Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 10 Sep 2019 09:39 from: RedgateModels

click the date to link to this post click member name to view archived images |

I'm planning a small layout with dual gauge standard and narrow gauge trackwork, this will involve some turnouts, with the narrow gauge track joining and leaving the standard gauge section, but also a custom built standard gauge turnout too. Will be using code 80 rail throughout (I have a lot of Peco "crazy track" to rob) Should I make the jump to OO-SF for the standard gauge trackwork? any pitfalls especially with the inclusion of narrow gauge flangeways etc or does the closer flangeways of OO-SF actually make sense in this application? |

||

|

posted: 10 Sep 2019 12:45 from: Ariels Girdle click the date to link to this post click member name to view archived images |

Depends on the wheels you plan to use for the stock. Much modern NG stock (eg Bachmann) has relatively fine flanges that will run through pointwork to P4 standards (I have tried!). If you already have stock then maybe best to do your own testing as few people actually do this sort of thing and all probably have a different variety of stock. | ||

|

posted: 10 Sep 2019 12:54 from: RedgateModels

click the date to link to this post click member name to view archived images |

Good point, at lease one NG loco will be using a Farish "08" chassis, so pretty old wheel specs. | ||

|

posted: 10 Sep 2019 14:32 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Narrow-gauge modellers often use the wheels and track standards from a smaller scale. For example 009 models at 4mm/ft typically use N gauge wheels. It defies logic to build a model where the wheels are to a different scale from the rest of the model, but it is a popular way to build a working narrow-gauge layout. Until that is, you want to build mixed-gauge pointwork. The important point to bear in mind for mixed-gauge track is that both gauges must use the same flangeway gap, and therefore need the same or similar wheel profile. For 00 RTR models, the practical minimum flangeway gap is 1.0mm (as 00-SF). But N gauge wheels require a flangeway gap of 0.85mm max. If they are run over crossings (frogs) having a 1.0mm gap they are going to fall into the crossings with a bump -- made worse by the small diameter of such wheels. If run over crossings having the standard 00 gap of 1.3mm they are very likely to derail. What to do about it? 1. most sensible -- use 4mm/ft scale wheels on 4mm/ft models, regardless of the track gauge. Discard the N gauge wheels. or 2. use sprung-wing crossings or swing-nose crossings to eliminate the flangeway gaps. Likewise use switch-diamonds for diamond-crossings. That would work very well for mixed-gauge, but it's a lot of work to do, and doesn't look right for UK narrow-gauge prototypes. or 3. devise your own track standard to accommodate your actual models. For example if the 00 models use only kit wheels (no RTR), such as Ultrascale/Alan Gibson/Markits wheels, you could possibly get the flangeway gap down to 0.85mm to match the N gauge wheels. The 00 track standard would then be: Check gauge: 15.2mm (same as for all 00). Flangeway gap: 0.85mm. Track gauge: 16.05mm. Back-to-back: 14.6mm (Ultrascale/Alan Gibson) 14.5mm (Romford/Markits) That might actually run very well for the 00 models providing there are no sharp train-set radii, but it won't work for 00 RTR wheels. Kit wheels only (and gentle curves only, if there are any Romford/Markits wheels). Gauge-widening needed for sharper curves. cheers, Martin. |

||

|

posted: 10 Sep 2019 14:42 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thanks Martin (I think LOL) I didn't realise that 00-9 track had such close flangeway gaps. I'll do some experiments but might have to compromise on 1mm as RTR OO stock is necessary - even if i have to put up with the OO-9 stock dropping in the crossings ..... In some of the cases the narrow gauge rails will leave the dual gauge section away from the OO "3rd rail" so the crossing can be to OO-9 standards as there is enough room in the back to backs to allow the OO wheel to run through .... hmmmmm |

||

| Last edited on 10 Sep 2019 14:47 by RedgateModels |

|||

|

posted: 12 Sep 2019 10:22 from: RedgateModels

click the date to link to this post click member name to view archived images |

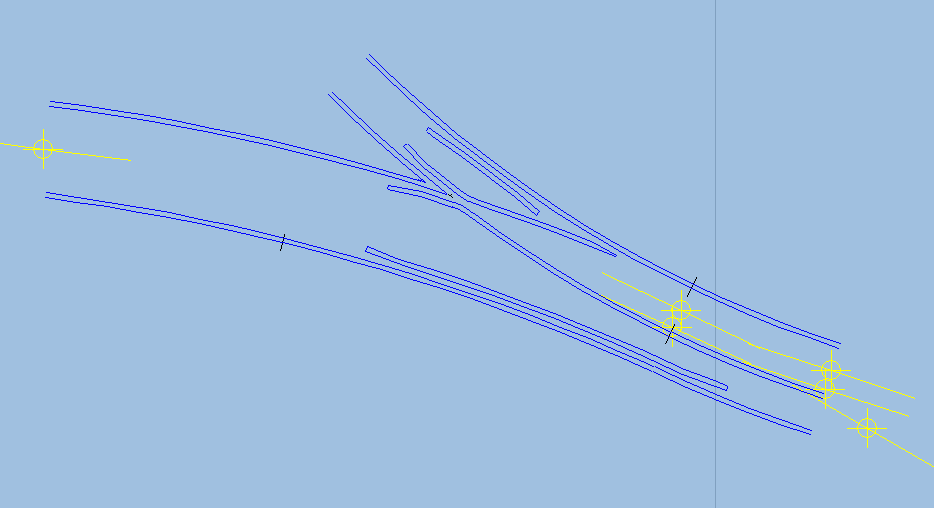

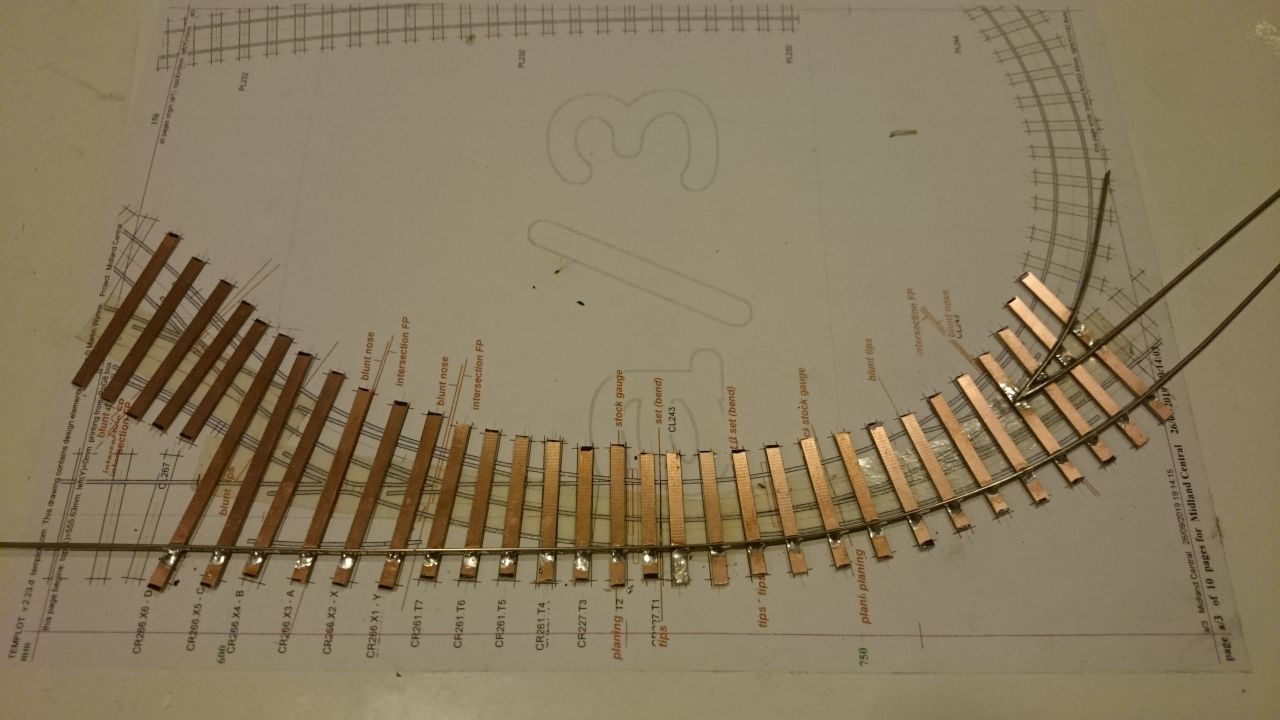

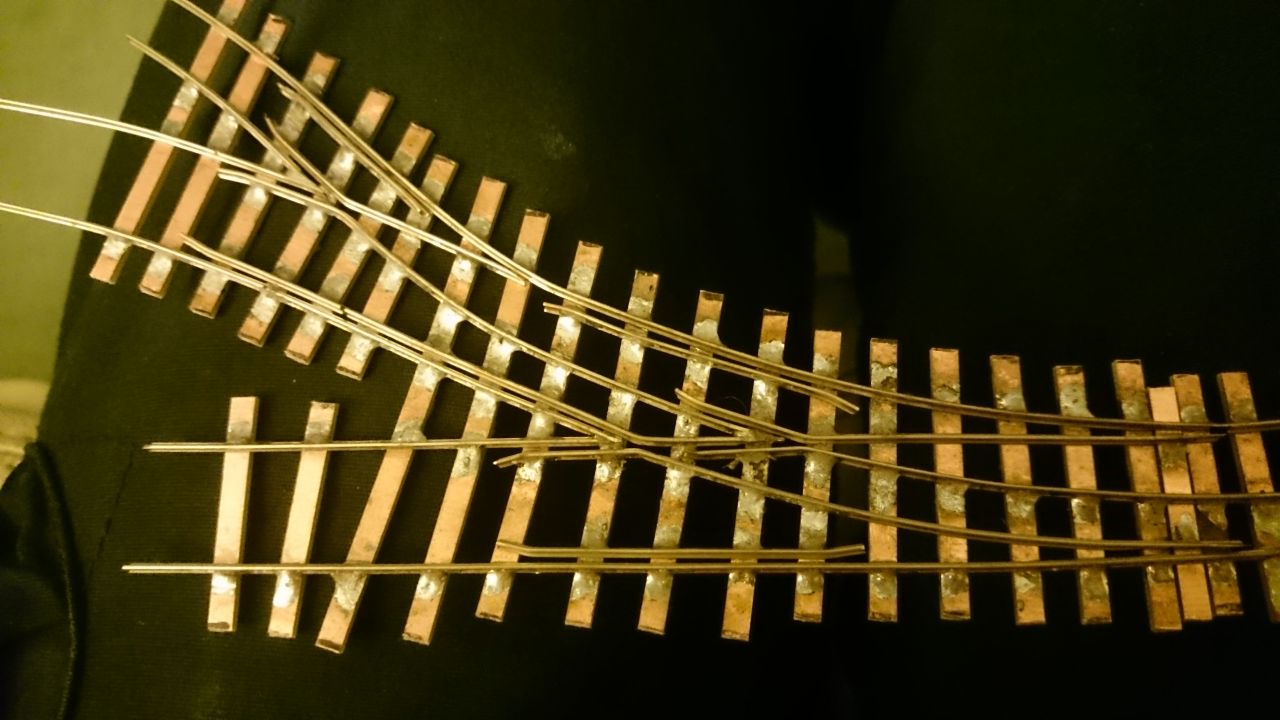

Had a little play last night, now this is VERY rough, I'm just working out the basic track plan at the moment but you can see the beginnings of the dual gauge track. Only one switch blade so far .... It will get more complex very soon though as I want a short standard gauge siding roughly where the "a" is on the plan. I realise the short length of dual gauge laid so far it far too tight a radius, this will be eased at some point. 2013_120510_110000000.jpg  Much to do, but it seems that I will need at least some 1mm flangeways so OO-SF (or a version of it) looks favourite |

||

|

posted: 13 Sep 2019 07:34 from: RedgateModels

click the date to link to this post click member name to view archived images |

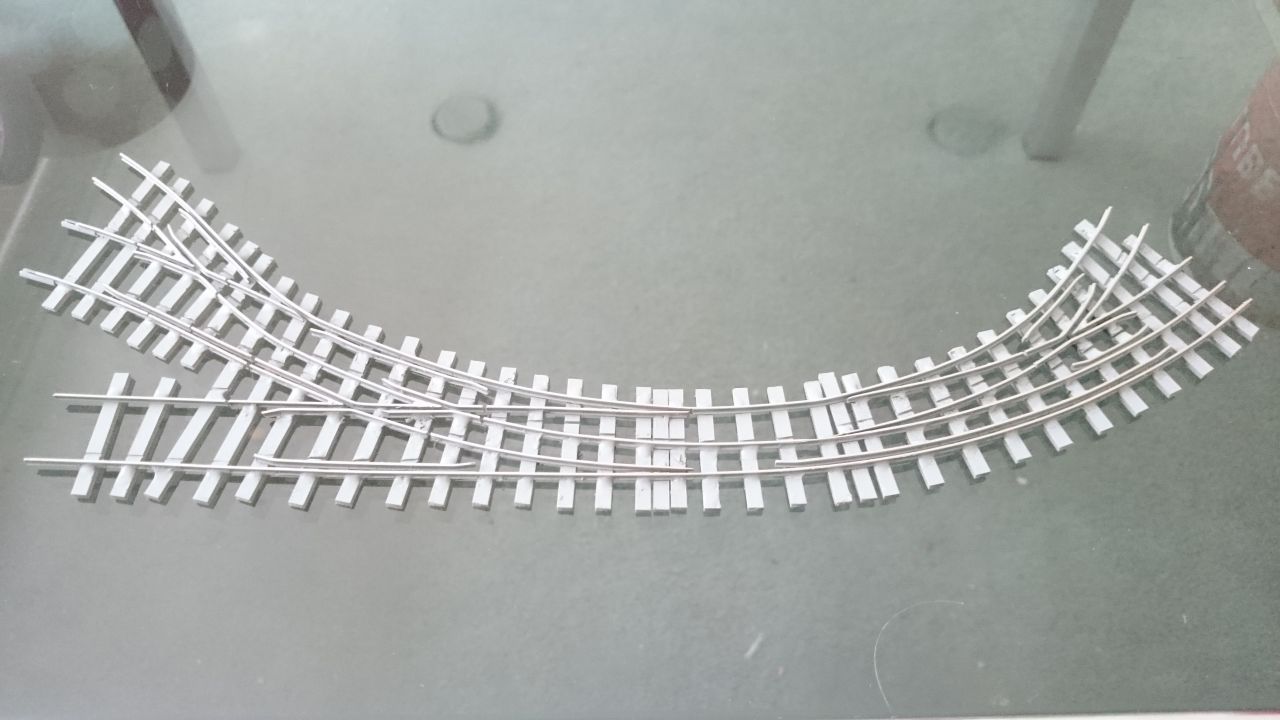

OK, getting there now, still no proper turnout templates, and frankly I have no idea how to start to convert the monster I have created. .box file left on the laptop too so will have to make do with a photo. Note carefully (!) drawn on common crossings .... 2013_130227_270000000.jpg  it's in OO at the moment too, will be to OO-SF standards through the crossings with 1mm flangeways when built, probably. Next steps are to order some PCB sleepers and gauges and have a go |

