice's guide to making trackwork, from Wild Swan publications. Take a quick peek before buying. Ask at a show, especially where they have demonstrators. Join a club, so you can sit, watch, ask questions, and maybe borrow some gauges. From what I can recall, the packs I've bought from C&L didn't have the V/wing rail assembly (often called the "frog") made up, so you could use whatever gauge jigs you needed. And you could curve the V slightly. I personally use wood/plastic chairs from a mix of sources*, with copperclad where it doesn't show. Copperclad can be tweaked afterwards, whereas superglue/wood is harder to modify. But it is a pain putting cosmetic chairs onto copperclad. A lot of this is down to personal choice, which is why I've suggested looking at what others do, and going with what you want. alan@york of DEMU *Exactoscale, C&L, old K&L, for chairs, wood strip from a doll's house shop for timbers/sleepers. |

||

| Last edited on 20 Dec 2011 20:31 by alan@york |

|||

|

posted: 20 Dec 2011 20:45 from: Martin Wynne

click the date to link to this post click member name to view archived images |

workev2000 wrote:Which Templot Gauge do I use for C&L components? I have seen the seperate file for their standard templates; but if I use 00-BF is that the equivalent, or is it 00-SF? I just need to understand which gauge better meets C&L 16.5mm components (by that I mean standard V's and crossings).Hi Ian, C&L assembled V-crossings have 1.0mm flangeway gaps. That means they are suitable for EM, 00-DOGAF and 00-SF. They are not suitable for 00-BF or 00-DOGAC which require 1.25mm flangeway gaps. The C&L 00 roller track gauge and back-to-back wheel gauge tools are suitable for 00-DOGAF only. For some discussion about all this, see: message 567 If you want to use C&L V-crossings in 00 gauge I would suggest 00-SF is your best bet as you won't then need to modify any wheels (unlike 00-DOGAF). More info and supply of 00-SF gauge tools at: http://00-sf.webs.com regards, Martin. |

||

|

posted: 20 Dec 2011 20:47 from: Nigel Brown click the date to link to this post click member name to view archived images |

I model in a different scale (3mm/ft) but use plastic chairs on plastic sleepers entirely. It works fine for me. If I was constructing a layout for heavy duty exhibition use I might reconsider that, but suspect I'd still take the above, for me, easy option. If you're attaching plastic chairs to anything, remember that if they come unstuck it only takes a moment to restick them. If you make a mistake, a sharp blade between chair and sleeper will separate the two. Remember, whatever gauge/standards you choose, getting hold of decent track gauges for that standard is critical. Nigel |

||

|

posted: 20 Dec 2011 20:48 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Hi Ian Welcome to Templot! I can't really comment about the various OO gauges and standards, but there is a thread somewhere about the benefits of using OO-SF (16.2mm gauge) to run RTR stock. You should be able to find it. I don't know what the flangeway gap is on the C&L crossings - OO-BF (16.5mm gauge) has a gap of 1.25mm whereas OO-SF has a gap of 1.0mm. edit by Martin -- C&L assembled crossings have 1.0mm flangeways. When making crossings, they all start out as straight, so a C&L one is no different in that respect. In most cases, the actual track through the crossing itself is straight (regular crossing) although in some cases the curve continues through the crossing (curviform crossing). Using a ready made crossing will help, although once you understand turnouts, you'll realise that they're not that hard to build yourself. If you've never built any track before, I would suggest you make a few turnouts with copperclad sleeper strip, even if you don't use them on a layout - just regard then as practise pieces. Once you understand how a turnout works, then try building with chairs. I've never used plastic sleepers/timbers, (I use plastic chairs/ply timbers) but I would imagine that once the chairs are glued, they're glued so adjustments will be near impossible. Once you've done the "copperclad apprenticeship" you might like to consider the plastic chair/ply timber approach as you get the realistic track with the ability to adjust if necessary. I think ply and rivet has had its day, although I'm sure there are some diehards still doing things the hard way One thing though, you need to decide which standard you are working to and get the appropriate gauges, then make sure that all the stock (I'm assuming RTR) meets those standards. The most important are the wheel back-to-back and flange thickness, coupled with the check gauge on the turnout. But really, you just need to have a go and don't be afraid to make mistakes! |

