Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 3 Mar 2009 00:28 from: Sol

click the date to link to this post click member name to view archived images |

While I personally have not used Templot in hand building points/turnouts, I can see the value of it when starting a new layout but I do have a question that is applicable to all hand made points/turnouts. Has anyone used solenoid motors to operate the hand built units & specifically the new Side mounted solenoid units from Peco & Hornby ? If so, do you have blades hinged or as one l;long flexing rail? Ron |

||

|

posted: 3 Mar 2009 01:13 from: Nigel Brown click the date to link to this post click member name to view archived images |

I haven't used solenoid motors on handbuilt points for a long time (when I did I think they were Seep). I currently use Tortoise point motors, and install the switch blades as per the prototype; i.e. I've built GWR flexible switches, with the switch blade heel held in place by two chairs, and GWR loose heel switches, where the heel pivots in a single chair. Both work OK. I think solenoids would work as well, provided that they've got some sort of springing mechanism which will hold the blade in place. |

||

|

posted: 3 Mar 2009 10:14 from: Paul Boyd

click the date to link to this post click member name to view archived images |

Hi SolIf so, do you have blades hinged or as one long flexing rail?The answer to that is simply that it depends on the prototype! I would be wary of using solenoids on hand-built turnouts because I feel that the sudden action could stress any soldered or glued joints. Over time, this could result in a failure. If I was to use ready-made turnout motors I would go with Tortoise although I'm experimenting with memory wire motors. Cheers |

||

|

posted: 3 Mar 2009 12:56 from: Martin Lloyd

click the date to link to this post click member name to view archived images |

We've used solenoid motors on two exhibition layouts, (Biggleswade in 00 and Stainmore Summit in EM) both with hand built points. We very rarely have failures of soldered rail to stretcher bar soldering but I dislike this type of motor. We have used Peco and Seep motors and neither of them is really reliable. They supposedly have ways of holding the switch blades over once they have been thrown but quite often don't succeed. Peco motors either rely on the spring in their proprietary points or you have to purchase an additional locking plate (which contains the same omega spring) if you use the motors on hand built points. They are a bit flimsy. Seep motors have a small spring which supposedly serves the same purpose but if the turnout offers some resistance the motor doesn't fully throw such that it doesn't lock out properly and the next power stroke, in the opposite direction is weaker. This is because the solenoid is starting from part way through its stroke. This in turn reduces the amount of effort the motor puts into the fully throwing the point home and so on. The only solenoid motor worth its salt is the old H&M motor but these are now collectors items. All solenoid motors require some form of capacitor discharge unit of some sort. I prefer the Fulgarex/Lemaco motors which are robust, slow acting and include micro switches which total upto 3 pole double throw (or 5 pole if you add extra switches). These switches are useful to return indication back to the panel, operating other motors (say in a crossover) and for interlocking with signals etc. With all these motors I have found that you need to position the motor far enough away from the stretcher bar to allow the motor to make its full stroke against the small movement of the point blades. The excess movement being absorbed by the flex in the piano wire operating rod. Martin 62005 |

||

| Last edited on 3 Mar 2009 12:56 by Martin Lloyd |

|||

|

posted: 3 Mar 2009 14:24 from: Glen Suckling

click the date to link to this post click member name to view archived images |

Hi Sol, Over the years I have tried just about every method of operating hand made points, from lever frames with tube and wire, solenoids of various types, screw drives and stall motors. Like Paul I recently bought some memory wire, at Guildex during a trip to europe, but I have not yet tried to use it. You are correct about solenoid motors being destructive although most of the destruction that I have experienced came from defective point construction (my workmanship). The solenoids will manage to find all of your weak solder joints, improperly glued chairs and ties (sleepers) etc. In that way solenoids may be a good thing because a properly constructed switch runs better and will last for ever - solenoid or not. I had some EM gauge points made which I made from Peco individulay components in the late 1950's and operated by H&M solenoids which survived until 2001 when I converted to O gauge. The H&M solenoids are still in use! If they were still in production I might not have switched to stall motors of which I find the tortoise to be the best. The other stall motors and screw drives that I tried are either burnt out or relegated to operating signals and accessories while the other solenoids are all long gone. As far as hinged or flexible switch blades go it really does not make much difference as long as the blades are a reasonable length. At one time I had some short switches, A4 ( short A3 ?) in an industrial siding which gave me some trouble until I cut them to create a hinge but if you use B or longer blades you will have no trouble. I use hinged blades but that has more to do with the era that I model and maintaining electrical isolation of the frog than it does with blade operation. Bullhead rail tends to be more flexible than flat bottom but if the blade is long enough you will not have a problem with either. I use code 125 bullhead rail in the visible sections and code 148 flat bottom through a longish tunnel and in the fiddle yard. I cannot help you on the side mount issue. I have stayed away from side mounted point motors on purely aesthetic grounds, although I do have a couple in the fiddle yard where they are not visible. These are just temporary until I get around to installing tortoises with rabits (or hares). I hope that this helps - I did not mean to be so long winded. Glen |

||

|

posted: 3 Mar 2009 20:27 from: Sol

click the date to link to this post click member name to view archived images |

Thanks gents for the various pieces of info - I still have some weighing upto do. Ron |

||

|

posted: 3 Mar 2009 22:42 from: wcampbell23

click the date to link to this post click member name to view archived images |

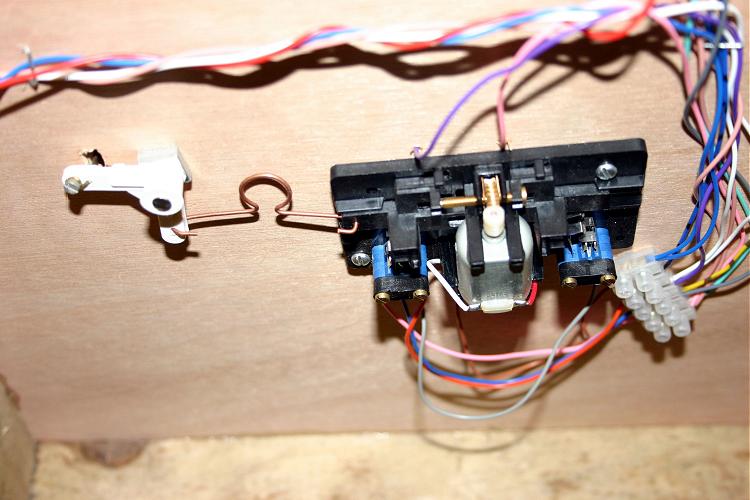

Martin Lloyd wrote: I prefer the Fulgarex/Lemaco motors which are robust, slow acting and include micro switches which total upto 3 pole double throw (or 5 pole if you add extra switches). These switches are useful to return indication back to the panel, operating other motors (say in a crossover) and for interlocking with signals etc. Hi everyone In our club layouts (East Kilbride MRC) we prefer to use this type of motor but not with the linkage suggested in the installation instructions. We use a crank or servo horn underneath the tie bar with an omega loop connection to the motor unit. We have found this much easier to install, adjust and maintain. A photograph of one of our installations is attached. bill_campbell_point_motor.jpg  Regards Bill Campbell |

||

|

posted: 8 Apr 2009 15:06 from: Stephen Freeman

click the date to link to this post click member name to view archived images |

Hi, Thought you might find this solution of interest, above and below shots of a Tortoise installation in 0 Gauge.gray1.jpg  tortoiseop2.jpg tortoiseop2.jpg |

||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |