Templot Club forums powered for Martin Wynne by XenForo :

TEMPLOT 3D PLUG TRACK - To get up to speed with this experimental project click here. To watch an introductory video click here. See the User Guide at Bexhill West.

Templot5 - To join this open-source project on GitHub click here. For news of the latest on-going developments click here. Templot5 is now included with Templot2 - download.

-

The Plug Track functions are experimental and still being developed. Some of the earlier pages of this topic are now out-of-date.

For an updated overview of this project see this topic. For some practical modelling aspects of using Plug Track see Building 3D Track.

The assumption is that you have your own machines on which to experiment, or helpful friends with machines. Please do not send Templot files to commercial laser cutting or 3D printing firms while this project is still experimental, because the results are unpredictable and possibly wasteful.

Some pages of this and other topics include contributions from members who are creating and posting their own CAD designs for 3D printing and laser-cutting. Do not confuse them with Templot's own exported CAD files. All files derived from Templot are © Martin Wynne. -

The Plug Track functions are experimental and still being developed.

For an updated overview of this project see this topic. For some practical modelling aspects of using Plug Track see Building 3D Track.

The assumption is that you have your own machines on which to experiment, or helpful friends with machines. Please do not send Templot files to commercial laser cutting or 3D printing firms while this project is still experimental, because the results are unpredictable and possibly wasteful.

Some pages of this and other topics include contributions from members who are creating and posting their own CAD designs for 3D printing and laser-cutting. Do not confuse them with Templot's own exported CAD files. All files derived from Templot are © Martin Wynne.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What printer should I get ?

- Thread starter Hayfield

- Start date

Quick reply >

_______________

message ref: 9549

_______________

message ref: 9550

_______________

message ref: 9568

_______________

message ref: 9591

_______________

message ref: 9592

Richie

_______________

message ref: 9593

_______________

message ref: 9594

The tan jigs are made with Sunlu PLA + and the black ones are Esun PLA+ on the ender.

I have subsequently discovered a combination of Esun on the Neptune is by far the best combination.

Sunlu on the ender will not even stay on the bed, on the Neptune its ok, it works but the Esun defiantly gives the better definition. There is quite a lot to fine tuning the machines to get the best out of them.

cheers

Phil,

_______________

message ref: 9595

It's the eSun PLA+ I have got following Martin's recommendation, so I'll let you know when I get there. I am probably about a week off being able to have an afternoon to put to one side to get it out, build it and start playing!

Richie

_______________

message ref: 9613

_______________

message ref: 9619

_______________

message ref: 9620

Hi David,

After a month with no contact, Kingroon suggested that I pay them an extra $100 for the S2 printer instead, and shipping from USA. I replied in the negative and they agreed to refund my original payment within 7 days. No sign of it yet after 4 days. If not received I shall start the dispute process on Paypal.

In contrast Altway in the UK can't be faulted. Full progress emails with tracking information and next-day delivery by DPD. But I suspect only while stocks last.

cheers,

Martin.

_______________

message ref: 9621

_______________

message ref: 9623

_______________

message ref: 9625

I am probably teaching everyone what they always know, when buying items mail order I like to surround myself with as much protection as possible, both in payment protection and guarantee. In some cases it involves paying a bit more,

I paid extra for my FDM printer and brought it from Amazon, it arrived in a day or so. I paid using Visa so I have a double protection on both receiving it and if anything goes wrong I have a contract with both VISA and Amazon to fall back on.

As for the guarantee, as I told Currys salesman when declining the 2 year warranty extension for my laptop, the sales of goods act protects me against faults for a reasonable time, with the 3D printer and computer this is well past the first 12 months, both of which my claim is against my bank where I obtained my credit card if the supplier defaults. Between Visa and Currys or Amazon my items are guaranteed well past 12 mths

OK I paid a bit more but so far had no hassle with either printer, I think buying either direct from China may reduce my consumer protection. I was relieved to find my resin printer came from Northampton despite having to pay in USD.

_______________

message ref: 9629

I find my problem it not so much not getting the items. Its more about making them work properly when I have them

can you suggest some protection for that

cheers

Phil.

_______________

message ref: 9630

Hi John,

Strange. I paid in pounds and mine came from Leicester.

Perhaps this is the reason Northampton has gone over to US dollars:

https://citizen-network.org/library/why-northamptonshire-went-bust.html

cheers,

Martin.

_______________

message ref: 9631

Sorry my Alkaid did come from Leicester, bad memory but was paid in USD and I got an extra charge on my credit card (they are getting back some of the free interest my credit card gives me by paying the bill in full and of course the product insurance that comes with credit cards)