||

|

posted: 14 Sep 2019 09:19 from: RedgateModels

click the date to link to this post click member name to view archived images |

Good morning, I've had a look and can't see how to make a new template for dual gauge track. Can someone point me in the right direction? Ideally OO-SF and N gauges with sleeper spacing to 4mm/ft Thanks |

||

|

posted: 14 Sep 2019 17:32 from: Tony W

click the date to link to this post click member name to view archived images |

RedgateModels wrote: Good morning, I've had a look and can't see how to make a new template for dual gauge track. Can someone point me in the right direction? You will need to create 2 templates superimposed. I would first make the OO-SF template as this has the sleepering you require. Then you will need to create a second template over it at N gauge rail spacing, but with the common rail as the reference datum. Not quite so easy as Templot uses the track center line as the reference datum. If you try to change the settings to N-gauge for the second template this will alter the flangeway widths and timber settings. The timbers of the second template can be hidden, but any turnouts will have N-gauge flangeways and not be compatible with the OO ones. Regards Tony. |

||

| Last edited on 14 Sep 2019 17:34 by Tony W |

|||

|

posted: 14 Sep 2019 17:54 from: Martin Wynne

click the date to link to this post click member name to view archived images |

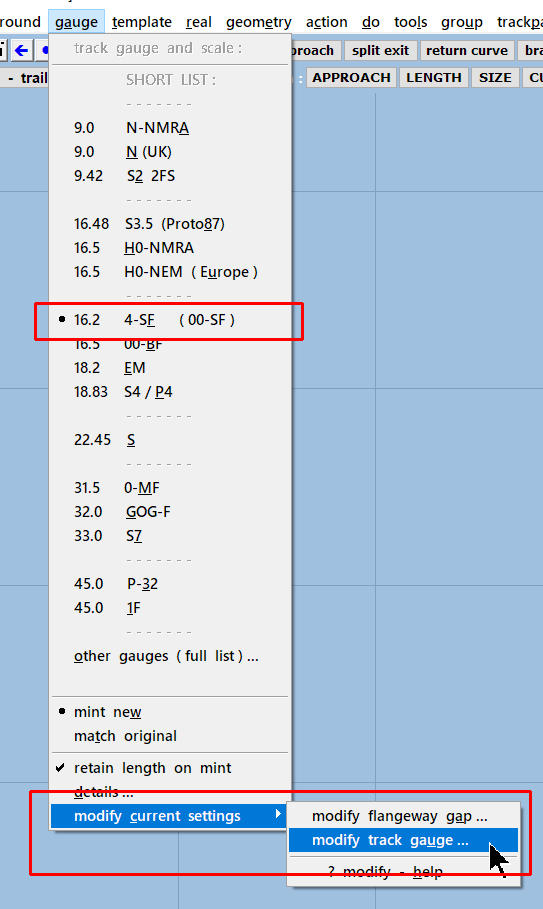

Tony W wrote:but any turnouts will have N-gauge flangeways and not be compatible with the 00 ones.Hi Tony, That's not the way to go, because the scales will be mixed -- a recipe for a total mess. Ian, ignore all the N gauge settings. For the narrow-gauge set to 00-SF and then change the track gauge to 9mm. You can do that at gauge > modify current settings > , or you can create a custom gauge/scale setting. That will also give you a common rail on one side. cheers, Martin. |

||

|

posted: 14 Sep 2019 18:08 from: Tony W

click the date to link to this post click member name to view archived images |

Hi Martin. That was what I was trying to imply, obviously not very clearly. Regards Tony. |

||

|

posted: 16 Sep 2019 08:27 from: RedgateModels

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Tony W wrote:Many thanks Martin, I only saw your message last night after I had packed away for the day. I need to make more tweaks anyway as I noticed that one check rail would have fallen where the switch blade taking the narrow gauge away from the dual gauge section was. I moved the half turnout and promptly put it over the baseboard strengthening rib!but any turnouts will have N-gauge flangeways and not be compatible with the 00 ones.Hi Tony, Do you think it will be possible to convert my rather unconventional arrangements into true turnout templates? |

