Hi everyone,

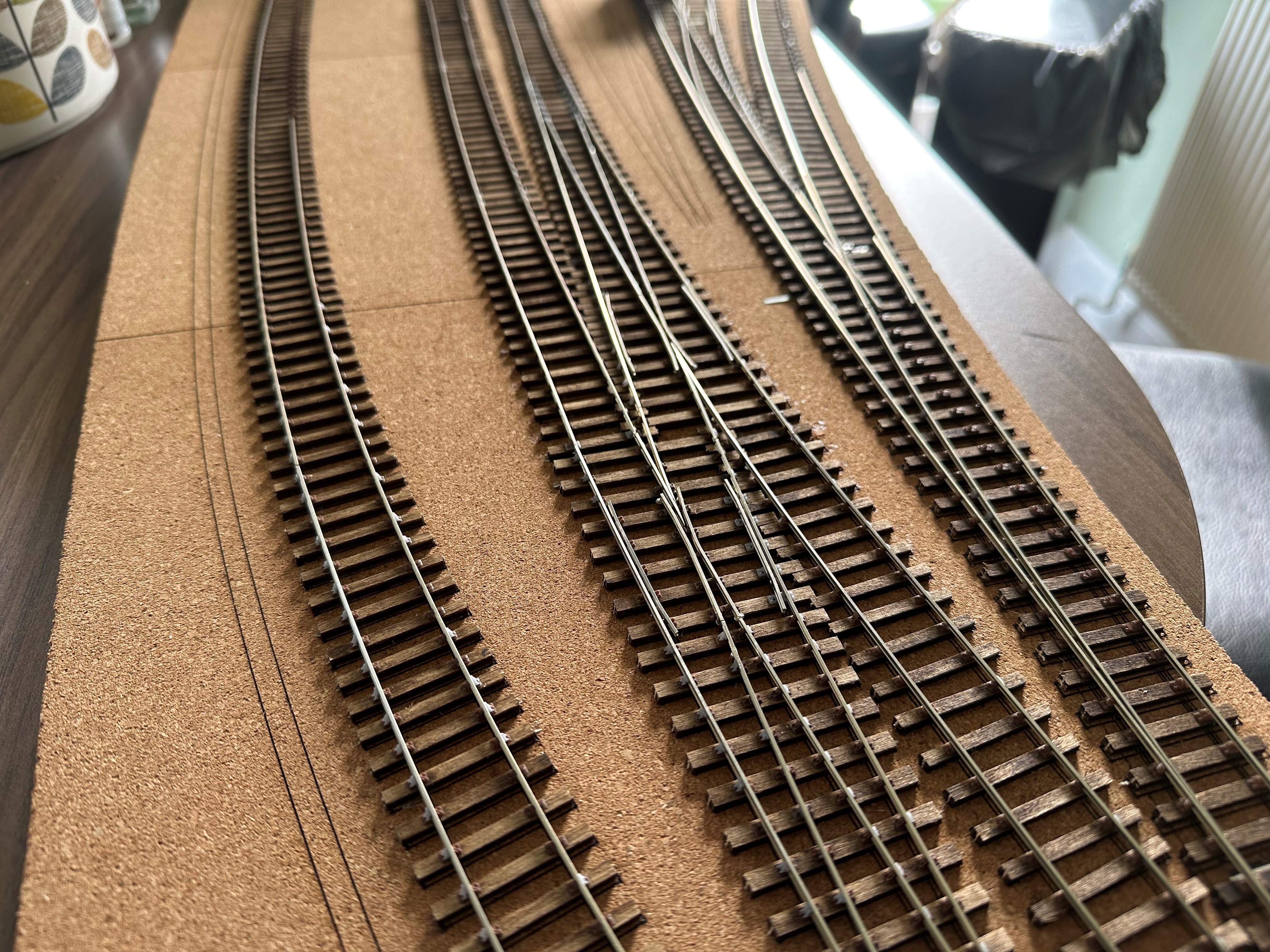

I've been a bit absent recently. I've had my head down laying some track and trying to ascertain what the difficulties might be in laying laser cut plug track in a layout setting.