_______________

message ref: 9634

Hi John,

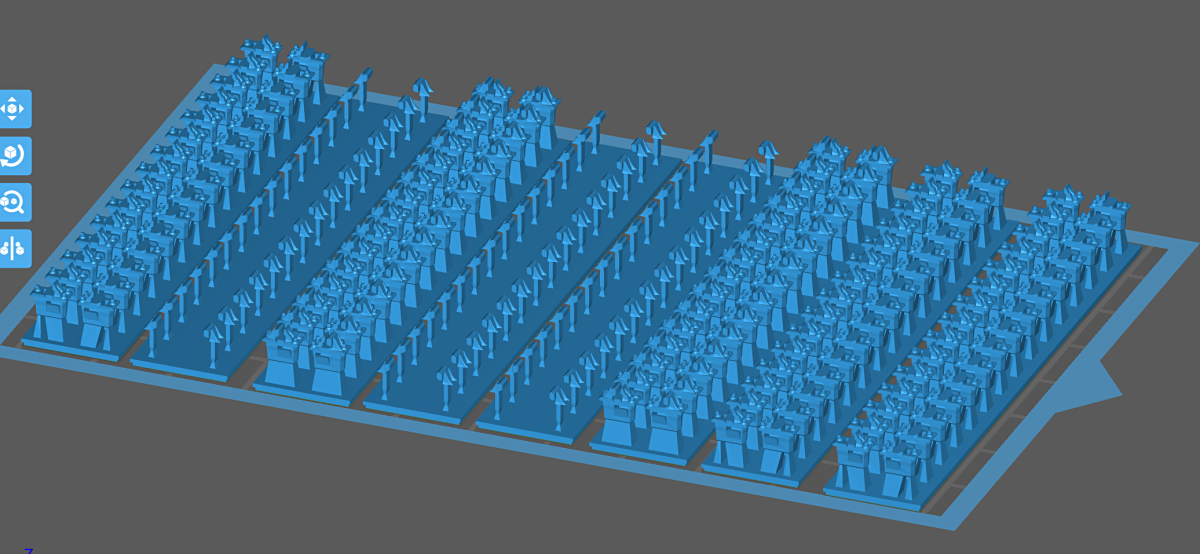

This file contains a mix of 150 S1 chairs in 4mm scale, using EMGS / C&L rail.

Some with slots, some loose jaws for them, some solid slide-on chairs:

This file is ready to use on the Alkaid or Mars2P printer, already sliced. Just copy it onto a USB stick and plug into the printer. Will take about 25 minutes to print.

For ABS-Like resin.

When washing, plunge it vigorously in the bucket of water to ensure the slots are washed through.

p.s. sorry not tested -- it's difficult to do any printing one-handed.

It is ready-to-go on the Alkaid or Mars2P printers using ABS-Like resin (not necessarily any other printers or resins).

edit: file removed -- faulty.

cheers,

Martin.

_______________

message ref: 9640

_______________

message ref: 9642

_______________

message ref: 9643

_______________

message ref: 9644

_______________

message ref: 9648

_______________

message ref: 9649

Hi Phil,

Which resin? I have found the loose jaws are more firmly attached to the supports when using the water washable ABS-Like resin.

At present I think the break-off neck size is fixed -- I will make it adjustable in the next program update.

cheers,

Martin.

_______________

message ref: 9650

still on original Elegoo ABS like as I got 5Kg and to be honest when my 5 Kg of Any-cubic 2 arrived, I found I had ticked the pro version which still requires Isopropanol alcohol so I will be on that for a long time yet.

cheers

Phil

_______________

message ref: 9655

Hi Phil,

10kg is a lot of resin -- that's about 100,000 4mm chairs!

Presumably you are planning to make lots of other stuff too?

cheers,

Martin.

_______________

message ref: 9656

yes I do more than chairs, All though I have 5K S1 in stock so far, but not the loose jaw keys I quickly found there better if fitted only a day or two after being made. They seem more pliable at that stage, there is only 2 Kg of my first Elegoo 5 kg left, but bit sad I ticked the wrong box for sure

yes I do more than chairs, All though I have 5K S1 in stock so far, but not the loose jaw keys I quickly found there better if fitted only a day or two after being made. They seem more pliable at that stage, there is only 2 Kg of my first Elegoo 5 kg left, but bit sad I ticked the wrong box for sure

cheers

Phil

_______________

message ref: 9657

_______________

message ref: 9658

_______________

message ref: 9659

_______________

message ref: 9660

_______________

message ref: 9690

Hi Steve,

Yes I would think so. Mine definitely fails -- it is possible to insert paper at one corner while holding the rule against the glass at the other corner.

I will post the G-code script for the Kingroon Pro S1 perimeter priming shortly. Do you have some PLA-Plus filament?

Have you downloaded the latest Cura? For how to set up a custom printer, see:

https://85a.uk/templot/club/index.php?threads/experimental-plug-track-continued.673/post-7361

cheers,

Martin.

_______________

message ref: 9691

_______________

message ref: 9704

_______________

message ref: 9709

so in this case is that for a boiled egg? or a poached egg?

cheers

Phil

_______________

message ref: 9710

_______________

message ref: 9711

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Hi Martin,

An update on my Kingroon KPS3 Pro S1 order.

Yesterday I received an email inviting me to pay an additional 80 USD in order to receive a KPS3 Pro S2!

I replied pointing out that I had already paid an extra 30 USD in response to their offer of shipping a KPS3 Pro S1 from China, and that if they could not supply a KPS3 Pro S1 could they refund my money so that I could source from elsewhere.

Today they sent me a message stating that they were refunding both the 169 USD and the 30 USD.

I have now ordered a Kingroon KPS3 Pro S1 from Altwaylab in the uk for the princely sum of £180.00 including tax and shipping.

https://altwaylab.co.uk/products/official-kingroon-kp3s-pro-s1-3d-printer

Steve

An update on my Kingroon KPS3 Pro S1 order.

Yesterday I received an email inviting me to pay an additional 80 USD in order to receive a KPS3 Pro S2!

I replied pointing out that I had already paid an extra 30 USD in response to their offer of shipping a KPS3 Pro S1 from China, and that if they could not supply a KPS3 Pro S1 could they refund my money so that I could source from elsewhere.

Today they sent me a message stating that they were refunding both the 169 USD and the 30 USD.

I have now ordered a Kingroon KPS3 Pro S1 from Altwaylab in the uk for the princely sum of £180.00 including tax and shipping.

https://altwaylab.co.uk/products/official-kingroon-kp3s-pro-s1-3d-printer

Steve

message ref: 9549

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Steve_Cornford

Hi Steve,

Many thanks for finding that. Now ordered one, on a proper web site with contact details:

Company Details:

I will now attempt to cancel my existing order on Kingroon and get a refund.

cheers,

Martin.

Hi Steve,

Many thanks for finding that. Now ordered one, on a proper web site with contact details:

Company Details:

- Company Name: ALTWAY (UK) LIMITED

- Company Address: Unit 2, Mansfield i-Centre Oakham Business Park, Hamilton Way, Mansfield, Nottinghamshire, NG18 5BR, United Kingdom

- Company Number: 08505518

- VAT: GB163396393

- Phone: +441623306026

- Email: sales.int@altwaylab.co.uk

I will now attempt to cancel my existing order on Kingroon and get a refund.

cheers,

Martin.

message ref: 9550

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Steve_Cornford

Hi Steve,

What a difference! Message from Altway says order packed and ready to be picked up by DPD. Tracking number provided.