||

| Attachment: attach_2893_3498_RpG1.box 152 | |||

|

posted: 16 Sep 2019 10:45 from: RedgateModels

click the date to link to this post click member name to view archived images |

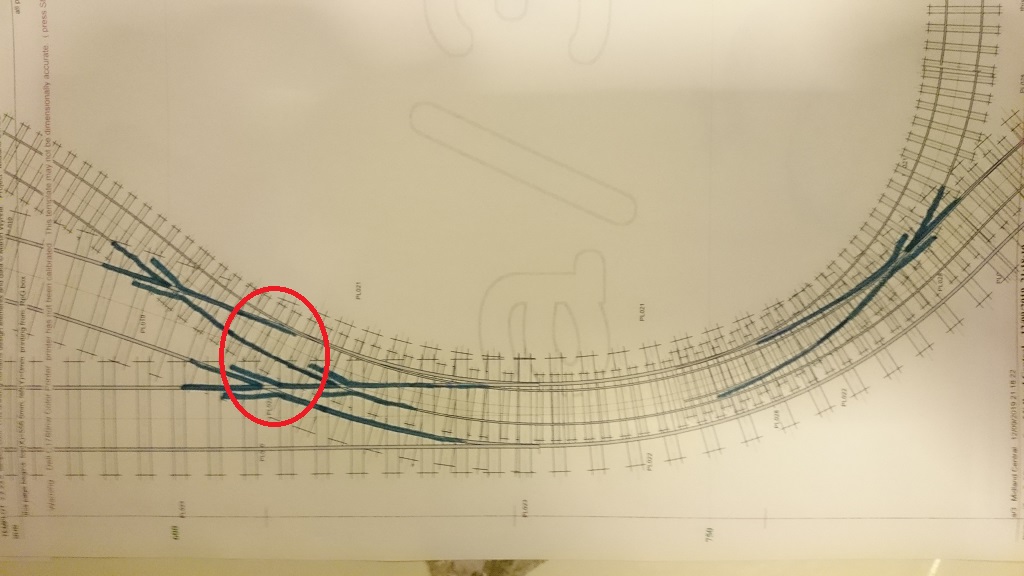

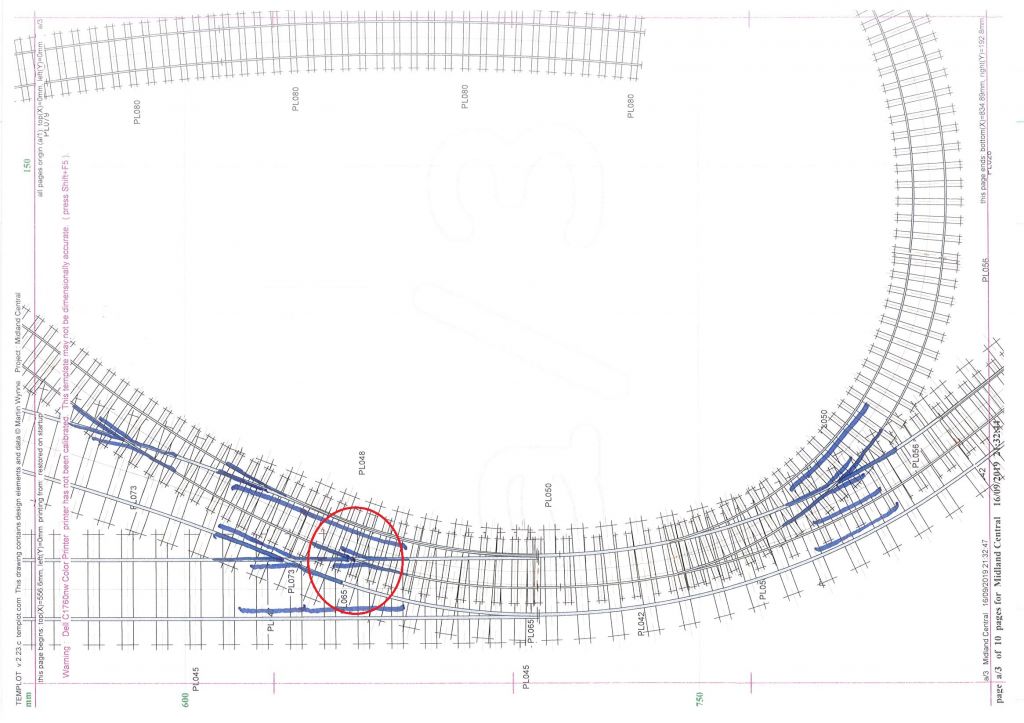

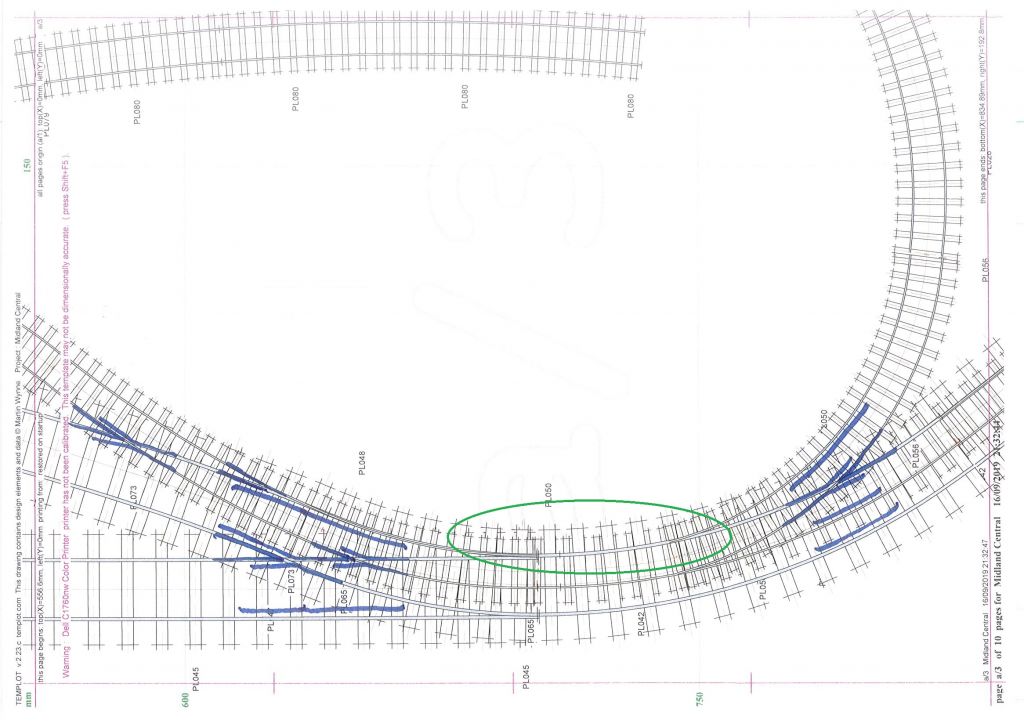

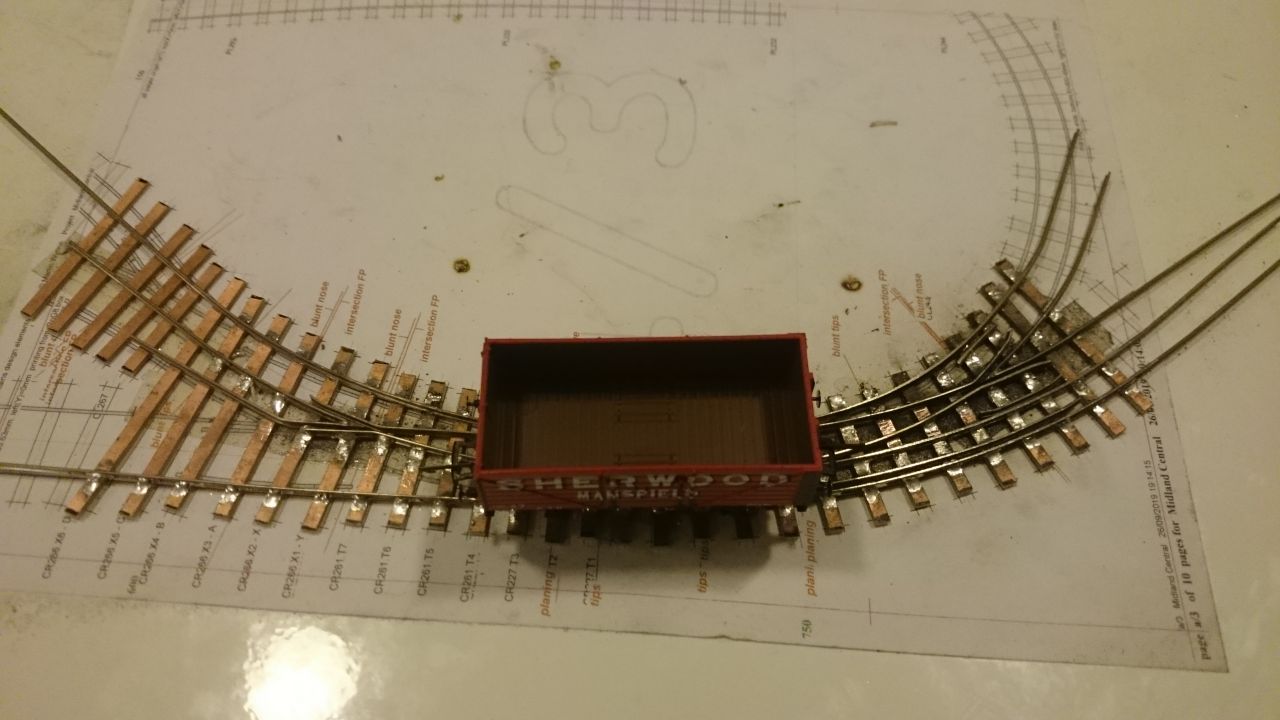

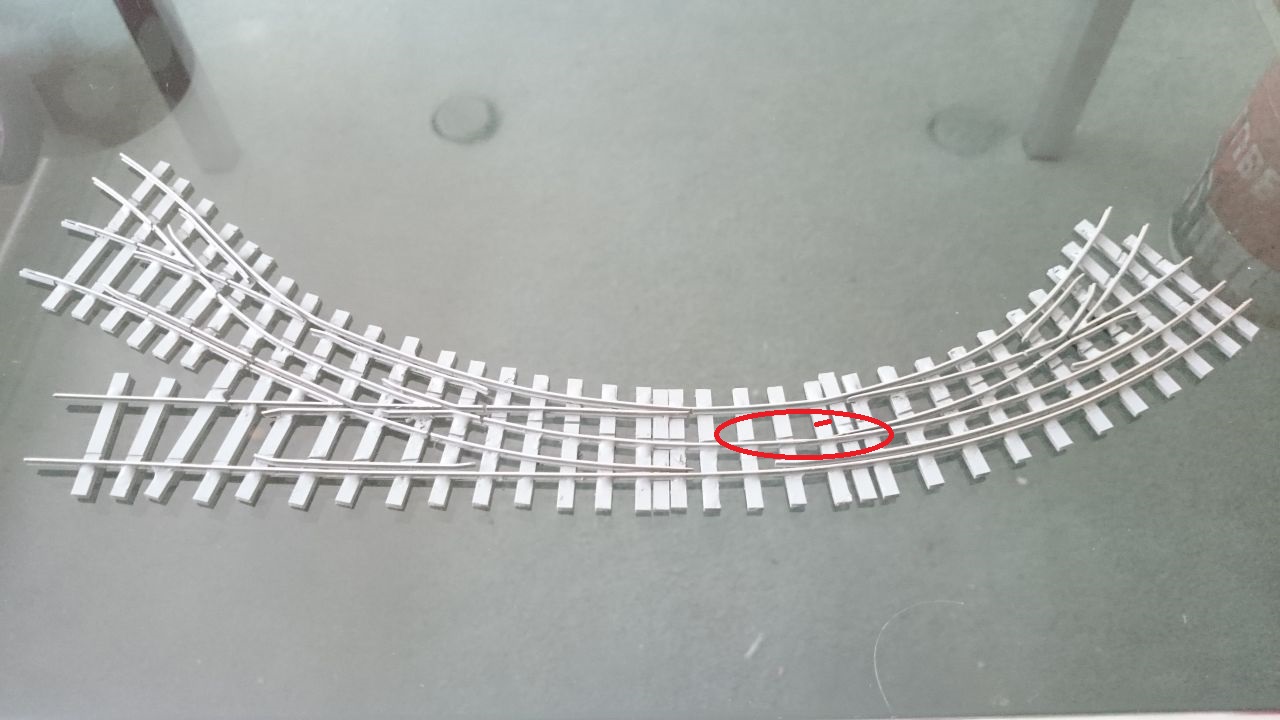

You can see the issue in the photo, circled in red. No room for the crossing checkrail unless I fixed it to the point blade! 2013_160541_090000000.jpg  As I said, I've moved the narrow gauge turnout away from the main one (with the double crossings) but it looks ugly and the tie bar falls over the baseboard rib. More jiggling with the plan needed. I'll move them closer and the whole arrangement a little to the right to clear the underboard obstructions. |

||

|

posted: 16 Sep 2019 12:23 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

RedgateModels wrote: You can see the issue in the photo, circled in red. No room for the crossing checkrail unless I fixed it to the point blade! With your very tight radii, it looks more like tramway track and in that case there wouldn't be a point blade in that position, but what would effectively be a half "K" crossing since you don't actually need a switch between the standard and narrow gauge tracks. If you've got a "Half K" then you will have check rails at the "K" which will check the other crossing. Jim. |

||

| Last edited on 16 Sep 2019 12:30 by Jim Guthrie |

|||

|

posted: 16 Sep 2019 12:51 from: RedgateModels

click the date to link to this post click member name to view archived images |

Like this?2013_160749_270000000.jpg  Solves two problems in one go EDIT: there is another turnout just off to the left on the narrow gauge trackwork that could be considered part of a "crossover" so I can use that crossing switch for now at least. A juicer might be better, but I'm waiting on a new test project from MERG for that. |

||

| Last edited on 16 Sep 2019 14:08 by RedgateModels |

|||

|

posted: 16 Sep 2019 16:06 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

RedgateModels wrote:

That's about it. Jim. |

||

|

posted: 16 Sep 2019 16:09 from: RedgateModels

click the date to link to this post click member name to view archived images |

I'll see if I can make some edits tonight. Thanks Jim |

||

|

posted: 16 Sep 2019 20:08 from: PRChappell

click the date to link to this post click member name to view archived images |

Martin I have been following this topic with interest mainly out of interest only as I do with all Templot topics. However, reading this message this evening I think there may be a wider issue here. I have spent part of today at our local model engineers club at Colchester CSMEE) where, amongst other things, we have a raised O Gauge/Gauge 1 combined oval of track with a passing loop. I note the comment asking for a mixed gauge template and wonder if a mixed gauge point template could be a possibility? This might be a wider general solution, with the user specifying the two gauges, and I am sure would be useful to many users in the larger scales. We also have a large 5/7.25" gauge track. By ignoring the straight road the original request would also be met. What do you think? Kind regards to Martin and all Temploters Peter |

||

|

posted: 16 Sep 2019 20:32 from: Martin Wynne

click the date to link to this post click member name to view archived images |

PRChappell wrote: I note the comment asking for a mixed gauge template and wonder if a mixed gauge point template could be a possibility?Hi Peter, Thanks for your thoughts. Templot has always been able to create mixed-gauge pointwork. See for example the sample mixed-gauge crossover here: topic 289 The .box file can be downloaded to see how it is made up from partial templates. Here is a copy of the download link: http://templot.com/samples/p4_gwr_mixed_gauge.box If you are asking for an automated function to create mixed-gauge pointwork, that would be a massive programming task, there are so many variables. The starting point in Templot is always the prototype, usually where there is mixed standard-gauge and narrow-gauge. I don't know how that would work for say mixed Gauge 0 / Gauge 1 -- what would be the model scale? What would the timber sizes be for example? The same applies to mixing 5" and 7.1/4" gauge pointwork, what would be the prototype? Also of course, mixed-gauge pointwork must have a common flangeway gap. For say mixed Gauge 0 and Gauge 1 that would mean using spring crossings or swing-nose crossings, and switch-diamonds, to avoid any wrong-size gaps. I will have a think about what might be possible. cheers, Martin. |

||

|

posted: 16 Sep 2019 22:09 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thanks all, more tweaks tonight and I've even started to put together a point template for the "main" dual gauge turnout. Got the crossing angle right etc but the length of the switches are too long and I need a very short if non existent approach length as there's a curve just before the blade tips... Anyone fancy a challenge? |

||

| Attachment: attach_2894_3498_RpG3.box 124 | |||

|

posted: 17 Sep 2019 07:59 from: RedgateModels

click the date to link to this post click member name to view archived images |

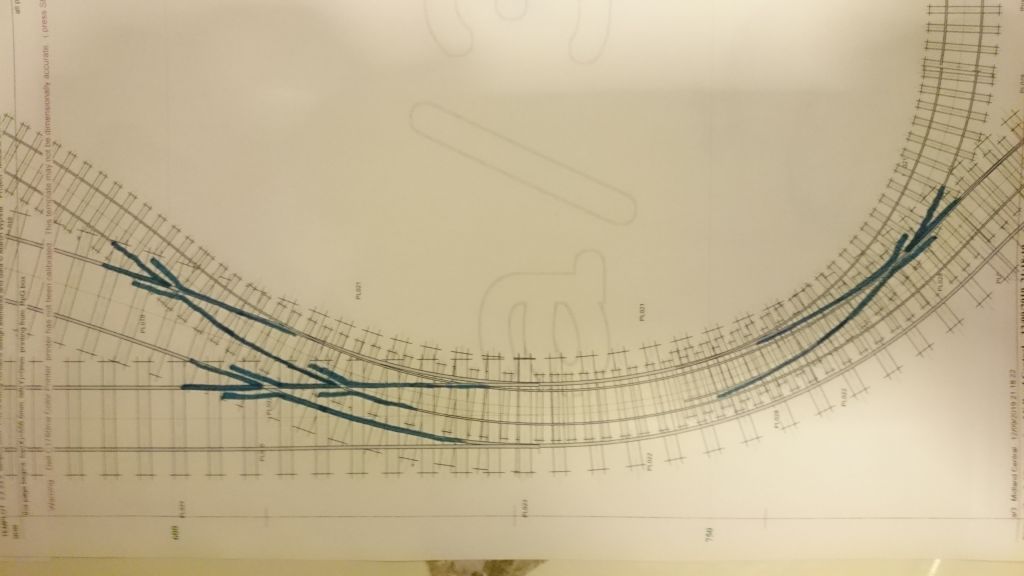

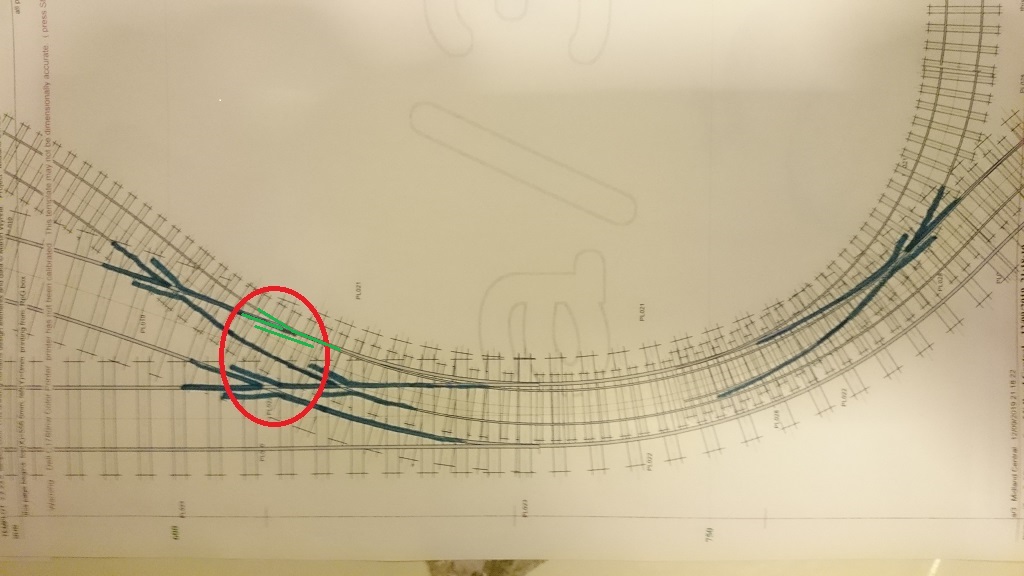

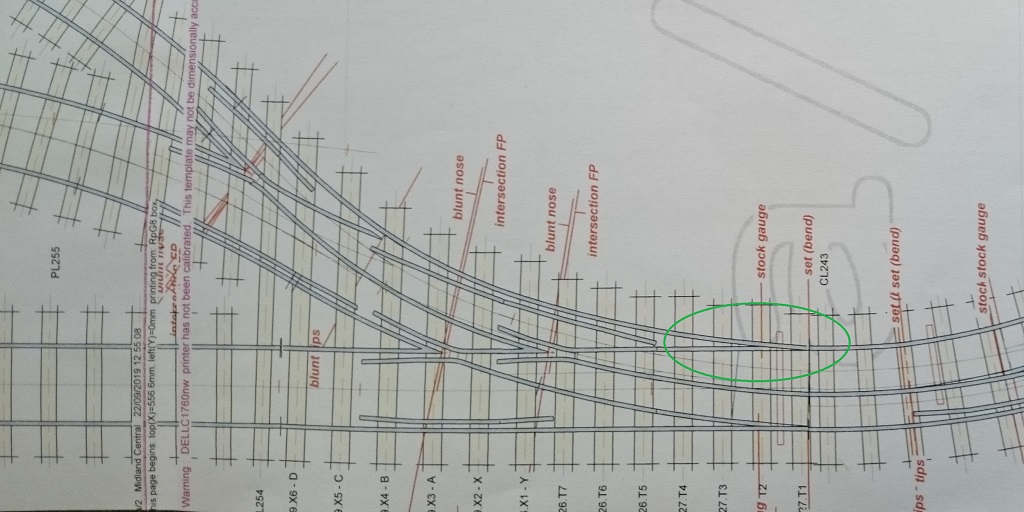

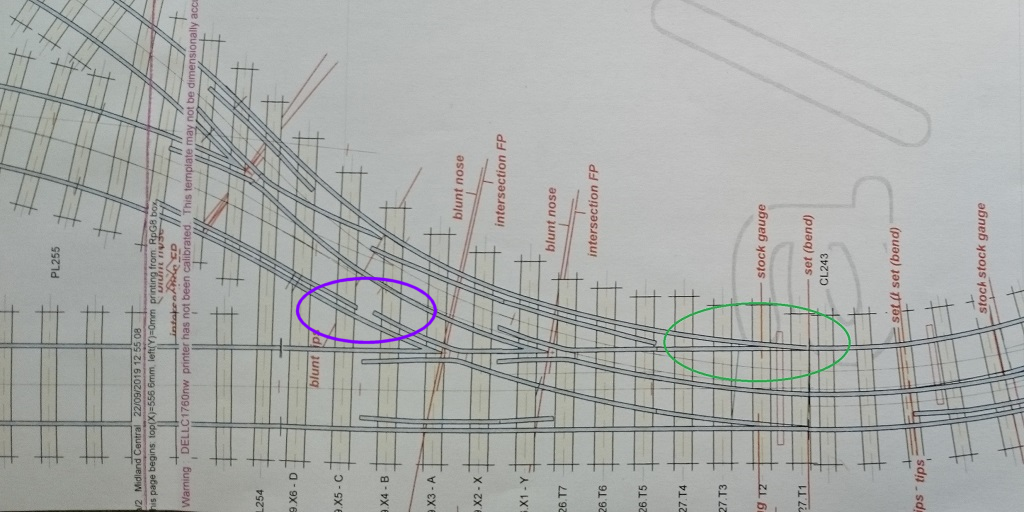

First thoughts this morning after looking at Martin's GWR mixed gauge example is should the circled crossing be a K? 2013_170255_370000000.jpg  Sorry Martin, i'm still scribbling on prints at the moment ..... Oh and another question, why when I change the gauge of a template does Templot whizz it off to somewhere else, generally off screen so I think it's disappeared? It would be nice for it to stay put. |

