Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Phil G

Hi Phil,

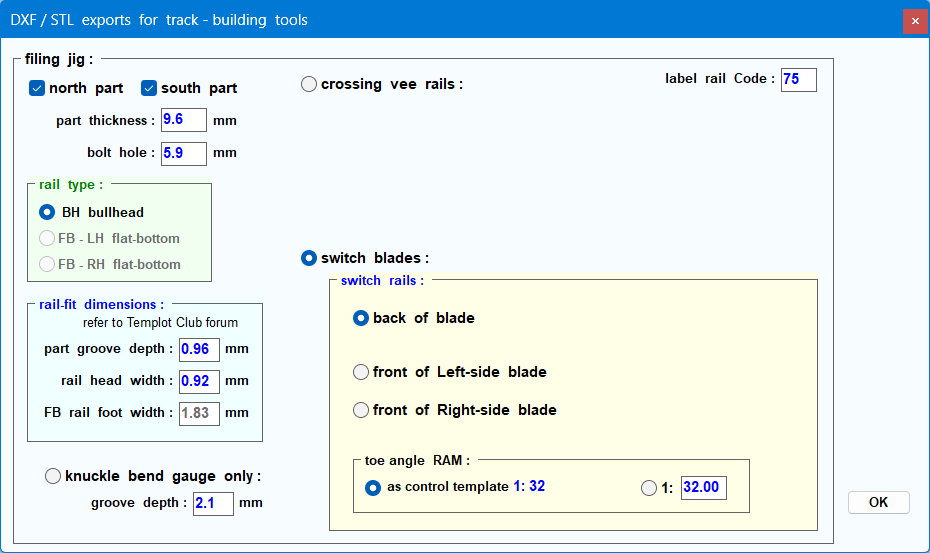

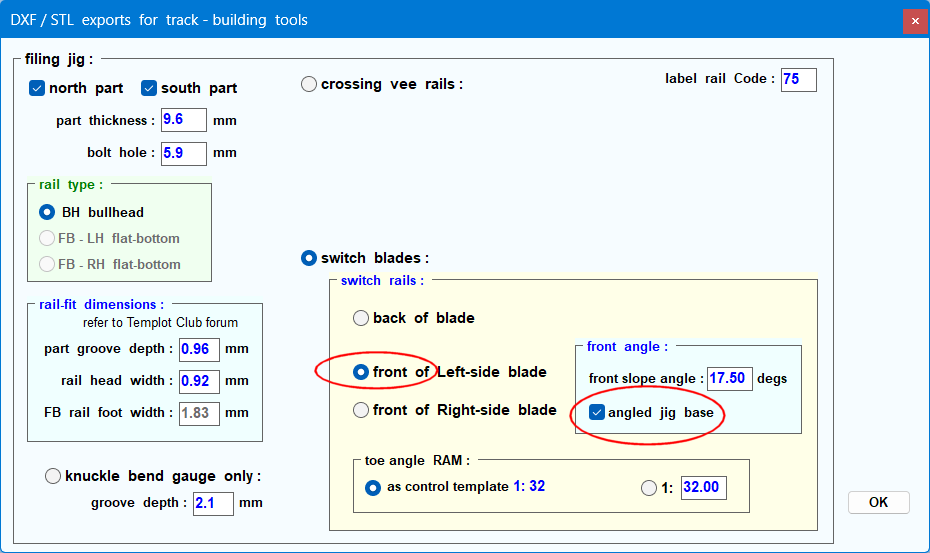

It seems I had already implemented your suggestion for the next update, and gone a bit further. All completely forgotten about last night:

will be in the next update. despite my reservations last night i will try to release it today or tomorrow, and just live with any BOX file tangles. otherwise it is going to be too long a break between updates.

martin.

Hi Phil,

It seems I had already implemented your suggestion for the next update, and gone a bit further. All completely forgotten about last night:

will be in the next update. despite my reservations last night i will try to release it today or tomorrow, and just live with any BOX file tangles. otherwise it is going to be too long a break between updates.

martin.

message ref: 9105

Search

Search