Keith Armes

Member

- Location

- Macclesfield

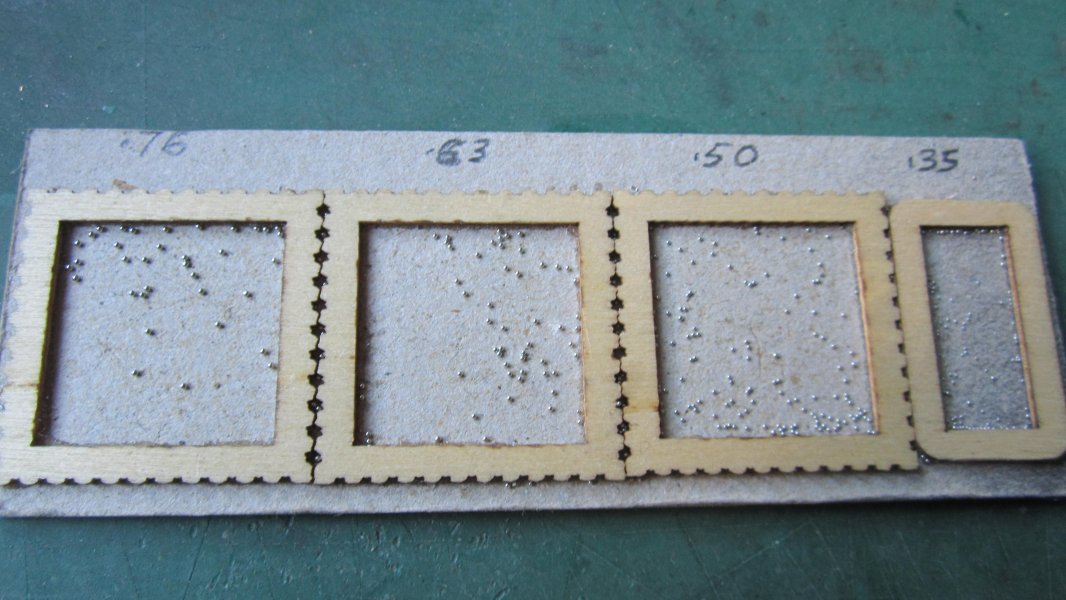

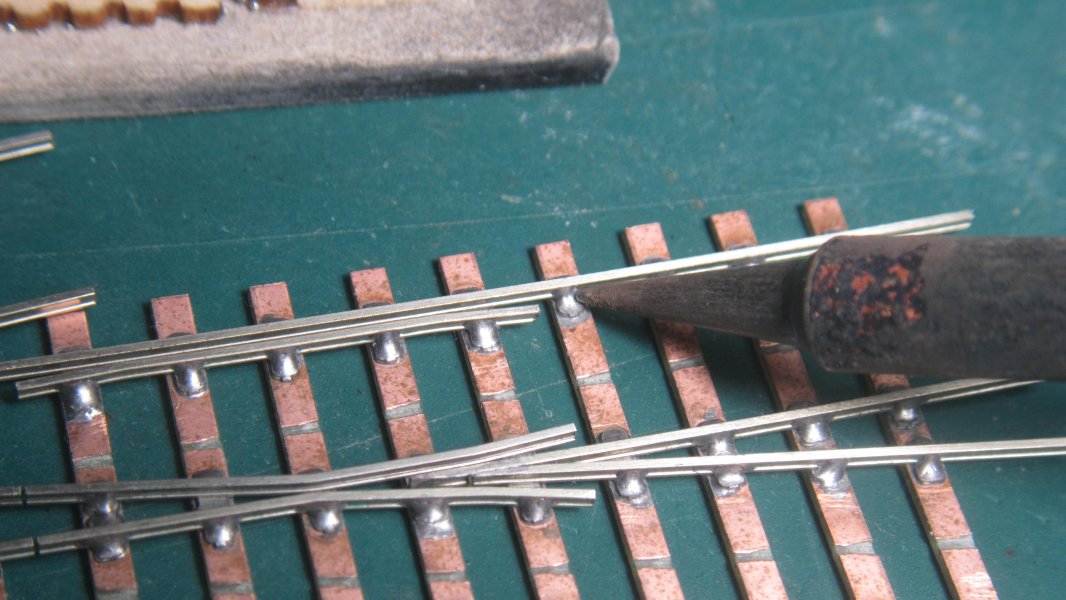

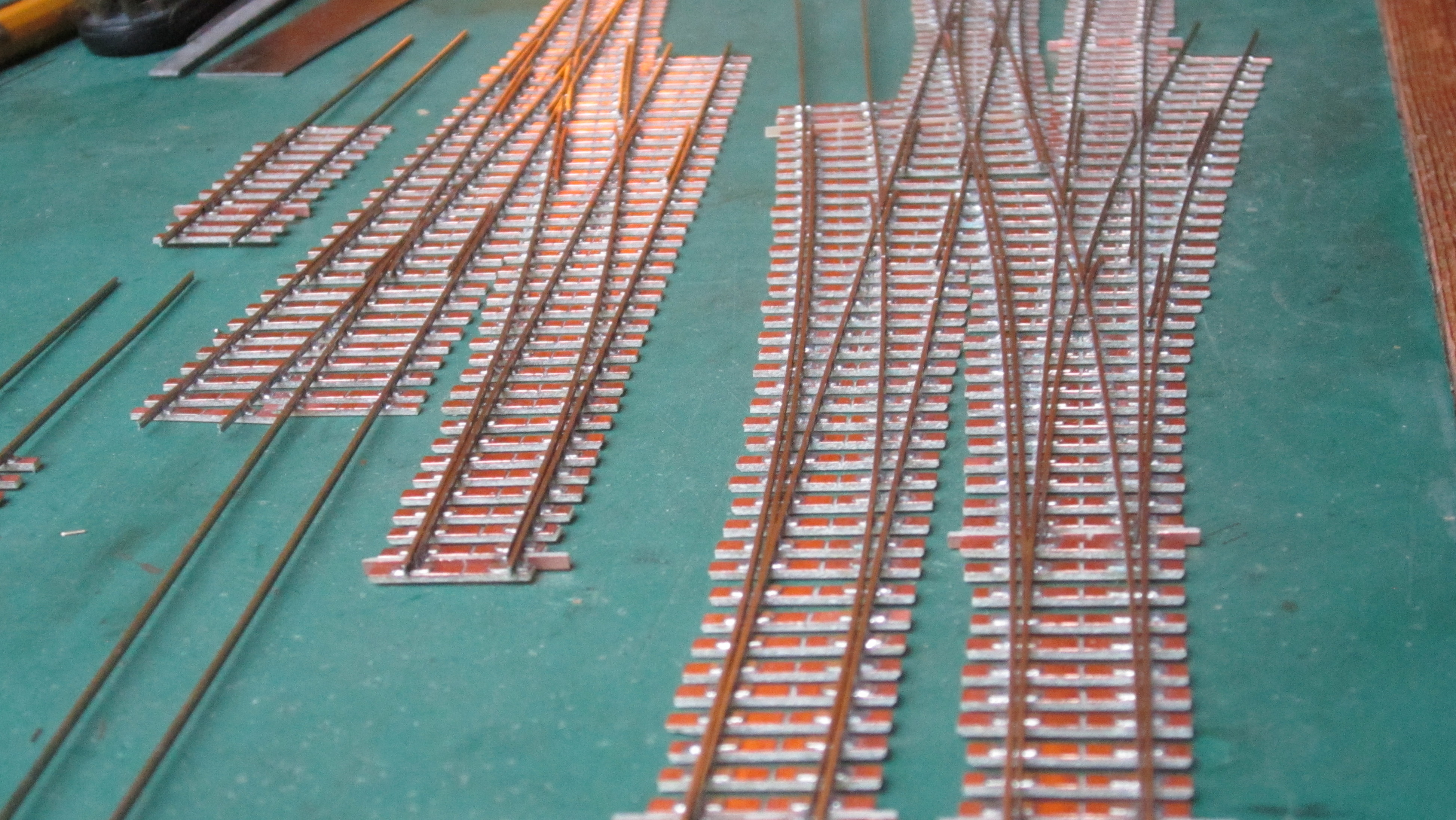