||

|

posted: 17 Sep 2019 12:20 from: RedgateModels

click the date to link to this post click member name to view archived images |

Think I've answered my own question, as the rails are not from the same "side" it needs to be a common crossing as scribbled |

||

|

posted: 17 Sep 2019 12:39 from: Martin Wynne

click the date to link to this post click member name to view archived images |

RedgateModels wrote:Oh and another question, why when I change the gauge of a template does Templot whizz it off to somewhere else, generally off screen so I think it's disappeared? It would be nice for it to stay put.Hi Ian, In your .box file you have two different gauge/scale settings in the same track plan, N gauge and 00. As I mentioned, that is never going to work. What you need to do is set 00-SF for the standard-gauge templates, and then click modify track gauge... for the narrow-gauge templates, so that everything is 4mm/ft scale, like this: 2_170730_420000000.png  Change it to 9mm gauge. You will still get some bumpy running as I mentioned, where the N gauge wheels run over the 1.0mm flangeway gaps. cheers, Martin. |

||

|

posted: 17 Sep 2019 12:44 from: RedgateModels

click the date to link to this post click member name to view archived images |

Ah, thanks Martin, knew there would be a reason. I'll have a go tonight, hopefully |

||

|

posted: 17 Sep 2019 13:06 from: RedgateModels

click the date to link to this post click member name to view archived images |

Following on from a question on the MERG forum, to remove the possibility of derailments from incorrectly set points could I change the circled switch blades for half K's and have just the remaining single blades controlling the direction? 2013_170806_170000000.jpg  |

||

|

posted: 17 Sep 2019 20:52 from: RedgateModels

click the date to link to this post click member name to view archived images |

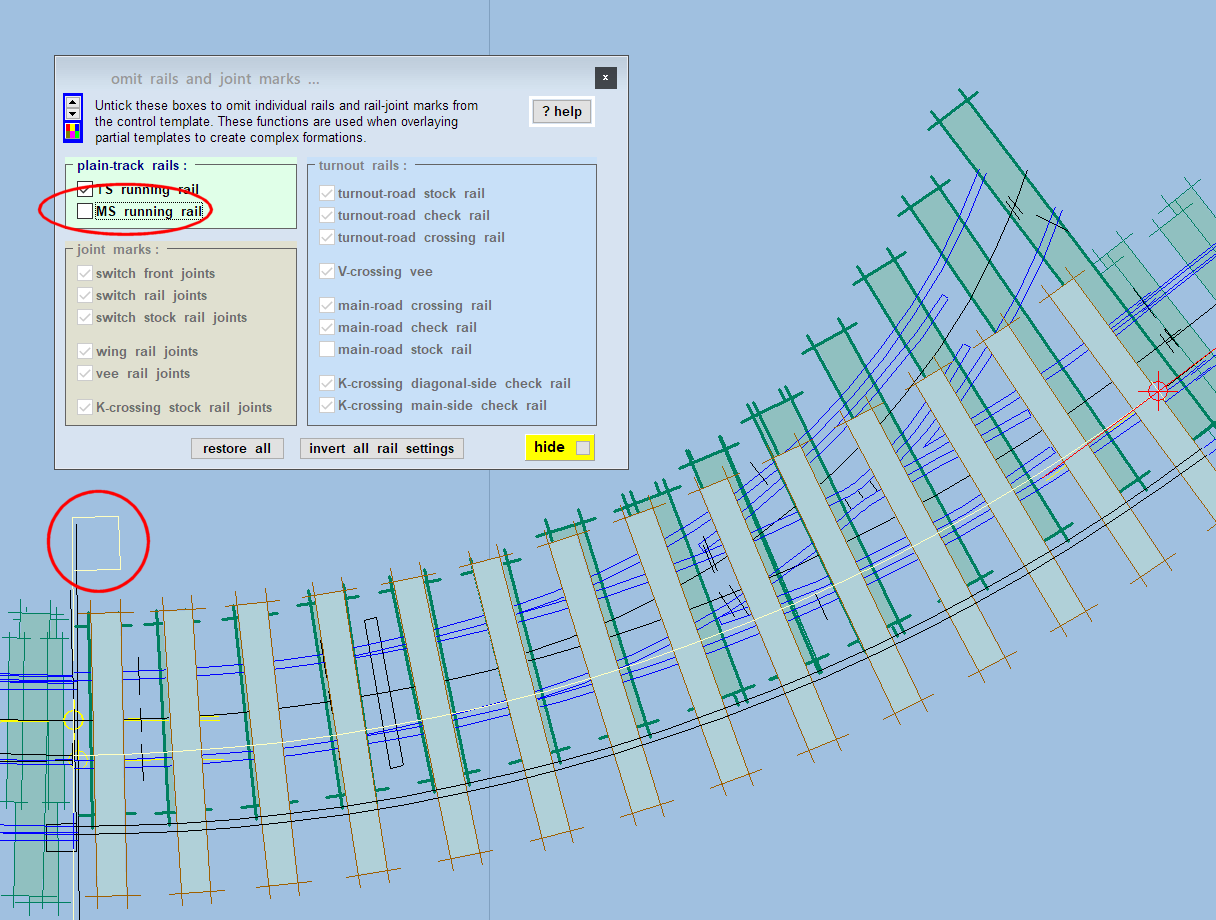

Thanks Martin, I believe I've got what you mean with the track gauge etc. I've even created the right hand narrow gauge only point template. Now,can I delete the extra rail from the standard gauge section that runs through it???? .box file attached |

||

| Attachment: attach_2895_3498_RpG4.box 84 | |||

|

posted: 17 Sep 2019 21:47 from: Martin Wynne

click the date to link to this post click member name to view archived images |

RedgateModels wrote: Thanks Martin, I believe I've got what you mean with the track gauge etc. I've even created the right hand narrow gauge only point template. Now,can I delete the extra rail from the standard gauge section that runs through it????Hi Ian, Untick this tickbox: 2_171643_280000000.png  That's at do > omit rails and joint marks menu item. You can see which is the MS side from the flag on the CTRL-1 end marker. cheers, Martin. |

||

|

posted: 17 Sep 2019 23:14 from: RedgateModels

click the date to link to this post click member name to view archived images |

Cheers Martin, can't believe I missed that option, looked at the do menu too. If I were to replace the top switch blade with a half k could it be done? With regards to the missing check rail on the standard gauge section should I change the plain rail to a turnout then delete everything apart from the lower rail and checkrail? I also have a plan for the standard gauge based turnout to get the curved approach - delete the stock rails and replace with partial plain track rails to the desired length and then shove a few timbers. Am I close? |

||

| Last edited on 18 Sep 2019 08:19 by RedgateModels |

|||

|

posted: 18 Sep 2019 09:16 from: RedgateModels

click the date to link to this post click member name to view archived images |

I'm itching to get on with this now (can you tell?), but can't install Templot at work (obviously) and only get the laptop at home when #2 son is in bed! | ||

|

posted: 18 Sep 2019 11:51 from: RedgateModels

click the date to link to this post click member name to view archived images |

just noticed that in making the "proper" turnout I have increased the crossing angle and thus the curve radius over the plain track mockup. Hopefully I can "roam" the crossing and reduce the crossing angle a bit to ease things later today. | ||

|

posted: 18 Sep 2019 13:47 from: Martin Wynne

click the date to link to this post click member name to view archived images |

RedgateModels wrote: I'm itching to get on with this now (can you tell?), but can't install Templot at work (obviously) and only get the laptop at home when #2 son is in bed!Hi Ian, I'm itching to get out in the sunshine. I have made you a quick bit of scruffy video: http://flashbackconnect.com/Default.aspx?id=EM_ENROSktwyUpc20zLIwQ2 p.s. put the peg at CTRL-0 when making gauge changes, I forgot to mention that in the video. cheers, Martin. |

||

|

posted: 18 Sep 2019 13:53 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thanks Martin, didn't know about the F9 crossing angle, I've been manually entering it |

||

|

posted: 18 Sep 2019 21:46 from: RedgateModels

click the date to link to this post click member name to view archived images |

Another go this evening, started with the other point etc. Now how do I drop in the half K and common crossing to allow the narrow gauge line to split off up to the Y turnout???? |

||

| Attachment: attach_2898_3498_RpG5.box 104 | |||

|

posted: 19 Sep 2019 01:50 from: Martin Wynne

click the date to link to this post click member name to view archived images |

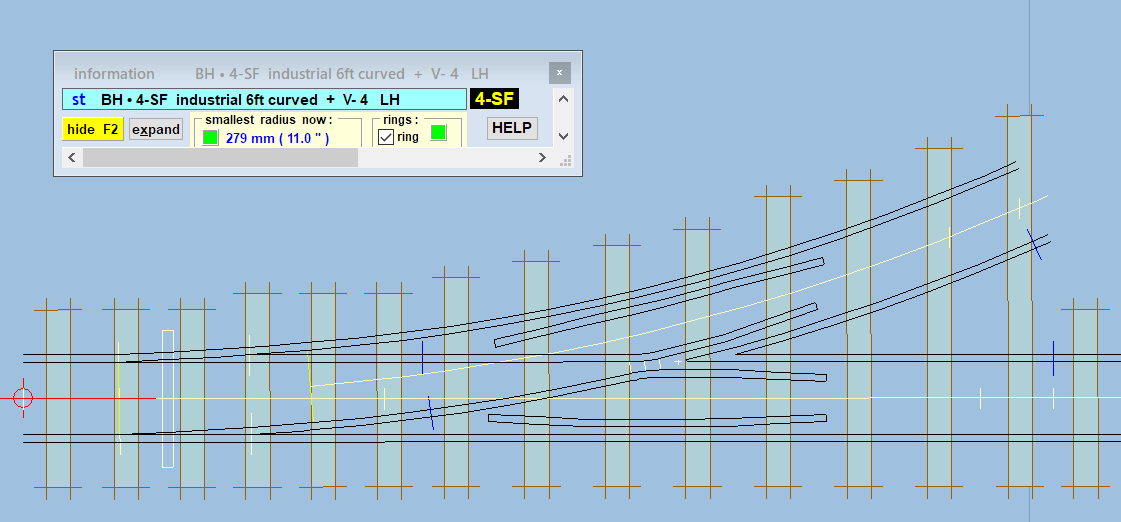

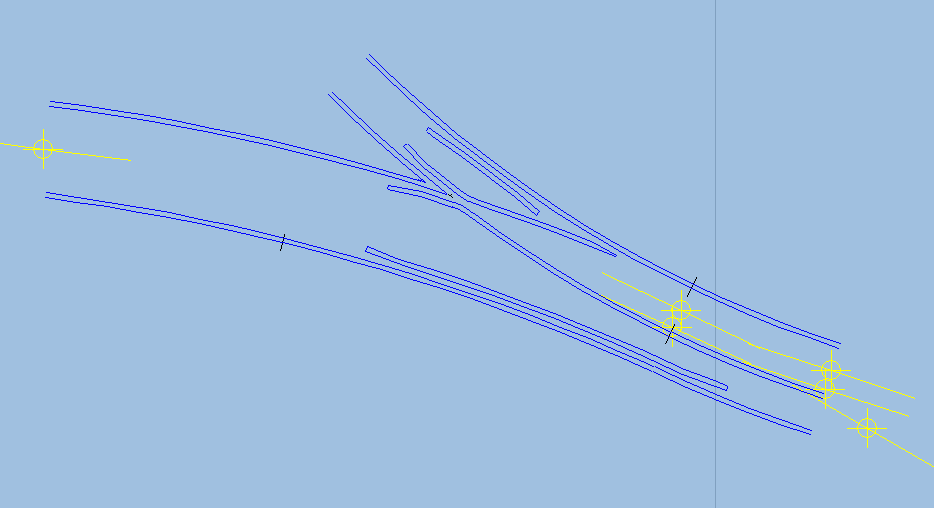

Hi Ian, What you are looking for is something like this: 2_182013_060000000.png  It's made up from 8 partial templates. Without your rather murderous reverse curve in the standard-gauge, it could probably be done with fewer. There is still the timbering to do of course. But it's rather more than your optimistic "dropping in" as you can see. To explain it fully from scratch is going to take me two or thee of hours of writing notes and making videos, and I'm afraid I just don't have time at present -- poor Bernard is still waiting for his metre-gauge tandems. All I can suggest is that you become a bit more familiar with Templot and working with partial templates on something simpler. There is an old video in this post about partial templates, but unfortunately unless you have Flash installed you won't be able to see it: topic 706 - message 3967 I will try to get a new one done soon. cheers, Martin. |

||

|

posted: 19 Sep 2019 07:35 from: RedgateModels

click the date to link to this post click member name to view archived images |

Yes that's exactly it 8 partials, wow. Yeah I realise that what I'm after is very unusual, but then if it was simpler I'd be using RTP ;) One question for today, promise. How can I produce a turnout with shorter switches? I guess I'm talking less than 1:24. Tonight's fun will be copying the Peco SL-E497. Have scanned it in so will import and try to match it dimensionally at least. Many many thanks for your help so far Martin |

||

| Last edited on 19 Sep 2019 10:52 by RedgateModels |

|||

|

posted: 19 Sep 2019 09:21 from: RedgateModels

click the date to link to this post click member name to view archived images |

Think I've found the answer - Mouse Action Real Adjust V Crossing Entry Straight? Also I've seen the use of CTRL F3, blanking. This would have removed the need for a couple of partials to get the switch tips right to the end of the turnout ... |

||

|

posted: 19 Sep 2019 12:38 from: Martin Wynne

click the date to link to this post click member name to view archived images |

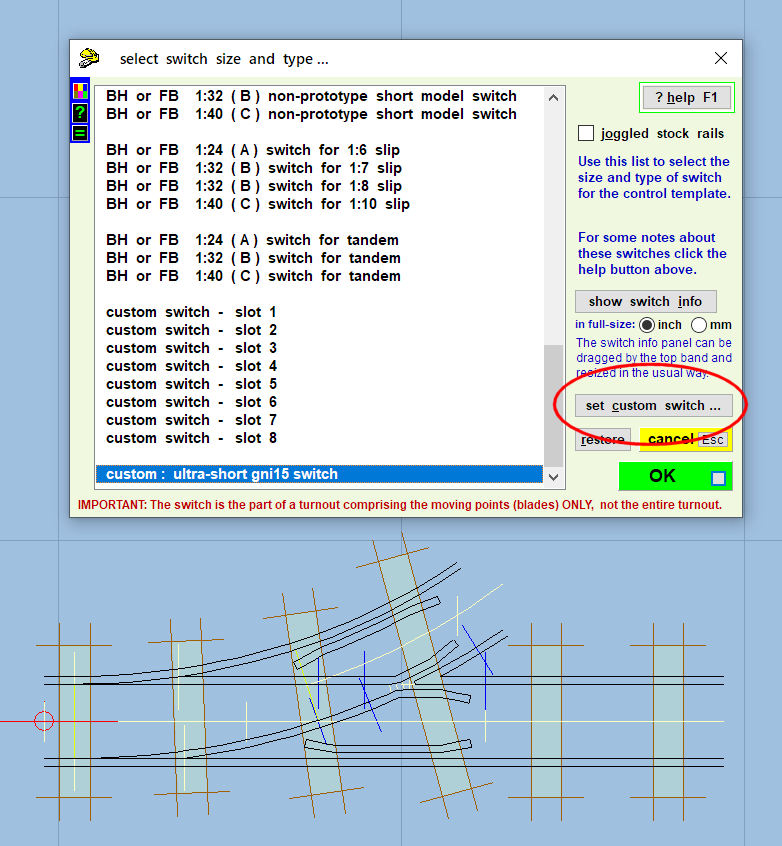

RedgateModels wrote: Think I've found the answer - Mouse Action Real Adjust V Crossing Entry Straight?Hi Ian, No, that won't shorten the switch, and is not available with curviform crossings. The shortest switch in the list of pre-sets is 1:24. You need to create a custom switch for something shorter, click the button: 2_190728_450000000.png  There is an extremely short custom switch in this old topic which you may be able to use instead of creating a new one: topic 280 - message 1566 The file can be downloaded from: http://85a.co.uk/forum/attachment.php?id=239 The custom switch will then be at the bottom of the list as shown above, which you can select for use in your turnouts. cheers, Martin. |

||

|

posted: 19 Sep 2019 12:45 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thanks again |

||

|

posted: 19 Sep 2019 13:15 from: RedgateModels

click the date to link to this post click member name to view archived images |

Looking at what I did last night I really need to sort out this shorter switch as using the 1:24 even with removing the rails before the switch tips forces the whole arrangement too far to the left and means a very tight curve to get everything joined up again. Thoughts of Half K crossings etc will have to wait ;) I have found some info on symmetrical Y points though and the .box file posted a while back should help a lot even though it's OO |

||

|

posted: 19 Sep 2019 14:54 from: Martin Wynne

click the date to link to this post click member name to view archived images |

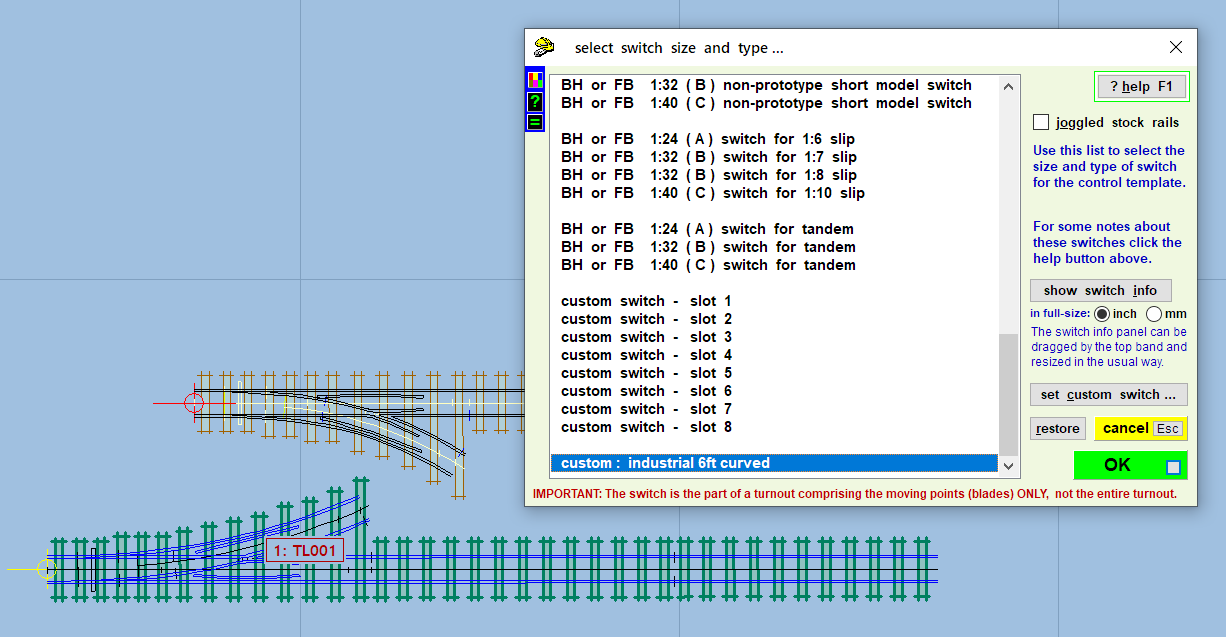

Hi Ian, It's a lovely sunny day. Switch the computer off and get outside. As I said, you need a short custom switch. I have come in just long enough to make you one: 2_190942_350000001.png  2_190942_350000000.png  It's a 6ft curved switch. After loading the attached .box file it will be in the bottom slot of the switch list, from where you can select it into your turnouts. Or alternatively use this turnout as-is. You can adjust the size to whatever you want using F5 or F9. At 1:4 it has a radius of 11" as above. At 1:3 the radius is 6". You can see the actual switch dimensions by clicking the show switch info button on the above dialog. It could probably be improved -- I did it very quickly off the top of my head, without proper prototype reference. cheers, Martin. |

||

| Attachment: attach_2899_3498_short_industrial_switch.box 79 | |||

|

posted: 19 Sep 2019 14:58 from: RedgateModels

click the date to link to this post click member name to view archived images |

lol, I'm at work. Many thanks again Domestic authorities have threatened a day out at the seaside on Saturday, that will halt any modelling plans! |

||

|

posted: 19 Sep 2019 21:23 from: RedgateModels

click the date to link to this post click member name to view archived images |

Well that was eventful, child breaks laptop so now I'm on my ancient Dell Inspiron 7000, under XP. Took a while but I'm set up, Templot runs surprisingly well Wifi is sketchy at best, so it will be plugged into the router when it comes time for printing ........ Good progress this evening, short switch point arrived at by modifying the one supplied by Martin and lo and behold I've made a fist at the K crossing narrow gauge exit. Timbering to sort and I've cheated by using the main road wing rail as a running rail but hey. Getting there now, any comments appreciated. |

||

| Attachment: attach_2900_3498_RpG6.box 135 | |||

| Last edited on 20 Sep 2019 07:38 by RedgateModels |

|||

|

posted: posted: 20 Sep 2019 20:17 from: RedgateModels

click the date to link to this post click member name to view archived images |

Doing the peco y tonight | ||

| Attachment: attach_2901_3498_SE-E497_Scan.jpg 135 | |||

|

20 Sep 2019 20:17 from: RedgateModels

click the date to link to this post click member name to view archived images |

One more file | ||

| Attachment: attach_2902_3498_peco_short_y_equiv.box 117 | |||

|

posted: 20 Sep 2019 20:57 from: Bernard Haste click the date to link to this post click member name to view archived images |

Bernard here! Just back from examining metre gauge track in Switzerland. When you get round TUIT for the three way points. I know you are busy. Many thanks, Bernard |

||

|

posted: 21 Sep 2019 09:05 from: RedgateModels

click the date to link to this post click member name to view archived images |

Well, 10 steps back, after cobbling a representation of the Peco SL-E497 the whole section does not fit. I've got to effectively scrap the k crossing section and start again. I'll make sure the standard gauge turnout fits the original sketch too. Oh well |

||

|

posted: 22 Sep 2019 13:54 from: RedgateModels

click the date to link to this post click member name to view archived images |

Rainly morning here in Mansfield and was left on my own, so much progress made Happy with this now, ok there are a few checkrails that are wonky and the K crossing on the right looks wrong but I think I have enough to start track building as soon as the N gauge roller gauges and sleepers arrive this week. |

||

| Attachment: attach_2906_3498_RpG8.box 133 | |||

|

posted: 23 Sep 2019 12:10 from: RedgateModels

click the date to link to this post click member name to view archived images |

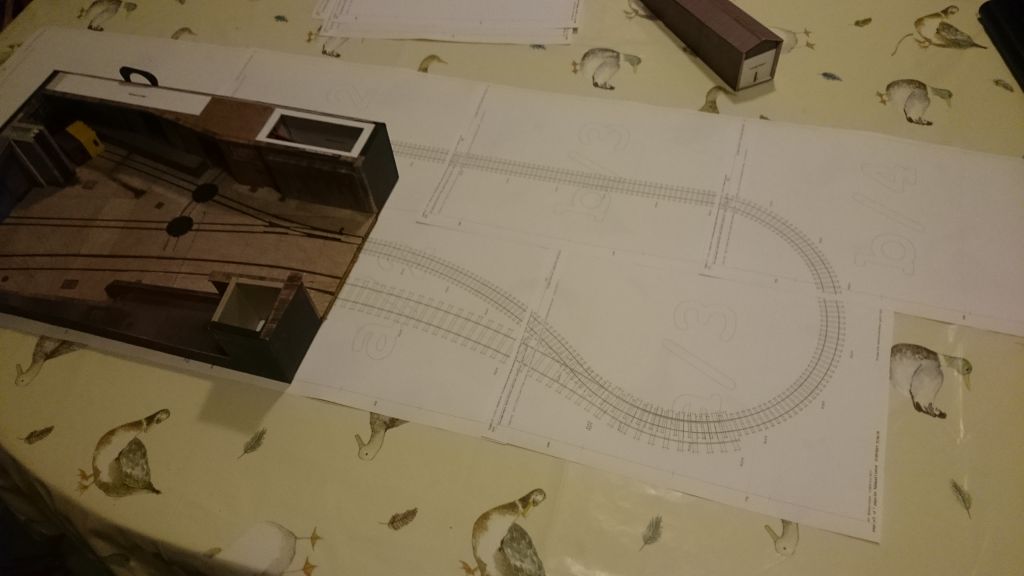

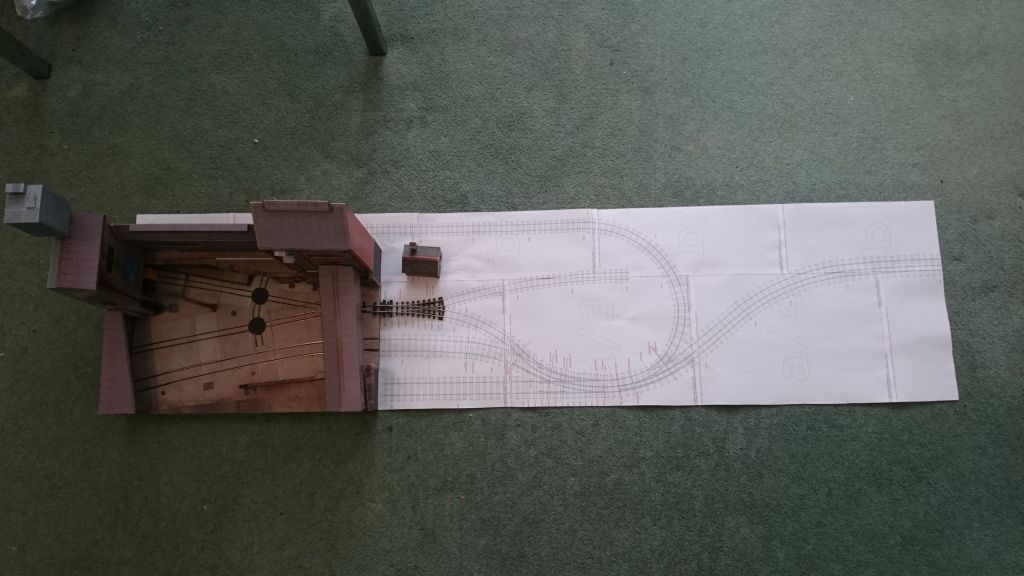

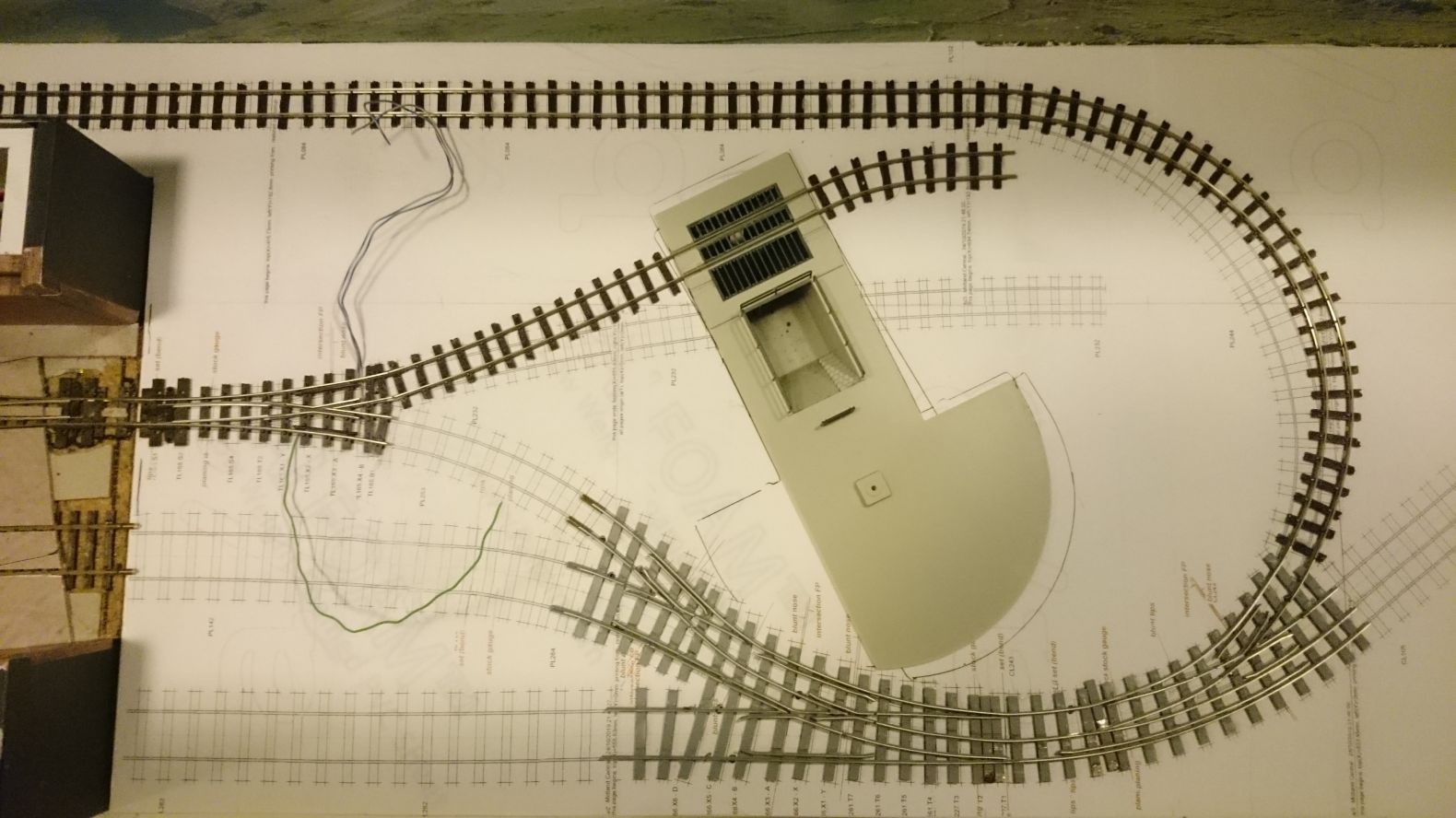

and for now here's a bird's eye view of how the new trackwork fits in with the existing Scalescenes Boxfile 2013_230709_100000000.jpg  Just waiting on a delivery of PCB sleepers and then I can get started |

||

|

posted: 23 Sep 2019 12:26 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Ian, Thanks for that. I've been wondering all along what you were trying to achieve. cheers, Martin. |

||

|

posted: 25 Sep 2019 21:18 from: RedgateModels

click the date to link to this post click member name to view archived images |

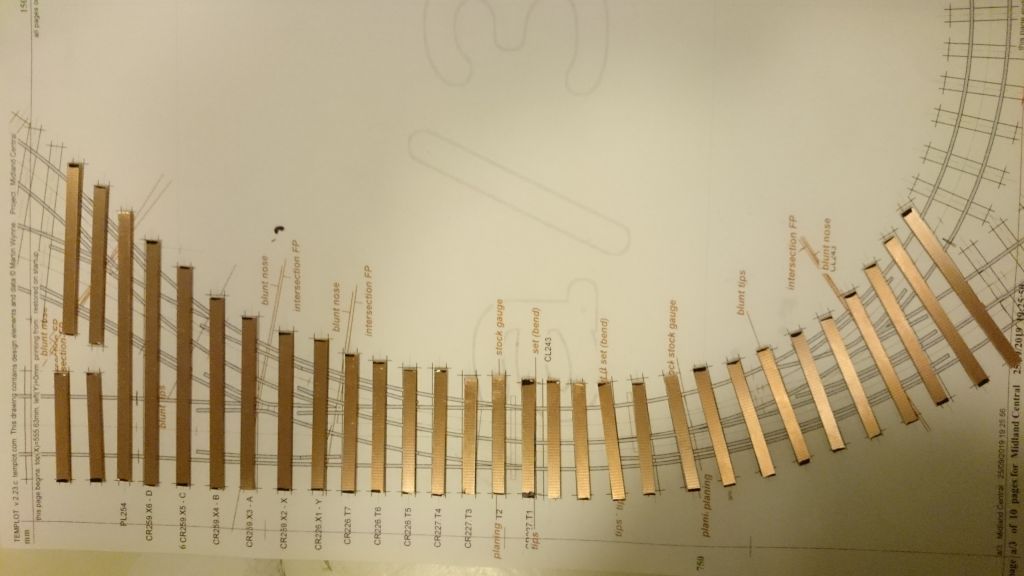

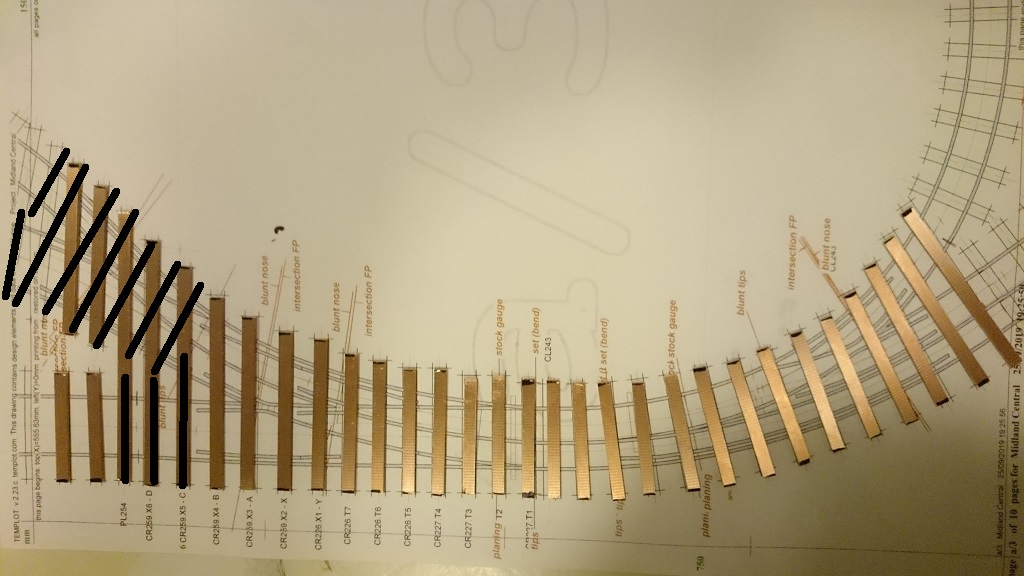

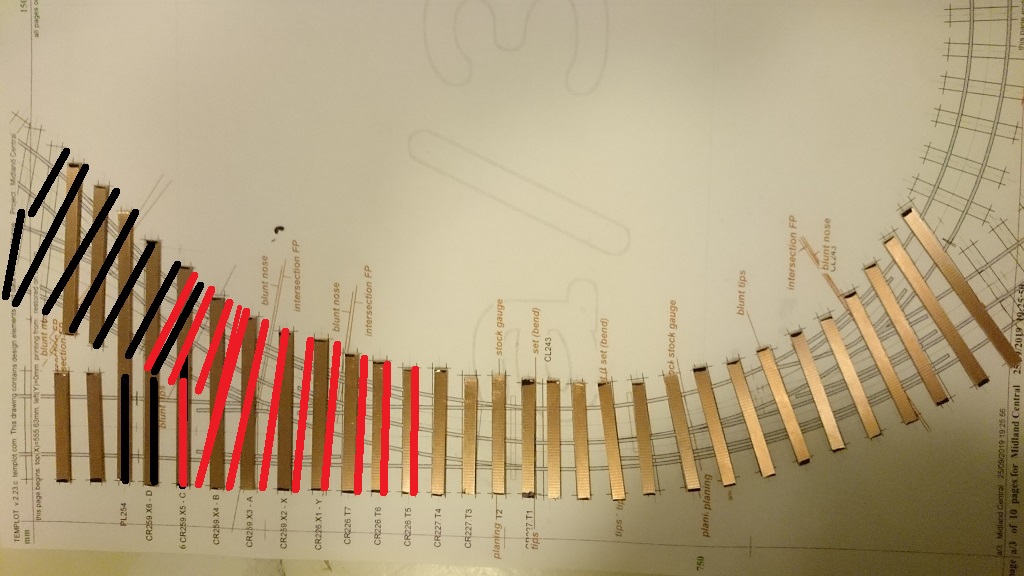

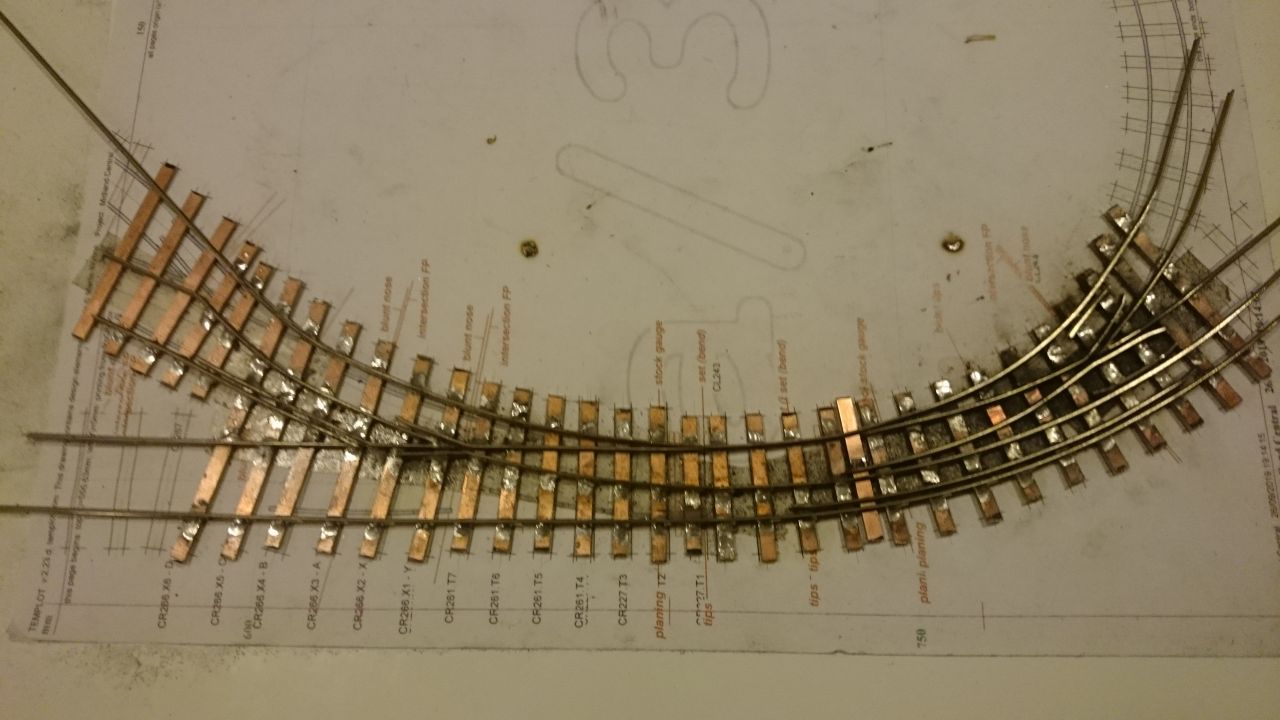

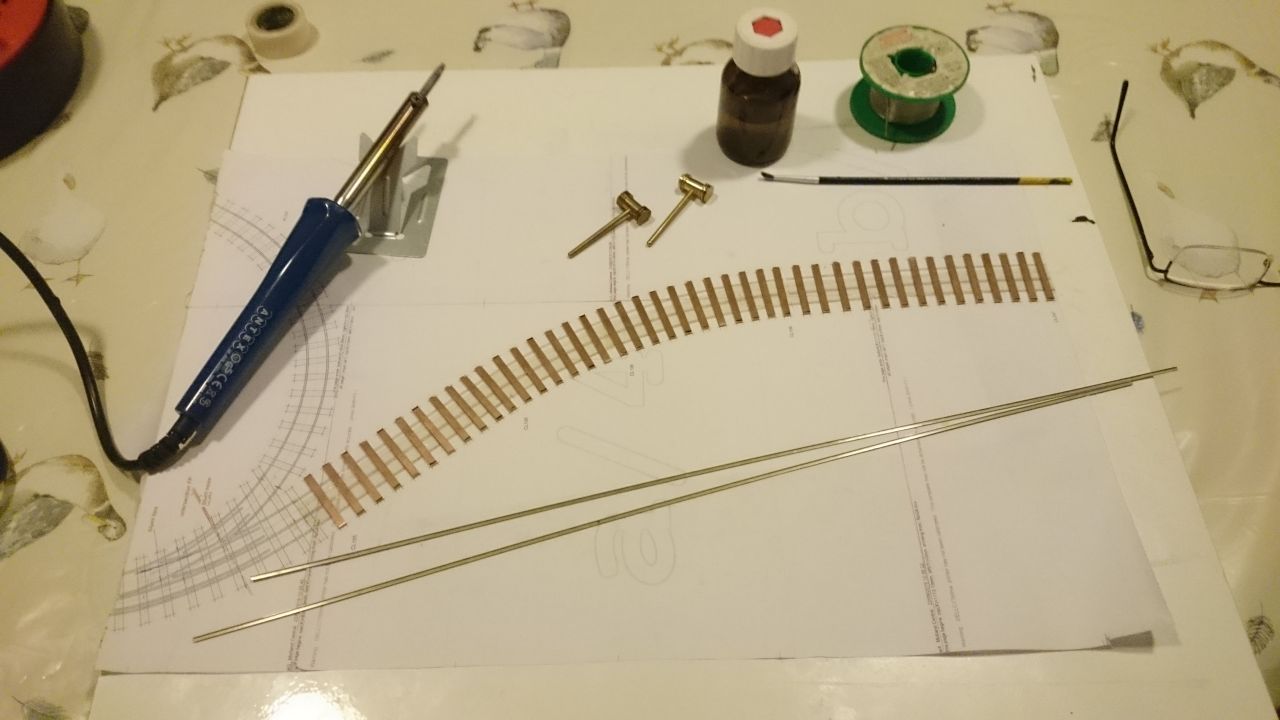

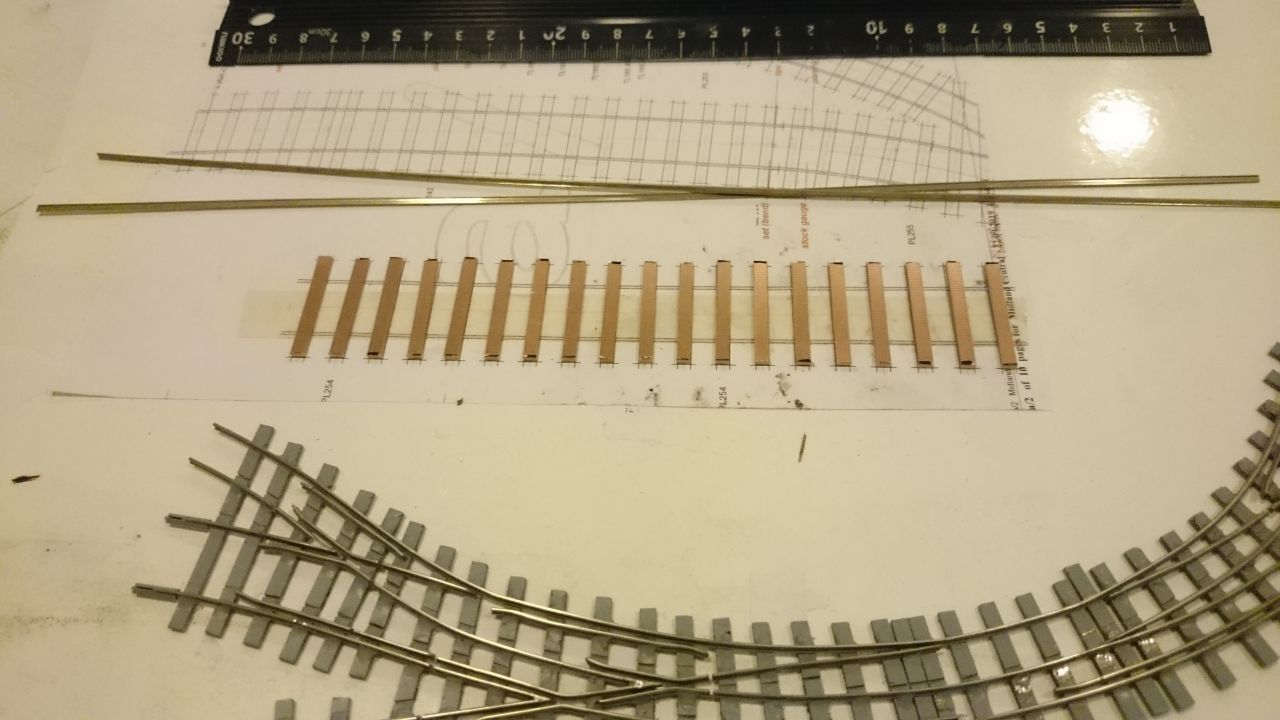

2013_251620_530000000.jpg Made a start Made a start |

||

| Last edited on 25 Sep 2019 21:21 by RedgateModels |

|||

|

posted: 26 Sep 2019 02:51 from: John Palmer click the date to link to this post click member name to view archived images |

A problem I can see with the lefthand-most narrow gauge turnout is the angle of the timbering. The extent of the timber skewing is such that I think it would be difficult to secure the special chairs for the crossing in 12" : 1' scale. A partial solution might be to adjust that turnout's timbering with 'Real' > 'Timbering' > 'Equalised'. choosing either incremental or constant according to what best suits the formation. This may also make it easier to interlace sleepers carrying the diverging n/g track. |

||

|

posted: 26 Sep 2019 07:34 from: RedgateModels

click the date to link to this post click member name to view archived images |

John Palmer wrote: A problem I can see with the lefthand-most narrow gauge turnout is the angle of the timbering. The extent of the timber skewing is such that I think it would be difficult to secure the special chairs for the crossing in 12" : 1' scale. A partial solution might be to adjust that turnout's timbering with 'Real' > 'Timbering' > 'Equalised'. choosing either incremental or constant according to what best suits the formation. This may also make it easier to interlace sleepers carrying the diverging n/g track.Thanks John, all input regarding timbering appreciated |

||

|

posted: 26 Sep 2019 07:46 from: RedgateModels

click the date to link to this post click member name to view archived images |

A sketch of what I should be aiming for would be great |

||

|

posted: 26 Sep 2019 09:20 from: Hayfield

click the date to link to this post click member name to view archived images |

How about some interlacing timberwork towards the heal of the crossings? | ||

|

posted: 26 Sep 2019 10:05 from: Bernard Haste click the date to link to this post click member name to view archived images |

I do hope they get better soon. | ||

|

posted: 26 Sep 2019 10:27 from: RedgateModels

click the date to link to this post click member name to view archived images |

Ha Ha, I see what you did there. Some constructive input on how I should arrange the sleepers perhaps? | ||

|

posted: 26 Sep 2019 11:19 from: RedgateModels

click the date to link to this post click member name to view archived images |

Something like this? 2013_260617_360000000.jpg  |

||

|

posted: 26 Sep 2019 12:08 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

It might also help if you equalise the timbers as far as the crossing nose then interlace the timbers on the exit roads after the crossing. Jim. |

||

|

posted: 26 Sep 2019 12:18 from: RedgateModels

click the date to link to this post click member name to view archived images |

More like this? 2013_260718_380000000.jpg  |

||

|

posted: 26 Sep 2019 17:31 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

Yes. Jim. |

||

|

posted: 26 Sep 2019 17:35 from: RedgateModels

click the date to link to this post click member name to view archived images |

I'll get nudging ;) | ||

|

posted: 26 Sep 2019 19:10 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

I was thinking that the turnout on the right side might also benefit from similar treatment. Jim |

||

|

posted: 26 Sep 2019 23:29 from: RedgateModels

click the date to link to this post click member name to view archived images |

Too late 2013_261829_160000000.jpg  |

||

|

posted: 27 Sep 2019 00:55 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

I think if you had been using chairs that you would had to have interlaced the timbers after the left hand crossing. :-) Jim. |

||

| Last edited on 27 Sep 2019 00:56 by Jim Guthrie |

|||

|

posted: 27 Sep 2019 11:10 from: RedgateModels

click the date to link to this post click member name to view archived images |

Probably true Jim, I think I've done enough "faffing" now and need to just get it built. Sleepers certainly look better though following your input. Hopefully my soldering will get better too, bet you can spot the first joint done LOL |

||

|

posted: 27 Sep 2019 15:04 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thanks for changing the topic title, I was looking how to do it |

||

|

posted: 27 Sep 2019 15:11 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Hi Ian, Are you using a liquid or paste flux ? If using liquid try using a little less and placing it at the junction of rail and PCB. Paste flux is good as it is easier to get just where it is wanted. The solder will usually only flow to where the flux is. Like you layout idea. Rob |

||

|

posted: 27 Sep 2019 15:17 from: RedgateModels

click the date to link to this post click member name to view archived images |

Liquid Rob, It just took a few to get back into the swing of it's been approx 5 years since I last built track ;) | ||

|

posted: 27 Sep 2019 15:26 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Practice makes perfect Ian. Have you got the rolling stock for the layout yet ? Rob |

||

|

posted: 27 Sep 2019 15:35 from: RedgateModels

click the date to link to this post click member name to view archived images |

Some, Kato diesel chassis and a farish 08 chassis for the NG, New Hornby Peckett for the Standard gauge and maybe the RMweb DJM Austerity if it can behave. Will need more wagons etc | ||

|

posted: 27 Sep 2019 19:10 from: Rob Manchester

click the date to link to this post click member name to view archived images |

Hi Ian, The Peckett is very nice. The Dave Jones Austerity is poor in my view but others like it. The chassis design is over complicated and neither of the two I had would run properly - the Hornby one is much simpler with slightly less detail. Rob |

||

|

posted: 30 Sep 2019 08:38 from: RedgateModels

click the date to link to this post click member name to view archived images |

Senior moment yesterday, couldn't work out why the solder was not flowing right, until I realised I was using Plastic Magic instead of phosphoric acid! I've got most of the right hand turnout done, but the NG diverging route check rail is way too long and is causing problems for the 0-6-0 chassis. Need to make it much shorter, just enough to ensure good running through the crossing. |

||

|

posted: 30 Sep 2019 09:13 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

RedgateModels wrote: I've got most of the right hand turnout done, but the NG diverging route check rail is way too long and is causing problems for the 0-6-0 chassis. Need to make it much shorter, just enough to ensure good running through the crossing.Have you got any gauge widening in the narrow gauge road since the radius looks very tight - even for narrow gauge? If you have applied some gauge widening then your check rail gap should be increased by the amount of gauge widening. If you have the normal check rail gap on that tight curve then you are probably asking for trouble with longer chassis where there is no room to allow for the angularity of the flanges of the outer axles. Jim. |

||

|

posted: 30 Sep 2019 09:17 from: RedgateModels

click the date to link to this post click member name to view archived images |

Yes Jim, there is some gauge widening and the check rail is currently way over the 1mm "standard" for this scheme. I need to tighten this however just at the crossing point to ensure smooth running through it. The check rail is frankly way too long and has to go. | ||

|

posted: 30 Sep 2019 11:27 from: RedgateModels

click the date to link to this post click member name to view archived images |

Having said all that I am very pleased with the way both standard and NG stock handle the half K crossing. It does look nothing like the Templot plan as expected. My first go with FB rail too, must remember to remove the foot where needed! |

||

|

posted: 30 Sep 2019 21:18 from: RedgateModels

click the date to link to this post click member name to view archived images |

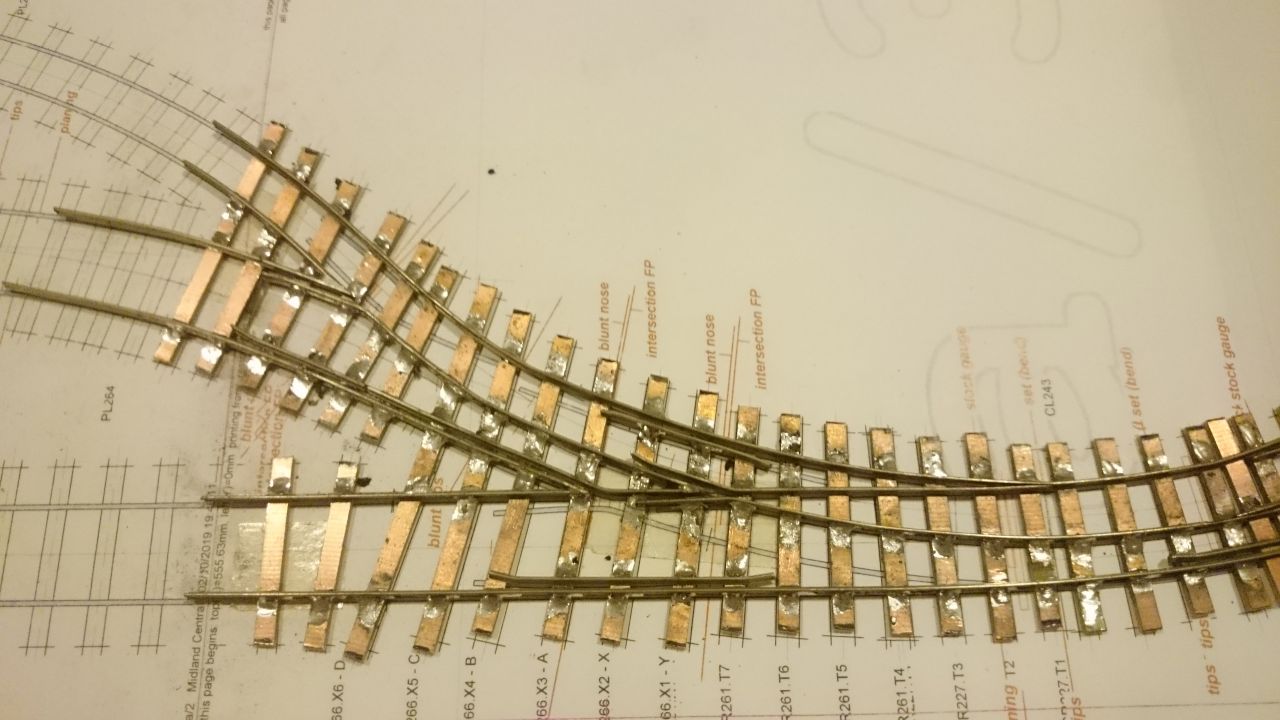

Progress this evening. The 16.2 routes are great, really smooth and the 009 exit works just with the 0-6-0 chassis. With a bit of weight should be fine 2013_301617_260000000.jpg  |

||

|

posted: 1 Oct 2019 07:41 from: RedgateModels

click the date to link to this post click member name to view archived images |

Realised last night that the main road switch blade on the left hand turnout should also be a half K as the narrow gauge diverging route could derail if the blades were set wrong. I was really happy with the fit of the blade to the stock rail too! 2013_010528_420000000.jpg  I have pondered long and hard over this one, and I could use an electrical solution to prevent the NG derailment by extending the diverging route crossing rail isolation break to just beyond the switch tips, the block cut-out would kill track power due to a short and I could then change the blades and away we would go. But this does not get rid of the idea that if this was real derailment could occur..... Oh well, it has to come out and be converted to a fixed rail, probably a good thing as by the time I've put an isolation gap in it the moving section would only have been secured to one sleeper - not good for long tern reliability. So only two moving blades left on the whole arrangement. |

||

| Last edited on 1 Oct 2019 11:28 by RedgateModels |

|||

|

posted: 1 Oct 2019 11:10 from: RedgateModels

click the date to link to this post click member name to view archived images |

Thinking about things how common is this approach of using 1 switch blade and a matching half K for controlling the route? I expect it would only be confined to yards etc as the security of two switches on main running lines is obvious. Seems like a reasonable approach for yards etc though as reducing the moving parts in turnouts would reduce maintenance etc. Certainly going to give my servos an easier time of things LOL |

||

|

posted: 1 Oct 2019 12:56 from: Martin Wynne

click the date to link to this post click member name to view archived images |

RedgateModels wrote: Thinking about things how common is this approach of using 1 switch blade and a matching half K for controlling the route?Hi Ian, Such designs were found in tram tracks, but in that case the wheels are guided by the special flanged tram rail and housed switch points. It won't work for ordinary standard-gauge because the opposite rail needs a check rail for the straight-ahead route. Which it can't have because the moving switch rail is in the way. See the long check rail in my previous diagram: 2_182013_060000000.png  In fact your design has a gap in that check rail just where it is needed: 2_010745_000000000.png  I'm intending in due course to use your mixed-gauge design as the basis for a tutorial on using partial templates. But you have gone ahead and built it at a rather more furious pace than we are used to in these parts. cheers, Martin. |

||

|

posted: 1 Oct 2019 13:02 from: RedgateModels

click the date to link to this post click member name to view archived images |

Could the open switch blade act as a check rail? That's how the NG main route is controlled on the right hand turnout ..... Thanks for pointing out the gap, I had spotted it and intend making it as your version, I'm just not as good as you with partial templates ;) Furious pace? blimey, I was worried I was procrastinating too much over it LOL - there are electronics, scenery, locos etc to build too ..... |

||

| Last edited on 1 Oct 2019 13:11 by RedgateModels |

|||

|

posted: 1 Oct 2019 13:20 from: Martin Wynne

click the date to link to this post click member name to view archived images |

RedgateModels wrote: Could the open switch blade act as a check rail? That's how the NG diverging route is controlled on the right hand turnout ....Hi Ian, No, because to act as a check rail it would be open by only 1.3/4" and the wheel flanges would hit the tip of it. Also generally it is bad news for wheels to hit the back of an open switch blade because it can damage stretcher bars and detection gear -- see the RAIB report on the Grayrigg accident. Admittedly that hardly applies for industrial sidings, but even so the lateral forces on check rails can be considerable in sharply curved track, and switch blades are not designed to resist it. In the open position they are unsupported and entirely free. That is not the case in tram track. cheers, Martin. |

||

|

posted: 1 Oct 2019 13:27 from: RedgateModels

click the date to link to this post click member name to view archived images |

hmmmm, OK so I keep the left hand blades as they are and need to consider the NG section of the right hand turnout. Bit loathed to change that now. I'll solder a temporary "tie bar" to the single blade and see how stock runs through in the straight ahead position from the toe direction. |

||

| Last edited on 1 Oct 2019 13:32 by RedgateModels |

|||

|

posted: 1 Oct 2019 16:01 from: Ariels Girdle click the date to link to this post click member name to view archived images |

RedgateModels wrote: Could the open switch blade act as a check rail? That's how the NG main route is controlled on the right hand turnout .....Some early railway turnouts were like this, but it was high maintenance because of the buffeting the single blade took when acting as a check rail etc. |

||

|

posted: 1 Oct 2019 16:09 from: RedgateModels

click the date to link to this post click member name to view archived images |

Ariels Girdle wrote: RedgateModels wrote:Good to know, I'll see how the built turnout performs and then decide on the other, but I do have an electrical solution to prevent derailments through that one at least.Could the open switch blade act as a check rail? That's how the NG main route is controlled on the right hand turnout .....Some early railway turnouts were like this, but it was high maintenance because of the buffeting the single blade took when acting as a check rail etc. |

||

|

posted: 1 Oct 2019 21:26 from: RedgateModels

click the date to link to this post click member name to view archived images |

So the NG stock seems to behave with the switch blade working as a check rail. I'll keep it like that. Progress on the left hand side too. I knew there was a problem with the templot plan around where the NG track departs, track gauges helped align things. It has a bit of a kick sideways so the curve is not as smooth as it could be but stock runs through fine. Onwards 2013_011620_400000000.jpg  |

||

| Last edited on 1 Oct 2019 21:27 by RedgateModels |

|||

|

posted: 2 Oct 2019 08:15 from: Phil O

click the date to link to this post click member name to view archived images |

The narrow gauge check rail looks to be a bit short at the right hand end, it should be extended back one more timber to cover the knuckle. Phil |

||

| Last edited on 2 Oct 2019 18:29 by Phil O |

|||

|

posted: 3 Oct 2019 07:59 from: RedgateModels

click the date to link to this post click member name to view archived images |

More progress last night, printed the adjoining section of plan and replaced onto a clean copy, looks better already. I can already see another check rail that is too short .... 2013_030257_190000000.jpg  |

||

|

posted: 3 Oct 2019 10:18 from: RedgateModels

click the date to link to this post click member name to view archived images |

Phil O wrote: The narrow gauge check rail looks to be a bit short at the right hand end, it should be extended back one more timber to cover the knuckle.I see what you mean Phil, however things are very tight through that section, any lengthening of that check rail will have to follow along the same lines as the end of the current item due to the need for the 0-6-0 chassis to get round the curves, so not sure if it will actually contribute anything. I will look at it once the main construction is complete. I will be replacing some heat damaged sleepers in that area anyway. |

||

|

posted: 3 Oct 2019 18:34 from: Phil O

click the date to link to this post click member name to view archived images |

If the check rail doesn't cover the knuckle, you may well get derailments in the facing direction with wheels striking the 'Vee'. | ||

|

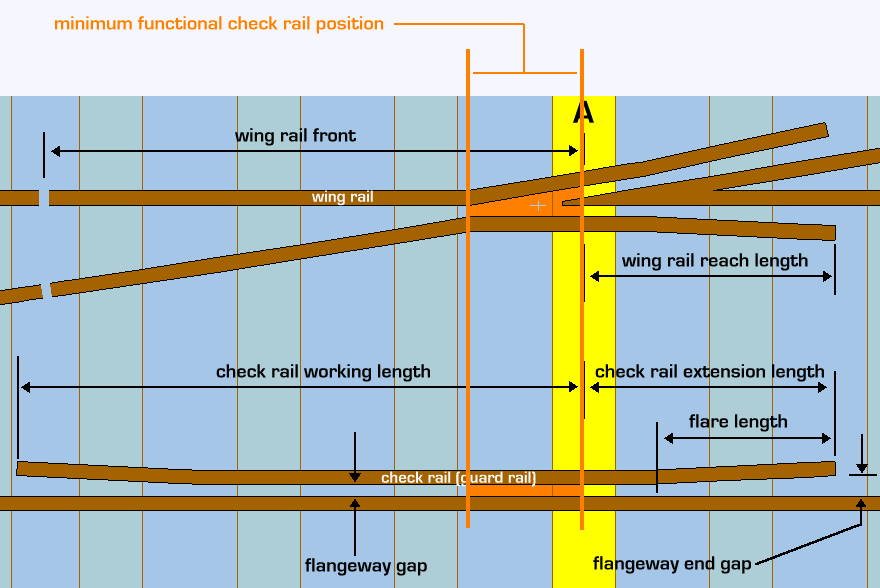

posted: 3 Oct 2019 22:26 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Phil O wrote: If the check rail doesn't cover the knuckle, you may well get derailments in the facing direction with wheels striking the 'Vee'.Hi Ian, As Phil explained, the purpose of a check rail is to prevent wheel flanges from striking the nose of the vee. If it doesn't adequately cover the gap in the opposite crossing, it can't do that and it effectively serves no purpose: minimum_check_rail_880x588.png  More about check rails here: http://templot.com/companion/check_and_wing_rails.php cheers, Martin. |

||

|

posted: 4 Oct 2019 07:46 from: RedgateModels

click the date to link to this post click member name to view archived images |

Cheers chaps, as I said I have rework to do on the right hand turnout set, I have removed the work from the workboard and given it a quick clean and a couple of sleepers need replacing in that area anyway. Probably too much heat when i was trying to solder with Plastic Magic rather than flux LOL I'll look at the check rail then. Here's a shot of the left hand combination now it's a bit cleaner. Got all the isolation gaps to do of course. 2013_040245_570000000.jpg  |

||

|

posted: 6 Oct 2019 14:44 from: RedgateModels

click the date to link to this post click member name to view archived images |

Happy with this. Might need more tweaking once laid and wired up. But so far so good. 2013_060943_360000000.jpg  Now, next mad idea is running the NG side into the middle of the standard gauge just before fiddle yard, I could then have common reversible cassettes.... |

||

|

posted: 7 Oct 2019 11:14 from: RedgateModels

click the date to link to this post click member name to view archived images |

As expected tweaks were needed, the gauge was too wide at the toe of the NG section circled. it allowed some stock to hit the nose of the fixed rail and as the geometry was fine for standard gauge stock, moving the NG centre rail was the obvious answer. I also missed a sleeper isolation break right next to the tie bar 2013_070607_350000000.jpg  I'm building it all onto fomecore which arrives this week, so need to get some dropper wires fixed before then, now where's that CAT5 cable ( brown, blue and green cores) |

||

|

posted: 7 Oct 2019 12:14 from: Jim Guthrie

click the date to link to this post click member name to view archived images |

RedgateModels wrote: As expected tweaks were needed, the gauge was too wide at the toe of the NG section circled. it allowed some stock to hit the nose of the fixed rail and as the geometry was fine for standard gauge stock, moving the NG centre rail was the obvious answer. I also missed a sleeper isolation break right next to the tie bar Looking at the check rail gap at the crossing to the right of fixed rail, I would have said that what you needed to do was open up the gap between the fixed blade and its stock rail. By roughly eye-balling the situation, if the nose of the fixed rail was taken back to the next timber, that might just about do it. Jim. |

||

|

posted: 7 Oct 2019 12:20 from: RedgateModels

click the date to link to this post click member name to view archived images |

Jim Guthrie wrote: RedgateModels wrote:That very wide check rail gap is to get the 0-6-0 farish chassis though. I think the slightly pizza cutter flanges are not helping. I think I will take 0.1mm off them which will improve things. I have not closed the gauge up to less than 9mm, I made it too wide in the first place ;) Opening up the gap by shortening the fixed blade is still an option but currently everything runs fine. Still need to power up though and do a final check with stock running under it's own steam rather than my finger ..... |

||

|

posted: 10 Oct 2019 08:31 from: RedgateModels

click the date to link to this post click member name to view archived images |

Made a start last night on the plain dual gauge section 2013_100328_540000000.jpg  Still toying with the idea of interesting another fixed blade/checkrail section to pull the narrow gauge into the centre of the standard gauge just before the fiddle yard exit. Will standardise on cassettes etc and give yet more variety to the trackwork .... |

||

|

posted: 16 Oct 2019 06:07 from: Andy Reichert click the date to link to this post click member name to view archived images |

RedgateModels wrote: Happy with this. Might need more tweaking once laid and wired up. But so far so good. I'm not a fan of the visual impact of using sleepers as tie bars, nor the poor reliability of rigid soldered construction. Since you are using FB rail, you have more options that don't need either rigidity or soldering. Andy |

||

|

posted: 16 Oct 2019 07:44 from: RedgateModels

click the date to link to this post click member name to view archived images |

Temporary Andy, well initially LOL. To be honest the single blade should be fine rigid as it can pivot on the drive pin etc. So what would you suggest? | ||

|

posted: 24 Oct 2019 12:13 from: RedgateModels

click the date to link to this post click member name to view archived images |

Final bit of track prepped last night. I was going to wait until Wycrail and buy another length of code 75 flexi, but then hey I have the rail and sleepers already, so zero extra cost. 2013_240713_120000000.jpg  I also like building track, even plain |

||

|

posted: 4 Nov 2019 08:51 from: RedgateModels

click the date to link to this post click member name to view archived images |

Pretty pleased after the weekend, I wired up the trackwork and soldered some temporary bars to the switch blades to lock them in place and test ran some trains. Couple of minor tweaks, mainly the check rail end on the left hand NG exit - my new NG covered wagons just hit the end of it so a little more angle and all was good. Time to get it planted on the layout |

||

|

posted: 20 Nov 2019 12:55 from: RedgateModels

click the date to link to this post click member name to view archived images |

As promised here it is planted on the layout, along with some of the more mundane ready to lay Peco track 2013_200754_080000000.jpg  |

||

| Please read this important note about copyright: Unless stated otherwise, all the files submitted to this web site are copyright and the property of the respective contributor. You are welcome to use them for your own personal non-commercial purposes, and in your messages on this web site. If you want to publish any of this material elsewhere or use it commercially, you must first obtain the owner's permission to do so. |