||

|

posted: 21 Dec 2011 07:25 from: Stephen Freeman

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: workev2000 wrote:Hi, I think Martin has covered this pretty well. I would just add that if you did decide to use plastic chairs with plywood timbering, I find it's best to use a special superglue designed for plastics such as plastizap (you can use this for plastic based timbering too). Most of my commissions these days are done this way and it's been a while since anybody asked for plastic timbering, I think you'd find it stronger and dimensionally more stable, especially compared to using solvent with plastic based timbers of the thin variety. As for common crossings, I make these too, to suit most of the various standards. (You'll find details on my website if you are interested). Stephen |

||

|

posted: 21 Dec 2011 11:18 from: workev2000

click the date to link to this post click member name to view archived images |

First of all thanks for the replies. I bought two B6 kits from C&L at Warley, and have watched Norman Solomon's Right Track DVD dozens of times, and spoke to him for some time at Warley. The turnout kits are plastic chairs and plastic sleepers, and include track guages which I think from reading the replies above are not to OO-SF standards (but to OO-DOGA); so where do I get an appropriate track gauge from (now a little confused, as is 16.5mm not 16.5mm)? To be honest I may actually move to EM gauge, so these are a trial of my skills at building track before I change any stock! Let me ask another question; which may be more basic. I want to build my own track as it looks better than Peco. I want to feel able to feel confident in track building before I move on to the decision of EM/OO as I will need to invest in the move to EM from a stock comversion perspective. So if I am to build my turnout kits, then maybe try a layout using templot and C&L components, do I need to buy a different track gauge for RTR stock; and if so where from? Sorry if these are silly questions, but I cannot afford expensive mistakes! Ian |

||

| Last edited on 21 Dec 2011 11:22 by workev2000 |

|||

|

posted: 21 Dec 2011 11:51 from: Nigel Brown click the date to link to this post click member name to view archived images |

Borg-Rail wrote: I think Martin has covered this pretty well. I would just add that if you did decide to use plastic chairs with plywood timbering, I find it's best to use a special superglue designed for plastics such as plastizap (you can use this for plastic based timbering too). Stephen I think I'd disagree with this; using superglue to fix plastic chairs to plastic sleepers (or indeed wooden sleepers) means that it's extremely difficult to adjust things if you need to. This may not apply to you given your experience in building track, but I think it applies to a lot (most?) people. Certainly I've found the ability to adjust chairs without destroying them is critical. If you use one of the recommended solvents to fix plastic chairs to plastic sleepers, by placing the chair in position then flowing a small amount of solvent around the edge, you find it works it's way under the chair by capillary action, mainly around the edges, which is where the chair and sleeper end up being joined. This is easily strong enough to keep chair in position; if by any chance it isn't you just flow a bit more solvent. Because the chair is mainly joined around the edge, if you need to adjust it, it is fairly simple to slip a sharp blade under the chair and ease it off, without damaging the chair. I'd suggest Ian gives it a go with recommended solvents and sees what he thinks. I'd also suggest he does a few inches or so of plain track first before dealing with the (slightly) more complex world of turnout construction. Cheers Nigel |

||

|

posted: 21 Dec 2011 12:36 from: Martin Wynne

click the date to link to this post click member name to view archived images |

workev2000 wrote: The turnout kits are plastic chairs and plastic sleepers, and include track guages which I think from reading the replies above are not to OO-SF standards (but to OO-DOGA); so where do I get an appropriate track gauge from (now a little confused, as is 16.5mm not 16.5mm)?Hi Ian, It's a bit confusing if you are just starting. 00 Gauge at 16.5mm gauge includes a significant amount of gauge-slop so that rolling stock can negotiate the sharp small-radius curves found in toy train sets. 1. To get better running on the much larger-radius curves found on scale model railways, you can do one of two things: a. Move the wheels further apart on the axles. This is called 00-DOGAF standard. This is the standard to which the gauge tools supplied by C&L conform.Both of these standards use 1.0mm flangeway gaps (as does EM gauge), so you can build either using the components supplied in C&L kits (but not using the gauge tools supplied). 2. If you are not concerned about better running, you can use the ordinary 00-BF standard which uses 16.5mm gauge with 1.25mm flangeway gaps. The gauge tools for this are available from Markits and elsewhere (but not from C&L or Brian Tulley). But you can't build to 00-BF standard using the C&L kits -- their 1.0mm flangeway gap is too narrow. Some of this stuff is contentious -- if you ask around you will get some strong opinions about the various options. If I was in your position I would discard the C&L gauge tools (eBay?), obtain gauge tools for 00-SF, and get some practice building 00-SF pointwork and running your rolling stock through it. Having done that you can decide later whether you want to change to EM and modify all your wheels. regards, Martin. |