Martin.

Hi Steve,

What a difference! Message from Altway says order packed and ready to be picked up by DPD. Tracking number provided.

Martin.

message ref: 9568

Phil G

Member

- Location

- New Zealand

Hi guys

Quick photo to show the difference on the jig made on the Ender 3 pro (with upgrades) and the stock Elegoo Neptune 3 Pro out of the box. Chalk and cheese. The Ender is ok for FDM timbers but not good enough for accurate jigs.

for Jigs I have to recommend, on my testing anyway. The Neptune 3 pro every time. Having made 8 jigs on the Neptune now I can confirm original rail settings work from a B switch to and E switch (that being the biggest I can get on the bed) such a different story to the nightmare that was the ender 3

cheers

Phil

Quick photo to show the difference on the jig made on the Ender 3 pro (with upgrades) and the stock Elegoo Neptune 3 Pro out of the box. Chalk and cheese. The Ender is ok for FDM timbers but not good enough for accurate jigs.

for Jigs I have to recommend, on my testing anyway. The Neptune 3 pro every time. Having made 8 jigs on the Neptune now I can confirm original rail settings work from a B switch to and E switch (that being the biggest I can get on the bed) such a different story to the nightmare that was the ender 3

cheers

Phil

message ref: 9591

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Alls well that Enders well!

And how were the meatballs?

And how were the meatballs?

message ref: 9592

BetweenTheTunnels

Member

- Location

- UK

Interesting comparison Phil. I have just got the Neptune 4 Pro, although its still boxed until I finish work an have time to investigate, but it will be interesting to compare what I get from it, against your N3P images.Hi guys

Quick photo to show the difference on the jig made on the Ender 3 pro (with upgrades) and the stock Elegoo Neptune 3 Pro out of the box. Chalk and cheese. The Ender is ok for FDM timbers but not good enough for accurate jigs.

for Jigs I have to recommend, on my testing anyway. The Neptune 3 pro every time. Having made 8 jigs on the Neptune now I can confirm original rail settings work from a B switch to and E switch (that being the biggest I can get on the bed) such a different story to the nightmare that was the ender 3

cheers

Phil

Richie

message ref: 9593

Phil G

Member

- Location

- New Zealand

Just to clarify B to E is 4 switch sizes all back filing jigs completed now working on the front right and left filing Jigs so 12 jigs in all required, I may even do an A size set just for the fun of it. Still working out how to get the F size made.

cheers

Phil,

cheers

Phil

cheers

Phil,

well I liked them more then the Ender that's for sureAlls well that Enders well!

And how were the meatballs?

cheers

Phil

message ref: 9594

Phil G

Member

- Location

- New Zealand

Hi Richie,Interesting comparison Phil. I have just got the Neptune 4 Pro, although its still boxed until I finish work an have time to investigate, but it will be interesting to compare what I get from it, against your N3P images.

Richie

The tan jigs are made with Sunlu PLA + and the black ones are Esun PLA+ on the ender.

I have subsequently discovered a combination of Esun on the Neptune is by far the best combination.

Sunlu on the ender will not even stay on the bed, on the Neptune its ok, it works but the Esun defiantly gives the better definition. There is quite a lot to fine tuning the machines to get the best out of them.

cheers

Phil,

message ref: 9595

BetweenTheTunnels

Member

- Location

- UK

Thanks Phil,Hi Richie,

The tan jigs are made with Sunlu PLA + and the black ones are Esun PLA+ on the ender.

I have subsequently discovered a combination of Esun on the Neptune is by far the best combination.

Sunlu on the ender will not even stay on the bed, on the Neptune its ok, it works but the Esun defiantly gives the better definition. There is quite a lot to fine tuning the machines to get the best out of them.

cheers

Phil,

It's the eSun PLA+ I have got following Martin's recommendation, so I'll let you know when I get there. I am probably about a week off being able to have an afternoon to put to one side to get it out, build it and start playing!

Richie

message ref: 9613

S-Club-7

Member

- Location

- Just south of Stansted Airport

I ordered a KP3S Pro S1 directly from Kingroon. It took them a week to reply to each of my emails and after a month of delayed conversation they eventually admitted:

I'm still waiting for them to confirm that my order has actually been cancelled but it has only been 5 days so I'm not due a reply from them for a few days yet...I’m sorry that the KP3S Pro S1 Printer in our local Warehouse is stop production

message ref: 9619

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Hi s-club-7,

Are you in the uk?

Steve

Are you in the uk?

Steve

message ref: 9620

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@S-Club-7I ordered a KP3S Pro S1 directly from Kingroon. It took them a week to reply to each of my emails and after a month of delayed conversation they eventually admitted:

I'm still waiting for them to confirm that my order has actually been cancelled but it has only been 5 days so I'm not due a reply from them for a few days yet...

Hi David,

After a month with no contact, Kingroon suggested that I pay them an extra $100 for the S2 printer instead, and shipping from USA. I replied in the negative and they agreed to refund my original payment within 7 days. No sign of it yet after 4 days. If not received I shall start the dispute process on Paypal.

In contrast Altway in the UK can't be faulted. Full progress emails with tracking information and next-day delivery by DPD. But I suspect only while stocks last.

cheers,

Martin.

message ref: 9621

S-Club-7

Member

- Location

- Just south of Stansted Airport

message ref: 9623

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Suggest you ask Kingroon for refund & get one from Altwaylab.co.uk instead

https://altwaylab.co.uk/products/official-kingroon-kp3s-pro-s1-3d-printer

That's what myself & Martin did.

https://altwaylab.co.uk/products/official-kingroon-kp3s-pro-s1-3d-printer

That's what myself & Martin did.

message ref: 9625

@S-Club-7

Hi David,

After a month with no contact, Kingroon suggested that I pay them an extra $100 for the S2 printer instead, and shipping from USA. I replied in the negative and they agreed to refund my original payment within 7 days. No sign of it yet after 4 days. If not received I shall start the dispute process on Paypal.

In contrast Altway in the UK can't be faulted. Full progress emails with tracking information and next-day delivery by DPD. But I suspect only while stocks last.

cheers,

Martin.

I am probably teaching everyone what they always know, when buying items mail order I like to surround myself with as much protection as possible, both in payment protection and guarantee. In some cases it involves paying a bit more,

I paid extra for my FDM printer and brought it from Amazon, it arrived in a day or so. I paid using Visa so I have a double protection on both receiving it and if anything goes wrong I have a contract with both VISA and Amazon to fall back on.

As for the guarantee, as I told Currys salesman when declining the 2 year warranty extension for my laptop, the sales of goods act protects me against faults for a reasonable time, with the 3D printer and computer this is well past the first 12 months, both of which my claim is against my bank where I obtained my credit card if the supplier defaults. Between Visa and Currys or Amazon my items are guaranteed well past 12 mths

OK I paid a bit more but so far had no hassle with either printer, I think buying either direct from China may reduce my consumer protection. I was relieved to find my resin printer came from Northampton despite having to pay in USD.

message ref: 9629

Phil G

Member

- Location

- New Zealand

Hi John,I am probably teaching everyone what they always know, when buying items mail order I like to surround myself with as much protection as possible, both in payment protection and guarantee. In some cases it involves paying a bit more,

I paid extra for my FDM printer and brought it from Amazon, it arrived in a day or so. I paid using Visa so I have a double protection on both receiving it and if anything goes wrong I have a contract with both VISA and Amazon to fall back on.

As for the guarantee, as I told Currys salesman when declining the 2 year warranty extension for my laptop, the sales of goods act protects me against faults for a reasonable time, with the 3D printer and computer this is well past the first 12 months, both of which my claim is against my bank where I obtained my credit card if the supplier defaults. Between Visa and Currys or Amazon my items are guaranteed well past 12 mths

OK I paid a bit more but so far had no hassle with either printer, I think buying either direct from China may reduce my consumer protection. I was relieved to find my resin printer came from Northampton despite having to pay in USD.

I find my problem it not so much not getting the items. Its more about making them work properly when I have them

can you suggest some protection for that

cheers

Phil.

message ref: 9630

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

my resin printer came from Northampton despite having to pay in USD.

Hi John,

Strange. I paid in pounds and mine came from Leicester.

Perhaps this is the reason Northampton has gone over to US dollars:

https://citizen-network.org/library/why-northamptonshire-went-bust.html

cheers,

Martin.

message ref: 9631

MartinHi John,

Strange. I paid in pounds and mine came from Leicester.

Perhaps this is the reason Northampton has gone over to US dollars:

https://citizen-network.org/library/why-northamptonshire-went-bust.html

cheers,

Martin.

Sorry my Alkaid did come from Leicester, bad memory but was paid in USD and I got an extra charge on my credit card (they are getting back some of the free interest my credit card gives me by paying the bill in full and of course the product insurance that comes with credit cards)

message ref: 9634

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@HayfieldMartins small sleeper test file was a godsend (have you got one for chairs using the Alkaid please)

Hi John,

This file contains a mix of 150 S1 chairs in 4mm scale, using EMGS / C&L rail.

Some with slots, some loose jaws for them, some solid slide-on chairs:

This file is ready to use on the Alkaid or Mars2P printer, already sliced. Just copy it onto a USB stick and plug into the printer. Will take about 25 minutes to print.

For ABS-Like resin.

When washing, plunge it vigorously in the bucket of water to ensure the slots are washed through.

p.s. sorry not tested -- it's difficult to do any printing one-handed.

It is ready-to-go on the Alkaid or Mars2P printers using ABS-Like resin (not necessarily any other printers or resins).

edit: file removed -- faulty.

cheers,

Martin.

message ref: 9640

Martin

Perfect thank you.

I have spent the latter part of the afternoon watching James's videos. The machine is set up and I have a couple of memory cards to jog my mind, I am just about to re-look at your latest release notes regarding the new function of chairs and their rafts.

Out later so making chair files will have to wait till tomorrow. I also need to rescue a bucket from the garden and buy a pastry brush and gloves and pinch a bit of tin foil from the kitchen

I think I will half fill the tray but I need to clean the print/build base as informed, thanks again for your assistance

When are we Zooming again ?

John

Perfect thank you.

I have spent the latter part of the afternoon watching James's videos. The machine is set up and I have a couple of memory cards to jog my mind, I am just about to re-look at your latest release notes regarding the new function of chairs and their rafts.

Out later so making chair files will have to wait till tomorrow. I also need to rescue a bucket from the garden and buy a pastry brush and gloves and pinch a bit of tin foil from the kitchen

I think I will half fill the tray but I need to clean the print/build base as informed, thanks again for your assistance

When are we Zooming again ?

John

message ref: 9642

I am so sorry but I have been looking for the updated instructions for making multiple chairs in the new dialog box.

I have spent ages going through plug track threads, but I just cannot find them. I have watched James's video but its been updated since filming

I have spent ages going through plug track threads, but I just cannot find them. I have watched James's video but its been updated since filming

message ref: 9643

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Hayfield

Hi John,

This recent scruff video clip shows how to make rafts of chairs in 7mm. For 4mm don't change the 15 to 8, leave it on 15:

https://flashbackconnect.com/Default.aspx?id=_LWLPBa47zf9Evgw0wwnkQ2

I explained about making chair rafts for check rail chairs in the last Zoom meeting. The recording is here:

https://85a.uk/templot/club/index.php?threads/scruff-zoom-recordings.643/post-9464

I'm sorry, I can no longer keep track of everything and remember where it is. I know I've explained it all several times. We can do another Zoom meeting to get you started if you say a time.

cheers,

Martin.