I've been working on my S4 challenge project, working with just the baseboard tops to begin with. I'm sure there are those who will say I should have built the complete baseboards before laying track, but there are several reasons for progressing this particular way, more of which later, but for now I thought I'd share my progress.

I must stress that at this stage, I am just testing out some ideas, and I'm happy to take all of this up and start again if need be, but so far so good. Stock all runs well (as far as I can test at this stage).

I found the assembly process really enjoyable, the major plus being being able to temporarily fit track to ensure alignment between timbering bases before gluing down, and also across baseboard joints. Everything I have laid here is removable, so very easy to go back and replace parts as required.

I've found that filing down some short lengths (40mm) of rail such that they fit into a chair socket useful. The help to hold a long rail length in place whilst chairing, especially on a curve. Other than that everything else has been pretty much to Martin's words and music.

There is still some fettling to do, but I hope this provides some inspiration for others to try.

Given that this layout will be exhibited (I hope), I've been experimenting with different methods to ensure reliability and hopefully eliminate damage to sensitive areas such as the common crossings and check rails etc. To that end I've played-around with various bits of nickel silver bonding strips, and brass pins soldered under the check rails to restrict movement. They look a bit crude at this stage, but everything is rock-solid. I've found that I can grind the protrusions away quite nicely so they should be pretty inconspicuous when complete. Of course, had I used FDM timbering then I would have incorporated Martin's neat little solution of the restraint wires.

I've packed it all away now as I've had enough of track for this weekend, but next time I'll get some more detailed photos.

