Martin Wynne

Admin

- Location

- West of the Severn UK

- Info

@Wayne Kinney

On the Templot home pages I have tried hard to explain that Templot is for hand-built track only, and has nothing to offer users of commercial trackwork.

Enter Wayne Kinney and his range of easy-build pointwork kits based on Templot designs:

https://www.britishfinescale.com

And today this post on RMweb:

https://www.rmweb.co.uk/topic/16023...-in-00-and-em/?do=findComment&comment=4845622

All of which leaves me wondering if the Templot home page needs some re-wording? I don't want to deter users of these excellent kits from using Templot to design their layouts, even when they might not consider themselves scratch track-builders.

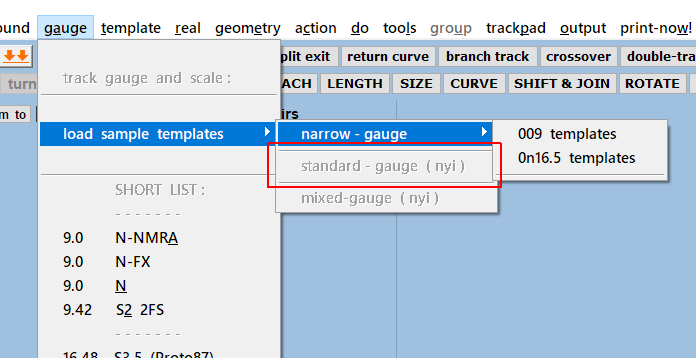

Also a couple of updates back I added this easy-access option to load a collection of library templates:

but have since done no more with it. To make it sensible for users of the Finetrax kits we need a mechanism to combine all the partial templates comprising say a double slip into some sort of single unit, independent of the existing group functions. I tried to do something like that once before, but got in a terrible muddle. Perhaps it's time to try again?

cheers,

Martin.

On the Templot home pages I have tried hard to explain that Templot is for hand-built track only, and has nothing to offer users of commercial trackwork.

Enter Wayne Kinney and his range of easy-build pointwork kits based on Templot designs:

https://www.britishfinescale.com

And today this post on RMweb:

https://www.rmweb.co.uk/topic/16023...-in-00-and-em/?do=findComment&comment=4845622

All of which leaves me wondering if the Templot home page needs some re-wording? I don't want to deter users of these excellent kits from using Templot to design their layouts, even when they might not consider themselves scratch track-builders.

Also a couple of updates back I added this easy-access option to load a collection of library templates:

but have since done no more with it. To make it sensible for users of the Finetrax kits we need a mechanism to combine all the partial templates comprising say a double slip into some sort of single unit, independent of the existing group functions. I tried to do something like that once before, but got in a terrible muddle. Perhaps it's time to try again?

cheers,

Martin.

message ref: 4476

Search

Search