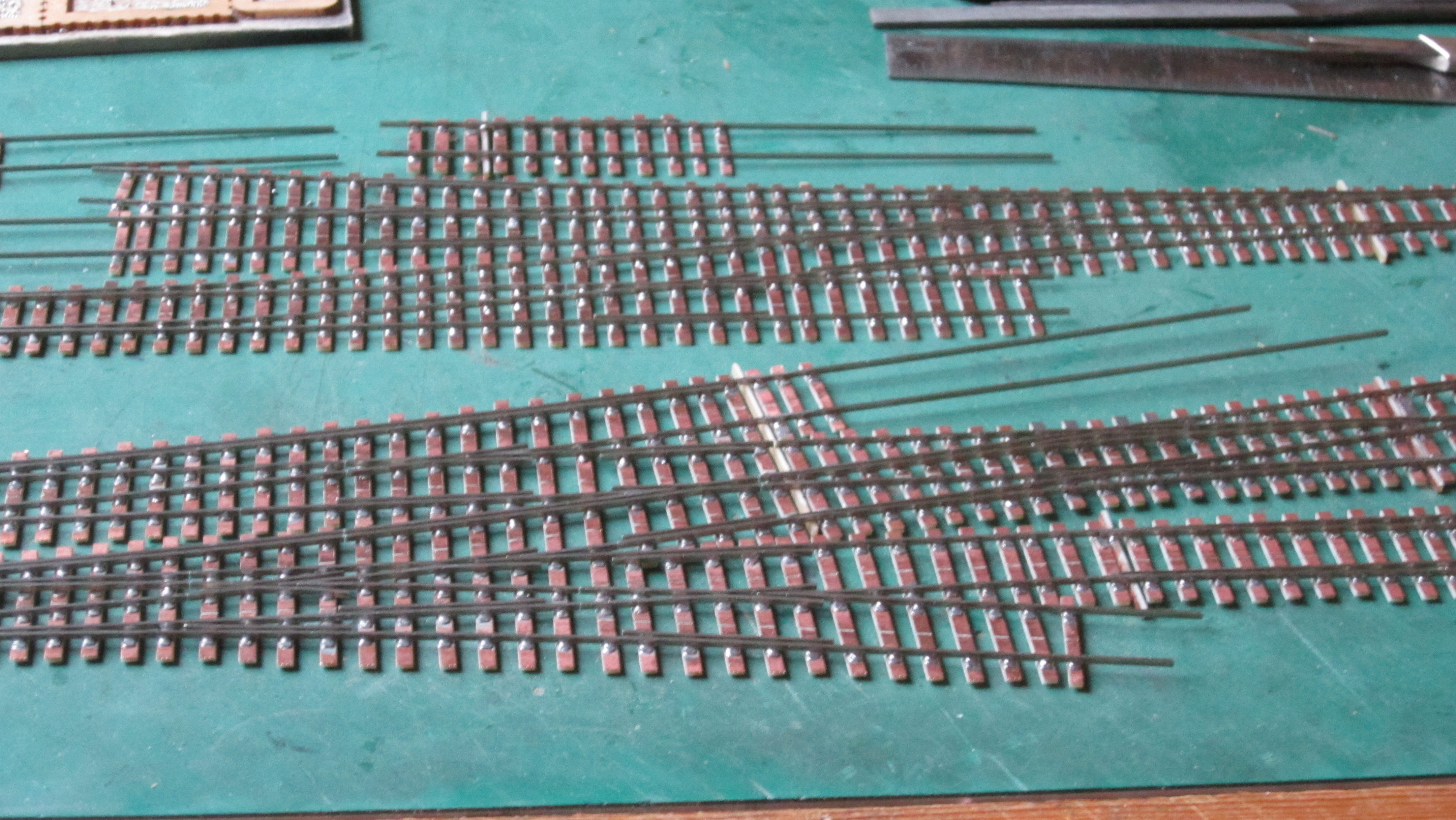

Two pictures of 2FS pointwork that has just left my workbench. It's going to Steve Martin in New Zealand, where he is building a model of St Erth station in Cornwall and the junction for the St Ives branch. People who take MRJ will have seen some of his excellent scenic and building work in there.

Keith

Keith

message ref: 387

Search

Search