||

|

posted: 21 Dec 2011 13:54 from: Geoff Cook

click the date to link to this post click member name to view archived images |

Borg-Rail wrote: Hi Ian, Sorry but I have to disagree with this choice of using superglue, Butanone sold by C&L or MEK are by far the best choice, for fitting chairs to wood or plastic sleepers, why try to change something that doesnt need changing Geoff Cook |

||

|

posted: 21 Dec 2011 13:56 from: Stephen Freeman

click the date to link to this post click member name to view archived images |

Nigel Brown wrote: Borg-Rail wrote:Hi,I think Martin has covered this pretty well. I would just add that if you did decide to use plastic chairs with plywood timbering, I find it's best to use a special superglue designed for plastics such as plastizap (you can use this for plastic based timbering too). It's not impossible to adjust using superglue - just make sure it's the right type (Plastizap - Ordinary superglue won't do), the bond can be softened using their de-bonder if necessary. For my needs, I don't really want the chairs to come off that easily! The problem with solvent is a) The fumes b) possibility of affecting plastic timbering according to some (especially of the thin variety) c) despite claims to the contrary- the bond to plywood is not as good as to plastic. Stephen |

||

|

posted: 21 Dec 2011 14:31 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Borg-Rail wrote:If you are thinking of going EM, just buy some EM Gauges. You can actually use them to build 00-SF as well if you wish (00-SF after all, is EM - 2mm) so the inner jaws should give a gauge of 16.2mm.er no, Stephen. I'm not prepared to have such misinformation spread via Templot Club and I have deleted it. Martin. |

||

|

posted: 21 Dec 2011 15:16 from: Stephen Freeman

click the date to link to this post click member name to view archived images |

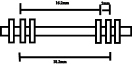

142_211030_500000000.png 142_211037_310000000.png 142_211037_310000000.png Err, Sorry, what I should have said is that the distance between the inner edge of the outer groove and the inner edge of the opposite inner groove on my EM gauges (C&L) is 16.2mm (fact), so why not? See attached jpg for clarification Martin Wynne wrote: Borg-Rail wrote:If you are thinking of going EM, just buy some EM Gauges. You can actually use them to build 00-SF as well if you wish (00-SF after all, is EM - 2mm) so the inner jaws should give a gauge of 16.2mm.er no, Stephen. |

||

| Attachment: attach_1281_1740_emgauge.jpg 515 | |||

| Last edited on 21 Dec 2011 15:39 by Stephen Freeman |

|||

|

posted: 21 Dec 2011 15:50 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Borg-Rail wrote: Err, Sorry, what I should have said is that the distance between the inner edge of the outer groove and the inner edge of the opposite inner groove on my EM gauges (C&L) is 16.2mm (fact), so why not?In that case the EM gauge tool is poorly made. Code 75 scale bullhead rail is 0.92mm (0.036") wide and the slots in the gauge tool should be 0.93mm (0.037") wide maximum. Accurate gauge tools are available from Brian Tulley for 00-SF. It does beginners no favours to suggest such bodges using the wrong tools. It's no wonder the 00 gauge standards are in such a mess when ideas like this are given currency. regards, Martin. |