Hi John,

This recent scruff video clip shows how to make rafts of chairs in 7mm. For 4mm don't change the 15 to 8, leave it on 15:

https://flashbackconnect.com/Default.aspx?id=_LWLPBa47zf9Evgw0wwnkQ2

I explained about making chair rafts for check rail chairs in the last Zoom meeting. The recording is here:

https://85a.uk/templot/club/index.php?threads/scruff-zoom-recordings.643/post-9464

I'm sorry, I can no longer keep track of everything and remember where it is. I know I've explained it all several times. We can do another Zoom meeting to get you started if you say a time.

cheers,

Martin.

message ref: 9644

Phil G

Member

- Location

- New Zealand

Hi John,

If you do print the STL raft Martin posted can you please let me know if most of the loose jaws survive the vigorous washing and plunging Martin rightly says is required.

Only asking as I am not sure if I am a bit too vigorous with the plunging but I find about 20 to 30% of the loose jaws part company with the raft in the process. I never blocked slots though

cheers

Phil

If you do print the STL raft Martin posted can you please let me know if most of the loose jaws survive the vigorous washing and plunging Martin rightly says is required.

Only asking as I am not sure if I am a bit too vigorous with the plunging but I find about 20 to 30% of the loose jaws part company with the raft in the process. I never blocked slots though

cheers

Phil

message ref: 9648

Phil G

Member

- Location

- New Zealand

Ps my solution is print rafts and jaws separately as that way I can control the wash rate required

works well for all premade chair raft combinations, not so good for speciality rafts though.

cheers

Phil

works well for all premade chair raft combinations, not so good for speciality rafts though.

cheers

Phil

message ref: 9649

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Phil GOnly asking as I am not sure if I am a bit too vigorous with the plunging but I find about 20 to 30% of the loose jaws part company with the raft in the process.

Hi Phil,

Which resin? I have found the loose jaws are more firmly attached to the supports when using the water washable ABS-Like resin.

At present I think the break-off neck size is fixed -- I will make it adjustable in the next program update.

cheers,

Martin.

message ref: 9650

Phil G

Member

- Location

- New Zealand

Hi Martin,@Phil G

Hi Phil,

Which resin? I have found the loose jaws are more firmly attached to the supports when using the water washable ABS-Like resin.

At present I think the break-off neck size is fixed -- I will make it adjustable in the next program update.

cheers,

Martin.

still on original Elegoo ABS like as I got 5Kg and to be honest when my 5 Kg of Any-cubic 2 arrived, I found I had ticked the pro version which still requires Isopropanol alcohol so I will be on that for a long time yet.

cheers

Phil

message ref: 9655

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Phil GHi Martin,

still on original Elegoo ABS like as I got 5Kg and to be honest when my 5 Kg of Any-cubic 2 arrived, I found I had ticked the pro version which still requires Isopropanol alcohol so I will be on that for a long time yet.

cheers

Phil

Hi Phil,

10kg is a lot of resin -- that's about 100,000 4mm chairs!

Presumably you are planning to make lots of other stuff too?

cheers,

Martin.

message ref: 9656

Phil G

Member

- Location

- New Zealand

@Phil G

Hi Phil,

10kg is a lot of resin -- that's about 100,000 4mm chairs!

Presumably you are planning to make lots of other stuff too?

cheers,

Martin.

cheers

Phil

message ref: 9657

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

.

First-time 3D printing using water-washable resin on the Alkaid printer:

1. the suggested resin for plug track chairs is AnyCubic Grey Water-Washable ABS-Like V2 resin. Available from Amazon at:

https://www.amazon.co.uk/gp/product/B0C7BFQZ2C

It is also possible to use the Pro version of ABS-Like resin, but that is not water washable and must be washed in IPA (Isopropyl Alcohol). Likewise other makes of ABS-Like resin. For water-washing check that the label says V2. This is current information at the above date.

2. shake the bottle of resin well, and leave it to stand for a while for any froth to clear.

3. if cold, run the bottle under the hot tap to warm it up.

4. remove the protection films from both sides of the tank base, and fix it on the printer.

5. remove the protection film (if any) from the build plate, and clean the build surface in hot soapy water before using it for the first time. Rinse and dry it.

6. fix it on the printer. Tighten the top knob firmly. Unlike FDM printing, there is some force involved in resin printing and things can come loose if not tightened firmly.

7. make sure the 4 levelling screws on the build plate are loose and floppy, and switch on.

8. perform the levelling process as explained in the manual and in James's video:

Alkaid video

See further notes 28. below.

9. take some time to get this right -- with luck you will only need to do it once. Nip up all 4 screws first, and then tighten them very firmly without disturbing the levelling.

10. exclude all daylight, and then half fill the tank with resin. Subdued indoor lighting can be used, but not fluorescent tubes.

11. put the yellow cover on the printer. You can allow daylight while the cover is on.

12. plug in the USB stick containing the CTB print file. On the Alkaid the USB socket is at the back (and upside down). It's a lot easier using one of these:

https://www.amazon.co.uk/dp/B00DX59EAG

13. use the touch screen to find the file and start the print. While printing some slurping and sucking noises are normal.

14. for 4mm scale chairs it will take about 25 minutes. Leave it dripping for about 5 minutes afterwards.

15. exclude daylight again. Remove the yellow cover and place an old biscuit-tin lid or piece of cardboard over the whole tank area to catch any further drips while removing and handling the build plate. Remove the build plate using the top knob -- don't disturb the levelling screws.

16. swish the build plate in a bowl of warm water. At this stage the chairs are soft and delicate, so don't bump them against the bottom of the bowl. Using a soft brush such as a pastry brush, wash 95% of the surplus resin from the back of the build plate and around the chairs. The water will be significantly contaminated with resin, so don't pour it down the drain, see 25. below.

