@Paul Boyd

Hi Paul,

Well done on getting started so quickly.

About nozzle sizes. It took me a long time to realise that the nozzle size is largely irrelevant, and nowhere did I find it mentioned as such on the web sites. But it's obvious when you think about it -- the width of the bead of polymer emerging from the nozzle is governed by

1. the volume rate at which polymer is injected into the nozzle, and

2. the height of the nozzle above the previous layer, and

3. the speed at which the nozzle moves across the work.

Since all the above data is available from your settings, you can calculate the bead size without regard to the nozzle size.

Unless extruding into fresh air, the nozzle size doesn't come into it, and controls only the velocity of the polymer as it emerges from the nozzle.

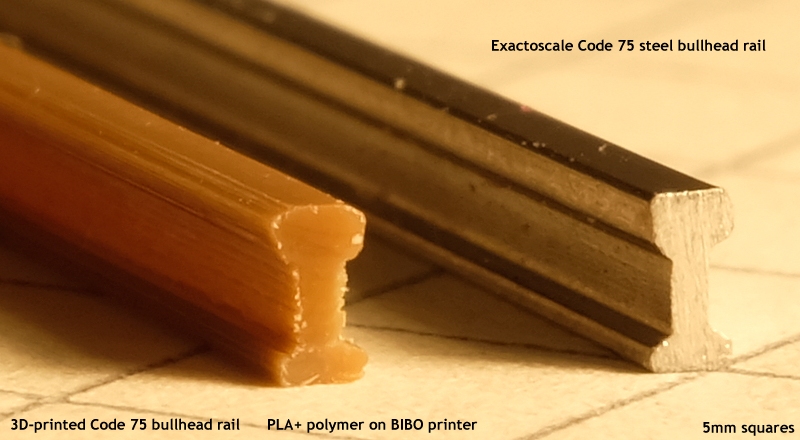

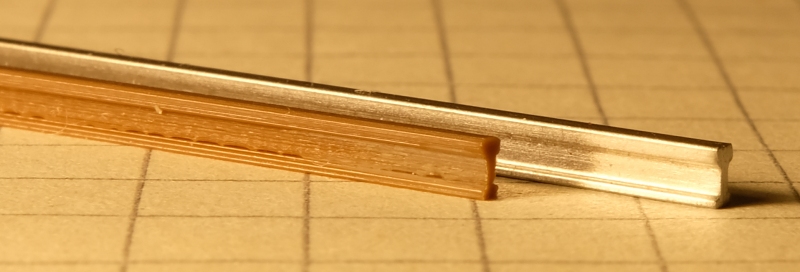

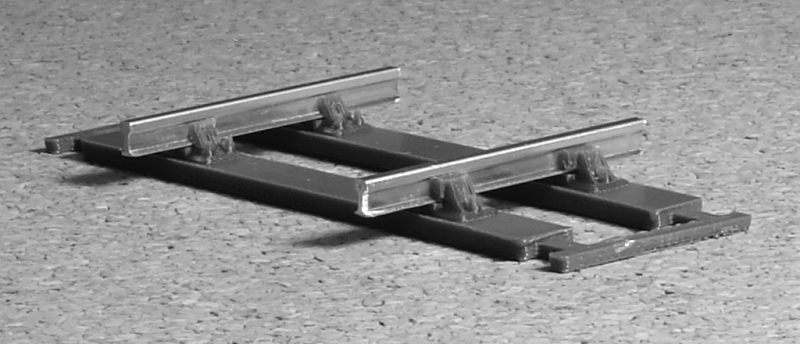

For example, this attempt to create code 75 bullhead rail in PLA+ was made using a 0.6mm nozzle, even though the rail web thickness is only 0.4mm:

The actual results also depend to some extent on the nozzle temperature, because this affects the fluidity of the molten polymer.

The volume rate at which polymer is injected into the nozzle is calculated from the filament feed rate (E numbers in the G code) and the known diameter of the filament. The filament volume per mm is calculated from the square of the diameter, so a small change in diameter makes a big change in the volume rate. One of the reasons the better-quality filaments produce better models is the closer tolerance on filament diameter.

I have found that you can get more accurate results by lying to Cura about the nozzle diameter -- if you have a 0.4mm nozzle fitted, set it as 0.35mm or 0.30mm. The print time will be longer and slower, but the results will be more accurate to size.

p.s. on the BIBO at least, changing nozzles has to be done

hot! , otherwise the set polymer in it locks it solid. If you can do it without burning your fingers you are better than me.

That's one reason to leave a large nozzle fitted and do the rest on the settings.

I don't think just ticking the box will make very much difference, to make a big difference you probably need to change the settings.

To reduce vibration I think the Jerk settings will make a bigger difference than Acceleration. Jerk is the instantaneous speed at which the steppers start off from rest, or reverse direction, before accelerating to running speed. On some printers I think Jerk is called Minimum Speed:

cheers,

Martin.

Search

Search