||

|

posted: 21 Dec 2011 17:47 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Stephen wrote:It's not impossible to adjust using superglue - just make sure it's the right type (Plastizap - Ordinary superglue won't do), the bond can be softened using their de-bonder if necessary. For my needs, I don't really want the chairs to come off that easily! The problem with solvent is a) The fumes b) possibility of affecting plastic timbering according to some (especially of the thin variety) c) despite claims to the contrary- the bond to plywood is not as good as to plastic.I must admit that it hadn't previously occurred to me that anyone was using anything other than solvent for fixing plastic chairs to ply timbers! I accept that the plastic-plastic solvent bond must be stronger than plastic-ply, but for my needs, plastic-ply is strong enough as the P&C work stays on the Bristol board templates. I'm also not shipping pointwork around the world! I've also been known to sneak in a few rivets... I will give the Plastizap method a go though because another problem with solvent d) it evaporates like nobody's business if the lid is left off, like when you're using it Cheers |

||

|

posted: 21 Dec 2011 20:59 from: workev2000

click the date to link to this post click member name to view archived images |

So just to confirm, the OO-SF gauge is 16.2, whereas the C&L gauge is 16.5 which is the OO-DOGA neasurement. Shame I bought 2 additional gauges! So unless I widen out the wheelsets to be 14.5 back-back (question???) of all my stock I need to buy a new set of gauges from Brian Tilley? I think I have a back-to-back gauge from C&L can I assume that should give me the correct wheelset dimensions? Ian |

||

|

posted: 22 Dec 2011 00:09 from: Martin Wynne

click the date to link to this post click member name to view archived images |

workev2000 wrote: So just to confirm, the 00-SF gauge is 16.2, whereas the C&L gauge is 16.5 which is the OO-DOGA neasurement.Hi Ian, Yes. 00-SF is 16.2mm track gauge. All other 00 standards including DOGA and 00-BF are 16.5mm track gauge. So unless I widen out the wheelsets to beMost 00 rolling stock is supplied at around 14.4mm - 14.5mm back-to-back. The C&L back-to-back gauge tool is 14.8mm to match the C&L track gauge tools (00-DOGAF standard). So to use those track gauge tools you would need to widen most of your wheels to 14.8mm back-to-back. If you leave them unchanged they will very likely jam on the check rails. Some 00 gauge wagon and coach wheels (Alan Gibson?) are supplied already widened to 14.8mm back-to-back. To use your existing stock with 14.4mm back-to-back wheels unchanged, you must discard the C&L gauge tools and obtain different ones from Brian Tulley (for 00-SF) or from Markits and others (for 00-BF). This situation has caught out many purchasers of C&L kits and components, and has been discussed on RMweb at length in the past. C&L do give the dimensions on their web site, but I think they could make it much clearer that they are for the 00-DOGAF standard (DOGA Fine), that most 00 wheels will need to be modified to suit that standard, and that other standards are available elsewhere which do not require wheels to be modified. regards, Martin. |

||

|

posted: 22 Dec 2011 09:24 from: workev2000

click the date to link to this post click member name to view archived images |

Martin, Finally the penny drops! Many thanks for the clarification! Better hope Santa drops a few quid down the chimney to pay for the OO-SF gauges! Ian |

||

|

posted: 22 Dec 2011 22:58 from: r_wilton

click the date to link to this post click member name to view archived images |

workev2000 wrote:So just to confirm, the OO-SF gauge is 16.2, whereas the C&L gauge is 16.5 which is the OO-DOGA neasurement. Hi Ian, Your C&L gauge (16.5mm) needn't go to waste, you can use them to widen out the gauge after the turnouts to suit the C&L Flexi-Track for the straight/curved sections. Ray. |

||

|

posted: 23 Dec 2011 13:59 from: workev2000

click the date to link to this post click member name to view archived images |

I did wonder about that! Oh its all so complicated..... Ian |

||

|

posted: 23 Dec 2011 15:32 from: BeamEnds click the date to link to this post click member name to view archived images |

Nigel Brown wrote: I model in a different scale (3mm/ft) but use plastic chairs on plastic sleepers entirely. It works fine for me.....In O gauge I've great success with plastic sleepers/timbers and chairs. I use solvent adhesive on most chairs, and superglue on the more critical ones. The advantage of solvent is that it is a relatively easy, damage-free, matter to prise the chairs off if changes are needed. Once tested, out comes the superglue to make things permanent on the vital bits. The result is remarkably robust, even surviving destruction testing by the cat (3ft onto the wood floor). Plus the plastic chairs look nice and are easy to cut when doing check rails etc. |

||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |