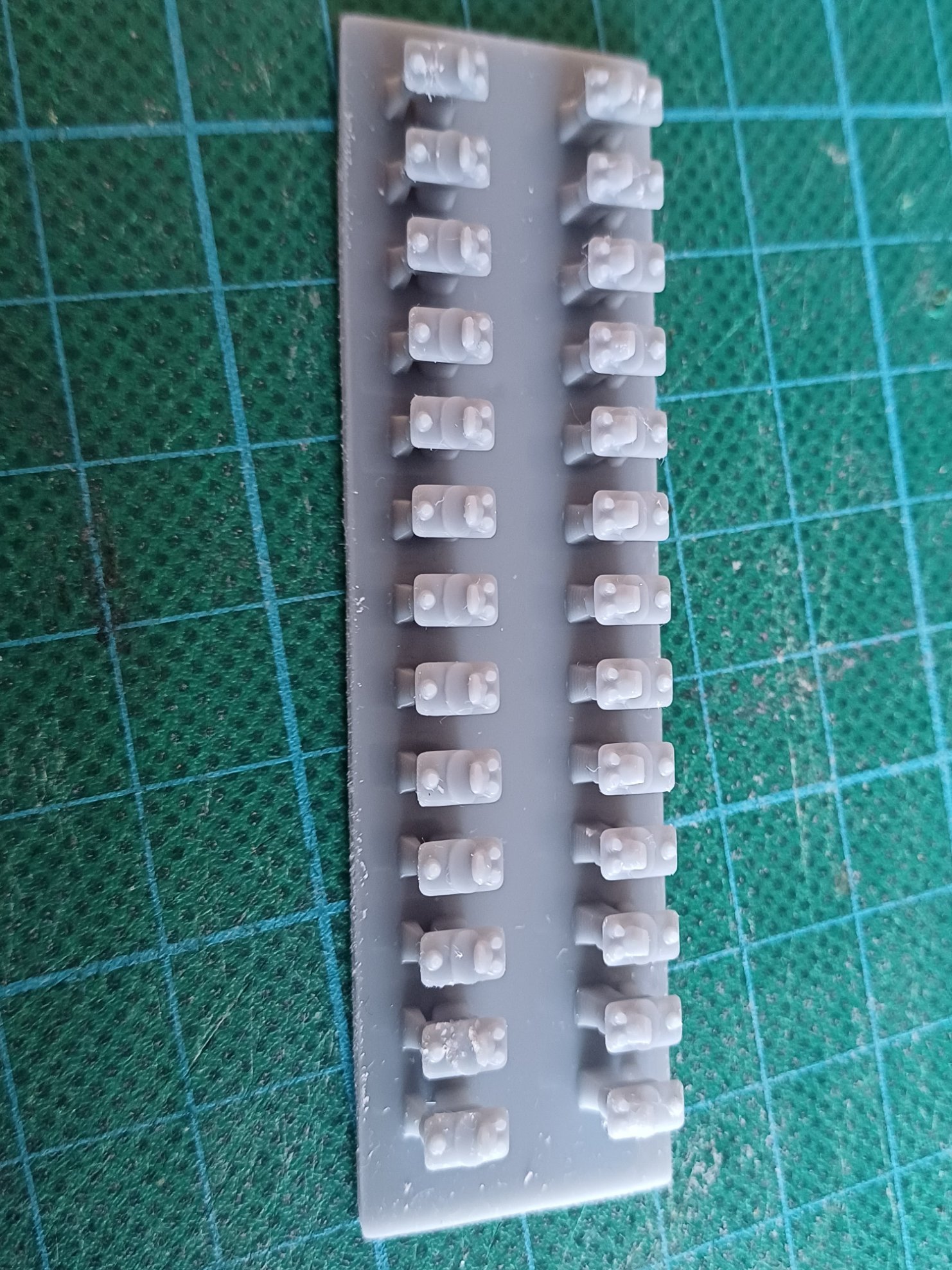

I have printed several versions of the loose jaw chairs , which appear to be complete apart from the slot for the loose jaw.

Anyone able to offer a simple remedy?

Geeetech Alkaid printer

Elegoo ABS like resin.

Resin settings taken from Elegoo website to what appears to be the nearest to this printer.

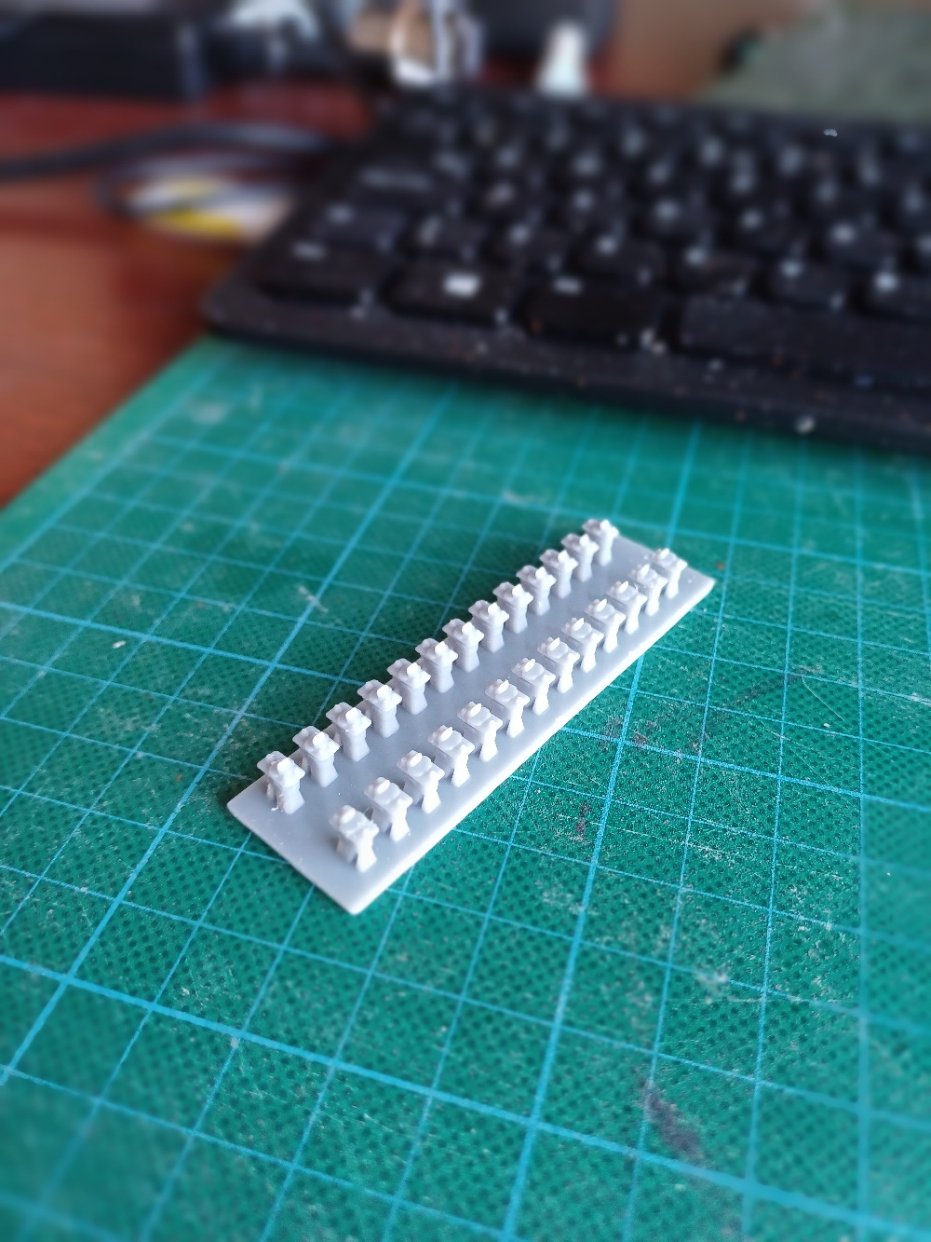

Anyone able to offer a simple remedy?

Geeetech Alkaid printer

Elegoo ABS like resin.

Resin settings taken from Elegoo website to what appears to be the nearest to this printer.

message ref: 9416

Search

Search