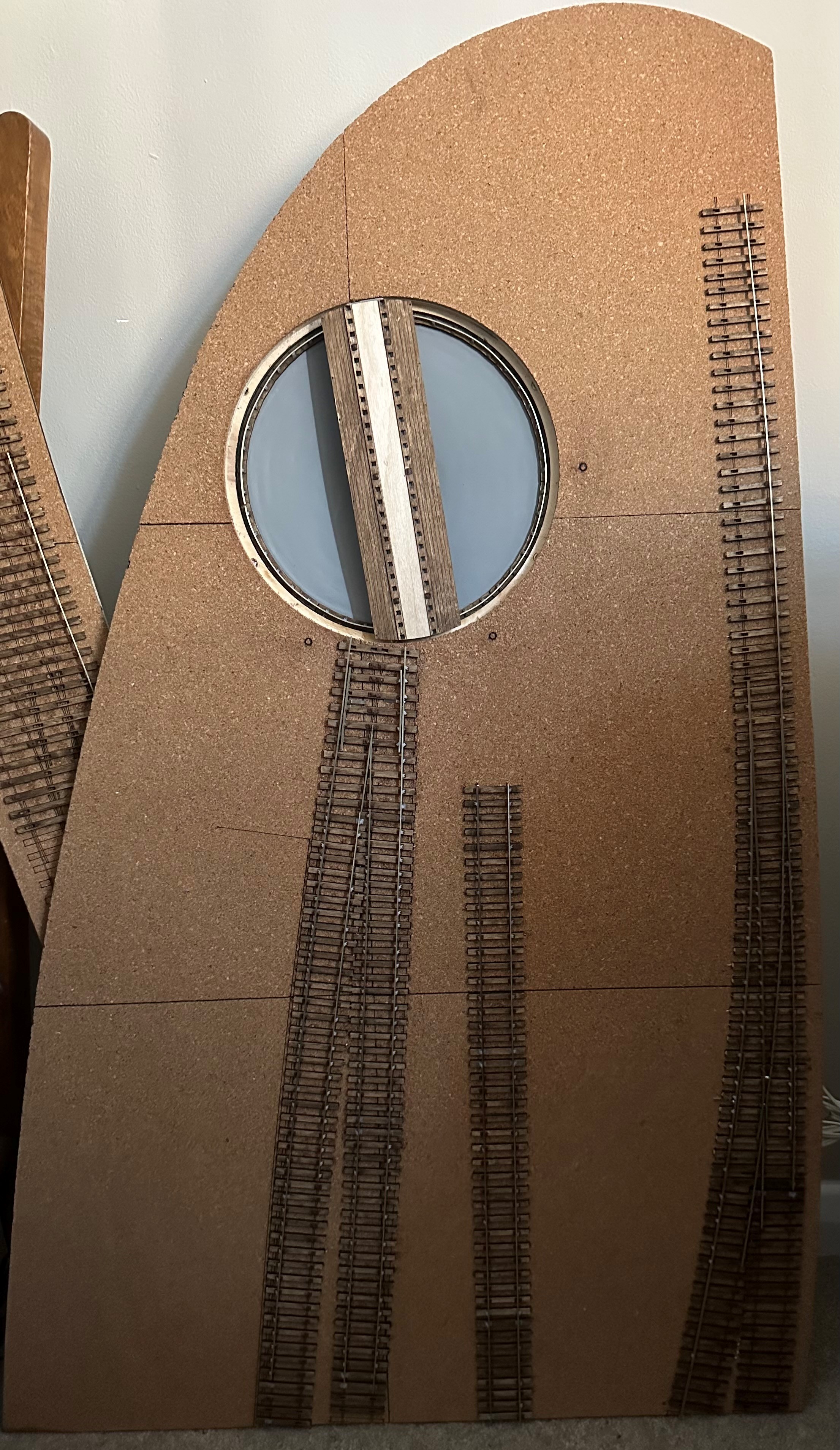

I've also built the well for a 50' Cowan's turntable, and used plug track chairs for the race rail.