17. plunge the build plate up and down vigorously in a bucket of warmish water. This is to remove the remaining 5% of resin, and force wash water through the tiny slots for the loose jaws, to ensure there is no surplus resin left in the slots. If you have some IPA or methylated spirits available, adding a little to the water will aid rapid drying. Likewise adding a few drops of washing-up liquid.

18. cover the tank with kitchen foil, and put the yellow cover back on the printer. You can now allow daylight again. Don't allow daylight until the chairs are fully washed.

19. dry the build plate and chairs with a hair dryer, or leave them on the radiator while you have a nice boiled egg and read the latest issue of the Railway Modeller. The chairs must be fully dry before UV curing.

20. examine all the chairs carefully. Make sure none are missing or only partially printed. If so it is bad news -- you will need to clean out the tank and filter the resin to find the missing bits before you can print again. See further notes 28. below.

• if loose jaws are missing they may have printed normally and be found detached in the wash water.

21. holding the build plate over a soft landing such as a piece of foam or bubble wrap, gently prise each raft from the build plate using a window scraper. At this stage the chairs are still soft and delicate, so handle them carefully.

22. collect up the rafts and expose them on both sides to UV light using whatever means you have available, until they are fully cured. Depending on the power of the UV this might take 10-20 minutes. Or if using a sunny window cill, several hours.

23. they will harden further over the next few days, and the rafts will very likely curl. The curling doesn't matter, but you can prevent curling by sticking the rafts to a scrap bit of wood with double-stick tape until you are ready to use them.

24. if you won't be using the chairs for several weeks/months, once they are fully cured store them in the dark.

25. the contaminated water from the bowl needs to be left out of doors in a transparent container for several days until the resin content has cured in daylight UV and precipitated to the bottom of the container. The clear water can then be decanted off and used to water the garden. Don't pour it down the drain. The cured resin residue can be left to dry out and then disposed of in the domestic waste for landfill.

26. the contamination will be at a low level in a full bucket of water, and it can be disposed of immediately by pouring thinly over the garden. Over time the slight resin content will cure naturally in daylight and become relatively harmless. Some garden plants may even thrive on it! Keep it well away from fish-ponds, pets, etc. Don't pour it down the drain.

27. after building track with these chairs, store it in the dark until you are ready to lay it, or cover it over, until you are ready to paint it. Painting the chairs helps to prevent them becoming brittle from daylight UV exposure in the long term.

28. Further notes:

After levelling and tightening the 4 screws (very tight), move the build plate about 2/3rds of the way up the column using the Z buttons on the screen. Press Tools > Manual > 10mm and then Up several times. When high enough press the green back arrows to finish. Be careful because there is no limit switch at the top to stop it if you go too far. There is a reason the Alkaid costs only £90.

Remove the build plate using the top knob. If you didn't give it a good clean before levelling, do it now. A good scrub under the hot tap to remove any factory dirt and finger marks, and dry it off. It needs to be kept really clean.

While it's removed, pour some resin into the tank about half full. Immediately put the build plate back on the machine and tighten the top knob firmly. Quickly put the yellow lid back on and you are ready to print. At the start of each print the machine will move the build plate down into the resin. After the print the machine will lift the build plate up high for the print to drip -- leave it dripping for about 5 minutes.

Take the yellow lid off and remove the build plate with the chairs on it. Put the yellow lid back on as soon as you can to protect the exposed resin from any stray UV light. Wash the build plate and chairs thoroughly as I described above. Likewise do the washing immediately before any of the surplus resin is exposed to any stray UV light. After washing you can relax and allow daylight again. Put the build plate and chairs somewhere warm to dry and/or use a hairdryer. When it's all dry, carefully remove the chair rafts from the build plate with a window scraper. Do it over something soft to catch them as they are still quite soft. They are now ready for UV curing.

There is no actual need to put the build plate back on the machine until you are ready to print next time. After levelling the first time, there is never normally any reason to press the Home button again or do any more levelling.

Check the chairs carefully each time to make sure they are complete with no parts missing. If so you can just leave the resin in the tank ready for next time. If you are leaving it for any length of time it's a good idea to cover the tank with some kitchen foil (or whatever) as extra UV protection inside the lid. Give it a good stir with the yellow paddle provided before each printing session.

If you are leaving it for any length of time it's a good idea to cover the tank with some kitchen foil (or whatever) as extra UV protection inside the lid. Give it a good stir with the yellow paddle provided before each printing session.

If there are any parts of the print missing they are likely to be in the tank stuck to the bottom film. You can feel through the resin for anything stuck to the bottom film using the yellow paddle. If so it will be necessary to empty and clean out the tank and remove them before you can print again.

The removed resin can be re-used if filtered, but use a separate light-proof container. Do not pour it back into the bottle of fresh resin because that may reduce its shelf life. Suitable filters and a spare yellow paddle are available from Amazon:

https://www.amazon.co.uk/dp/B09Y1HTV7Y

cheers,

Martin.

First-time 3D printing using water-washable resin on the Alkaid printer:

1. the suggested resin for plug track chairs is AnyCubic Grey Water-Washable ABS-Like V2 resin. Available from Amazon at:

https://www.amazon.co.uk/gp/product/B0C7BFQZ2C

It is also possible to use the Pro version of ABS-Like resin, but that is not water washable and must be washed in IPA (Isopropyl Alcohol). Likewise other makes of ABS-Like resin. For water-washing check that the label says V2. This is current information at the above date.

2. shake the bottle of resin well, and leave it to stand for a while for any froth to clear.

3. if cold, run the bottle under the hot tap to warm it up.

4. remove the protection films from both sides of the tank base, and fix it on the printer.

5. remove the protection film (if any) from the build plate, and clean the build surface in hot soapy water before using it for the first time. Rinse and dry it.

6. fix it on the printer. Tighten the top knob firmly. Unlike FDM printing, there is some force involved in resin printing and things can come loose if not tightened firmly.

7. make sure the 4 levelling screws on the build plate are loose and floppy, and switch on.

