- Location

- West of the Severn UK

- Info

.

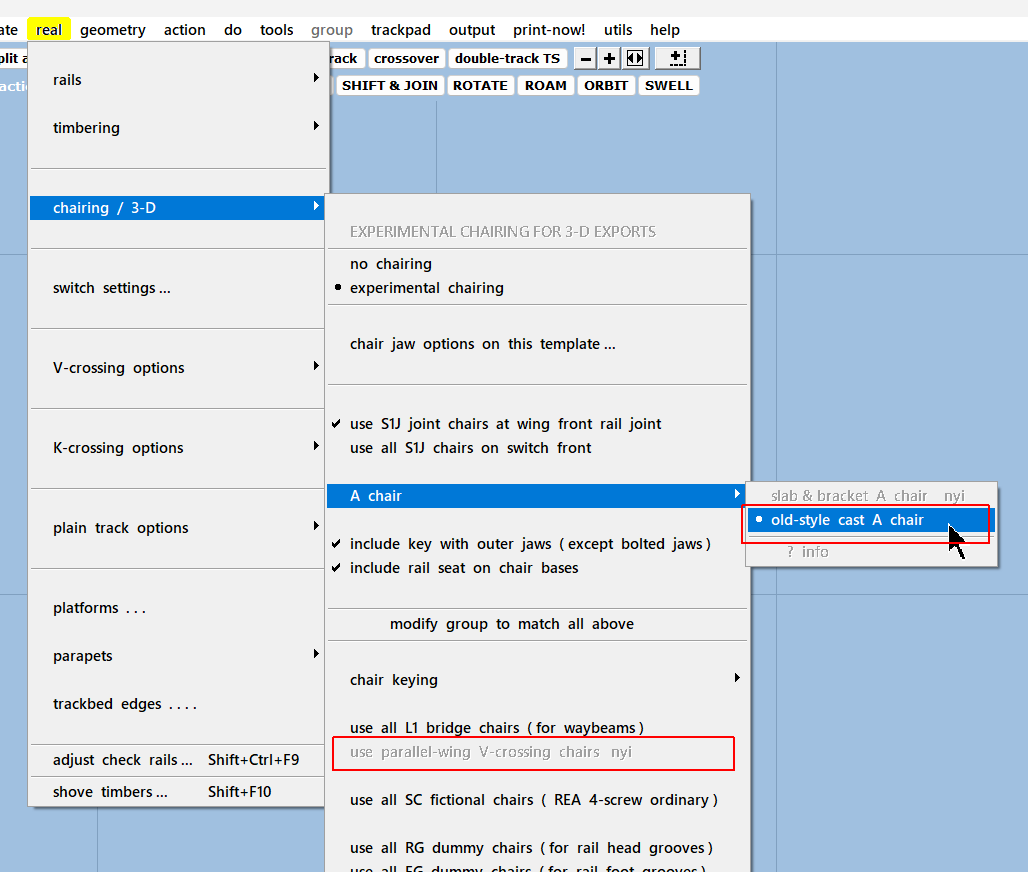

A couple of additional menu items will be in 239a, neither of any immediate use:

To save time in getting the crossing chairs out, I shall be starting with the old-style cast "A" chairs with jaws and keys. The later slab & bracket design option will follow afterwards.

I just know this will produce a stream of messages telling me that I have got it wrong, and that the "A" chair should be the slab & bracket pattern. In reply I can post this screenshot.

The option for parallel wing crossings will have to wait until the "chair heaving" function is done, so that the chairs in the exit can be swapped to CC check rail chairs.

cheers,

Martin.

A couple of additional menu items will be in 239a, neither of any immediate use:

To save time in getting the crossing chairs out, I shall be starting with the old-style cast "A" chairs with jaws and keys. The later slab & bracket design option will follow afterwards.

I just know this will produce a stream of messages telling me that I have got it wrong, and that the "A" chair should be the slab & bracket pattern. In reply I can post this screenshot.

The option for parallel wing crossings will have to wait until the "chair heaving" function is done, so that the chairs in the exit can be swapped to CC check rail chairs.

cheers,

Martin.

message ref: 6867

Search

Search