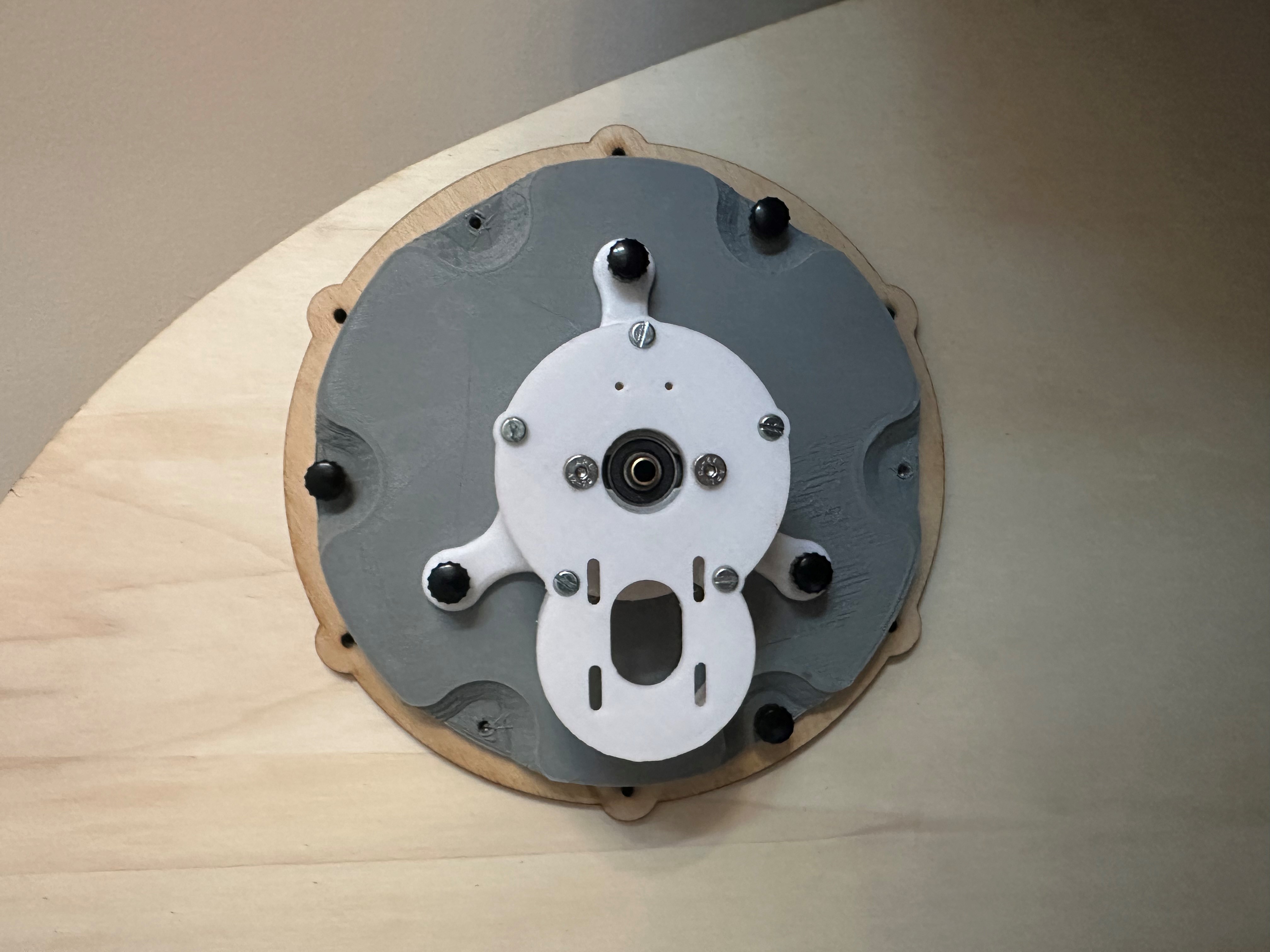

The TT well and its motor are quick-release, being held by thumbscrews.

I've been a bit absent recently. I've had my head down laying some track and trying to ascertain what the difficulties might be in laying laser cut plug track in a layout setting.

I've been working on my S4 challenge project, working with just the baseboard tops to begin with. I'm sure there are those who will say I should have built the complete baseboards before laying track, but there are several reasons for progressing this particular way, more of which later, but for now I thought I'd share my progress.

I must stress that at this stage, I am just testing out some ideas, and I'm happy to take all of this up and start again if need be, but so far so good. Stock all runs well (as far as I can test at this stage).

I found the assembly process really enjoyable, the major plus being being able to temporarily fit track to ensure alignment between timbering bases before gluing down, and also across baseboard joints. Everything I have laid here is removable, so very easy to go back and replace parts as required.

I've found that filing down some short lengths (40mm) of rail such that they fit into a chair socket useful. The help to hold a long rail length in place whilst chairing, especially on a curve. Other than that everything else has been pretty much to Martin's words and music.

There is still some fettling to do, but I hope this provides some inspiration for others to try.

Given that this layout will be exhibited (I hope), I've been experimenting with different methods to ensure reliability and hopefully eliminate damage to sensitive areas such as the common crossings and check rails etc. To that end I've played-around with various bits of nickel silver bonding strips, and brass pins soldered under the check rails to restrict movement. They look a bit crude at this stage, but everything is rock-solid. I've found that I can grind the protrusions away quite nicely so they should be pretty inconspicuous when complete. Of course, had I used FDM timbering then I would have incorporated Martin's neat little solution of the restraint wires.

I've packed it all away now as I've had enough of track for this weekend, but next time I'll get some more detailed photos.

I've also built the well for a 50' Cowan's turntable, and used plug track chairs for the race rail.

The TT well and its motor are quick-release, being held by thumbscrews.

message ref: 10497

Search

Search