8. perform the levelling process as explained in the manual and in James's video:

Alkaid video

See further notes 28. below.

9. take some time to get this right -- with luck you will only need to do it once. Nip up all 4 screws first, and then tighten them very firmly without disturbing the levelling.

10. exclude all daylight, and then half fill the tank with resin. Subdued indoor lighting can be used, but not fluorescent tubes.

11. put the yellow cover on the printer. You can allow daylight while the cover is on.

12. plug in the USB stick containing the CTB print file. On the Alkaid the USB socket is at the back (and upside down). It's a lot easier using one of these:

https://www.amazon.co.uk/dp/B00DX59EAG

13. use the touch screen to find the file and start the print. While printing some slurping and sucking noises are normal.

14. for 4mm scale chairs it will take about 25 minutes. Leave it dripping for about 5 minutes afterwards.

15. exclude daylight again. Remove the yellow cover and place an old biscuit-tin lid or piece of cardboard over the whole tank area to catch any further drips while removing and handling the build plate. Remove the build plate using the top knob -- don't disturb the levelling screws.

16. swish the build plate in a bowl of warm water. At this stage the chairs are soft and delicate, so don't bump them against the bottom of the bowl. Using a soft brush such as a pastry brush, wash 95% of the surplus resin from the back of the build plate and around the chairs. The water will be significantly contaminated with resin, so don't pour it down the drain, see 25. below.

17. plunge the build plate up and down vigorously in a bucket of warmish water. This is to remove the remaining 5% of resin, and force wash water through the tiny slots for the loose jaws, to ensure there is no surplus resin left in the slots. If you have some IPA or methylated spirits available, adding a little to the water will aid rapid drying. Likewise adding a few drops of washing-up liquid.

18. cover the tank with kitchen foil, and put the yellow cover back on the printer. You can now allow daylight again. Don't allow daylight until the chairs are fully washed.

19. dry the build plate and chairs with a hair dryer, or leave them on the radiator while you have a nice boiled egg and read the latest issue of the Railway Modeller. The chairs must be fully dry before UV curing.

20. examine all the chairs carefully. Make sure none are missing or only partially printed. If so it is bad news -- you will need to clean out the tank and filter the resin to find the missing bits before you can print again. See further notes 28. below.

• if loose jaws are missing they may have printed normally and be found detached in the wash water.

21. holding the build plate over a soft landing such as a piece of foam or bubble wrap, gently prise each raft from the build plate using a window scraper. At this stage the chairs are still soft and delicate, so handle them carefully.

22. collect up the rafts and expose them on both sides to UV light using whatever means you have available, until they are fully cured. Depending on the power of the UV this might take 10-20 minutes. Or if using a sunny window cill, several hours.

23. they will harden further over the next few days, and the rafts will very likely curl. The curling doesn't matter, but you can prevent curling by sticking the rafts to a scrap bit of wood with double-stick tape until you are ready to use them.

24. if you won't be using the chairs for several weeks/months, once they are fully cured store them in the dark.

25. the contaminated water from the bowl needs to be left out of doors in a transparent container for several days until the resin content has cured in daylight UV and precipitated to the bottom of the container. The clear water can then be decanted off and used to water the garden. Don't pour it down the drain. The cured resin residue can be left to dry out and then disposed of in the domestic waste for landfill.

26. the contamination will be at a low level in a full bucket of water, and it can be disposed of immediately by pouring thinly over the garden. Over time the slight resin content will cure naturally in daylight and become relatively harmless. Some garden plants may even thrive on it! Keep it well away from fish-ponds, pets, etc. Don't pour it down the drain.

27. after building track with these chairs, store it in the dark until you are ready to lay it, or cover it over, until you are ready to paint it. Painting the chairs helps to prevent them becoming brittle from daylight UV exposure in the long term.

28. Further notes:

After levelling and tightening the 4 screws (very tight), move the build plate about 2/3rds of the way up the column using the Z buttons on the screen. Press Tools > Manual > 10mm and then Up several times. When high enough press the green back arrows to finish. Be careful because there is no limit switch at the top to stop it if you go too far. There is a reason the Alkaid costs only £90.

Remove the build plate using the top knob. If you didn't give it a good clean before levelling, do it now. A good scrub under the hot tap to remove any factory dirt and finger marks, and dry it off. It needs to be kept really clean.

While it's removed, pour some resin into the tank about half full. Immediately put the build plate back on the machine and tighten the top knob firmly. Quickly put the yellow lid back on and you are ready to print. At the start of each print the machine will move the build plate down into the resin. After the print the machine will lift the build plate up high for the print to drip -- leave it dripping for about 5 minutes.

Take the yellow lid off and remove the build plate with the chairs on it. Put the yellow lid back on as soon as you can to protect the exposed resin from any stray UV light. Wash the build plate and chairs thoroughly as I described above. Likewise do the washing immediately before any of the surplus resin is exposed to any stray UV light. After washing you can relax and allow daylight again. Put the build plate and chairs somewhere warm to dry and/or use a hairdryer. When it's all dry, carefully remove the chair rafts from the build plate with a window scraper. Do it over something soft to catch them as they are still quite soft. They are now ready for UV curing.

There is no actual need to put the build plate back on the machine until you are ready to print next time. After levelling the first time, there is never normally any reason to press the Home button again or do any more levelling.

Check the chairs carefully each time to make sure they are complete with no parts missing. If so you can just leave the resin in the tank ready for next time.

If there are any parts of the print missing they are likely to be in the tank stuck to the bottom film. You can feel through the resin for anything stuck to the bottom film using the yellow paddle. If so it will be necessary to empty and clean out the tank and remove them before you can print again.

The removed resin can be re-used if filtered, but use a separate light-proof container. Do not pour it back into the bottle of fresh resin because that may reduce its shelf life. Suitable filters and a spare yellow paddle are available from Amazon:

https://www.amazon.co.uk/dp/B09Y1HTV7Y

cheers,

Martin.

message ref: 9658

Thanks and you have made my wife's year, as she wants me to have blinds on the dens window, looks like printing at night in the short term,

Thanks for the description of the printing process, especially as I did not realize that the print head had to be removed each time, thats why there is a big black knob to loosen the head !!

