- Location

- West of the Severn UK

- Info

@Michael Woods

Hi Michael,

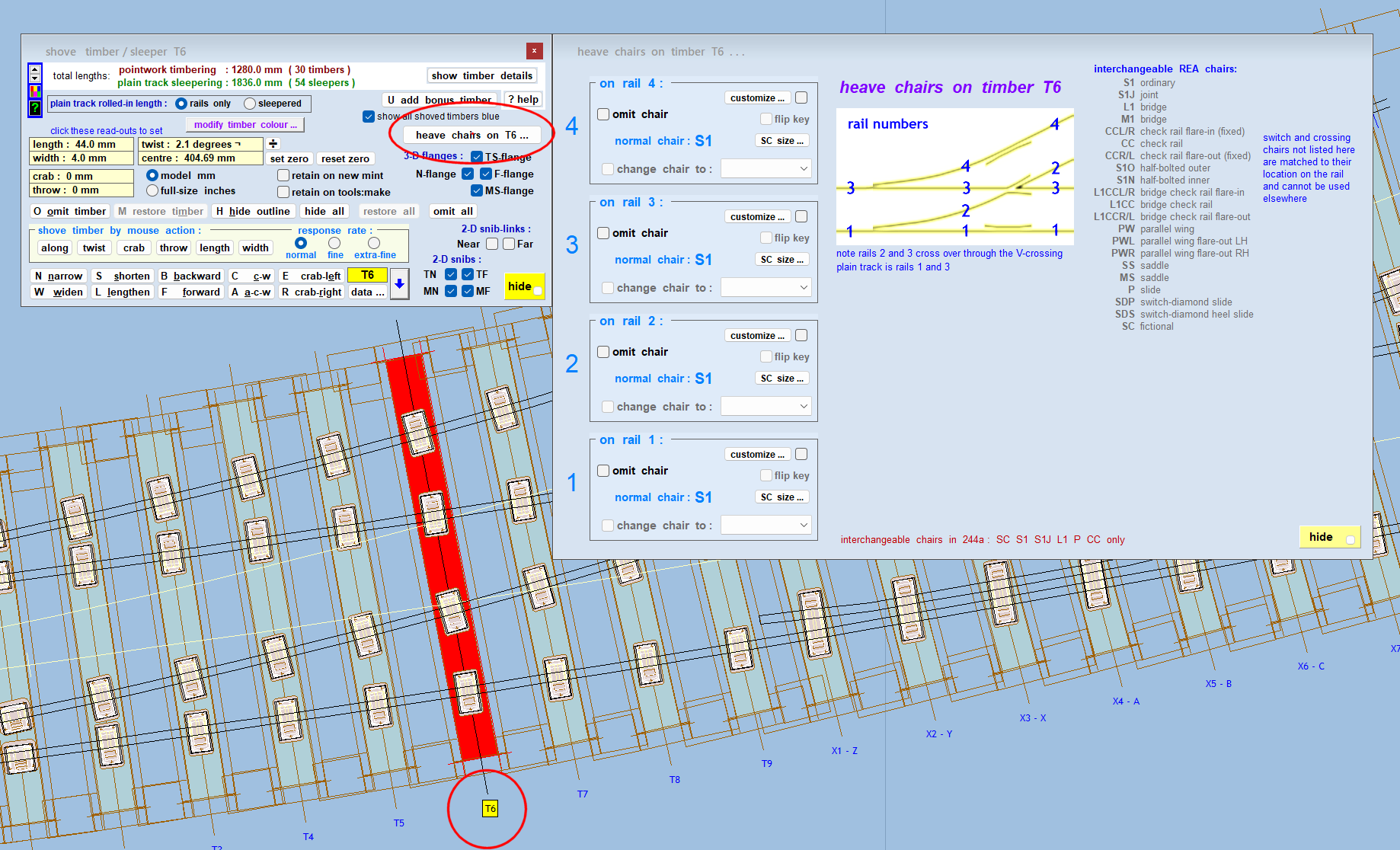

Chair heaving is part of the shove timbers function. That's at real > shove timbers or just press the comma key.

Click on the timber number, and then click the heave chairs button:

A new dialog appears on which you can heave (i.e. change) or omit any of the chairs on that timber.

If you click the customize... button you can change the jaw options for the one specific chair.

If you change it to an SC chair (bottom of the list) you can also click the SC size... button to change its outline dimensions.

n.b. you are changing the control template. It will need to be stored before you can do the 3D exports.

The dialog is rather large but it can be dragged around out of the way using the top bar. I will try to shrink it down a bit when I have finished adding things to it.

edit: posts crossed.

cheers,

Martin.

Hi Michael,

Chair heaving is part of the shove timbers function. That's at real > shove timbers or just press the comma key.

Click on the timber number, and then click the heave chairs button:

A new dialog appears on which you can heave (i.e. change) or omit any of the chairs on that timber.

If you click the customize... button you can change the jaw options for the one specific chair.

If you change it to an SC chair (bottom of the list) you can also click the SC size... button to change its outline dimensions.

n.b. you are changing the control template. It will need to be stored before you can do the 3D exports.

The dialog is rather large but it can be dragged around out of the way using the top bar. I will try to shrink it down a bit when I have finished adding things to it.

edit: posts crossed.

cheers,

Martin.

message ref: 10752

Search

Search