Hi Trevor,

All the 3d printed chairs you will have seen on my YouTube channel have been printed with the Geetech Alkaid printer.

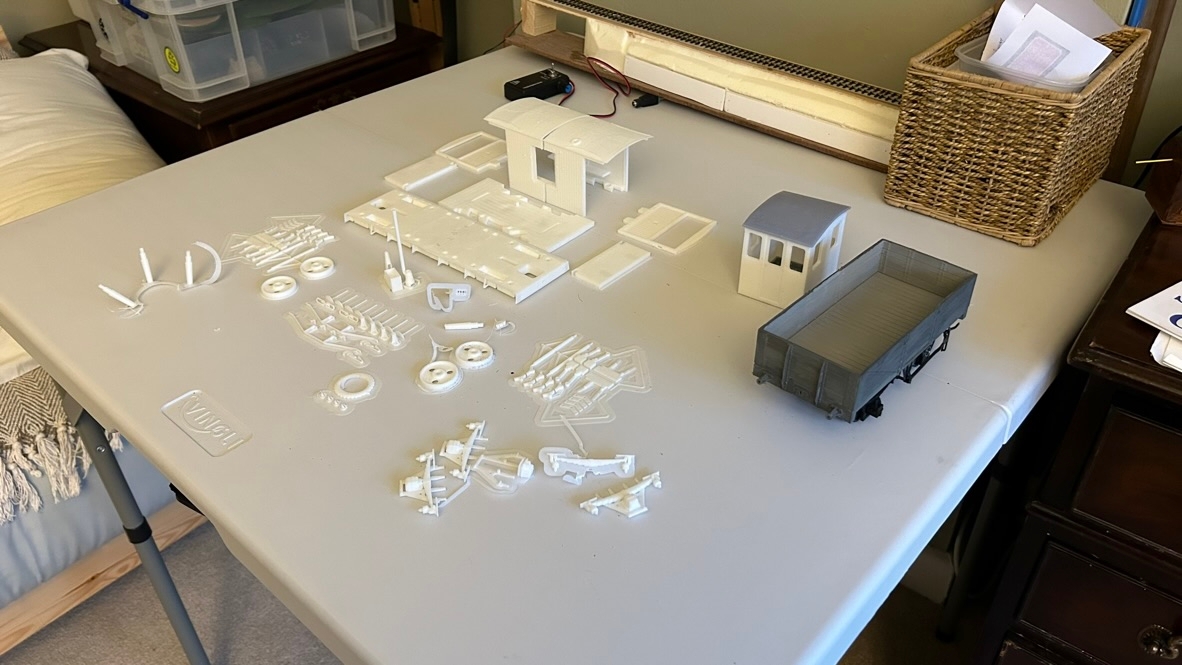

The 3mm scale chairs in the above image were printed on an Anycubic Mono 5s printer.

With regard to the chairs, bigger is not necessarily better, the little Alkaid printer will produce them far faster that one can lay them.

I use a Sunlu S9plus FDM printer for FDM track bases. I wouldn't recommend it, I have nothing but trouble with it.

For the laser cut track bases you will have seen, I use an OMTech 130w Co2 laser with a 1500 x 900mm bed. It's a useful machine but far too big and unnecessarily powerful for Plug Track use. The Creality Falcon2 22w laser which I recently reviewed is excellent, and I would say perfect for Plug Track use. I'll be reviewing the Atomstack 24w Pro laser next. I would expect that to be excellent as well, although it has a slightly smaller bed size.

As an aside, I think the ideal 3d FDM printer size-wise is likely to be the smallest that you

need, rather than the biggest you can get. For the reason that a smaller bed size is easier to level and will be more consistent across the bed. I made the mistake of getting the Sunlu S9, because I went for a larger bed size than I really needed, and it is that which is at the root of many of the problems I have with it.

Martin and others are achieving excellent results with 'little' printers such as the Kingroon which I think will be my next purchase.

Remember, the trackbases can be split into small segments and joined accurately without being unwieldy.

I laser cut a 1200mm long triple track base for Bexhill West recently, and whilst it was nice to have it in one piece, it was verging on unmanageable to lay. I wont be doing that again.

I hope that helps.

Search

Search