I was hoping to go out and buy a few bits today, but domestic duties got in the way and the alarm is being serviced this afternoon. So homework and preparation time will be the order of the afternoon

Building a switch rail filing jig (inner left) today. in my hast to get it going before I got on with some DIY, I had two false starts ( the second was not a false start) school boy errors, which in one way is good in that I am sensing what is wright and wrong. Still on a learning curve with the FDM printer but much further along. Plus now I am not starting off afresh with the resin printer as some of the processes seem similar to FDM in the file design phase

Thanks again for all the help and unlike with the FDM printer I am happy to keep soaking up the info before I start, which hopefully will not be long. But what you have written down is a great help for me and hopefully others

Thanks for the description of the printing process, especially as I did not realize that the print head had to be removed each time, thats why there is a big black knob to loosen the head !!

I was hoping to go out and buy a few bits today, but domestic duties got in the way and the alarm is being serviced this afternoon. So homework and preparation time will be the order of the afternoon

Building a switch rail filing jig (inner left) today. in my hast to get it going before I got on with some DIY, I had two false starts ( the second was not a false start) school boy errors, which in one way is good in that I am sensing what is wright and wrong. Still on a learning curve with the FDM printer but much further along. Plus now I am not starting off afresh with the resin printer as some of the processes seem similar to FDM in the file design phase

Thanks again for all the help and unlike with the FDM printer I am happy to keep soaking up the info before I start, which hopefully will not be long. But what you have written down is a great help for me and hopefully others

message ref: 9659

Martin

I have now printed off those notes firstly as a check list, but the actual process of printing part I will turn into a set of memory prompts

Thank you very much and a great help both for me and hopefully for others, a great set of instructions

I have now printed off those notes firstly as a check list, but the actual process of printing part I will turn into a set of memory prompts

Thank you very much and a great help both for me and hopefully for others, a great set of instructions

message ref: 9660

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Hi Martin,

My KPS3 Pro S1 arrived on Wednesday.

So far I have only had time to check the flatness of the underneath of the glass plate.

I placed the edge of a 12" steel rule diagonally across the glass and it does appear to be flat.

Is that a sufficient test?

STeve

My KPS3 Pro S1 arrived on Wednesday.

So far I have only had time to check the flatness of the underneath of the glass plate.

I placed the edge of a 12" steel rule diagonally across the glass and it does appear to be flat.

Is that a sufficient test?

STeve

message ref: 9690

Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Steve_CornfordHi Martin,

My KPS3 Pro S1 arrived on Wednesday.

So far I have only had time to check the flatness of the underneath of the glass plate.

I placed the edge of a 12" steel rule diagonally across the glass and it does appear to be flat.

Is that a sufficient test?

STeve

Hi Steve,

Yes I would think so. Mine definitely fails -- it is possible to insert paper at one corner while holding the rule against the glass at the other corner.

I will post the G-code script for the Kingroon Pro S1 perimeter priming shortly. Do you have some PLA-Plus filament?

Have you downloaded the latest Cura? For how to set up a custom printer, see:

https://85a.uk/templot/club/index.php?threads/experimental-plug-track-continued.673/post-7361

cheers,

Martin.

message ref: 9691

Phil G

Member

- Location

- New Zealand

Hi Martin,

Do you have any sort of temp probe you could checkout the hot end and the bed? ( given you have 5 or is it now 6 machines)

only asking because I was getting such different results between my Elegoo and my Ender that I wondered how accurate they were at temp reading. To my surprise the answer in my case is not very accurate at all.

On the Elegoo a setting of 190 is actually 202 and on the ender 205 is 200.

The bed is better but still Elegoo set at 55 is reading 60 degrees and the ender at setting 60 is 59 degrees.

Either Elegoo is actually hotter than the set value, and the ender is slightly colder, but maybe a bit closer. or there both wrong.

The values were measured with a digital optical temp device which was also not calibrated, so don't know which if any are actually correct.

I am only mention this as giving temp recommendations needs to be off set with the possibility they can only be guidelines as we can't be 100% sure any two machines are actually reading the same values.

cheers

Phil

Ps I am in no way disagreeing with the basic concept that lower temps do give less stringing. They clearly do.

Do you have any sort of temp probe you could checkout the hot end and the bed? ( given you have 5 or is it now 6 machines)

only asking because I was getting such different results between my Elegoo and my Ender that I wondered how accurate they were at temp reading. To my surprise the answer in my case is not very accurate at all.

On the Elegoo a setting of 190 is actually 202 and on the ender 205 is 200.

The bed is better but still Elegoo set at 55 is reading 60 degrees and the ender at setting 60 is 59 degrees.

Either Elegoo is actually hotter than the set value, and the ender is slightly colder, but maybe a bit closer. or there both wrong.

The values were measured with a digital optical temp device which was also not calibrated, so don't know which if any are actually correct.

I am only mention this as giving temp recommendations needs to be off set with the possibility they can only be guidelines as we can't be 100% sure any two machines are actually reading the same values.

cheers

Phil

Ps I am in no way disagreeing with the basic concept that lower temps do give less stringing. They clearly do.

message ref: 9704

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Hi Phil,

What temperature does your water boil at ?

Steve

What temperature does your water boil at ?

Steve

message ref: 9709

Phil G

Member

- Location

- New Zealand

That's a similar question to how fast does a swallow fly! It would depend if its a European swallow or African swallow,Hi Phil,

What temperature does your water boil at ?

Steve

so in this case is that for a boiled egg? or a poached egg?

cheers

Phil

message ref: 9710

Steve_Cornford

Member

- Location

- Brighton, East Sussex

Poached is more of a simmer!

message ref: 9711

Related topics

- Replies

- 23

- Views

- 8K

Search

Search