Many thanks for the comments. All in all a pleasing result for a first effort.

The pong wasn't quite as bad as I feared, although it is very pervasive and still strong in that room this morning. I had the window wide open and a big fan blowing out through it as an extractor. A more engineered version of an extractor fan is on the cards.

The unsung hero of the evening, and not even mentioned in the instructions, is the plastic hook thingy to hold the build plate at 45 degrees while it drips the worst off. The print took 19 minutes and I left it dripping afterwards for about 20 minutes. All that time with the lid on and the air filter doing its stuff. I don't know how much effect the filter had, but the pong in the room got significantly worse later while cleaning up.

I then transferred the build plate quickly to the washer. With the holder at its lowest setting it required 1.5 litres of IPA (half the full capacity of the tub) to cover the plate. After finally realising that the washer won't start without the lid on (!) I gave it 5 minutes machine washing. Then a further 0.5 litres of IPA in an ice cream tub for brush washing (with a Lidl no.12 flat watercolour brush, other brushes are available). With intricate detailed parts I imagine thorough cleaning with a fine brush is important to reveal the full detail.

After which the print peeled away from the build plate quite easily with minimal persuasion from the scraper. Finally I put it in the basket for another 5 minutes machine washing, although whether that made any difference I don't know. I ideally you need a second tub with clean IPA for a final wash -- I will look at getting one.

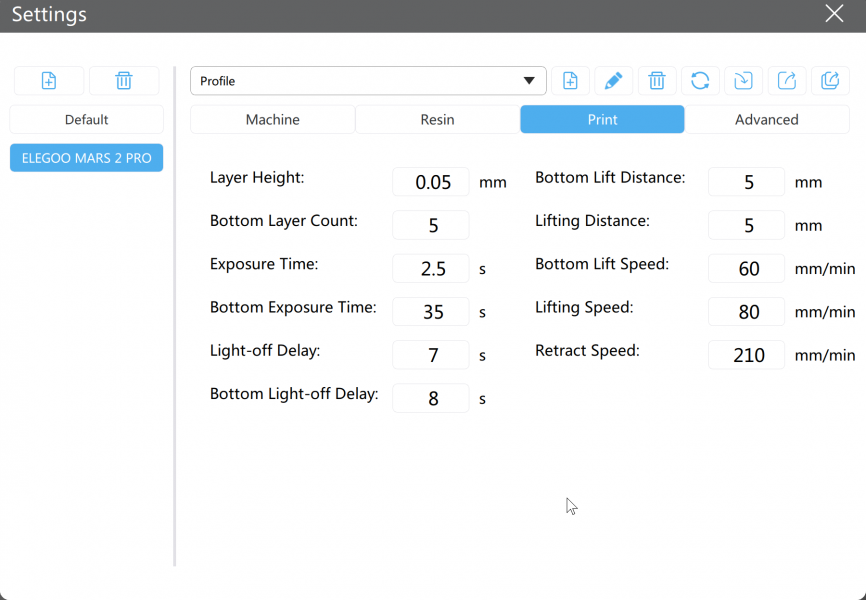

Then a blast with the air gun which I use for removing dust when scanning negatives (other hairdryers are available) to dry it off. Finally back into the machine for curing. The turntable is a fiddly thing to engage the two studs. I supported the print on a small glass jar to put it more central within the UV lighting. I gave it 2 minutes as suggested, but it was still quite soft and flexible when removed. It has since hardened noticeably on the window cill this morning, so I may give it longer next time.

I didn't want to put the used resin back in with the new, so I found a black polypropylene container for it until next time. I couldn't find any information about a suitable container for it, but so far there has been no reaction with the polypropylene. I used a plastic funnel to support the disposable filter supplied -- bad move as it made one more thing to clean up afterwards. In future I shall use the disposable filter unaided (10 supplied).

The messiest job is cleaning up the resin tank. I wiped it out as clean as possible with kitchen roll, and then dunked it in the ice cream tub for brush washing. Obviously any smears of resin left on the film will harden and interfere with future prints, so it's important to get it completely clean. In case there is any resin left on it, I have stored it in the dark until next time (actually in the box the toolkit came in). There is a pouring lip in one corner of the tank, but clearly it was designed by a left-handed person because for me it seems to be in the wrong corner.

I've learned for next time that you need lots of clear bench space for putting things down, several old biscuit-tin lids ready to put them on, a big roll of kitchen towels, and a big tie-handle plastic bag to put the used ones in. The whole process seems a bit environmentally suspect, but we are not planning to make chairs on an industrial scale.

All in all a lot to learn, and it's a bit unpleasant to work with. Unlike using the Bibo FDM printer, which is a laid-back breeze in comparison, with a pleasant smell reminding me of childhood jam-making and blackberrying on summer afternoons long ago. The Elegoo reminds me only of my A-level Chemistry exam.

cheers,

Martin.

Search

Search