Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

With the release of Templot update 241b we have reached a stage where plug track is now a feasible means of building chaired bullhead track. At least for track formations which don't need K-crossings -- single turnouts, crossovers, tandem turnouts. The chairs for K-crossings will come later this year, hopefully.

I've started this separate topic to extract the basics of plug track from the maze of experimental discussions and ideas which have been posted in several other topics over recent months and years. All you need to know to get started is here.

The two essential components are:

1. 3D resin-printed chairs, having a chunky tapered plug part below the visible chair base.

2. a timbering base having rectangular socket cut-outs in each timber, into which the chairs can be plugged.

This puts each chair in its correct position and rail alignment, and also gauges the rail. No separate track gauge tools are needed when building plug track.

Templot creates the 3D files needed to make these components for any track plan, including complex formations. The 3D files are ready to use, no CAD package or CAD drawing skills are needed. It is however a good idea to have a basic grasp of Templot track-planning before starting the plug track journey.

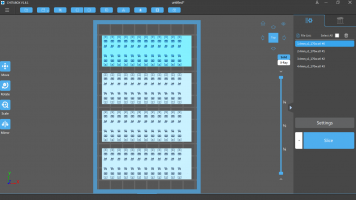

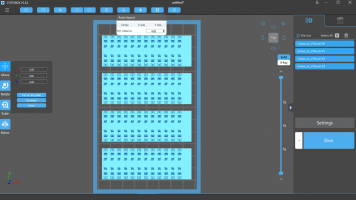

The timbering base can be 3D FDM (filament) printed, or laser-cut from plywood or card, or CNC-milled into a solid panel, as preferred. The socket sizes can be adjusted so that the chairs will dry clip-fit or press-fit without needing adhesive, or if preferred the sockets can be made a little larger to allow the chairs to be glued in place.

For home track building FDM 3D printing is likely to be the most attractive option. Armed with a resin printer and an FDM printer, material costs are very low compared with other construction methods. Large areas of model trackwork can be constructed for little more than the cost of the rail. The 3D printers will earn their keep from the many other modelling tasks which they can perform.

Plywood timbers are liked for being real wood, but FDM-printed plastic timbers can be given a wood-like surface texture by streaking them with fast-drying typing correction fluid (still used in schools) before painting:

There are 3 different methodologies for using the plug track components. I'm calling them OPT, FTK and LOJ for easier reference later. They can be mixed and matched as you wish, but it's likely you will come to prefer one of them over the others.

OPT : Original Plug Track

• For one-piece chairs having solid outer jaws and keys.

This is the system I had in mind when I obtained a small resin printer (Elegoo Mars 2 Pro) in early 2021, and first started to experiment with this idea. I later coined the term "plug track" to describe it.

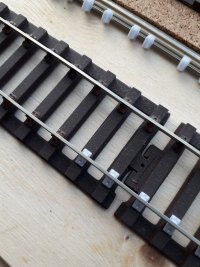

The resin-printed chairs are threaded onto a prepared length of rail, and spaced along it to match the printed paper template. The chaired rail is positioned over the timbering base, and each chair is located loosely in its socket. You then work to and fro along the rail, gradually firming each chair into its socket until all the chairs are fully home. A small block of hardwood makes a suitable tool for this purpose:

Installing the chairs into the base with the rail already through them makes it possible to fix the rail in place vertically between other existing rails. This makes it possible to build complex track formations which are not possible when rails are threaded horizontally into the chairs from one end. The rail makes a convenient means to apply pressure to the chairs without damaging them.

FTK : Fine Track Kits

• For one-piece chairs having solid outer jaws and keys.

This essentially means creating a home-made version of a turnout kit. The chairs are inserted in the timbering base in advance to create a fully chaired base unit. The rails then slide into place from the ends, in a similar manner to the Finetrax turnout kits:

This does place some restrictions on the track design and prototype details. For example it is necessary to break the wing rail into two sections at the knuckle bend.

Unlike kits available only for fixed sizes and geometry, with plug track you can create your own "kit" for any turnout size from A-4 to F-20, curved onto any radius.

LOJ : Loose Outer Jaws

• For two-part chairs having separate outer jaws and keys.

In this case the chair is made in two separate parts. The outer jaw and key part is added to the chair after it is fixed in the timbering base, and the rail is standing on it. Adding the outer jaw then clips the rail into the chair.

Many experienced track-builders reading this seemingly crazy idea for the first time might think it madness. At least in 4mm/ft scale.

But it has the great advantage that there is no need for the frustrating sore-fingers process of threading chairs onto the rails, or chamfering the rail ends to permit it. Track can be built up in the prototype manner, dropping a prepared rail into the chairs and only then keying it in place in each one.

The loose outer jaw has a long pin below it which locates into a slot in the chair. This makes it quite easy to handle with tweezers. The process is soon learned with a little practice and can be done quite quickly:

Not having to slide the chairs along the rail also means that electrical dropper wire connections can be made neatly to the underside of the rail before assembly.

to be continued . . .

Martin.

For the User Guide, go to:

https://85a.uk/bexhillwest/

For the latest software developments, see:

https://85a.uk/templot/club/index.php?threads/more-plug-track-developments.792/

More information is in the many topics at:

https://85a.uk/templot/club/index.php?forums/plug-track.34/

Practical topics about 3D printers, laser-cutters and building 3D track can be found at:

https://85a.uk/templot/club/index.php?forums/models-methods-and-materials.11/

message ref: 7575

Search

Search